704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

1865 Results Found

704-841-2001

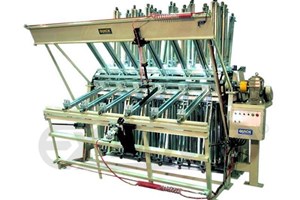

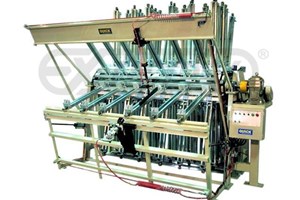

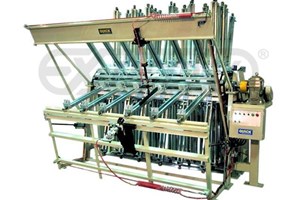

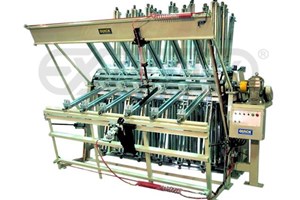

QUICK 20 Section Heavy Duty Pneumatic Clamp Carrier: -- Clamp Carrier: (20) Sections with 8-1/2' width cap., (6) heavy duty zinc plated clamps per section (120 clamps total), 44" opening on clamps (other lengths available). -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- For face gluing, Rocking Plates available as optional equipment. -- Equipped with: Panel Flattener with easy to use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation: Push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time! -- Complete with & Includes: Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: 20 Section machine can produce up to (500) panels per shift!

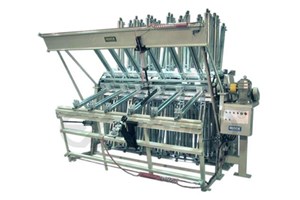

Quick Heavy Duty Pneumatic Clamp Carrier with 20-sections and 12-1/2' width capacity. -- (8) Heavy Duty zinc plated clamps per section for 10 section, clamp opening 44" -- (10) Heavy Duty zinc plated clamps per section for 10 section, clamp opening 44" -- Includes 180 clamps with 44" openings and 3.5" high x 4-3/4" wide jaws with 1° inward draft. -- Pneumatic overhead panel flattener along with tightener -- Pneumatic panel flattener for second operator -- Semi-Automatic Pneumatic clamp tightener . -- Semi-Automatic panel tightener for second operator -- Single button automatic electric motor rotation cycle with indexing. -- Heavy Duty frame with 3" diameter shafts and 6" I-beam legs. -- Includes foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating and tool box with spare parts & tools.

Call for Price

QUICK 30 Section Automatic Clamp Carrier: -- Clamp Carrier: (30) Sections with 8-1/2' width cap., (6) heavy duty zinc plated clamps per section (180) clamps total), 40" opening on clamps with quick adjustment (other lengths available). -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- For face gluing, Rocking Plates available as optional equipment. Equipped with: -- Fully Automatic Hydraulic Clamp Tightener with adjustable torque limiter, integral Hydraulic Panel Flatteners and Electric Motor Drive with fully Automatic Carrier Rotation Cycle. Two control panels maximize ease-of use. Rack and pinion carriage traverse system is solid and quietFeatures: -- The QUICK Automatic Clamp Carrier is the ideal labor-saving device for the high-production furniture or cabinet manufacturer. The Automatic Clamp Carrier cuts labor costs in half by allowing the Clamp Carrier operator to perform other tasks (such as applying glue to stock, etc.) while the machine automatically flattens panels, tightens clamps, rotates, and loosens clamps. -- After loading wood into a section of clamps, the operator presses the "Auto Tighten" button. The hydraulic Automatic Carriage then traverses from left to right, flattening panels and tightening clamps that it finds along the way. When the Carriage reaches the right end of its traverse, the machine performs an automatic rotation cycle, which brings the next section of clamps down to the operator’s position. The Carriage then traverses from right to left, loosening clamps that it finds along the way. -- The Fully Automatic Clamp Carrier can also be used in manual or semi-automatic modes, by pressing buttons on the Control Panels.Complete with & Includes: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.

QUICK 6-Section Pneumatic Clamp Carrier with 20-1/2' width cap. & Dual Operator's Stations, -- (16) Heavy Duty zinc plated clamps per section (96) clamps total), 50" opening on clamps. Jaw sizes of clamps is 3-1/2" high x 4-3/4" wide, with 1° inward draft. Equipped with DUAL OPERATOR'S STATIONS including: -- (2) Pneumatic overhead panel flatteners, -- (2) Pneumatic clamp tighteners -- Semi-automatic rotation via electric motor drive; with separate buttons for Front Rest Out, Rotate Reverse, Rotate Forward, and Front Rest In.Standard Supply includes: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high-quality urethane finish coating, and toolbox with spare parts & tools.

QUICK 20-Section Heavy Duty Pneumatic Clamp Carrier with 10-1/2' width capacity -- With (8) Standard zinc plated clamps per section (160 clamps total), 38" opening on clamps.Standard Features include: -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Panel Flattener with easy to use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation 2 HP; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time!Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: A 20-Section Clamp typically produces 500 panels per shift.

QUICK 20-Section Pneumatic Clamp Carrier with 10-1/2' width capacity -- With (8) Standard zinc plated clamps per section (160 clamps total), 38" opening on clamps. Standard Features include: -- Clamps jaws are 2-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Panel Flattener with easy to use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time!Complete with: Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: A 20-Section Clamp typically produces 500 panels per shift.

QUICK 6-SECTION, 12-1/2' Wide Pneumatic "Standard" Clamp Carrier: 6-Section Clamp, typically produces (144) high-quality edge glued panels per day (3 panels per section x 6 sections x 8 hours). Equipped with: -- (6) Sections with (9) clamps per section and 12-1/2' width capacity. -- (54) Clamps with 38" opening and 2-1/2" high x 4-3/4" wide jaws with 1° inward draft. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- Rocker Plates are available as optional equipment for face gluing. Features: -- Semi-automatic electric motor drive. -- Pneumatic Panel Flattener for 10-1/2' wide Carrier with easy-to-use controls. -- Pneumatic Clamp Tightener with a 3,000 RPM air wrench is (5 -10) times faster than competitive tighteners; the 2-handed, trigger-activated tightener is more confidence-inspiring than the older, ergonomically awkward "swing-style" clamp tighteners. -- Fast tightening and full-length clamp screws eliminate the need for manual adjustment of rear clamp jaws. Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, and automatic air line oiler; -- High-quality Urethane finish coating, and tool box with spare parts & tools.Floor space requirement: 195"W X 125" H X 127"D

QUICK 6-SECTION, 10'-1/2' Wide Pneumatic "Standard" Clamp Carrier: 6-Section Clamp typically produces (144) high quality edge glued panels per day (3 panels per section x 6 sections x 8 hours). Equipped with: -- (6) Sections with (8) clamps per section and 10-1/2' width capacity. -- (48) Clamps with 50" opening and 2-1/2" high x 4-3/4" wide jaws with 1° inward draft. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. Features: -- Electric motor drive. -- Pneumatic Panel Flattener for 10-1/2' wide Carrier with easy to use controls. -- Pneumatic Clamp Tightener with 3,000 RPM air wrench is (5 -10) times faster than competitive tighteners; 2-handed, trigger activated tightener is more confidence inspiring than the older, ergonomically awkward "swing-style" clamp tighteners. -- Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality Urethane finish coating, and tool box with spare parts & tools. --

QUICK 14-Section Heavy Duty Hydraulic Clamp Carrier with 20-1/2' width capacity With (16) Standard zinc plated clamps per section (224) clamps total), 38" opening on clamps Standard Features include: -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Pneumatic Panel Flattener with easy to use controls. -- Pneumatic panel flattener for second operator -- Hydraulic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Hydraulic clamp tightener for second operator -- Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time! Complete with:Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools. 14-Section Clamp will produce 300 panels

QUICK 6-SECTION, 10'-1/2' Wide Pneumatic "Standard" Clamp Carrier: 6-Section Clamp typically produces (144) high quality edge glued panels per day (3 panels per section x 6 sections x 8 hours). Equipped with: -- (6) Sections with (8) clamps per section and 10-1/2' width capacity. -- (48) Clamps with 38" opening and 2-1/2" high x 4-3/4" wide jaws with 1° inward draft. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. Features: -- Semi-automatic electric motor drive. -- Pneumatic Panel Flattener for 10-1/2' wide Carrier with easy to use controls. -- Pneumatic Clamp Tightener with 3,000 RPM air wrench is (5 -10) times faster than competitive tighteners; 2-handed, trigger activated tightener is more confidence inspiring than the older, ergonomically awkward "swing-style" clamp tighteners. -- Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality Urethane finish coating, and tool box with spare parts & tools. -- NOTE: Clamp Carrier can be expanded to (14) or (20) sections at a later time. 14-Section Clamp will produce (300) panels per shift; 20-Section machine, (500) panels per shift.

Call for Price

QUICK 20 Section Automatic Clamp Carrier: -- Clamp Carrier: (20) Sections with 8-1/2' width cap., (6) heavy duty zinc plated clamps per section (120 clamps total), 32" opening on clamps (other lengths available). -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- For face gluing, Rocking Plates available as optional equipment. -- Equipped with: -- Fully Automatic Hydraulic Clamp Tightener with adjustable torque limiter, integral Pneumatic Panel Flatteners and Electric Motor Drive with fully Automatic Carrier Rotation Cycle. Two control panels maximize ease-of use. Rack and pinion carriage traverse system is solid and quietFeatures: -- The QUICK Automatic Clamp Carrier is the ideal labor-saving device for the high-production furniture or cabinet manufacturer. The Automatic Clamp Carrier cuts labor costs in half by allowing the Clamp Carrier operator to perform other tasks (such as applying glue to stock, etc.) while the machine automatically flattens panels, tightens clamps, rotates, and loosens clamps. -- After loading wood into a section of clamps, the operator presses the "Auto Tighten" button. The hydraulic Automatic Carriage then traverses from left to right, flattening panels and tightening clamps that it finds along the way. When the Carriage reaches the right end of its traverse, the machine performs an automatic rotation cycle, which brings the next section of clamps down to the operator’s position. The Carriage then traverses from right to left, loosening clamps that it finds along the way. -- The Fully Automatic Clamp Carrier can also be used in manual or semi-automatic modes, by pressing buttons on the Control Panels. -- Complete with & Includes: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: 20 Section machine can produce up to (500) panels per shift!

QUICK 14-Section Pneumatic Clamp Carrier with 16-1/2' width capacity and Glue applicatorWith (15) Standard zinc plated clamps per section (210 clamps total), 48" opening on clamps Standard Features include: Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment (2) Panel Flattener with easy to use controls.(2) Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time! Complete with:Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.14-Section Clamp will produce 300 panels

QUICK 40 Section 10.5' Heavy Duty Hydraulic Clamp Carrier: -- Clamp Carrier: (40) Sections with 10-1/2' width cap., -- (10) heavy duty zinc plated clamps per section (400 clamps total), 40" opening on clamps with quick adjustment (other lengths available). -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- For face gluing, Rocking Plates available as optional equipment.Equipped with: -- (1) Hydraulic clamp tightener for 10.5' -- (1) Hydraulic clamp tightener 10.5' for second operator -- (1) Pneumatic Panel Flatteners for 10.5' wide -- (1) pneumatic panel fattener 10.5' wide for second operatior -- Electric Motor Drive with fully Automatic Carrier Rotation Cycle.Two control panels maximize ease-of use. Rack and pinion carriage traverse system is solid and quiet -- Complete with & Includes: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.Note: this machine has 2 hydraulic tightener and 2 Pneumatic panel flattener for (2) operator)If one operator is fine the machine price could be reduce by $3,600

SCM Sandy 10 -RCS-110 Wide Belt Sander (2) Heads43" Width cap. Drum, Combination HeadHead Configuration:1st. Head: 7" diameter corrugated metal roller for calibration 35 HP ( Drives both Heads )2nd Head: Combination head with 7" dia. contact roller (spiral grooved rubber covered); air/jump finishing platen controlled with timers to eliminate any rounding on leading & trailing edges of the panel, 2" wide platen.Specifications --103" long x 43" wide Abrasive belts --Air tracking, floating & rigid bed for sanding of veneers & solid panels; infeed & outfeed spring loaded holddown rolls -- Minimum workpiece length 16" --Thickness capacity 6.25". --Separate 2.5 H.P. variable speed feed motor delivering feed speeds from 15 to 70 FPMNote: The seller has 20 boxes of various sandpaper belts (80 – 150 grit) that will be included.

SCMI STARTECH/23 23-Spindle Construction Boring Machine.Specifications: -- Distance between spindles 32 mm (1.26"), Maximum drilling head distance 704 mm (27.72"), Maximum drilling depth 45 mm (1.77"). -- Panel thickness 10 - 75 mm (0.39" - 2.95"), Maximum panel width under bridge 1,000 mm (39.37"). -- Maximum panel size:270 mm(10.63") (with vertical head), 130 mm (5.12") (with horizontal head). -- Drilling head stroke 63 mm (2.48"), Tool diameter 5 - 10 mm (0.20" - 0.39"), Tool length 55 - 75 mm (2.17" - 2.95"). -- 26-1/4" x 40" x 33-1/2" H Table, 2.64 kW (3-1/2 HP) 3,390 RPM Motor.Equipped with: -- 23-Spindle Boring head (Aluminum alloy single block), Drills vertically from top & horizontally from rear. -- Manual tilt with Gas shock cylinder assist, Positive stop at 45° for boring at angle. -- 6-Position Turret depth stop. -- (2) 3" Diameter Air hold-down clamps, Foot pedal operated. -- Index pins for line boring, 15-1/4" L x 1-1/2" H Side fences.Complete with: Operation & Maintenance Manual & SHOP FOX Mobile Base with Swivel Casters. -- Dimensions: 58" x 48" x 46" H. Weight: 1,100 Lbs.

SCM SIGMA SZ 110 PLAST Automatic Panel Saw;This machine is Ideal for Plastic Materials. -- Specifications: Working cap. 149.6" (3,800 mm) Max. rip cut cap. 149.6" (3,800 mm) pusher stroke; 4.5" (115 mm) max. saw blade projection.24 HP (17.8 KW) main saw motor Inverter controlled for various plastics, variable speed from 0 - 3,900 RPM; 2 HP (1.5 kW) scoring saw motor (4,200 RPM).Main blade diameter: 15.75" (400 mm), Main blade arbor diameter: 80 mm; Scoring blade diameter: 7.87" (200 mm), Scoring blade arbor diameter: 80 mm.Manual scoring blade adjustment with digital indicator. Automatic exclusion of scoring unit when motor is in off position. -- Saw carriage: Feed speed 0 - 442 FPM (0 - 134 MPM), return speed 442 FPM (134 MPM),Automatic saw carriage lubrication, balanced on hardened cylindrical guides; external score saw adjustment, THK guides for vertical saw movement. -- Pusher Fence Feed Speed 0 - 230 FPM (0 - 70 MPM) forward speed, 230 FPM (70 MPM) reverse speed.Programmable rear fence with (9) material gripper clamps with twin fingers for thin materials, rack & pinion movement,Grippers fit into a slotted pressure beam for positive material control during the final cut. -- Operator & Machine Control:PC front-end with SCM Real-time "WinCut" + Windows "7" operating system; Pentium 300 MHz, 6.4 GB hard drive, 64 MB RAM,17" Color VGA flat panel Touchscreen monitor, on-screen diagnostics & production reports; (2) serial ports & (1) parallel port, spacing available for networking cards. "Cutty" optimization software is included which allows for (2) different sheet sizes and (22) different parts, each part is allowed a max. quantity of 300. -- Complete with: Side alignment device: Min. part width 2.8"; Max. part width 47.24". Rear support rails with rollers.(1) Front fixed air table 98" x 23" (2,500 x 584 mm), (2) Adjustable air tables 98" x 23" (2,500 x 584 mm).Plastic safety guards, emergency stop bar; enclosed cutting area; triple dust collector outlet.Actual model is SCM SIGMA SZ 110 PLAST.

SCM K400 E EDGEBANDER Edge Capacity,0.4 to 6 mm (0.016to 1/4")for strip feeding. -- Panel Capacity, min. width65 mm and 140 mm min. length, (2-3/8" and 5-1/2"). Panel thickness min./max. 8 - 60 mm (3/8" - 2-1/2").Equipped with: -- Automatic strip & coil feed magazine, Teflon coated glue pot (heat-up time 10 Min), -- 3 mm cap. guillotine, 3-roll pressure unit. -- Startouch control system with large 12" screen, graphic display with one touch, memory capacity up to 60 working programs. --Workstations: -- Double motor front & rear end trim "K-2" mounted on THK guides (0.4 HP - 12,000 RPM) , tilts 0° - 15°, rapid set up between straight and angled cutting with the automatic tilting device. -- Top & bottom flush & bevel trims "RI/800" (0.7 HP - 12.000 RPM), bevels 0° - 15° with precision digital indicators for quick setup. -- Top & bottom "RAS/V" scraping unit with container with filter for long chips; -- Top & bottom buffing unit (0.25 HP - 2,800 RPM ). -- 36 FPM Fixed feed speed, 0.75 HP feed drive.Complete with: -- Full cover sound enclosure, mechanical digital readouts for setup adjustments, frequency inverter and outboard panel support. -- Actual Model: "OLIMPIC K 400 E".

$9,000

SCM OLIMPIC K 201 HFA Automatic Compact Edgebander, with 3 mm Max. Coiled Edgebanding Thickness & High Frequency MotorsSpecifications: -- Edgebanding thickness cap. (for both coil & strip) 0.4 - 3 mm (0.02" - 0.19"). -- Min. panel length for coiled edges (Min. width 200 mm) 140 mm (5.51"). -- Min. panel width for coiled edges 65 mm (2.56"). -- Panel thickness 8 - 40 mm (0.31" - 1.57"). -- Feed speed 9 MPM (29 FPM).Equipped with: -- Automatic adjustment of all units when panel thickness is changed. -- 20" Dia. Coil table. -- Automatic coil feed magazine, Manual strip feed. -- Teflon-coated glue pot. -- 1.2 mm (0.05") Cap. guillotine. -- Eye-level control, with GEFRAN "1000" LED Temperature controller. -- Adjustable feet.Workstations: -- Single-motor end trimming unit, with (1) 0.19 kW (1/4 HP) 12,000 RPM High-frequency motor & Copying device. -- Top & bottom flush trimming unit, with (2) 0.35 kW (1/2 HP) 12,000 RPM High-frequency motors and Front & Vertical copying devices.

$10,700

SCM P-170 Feed Through Moulder5-Head, 6-5/8" x 4-3/4" capacity. Specifications: -- Head sequence: Bottom 6.5 HP, right 6.5, left 6.5 HP, top 9 HP, Universal 9 HP motor; -- 1-13/16" Dia. spindles at 6,000 RPM, spindles equipped with high cap. precision bearings, all set-up adjustments on front side of machine. -- 15 - 85 FPM Feed speed, 3.6 HP Cardan (chainless) feed drive, motorized feed beam with air-loaded feed wheels.Complete with: -- 84" Long infeed table with quick lever thickness adjustment for stock removal, manual Waxilit bed lubrication. -- Note: No cutterheads or tooling included.

$4,900

20" (520 mm) Width cap.7,5 HP (5,5 kW) main motor ÷4-knife cutterhead÷1/8" to 9-1/2" (3 - 240 mm) ÷motorized opening mechanical scale for bed position max. depth of cut 5/16"÷10" min. length of workpiece ÷(4) feed speeds at 18/30/39/51 FPM (6/10/13/17 m/min.)÷table size 20-3/4" x 33-1/4". ÷Includes: Knife sharpening attachment ÷ Equipped with: Chipbreaker, sectional grooved infeed & solid outfeed roller.