Edgebanders For Sale

Category

Edgebanders

196 Results Found

$ 15,000

Call for Price

Min. Panel Thickness: 0.39? Max Panel Thickness: 2.36? Height of Edge-Band Material: 0.55-2.51? Min. Banding Thickness: 0.01? Max Banding Thickness: 0.39? Min. Panel Length: 5.51? Min. Panel Width: 1.96? 2 Feed Speeds: 39ft/min & 59ft/min Electrical: 230V, 60Hz, 3Phase Equipped With Siemens TD200

Call for Price

BIESSE AKRON 855 EDGEBANDER (W/PRE-MILL & CORNER ROUNDING):Specifications: -- Edge & Workpiece Capacity: 0.4 -15 mm (0.016" - 0.59"), Edge thickness, 14 - 65 mm (0.55" - 2.56"), Edge height, 10 - 60 mm (0.39" - 2.36"), Panel thickness:140 mm (5-1/2") Min. panel length, 85 mm (3.3") Min. panel width.Infeed Section: -- Pre-Milling Unit, "FI-701 Rectifies face to be edged before applying glue, Horizontal & vertical movement of (2) motors on linear guides, Independent automatic temporized intervention of (2) 1.8 kW (2-1/2 HP) 12,000 RPM Motors, Independent copying pads on each unit, Auto-set device to ensure optimum positioning of cutters according to the thickness of panel being machined. -- Edge Feeding, Gluing & Pressing Unit, "VC-710": with Automatic edge magazine for strip & coil stock, 3 mm (0.04") PVC Guillotine, "TEKNO-GLUE" System Includes: Pre-Melt, "QM-701", For quick heating & tank changing with floating & bidirectional glue roller applicator, and NC axis idle presser roller movement device. -- Pressure Section: (1) Large driven & (5) Idle rollers, Independent pneumatic pressure control, Programmable servo motor for quick edge thickness changeover, Feed speeds 10, 14 & 20 MPM (33, 46 & 65 FPM).Workstations: -- End (Edge) Trimming Unit, "IN-701-V": (2) 0.35 kW (1/2 HP) 12,000 RPM Motors, Automatic 4-position programmable chamfer from control panel (0°, 3.6°, 11°, 15°), Sliding in slicing motion on 45° precision guide bar with oversized bearing blocks. -- Superimposed Flush (Double Edge) Trimming Unit: "RS-701": Top & bottom, (2) 0.8 kW (1 HP) 12,000 RPM Motors with Superimposed motor position, 1° Tilt capability. Includes: Pneumatic exclusion device & Pneumatic top/bottom motor positioner. -- Tilting Top & Bottom Trimming Unit, "RI-701": (2) 0.65 kW (0.87 HP) 12,000 RPM Motors, For radius top & bottom fine trimming, Unit can be tilted 0° - 45°. Includes: NC axis multiple machining device. -- Corner Rounding Unit, "CR-200V": For corner rounding, top & bottom trimming on panel edge with synthetic material & wood edgebanding up to 5 mm (0.20") Maximum edge thickness. -- Edge Scraping Unit, "RB-701": For finishing rounded-off edges in PVC or ABS up to 5 mm (.20")thickness; Includes: Pneumatic unit lifter. -- Flat (Glue) Scraper, "RCC-700":Top & Bottom, removes potential excess glue before buffing unit. -- Buffing Unit, "SPL-700": Top & bottom. -- Hot Air Blower Unit, "PH-700", (2) STEINEL "2346" 2,000 W, Reactivates color of thick plastic.Complete with: -- PC-based control panel with 15" Color LCD monitor, HF (High-frequency motors on all cutting & trimming workstations. --Top pressure beam programmable via positioning motor, Top pressure provided by belt hold-down. -- 36" Diameter Coil table, Padded sound enclosure. -- Manuals (as pictured). -- Dimensions: 280" x 42" x 72" H. Weight: 3500 kG (7,750 Lbs).

Call for Price

BIESSE STREAM A 6.0 EDGEBANDER (W/PRE-MILL & CORNER ROUNDING), High Production w/NC AXIS PACKAGE:Features: -- "NC AXIS PACKAGE": The machine adapts to the process being executed based on the edge's thickness and material.Machine management 100% touch with no need for external devices. Intelligent language management.Easy program management and usability with rapid transition from one machining operation to the next. Specifications: -- Edgebanding Capacity: Edge thickness for strips min./max. 0.4 - 22 mm (0.02" - 0.87"), coiled material from 0.4 - 3 mm (0.02 - 0.12");Panel thickness from 10 - 60 mm (0.39 - 2.36"), workpiece width min. of 85 mm (3.34"); workpiece length min. 140 mm (5.51");Feed speeds 12 - 18 - 20 - 25 MPM (39 - 59 - 65 - 82 FPM).Machine In-Feed Configuration: -- Pre-Milling Station:(2) 1.8 kW (2.4 HP) - 12,000 RPM Motors, LH & RH Counter Rotating Spindles, NC (servo) controlled with automatic intervention that guarantees a perfect base for gluing. -- Anti-Adhesive:Automatic Spray Unit with: Glue release agent preventing glue to adhere to work piece's surfaces. -- Infrared Heating Lamp:Preheating workpiece edge to ensure best possible surface adhesion quality of edgebanding material. -- Edge Magazine: Automatic 2-coil/position magazine for processing coiled and strip edgebanding material in real time. -- Pressure Section:Servo controlled programmable pressure section with (1) large driven roller and (4) idle rollers.Gluing System w/ Pre-Melter: -- EVA (Hot Melt), Quick premelting granulate with glue roller applicator to cover conventional edgebanding material. Workstations: -- End Trimming: Front & rear Linear end trimmer with Tilt Function for high speeds with (2) 0.8 kW (1.0 HP) - 12,000 RPM motors). The machine axis movement on linear tracks, allows the achievement of very high processing speeds.The copying and tracing system guarantees optimal finish quality also on high-gloss edges with film. -- Flush/Bevel Trimming Unit:Top & bottom flush or bevel trims with (2) "Quick Change" 0.65 kW (0.8 HP) - 12,000 RPM motors. -- Fine Trimming Unit: (2) 0.65 kW (0.8 HP) - 12,000 RPM Motors. (2) Servo motors for tool positioning (one for horizontal tool position, one for up/down tool position);Pre-positioning of motors by pneumatic air cylinders. while using a combination bevel/radius/flush insert knives;Absolute machining flexibility, thanks to the full adjustment of the machine according to the required edge thickness. -- Corner Rounding Unit: (2) 0.65 kW (0.8 HP) - 12,000 RPM Motors for front/back corner and upper & lower edge profiling.The controlled axis on the Corner Rounding unit supports the management of infinite machining settings. -- Profile Scraping Unit:Top/Bottom 2-axis NC programmable knife positioning (i.e. 2 - 3 mm radius) for PVC edges. -- Glue Scraping Unit: Flat, top/bottom, digital positioning indicators, pneumatic controlled for in/out position. -- Buffing Station: Top & Bottom buffing motors 0.37 kW

Call for Price

$ 8,950

BIESSE AKRON 420 EDGEBANDER --Machine Capacity: -- Thickness of banding rolls 0.4 - 3 mm (0.12"), Thickness of strips (HPL, veneer, solid wood strips) .0.4 - 6 mm (0.24"). Panel thickness 60 mm (2.4") max. & 10 mm min., Minimum panel length 140 mm.(5.5"). Minimum panel width 85 mm (3.3") --Equipped with: --÷ Feed/Glue Unit: automatic strip & coil feed magazine with robust shear-type 3 mm PVC guillotine. --÷ Hot Melt glue system, 10 Minute heat-up time with Teflon coated gluepot, digital thermostats with automatic kick-down when machine is in idle mode.÷ •1" Dia. glue applicator roller; pressure section with (1) large dia. "non-stick" coated drive roller & (2) chrome plated idle rollers with pneumatic positioning. --Workstations: --÷ Inclined travel Front & Rear End Trims (0.25 HP - 12,000 RPM motors), motors travel on (2) straight slides and pneumatic tilt 0° - 15° on horz. plane. --÷ Top & Bottom Fine Trims with motors (0.5 HP - 12,000 RPM motors), numeric readouts for easy setup. -- Top & Bottom Buffing Station (0.5 HP - 2,800 RPM motors), units tilt 0° - 30°. --÷ Feed Speed of 12 MPM (39 FPM), 3 HP feed drive. --Complete with: Insulated sound enclosure over all trim stations, extendible side panel support rail.

$ 15,950

BIESSE SPARK 3.3 Edgebander (Compact)0.4 mm to 3 mm Material thickness. Min. panel thickness 10 mm, max. panel thickness 40 mm. Min. panel width 90 mm, min. panel length 140 mm.Equipped with: -- 2 Liter Glue Teflon coated tank with quick heating system. -- Top pressure beam with manual adjustment through numerical read-out equipped with rubberized holddown wheels. -- Pneumatic Guillotine knife for automatic edge cutting with a max thickness of 3 mm with automatic “kickback” of the edge. -- Adjustable edge pressure unit with (2) rollers: 1st roller motorized with separate adjustable pressure system; 2nd idle roller with separate adjustable pressure system. Workstations: -- Double Motor End Trimming Unit - 2 tilting motors HF 0.5 HP each. -- Top and bottom Trim with (2) HF motors, 0.75 HP (0.55 kW) each and micrometric adjustment with numerical read-out. Cutters with 3 mm radius with (4) knives. -- Top and bottom Buffing station. -- Material feed speed 12 MPM (39 FPM).

$ 34,750

BIESSE STREAM B1 9.0 ... Production Edgebander with Pre-Milling & Corner Rounding Specifications: -- Capacity, 0.4 - 15 mm edge thickness cap., min. panel width 100 mm, panel thickness 10 - 60 mm, min. panel length 150 mm. -- Pre-Milling Unit: With jump control & side copying unit for managing warped panels, 2-position infeed fence, digitals readouts. -- NC 410 Controller with: Graphic interface on MS-Windows 2000 Professional, 32-bit operating system; high resolution LCD color screen, unlimited" number of working programs, each with functions for remote control of processing units; fault diagnostic, bar code reader adaptable; etc. -- Automatic (2) coil vertical feed magazine for coil material up to 3 mm thickness with automatic changeover. -- Patented Glue System w/pre-melt, large separated granular hopper for easy filling & high gluing capacity, with roller applicator (reversible); -- Pressure Section, (1) large driven pressure roller & (6) pneumatic secondary pressure rollers. Workstations: -- End Trimming:Double motor front & rear linear end trimming unit "IT 46" (0.4 HP/0.3 kW - 12,000 RPM motors ea.); pneumatic chamfer setting, 0° - 15° adjustable. --÷ Pre/Rough Trimming:Top & bottom "RS 10" (1.75 HP/1.3 kW - 12,000 RPM motor ea.), pneumatic exclusion & positioning from control panel. -- Radius/Bevel Trimming:Top & bottom (0.87 HP/0.65 kW - 12,000 RPM motor ea.), tiltable 0° - 30°, pneumatic exclusion from operator panel. -- Corner Rounding:4-Motor for leading & trailing edges. -- Profile Scraping Unit:Top & bottom with collection box. -- Flat Glue Scrapers:Top/bottom to remove potential glue squeeze-out. -- Buffing Unit:Top/bottom, ozcillating/tilting "SZ 30" w/pneumatic exclusion control from control panel & 0.67 HP/0.5 KW- 1,400 RPM motors; -- Hot Air Unit:Top/Bottom hot air blowers to reactivate/smooth heavy pvc radiused edges. Complete With:- Motorized top pressure beam with powered V-belt hold-down, electronic positioning by NC controller.- 80 mm wide Heavy Duty feed chain w/rubber pads, - 4 HP feed drive for feed variable speeds of 26 - 78 FPM. - Pneumatic Pre-set Stop System for most adjustments via the control panel on top & bottom trim, fine trim, and scraper station,- Electronic frequency inverter, electronic DC brakes on all trim motors.- Sound cabins for all trim work stations, outboard panel support.Note: Actual Model ... BIESSE STREAM B1 9.0

Call for Price

The seller has confirmed that this Biesse Lato is in great working/running condition. This is ready to load! - User Friendly PLC Controller - Adjustable Pressure Beam - Quick Heat-Up Glue System with Dual Temperature Control and Auto Cool Down Feature when Machine is Idle. - Pneumatically Controlled Pressure System - Front & Rear End Trimming w/Tilt - Top & Bottom Edge Trimming Units - Top & Bottom Edge Profile Trimming Unit w/Tilt and Pneumatic ExclusionTop & Bottom Profile Scraping Unit with Pneumatic Exclusion - Top & Bottom Hot Air Blower - Top & Bottom Buffing Units - Specifications : - Min. Panel Thickness:.........10mm - Max. Panel Thickness:.........60mm - Height of Edge-Band Material: 14-64mm - Min. Banding Thickness:......0.4mm - Max. Banding Thickness:.....10mm - Min. Panel Length:................140mm - Min. Panel Width:.................. 50mm - 2 Feed Speeds:.....................12m./min & 18 m/min - Electrics : 230V, 3 Phase - Machine Dimensions: 174" L x 39" W x 57" H - Machine Weight: 1800 lbs

$ 25,000

BIESSE AKRON 855 EDGEBANDER (W/PRE-MILL & CORNER ROUNDING):Specifications: -- Material infeed for strips & coiled edge material like PVC, ABS, veneer, and solid wood.0.4 - 3 mm (0.118"), Panel thickness 10-60 MM ( 0.39" - 2.36"), min. panel length 140 mm (5.5") and 85 mm (3.34") min. widthInfeed System Equipped with: -- Independent copying guide pads on each unit with manual adjustment & mechanical digital indicator.Pre-Milling Unit (FI-701) (2) 1.8 kW motors (2.5 HP), 12,000 RPM with Auto-Set device to ensure optimum positioning of the cutters according to the thickness of the panel being machine; -- "VC-710" edge feeding, gluing & pressing unit with automatic edge magazine for strip & coil stock; 3 mm PVC guillotine. -- "TEKNO-GLUE" System, Pre-Melt "QM-701" for quick heating & tank changing with floating & bi-directional glue roller applicator.Pressure Section: (1) Large motorized pressure wheel with clutch, plus (5) idle rollers, independent pneumatic pressure control & digital counters for quick edge thickness changeover.Edgebanding Workstations: -- Double Motor End Trim, tiltable from 0ø - 15ø, each motor 0.5 kW (0.6 HP) - 12,000 RPM; sliding in a slicing motion on a 45ø precision guide bar with oversized bearing blocks. -- Top & Bottom Rough Trim: Top/bottom (2) motors, each 1.8 kW (2.5 HP) 12,000 RPM with superimposed motor position, 0ø - 45ø tilt capability, straight cutterheads (80 x 25 x 16 mm) w/insert knives; includes pneumatic exclusion from control panel. -- Top & Bottom Fine Trim: Top/bottom (2) motors, each 1.8 kW (2.5 HP) 12,000 RPM with superimposed motor position, 0ø - 45ø tilt capability, straight cutterheads (80 x 25 x 16 mm) w/insert knives; includes pneumatic exclusion from control panel. -- Multifunction 4-Motor Corner Rounding Unit "CR-202": (4) Motors, each 0.65 kW (0.87 HP) - 12,000 RPM; motors carry out Corner Rounding and Top & Bottom Trimming on panel edge with PVC, ABS, etc. material and wood edgebanding up to 5 mm max. edge thickness. --Top & Bottom Radius Scraping (PVC): Knives R = 2 mm, with mechanical digital indicators for precision setup, pneumatic exclusion of the unit from the machining line, PVC scrape collection box. -- Top & Bottom Flat Scraper (Glue): self-adjusting with copy wheels & flat insert knives, removing potential excess glue before buffing unit. -- Top & Bottom Oscillating Buffing Station: (2) motors, each 0.37 kW (0.5 HP) - 2,800 RPM. -- Top & Bottom Hot Air Blowers is made by two 2000 W hotair blowers to reactivate the color of PVC/ABS edges after the machining.The air temperature is adjustableFeatures & Feed: -- All cutting & trimming workstations have HF motors and enclosed by padded sound enclosure, top pressure is provided by staggered double-row holddown wheels mounted on ball bearings. -- Feed chain track speed : 10 - 14 - 20 MPM (33 - 46 - 65 FPM). -- Complete with:CNi PC w/Flat, Color "REAL TIME" graphic interface design on 17” flat screen (TFT) with high resolution

Call for Price

BIESSE AKRON 855 EDGEBANDER (W/PRE-MILL & CORNER ROUNDING):Specifications: -- Material infeed for strips & coiled edge material like PVC, ABS, veneer, and solid wood.0.4 - 19 mm (0.118" - 0.75"), Panel thickness 10-60 MM (0.39" - 2.36"), min. panel length 140 mm (5.5") and 85 mm (3.34") min. widthInfeed System Equipped with: -- Independent units on each unit with manual adjustment & mechanical digital indicator.Pre-Milling Unit: (2) 1.8 kW motors (2.5 HP), 12,000 RPM with NC controlled Auto-Set devices to ensure optimum positioning of the cutters according to the thickness of the panel being machine; -- Edge feeding: Gluing & pressing unit with automatic edge magazine for strip & coil stock; 3 mm PVC guillotine. -- "TEKNO-GLUE" System, Pre-Melt for quick heating & tank changing with floating & bi-directional glue roller applicator. -- Pressure Section: (1) Large motorized pressure wheel with clutch, plus (5) idle rollers, independent pneumatic pressure control & digital counters for quick edge thickness changeover.Edgebanding Workstations: -- Double Motor End Trim, tiltable from 0ø - 15ø, each motor 0.5 kW (0.6 HP) - 12,000 RPM; sliding in a slicing motion on a 45ø precision guide bar with oversized bearing blocks. -- Top & Bottom Rough Trim: Top/bottom (2) motors, each 1.8 kW (2.5 HP) 12,000 RPM with superimposed motor position, 0° - 45° tilt capability, straight cutterheads (80 x 25 x 16 mm) w/insert knives; includes pneumatic exclusion from control panel. -- Top & Bottom Fine Trim: Top/bottom (2) motors, each 1.8 kW (2.5 HP) 12,000 RPM with superimposed motor position, 0ø - 45ø tilt capability, straight cutterheads (80 x 25 x 16 mm) w/insert knives; includes pneumatic exclusion from control panel. -- Multifunction 4-Motor Corner Rounding Unit: (4) Motors, each 0.65 kW (0.87 HP) - 12,000 RPM; motors carry out Corner Rounding and Top & Bottom Trimming on panel edge with PVC, ABS, etc. material and wood edgebanding up to 5 mm max. edge thickness. --Top & Bottom Radius Scraping (PVC): Knives R = 2 mm, with mechanical digital indicators for precision setup, pneumatic exclusion of the unit from the machining line, PVC scrape collection box. -- Top & Bottom Flat Scraper (Glue): self-adjusting with copy wheels & flat insert knives, removing potential excess glue before buffing unit. -- Top & Bottom Oscillating Buffing Station: (2) motors, each 0.37 kW (0.5 HP) - 2,800 RPM.Features & Feed: -- All cutting & trimming workstations have HF motors and are enclosed by a padded sound enclosure, top pressure is provided by staggered double-row hold-down wheels mounted on ball bearings. -- Feed chain track speed: 10 - 14 - 20 MPM (33 - 46 - 65 FPM). -- Complete with:CNi PC w/Flat, Color "REAL TIME" graphic interface design on 17” flat screen (TFT) with high resolution.Actual model is BIESSE AKRON 855

$ 16,900

BIESSE - AKRON 855, ...Computer Controlled Production Edgebander.Features & Main Specifications: -- Computer-controlled interface for workstations with: Servos and pneumatic positioning devices. -- Programmable selections for "1-touch" changeover between edgebanding types and thicknesses. -- Edgebanding thickness: 0.4 - 19 mm Capacity. -- Min. panel: Width 85 mm & length 140 mm; thickness of 10 - 50 mm. -- Feed speed variable from 10 - 20 MPM, 3 HP feed drive.Frontend Equipped with: -- Premilling Unit with: (4) Positions for automatic changeover between premill settings, NC controlled. -- Strip & Coil Edge magazine: Automatic, "HD" shear-type guillotine. -- Top Pressure Beam: On-screen adjustable for height positioning. -- Hot-Melt Glue System: 12 Min heat up time, Teflon® coated gluepot; digital thermostats with automatic kick-down when machine is in idle mode. -- Side Pressure Section with: (1) Large dia. "non-stick" coated drive roller; (5) Teflon® plated idle rollers with Servo positioning, and NC controlled material thickness adjustment. Workstations: -- End Trimming Unit: Front & Rear (0.33 HP - 12,000 RPM motors), motors travel on (2) straight slides and pneumatic tilt 0° - 15° on horizontal. plane, NC controlled. -- Flush Trimming Unit: Top & Bottom with "Quick Change" motors, 1.0 HP - 12,000 RPM motors; digital readouts for easy setup. - 2-Position NC controlled. -- Flush/Bevel/Radius Trimming Unit: Multiuse top & bottom, 2-motor (0.3 HP - 12,000 RPM). Servo driven positioning of motors for different edge trimming setups. NC Controlled adjustment between profiles and positions. -- Corner Rounding Unit: 4-Motor (0.3 HP - 12,000 RPM motors) for trimming leading & trailing upper & lower edge/corners with "Fast Position"; can be used as a 2nd Top & Bottom fine trimmer, as well. -- Profile Scraping Unit: Top & Bottom for 2 mm or 3 mm thick PVC banding; digitals for horiz. adjustments. -- Flat Scraping Unit: Top & Bottom for glue and fine panel scraping. -- Buffing Unit: Top & Bottom (0.5 HP - 2,800 RPM motors), units tilt 0° - 30°. -- Hot Air Blower Unit: Top & Bottom edge reactivation station (2,000 Watt), hot air blowers with temperature adjustment. Complete with: -- Programmable processor for workstations & feed speed. -- Insulated sound enclosure over all trim stations with: Triple split dust & safety hood enclosure, industrial lights, and viewing windows. -- Extendable side panel support rail. -- 12 KVA - 240 Hz Digital frequency inverters.Includes: -- Used tooling on all workstations. -- Extra set of diamond tooling for premill unit. -- (1) Premill motor. -- NOTE: Chain pads have been replaced (2) years ago

$ 18,500

BIESSE - AKRON 855, ...Edgebander with Premill & Corner Rounding (Loaded!)Specifications: -- Edge & Workpiece Capacity: 0.4 - 15 mm (0.016" - 0.59") Edge thickness; 14 - 65 mm (0.55" - 2.56") edge height; 10 - 60 mm (0.39" - 2.36") panel thickness; 140 mm (5-1/2") min. panel length; 85 mm (3.3") min. panel width. Infeed Section: -- Premilling Unit - "FI-701"Rectifies face to be edged before applying glue; horizontal & vertical movement of (2) motors on linear guides; independent automatic temporized intervention of (2) 1.8 kW (2-1/2 HP) - 12,000 RPM motors; independent copying pads on each unit, Autoset device to ensure optimum positioning of cutters according to thickness of panel being machined. -- Edge Feeding, Gluing & Pressing Unit - "VC-710"With automatic edge magazine for strip & coil stock; 3 mm (0.04") PVC guillotine; "TEKNO-GLUE" System includes: Pre-Melt "QM-701"; for quick heating & tank changing with floating & bidirectional glue roller applicator & NC axis idle presser roller movement device. -- Pressure Section: (1) Large driven & (5) Idle rollers, Independent pneumatic pressure control, Programmable servo motor for quick edge thickness changeover, Feed speeds 10, 14 & 20 MPM (33, 46 & 65 FPM).WORKSTATIONS: -- End (Edge) Trimming Unit - "IN-701-V"(2) 0.35 kW (0.5 HP) - 12,000 RPM Motors; automatic 4-position programmable chamfer from Control Panel (0°, 3.6°, 11°, 15°); sliding in slicing motion on 45° precision guide bar with oversized bearing blocks. -- Superimposed Flush (Double Edge) Trimming Unit - "RS-701"Top & bottom; (2) 0.8 kW (1 HP) - 12,000 RPM motors with superimposed motor position; 1° tilt capability; includes: Pneumatic exclusion device & Pneumatic top/bottom motor positioner. -- Tilting Top & Bottom Trimming Unit - "RI-701"(2) 0.65 kW (0.87 HP) - 12,000 RPM Motors; for radius top & bottom fine trimming; unit can be tilted 0° - 45°; includes: NC axis multiple machining device. -- Corner Rounding Unit - "CR-200V"For corner rounding; top & bottom trimming on panel edge with synthetic material & wood edgebanding up to 5 mm (0.20") max. edge thickness. -- Edge Scraping Unit - "RB-701"For finishing rounded off edges in PVC or ABS up to 5 mm (0.20") thickness includes: Pneumatic Unit Lifter. -- Flat (Glue) Scraper - "RCC-700"Top & Bottom, Removes potential excess glue before buffing unit. -- Buffing Unit, "SPL-700":Top & Bottom. -- Hot Air Blower Unit - "PH-700" - (2) STEINEL "2346" 2,000 W; reactivates color of thick plastic.Complete with: -- PC-Based Control Panel with: 15" Color LCD monitor, HF (High Frequency motors on all cutting & trimming workstations. Top pressure beam programmable via positioning motor; top pressure provided by belt holddown. 36" Dia. Coil table: Padded sound enclosure. -- Manuals (as pictured).Dimensions: 280" x 42" x 72" H. - Weight: 3,500 kG (7,750 Lbs.).

$ 17,950

BIESSE SPARK 3.3 Edgebander (Compact)0.4 mm to 3 mm material thickness. Min. panel thickness 10 mm, max. panel thickness 40 mm. Min. panel width 90 mm, min. panel length 140 mm.Equipped with: -- 2 Liter Glue Teflon coated tank with quick heating system. -- Top pressure beam with manual adjustment through numerical read-out equipped with rubberized holddown wheels. -- Pneumatic Guillotine knife for automatic edge cutting with a max thickness of 3 mm with automatic “kickback” of the edge. -- Adjustable edge pressure unit with (2) rollers: 1st roller motorized with separate adjustable pressure system; 2nd idle roller with separate adjustable pressure system. Work stations: -- Double Motor End Trimming Unit - 2 tilting motors HF 0.5 HP each. -- Top and bottom Trim with (2) HF motors, 0.75 HP (0.55 kW) each and micrometric adjustment with numerical read-out. Cutters with 3 mm radius with (4) knives. -- Top and bottom Buffing station. -- Material feed speed 12 MPM (39 FPM).

Call for Price

BIESSE EDGE - ROXYL 6.0 Edgebander, ...with (429) Hrs. Only!Specifications: -- Edgebanding thickness: 0.4 - 22 mm (0.02" - 0.87") Strip, 0.4 - 3 mm (0.02 - 0.12") Coil. -- Panel thickness 10 - 60 mm (0.39 - 2.36"), Min. panel width 85 mm (3.35"), min. panel length 140 mm (5.51"). -- Feed speeds: 10, 14, 18, & 20 MPM (33, 46, 59, & 65 FPM).Equipped with: -- "FI-502" Premilling Unit with: (2) Servo controlled spindles with Left-hand & Right-hand rotation & Auto-set device. -- "ADZ-700" Automatic anti-adhesive spray unit. -- 31" Dia. Coil table. -- Servo controlled infeed fence. -- Automatic edge Magazine for strips & coiled material. -- "VC-710" Hot melt glue system with: "QM-705" Premelt system for EVA. -- Servo controlled pressure section with: (1) Large driven roll & (4) idler rolls. -- PC-Based control with: 19" LCD Display, "ROXYL-MATIC" automated machine setup, MICROSOFT "WINDOWS" Operating System. -- 3-1/8” W Feed chain with: 3 kW (4 HP) Motor. -- Programmable top pressure beam with: Driven flat belt & 0.22 kW (1/3 HP) Motor. -- 19-1/2” Outboard support adjustment. -- Sound enclosure.Workstations: -- "IN-801" Front & rear end trim unit with 0° - 15° Bevel; pneumatic tilt & angle preselection from control. -- "RS-100" Top & Bottom rough/flush trim unit. -- "RF-400" Multifunction tilting Top & Bottom chamfering unit with: (2) HSD "ROTAX AT/MT 1073-120" 2.7 HP - 12,000 RPM Air-Cooled Electrospindles, (4) Servo motors: (2) For horizontal position & (2) for up/down position; Combination bevel/radius/flush insert knives, Pneumatic prepositioning of motors. -- "CR-202" 2-Motor Corner rounding unit. -- "RBK-503" Top & Bottom profile scraping unit with: 2-Axis Servo controlled knife positioning, 2 - 3 mm radius, for PVC edges; "RCC-701" Top & Bottom flat glue scraping unit with Pneumatic controlled in/out position. -- "SP-501" Top & Bottom buffing unit with: (2) 0.37 kW (1/2 HP) - 3,430 RPM Motors. -- STEINEL "3426" 2,000 W Hot air blowers.Complete with: -- Transformer.Dimensions of this specific machine with outboard support extended: 296" x 64" x 72" H.NOTE: Buy the TAYLOR "38A-M3" Return Conveyor (EXF# FR-010320) and keep the set together!

Call for Price

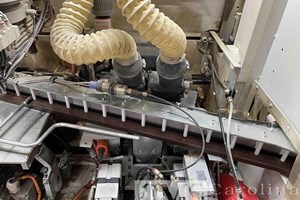

--at Auction, Seller Loading, Powered Inspection Available-- BIESSE AKRON 440 AX Edgebander, with Pre-Mill & Corner Rounding Specifications: - Material infeed for strips & coiled edge material like PVC, ABS, veneer, and solid wood. - Edge & Workpiece Capacity: 0.4 - 3 mm (0.016 - 0.12") Edge; 10 - 60 mm (0.39 - 2.36") panel thickness; 140 mm (5.5") min. panel length, and 85 mm (3.3") min. width. Working Units: - Pre-Milling Station: (2) 3 kW (4 HP) - 150 Hz, 9,000 RPM Motors; equipped with panel blow-off device and SIKO digital counters for adjustments. - EVA Gluing Unit: Edge Feeding and Pressing Unit; Automatic loading of tape in rolls and strips; Quick change glue pot system. - Pressure Section: (1) Large 150 mm dia. driven & (5) idle pressure rollers. - Feed Speeds: Operating feed speeds 12 & 18 MPM (39 & 60 FPM). Workstations: - Double Motor End Trim; Tiltable from 0° - 15°, each motor 0.8 kW (1 HP) - 12,000 RPM; sliding in a slicing motion on a 45° precision guide bar with oversized bearing blocks. - Top and Bottom Trimming; (2) Motors 0.65 KW (0.87 HP) each - "Pro-Nesting" copiers - Cutters R=2 mm. - Fine Trim/Corner Rounding Unit: (2) Motors, each 0.65 kW (0.87 HP) - 12,000 RPM; motors carry out Corner Rounding and Top & Bottom Trimming on panel edge with PVC, ABS, etc. material and wood edge banding up to 3 mm max. edge thickness. - Top & Bottom Flat Glue Scrapper, to remove potential glue squeeze-out. - Buffing Station: Top & Bottom, (2) motors, each 0.37 kW (0.5 HP) - 2,800 RPM. Operator & Machine Control: - Operator control panel, "HDI" High-Definition touch screen control Windows XP based. - User-friendly graphic user interface with diagnostic and assisted maintenance. - USB and Ethernet port. 1.44 MB floppy drive, automatic or manual startup. Complete with: - High-frequency motors (200 HZ): Padded sound enclosure: - Top pressure beam with staggered double-row hold-down wheels mounted on ball bearings. NOTE: Includes new Glue Pot, extra knives & misc. parts.

Call for Price

BIESSE - JADE 240, ...Edgebander w/Premill & Corner Rounding -- Specifications: Edgebanding thickness: 0.4 - 8 mm (0.01" - 0.31"); Min. panel width 85 mm (3-1/2"); min. length 150 mm (5.9"); max. panel thickness 10 - 60 mm (0.39 - 2.36"). -- Premill Unit: (2) 1.8 kW (2.4 HP) - 12,000 RPM Motors; "AUTO-SET" device ensures optimum positioning of the cutters according to the thickness of the panel being machined; numerical readout; pneumatic exclusion when not needed. Workstations: -- End Trimming: Front & rear end trims: 0.8 kW (1.0 HP) - 12,000 RPM Motors; motors travel on 45° slides and pneumatic tilt 0° - 15° from the Control Panel. -- Flush/Bevel Trimming Unit: Top & bottom flush or bevel trims with: "Quick Change" Motors; 0.65 kW (0.8 HP) - 12,000 RPM motors; digital readouts for easy setup. -- Corner Rounding Unit: (2) Motors, 0.65 kW (0.8 HP) - 12,000 RPM for trimming leading & trailing upper & lower edge/corners with 2-position pneumatic set-up for corner rounding. -- Edge Scraping Unit: Finishing unit to eliminate previous machining imperfections; pneumatic exclusion from the machine control. -- Glue Scraping Unit:Top & Bottom scrapers for 3 mm thick PVC banding. -- Buffing Station: Top & Bottom.Operator & Machine Control: -- BIESSE "Smart Touch 7" + Windows Operating System: User-friendly touchscreen Control Panel for workstations; rotating Operator Control Panel w/keypad and LCD readout.Graphic 7" display touchscreen; high-resolution screen for defined and intuitive images and text; integrated 4 GB hard disk for filing media files and the programs back up.USB Port for managing in a simple and efficient way multimedia files, programs, and updates; Ethernet port for connecting the machine to the net.Complete with: -- Top pressure beam & motorized feed track with "anti-slip" "Quick Change" snap on 80 mm wide x 60 mm long rubber pads; low friction nylon graphite self-lubricating chain pads. -- Sound Enclosure & Panel Support: Over all trimming stations; industrial lights and viewing windows; extendable side panel support rail. -- Fixed feed speed at 39 FPM (12 MPM); 3 HP feed drive.Options include: -- Anti-Adhesive Unit:The unit applies an anti-adhesive liquid on the Top & Bottom surface of the panel. It is positioned before the Premilling Unit.The anti-adhesive liquid is applied with precision by means of injectors controlled by the machine control. -- Nesting Package:Allows trimming of premachined panels. -- Transformer:230 Volt autotransformer. -- Actual Model is BIESSE JADE 240

$ 26,500

BIESSE - AKRON 440 AX Edgebander (w/Premill & Corner Rounding): -- Specifications: Material infeed for strips & coiled edge material like PVC, ABS, veneer, and solid wood. -- Edge & Workpiece Capacity: 0.4 - 3 mm (0.016 - 0.12") Edge; 10 - 60 mm (0.39 - 2.36") panel thickness; 140 mm (5-1/2") min. panel length, and 85 mm (3.3") min. width. -- Working Units:Premilling Station: (2) 3 kW (4 HP) - 150 Hz, 9,000 RPM Motors; equipped with panel blowoff device and SIKO digital counters for adjustments. -- EVA Gluing Unit: Edge Feeding & Pressing Unit; automatic loading of tape in rolls and strips; quick-change glue pot system. -- Pressure Section: (1) Large 150 mm dia. driven & (5) idle pressure rollers. -- Feed Speeds: Operating feed speeds 12 & 18 MPM (39 & 60 FPM). -- Workstations: Double Motor End Trim; tiltable from 0° - 15°; each motor 0.8 kW (1 HP) - 12,000 RPM; sliding in a slicing motion on a 45° precision guide bar with oversized bearing blocks. -- Top & Bottom Trimming: (2) Motors 0.65 kW (0.87 HP) each; "Pro-Nesting" copiers; cutters R=2 mm. -- Fine Trim/Corner Rounding Unit: (2) Motors; each 0.65 kW (0.87 HP) - 12,000 RPM; motors carry out Corner Rounding and Top & Bottom Trimming on panel edge with PVC, ABS, etc. material, and wood edge banding up to 3 mm max. edge thickness. -- Top & Bottom Flat Glue Scrapper: To remove potential glue squeeze out. -- Buffing Station: Top & Bottom, (2) motors, each 0.37 kW (0.5 HP) - 2,800 RPM. -- Operator Interface:Operator Control Panel, "HDI" High-Definition touchscreen control, Windows XP based. -- User-friendly graphic user interface with diagnostic and assisted maintenance. -- USB and Ethernet port; 1.44 MB floppy drive, automatic or manual startup. -- Complete with:High frequency motors (200 HZ): Padded sound enclosure. -- Top pressure beam with staggered double-row holddown wheels mounted on ball bearings. -- Actual Model is: BIESSE AKRON 440 AX

$ 39,700

BIESSE AKRON 855 EDGEBANDER (W/PRE-MILL & CORNER ROUNDING):Specifications: -- Material infeed for strips & coiled edge material like PVC, ABS, veneer, and solid wood.0.4 - 3 mm (0.118"), Panel thickness 10-60 MM ( 0.39" - 2.36"), min. panel length 140 mm (5.5") and 85 mm (3.34") min. widthInfeed System Equipped with: -- Independent copying guide pads on each unit with manual adjustment & mechanical digital indicator.Pre-Milling Unit (FI-701) (2) 1.8 kW motors (2.5 HP), 12,000 RPM with Auto-Set device to ensure optimum positioning of the cutters according to the thickness of the panel being machine; -- "VC-710" edge feeding, gluing & pressing unit with automatic edge magazine for strip & coil stock; 3 mm PVC guillotine. -- "TEKNO-GLUE" System, Pre-Melt "QM-701" for quick heating & tank changing with floating & bi-directional glue roller applicator.Pressure Section: (1) Large motorized pressure wheel with clutch, plus (5) idle rollers, independent pneumatic pressure control & digital counters for quick edge thickness changeover.Edgebanding Workstations: -- Double Motor End Trim, tiltable from 0° - 15°, each motor 0.5 kW (0.6 HP) - 12,000 RPM; sliding in a slicing motion on a 45° precision guide bar with oversized bearing blocks. -- Top & Bottom Rough Trim: Top/bottom (2) motors, each 1.8 kW (2.5 HP) 12,000 RPM with superimposed motor position, 0° - 45° tilt capability, straight cutterheads (80 x 25 x 16 mm) w/insert knives; includes pneumatic exclusion from control panel. -- Top & Bottom Fine Trim: Top/bottom (2) motors, each 1.8 kW (2.5 HP) 12,000 RPM with superimposed motor position, 0° - 45° tilt capability, straight cutterheads (80 x 25 x 16 mm) w/insert knives; includes pneumatic exclusion from control panel. -- Multifunction 4-Motor Corner Rounding Unit "CR-202": (4) Motors, each 0.65 kW (0.87 HP) - 12,000 RPM; motors carry out Corner Rounding and Top & Bottom Trimming on panel edge with PVC, ABS, etc. material and wood edgebanding up to 5 mm max. edge thickness. -- Top & Bottom Radius Scraping (PVC): Knives R = 2 mm, with mechanical digital indicators for precision setup, pneumatic exclusion of the unit from the machining line, PVC scrape collection box. -- Top & Bottom Flat Scraper (Glue): self-adjusting with copy wheels & flat insert knives, removing potential excess glue before buffing unit. -- Top & Bottom Oscillating Buffing Station: (2) motors, each 0.37 kW (0.5 HP) - 2,800 RPM. -- Top & Bottom Hot Air Blowers is made by two 2000 W hotair blowers to reactivate the color of PVC/ABS edges after the machining.The air temperature is adjustableFeatures & Feed: -- All cutting & trimming workstations have HF motors and enclosed by padded sound enclosure, top pressure is provided by staggered double-row holddown wheels mounted on ball bearings. -- Feed chain track speed : 10 - 14 - 20 MPM (33 - 46 - 65 FPM). -- Complete with:CNi PC w/Flat, Color "REAL TIME" graphic interface design on 17” flat screen (TFT) with high resolutio

Call for Price

Machine Equipped as follows: NC 410 PC Based Controller Keyboard with Floppy Drive Automatic Strip Feed Magazine Belt Driven Top Pressure Beam Multi-Coiled Infeed Magazine RT63 Pre-Milling Unit SP20 Glue System w/ Pre-Melt Unit Hot Air Gluing system Automatic Infeed Pressure System T45 Front & Rear End Trimming Units w/Tilt RS10 Top & Bottom Rough Trimming Units RF30 Top & Bottom Fine Trimming Units AR10 4 Motor Corner Rounding Trimming Units RB30 Top & Bottom Profile Scraping Units RC10 Top & Bottom Glue Scraping Units SZ30 Top & Bottom Oscillating Buffing Units PH10 Top & Bottom Edge Heaters Specifications: Min. Panel Thickness:....................10mm? Max. Panel Thickness:....................60mm? Height of Edge-Band Material:…..15-65mm? Min. Banding Thickness:.................0.3mm ? Max. Banding Thickness:........ ...... 20mm? Min. Panel Length:...........................150mm? Min. Panel Width:............................ 100mm? Feed Speeds:.................................10-24m./min? Electrics: ......................................... 460-480V 3 Phase

.gif)