Planers For Sale

Category

Planers

161 Results Found

Call for Price

Selling a complete Planermill Line -Infeed, tilthoist, landing table, pineapple feed and transfer. -Stetson Ross 6-10-A1 Planer/Moulder c/w assortment of changeable 12 knife side heads can dress up to 6” thick, 8 knife top/bottom heads, 12” wide. Moulder heads with plenty of attachments. -Outfeed Belt, Slowdown Belt, accumulation transfer, lug loader, board turner, Canadian Trimmer with an assortment of trim length stops, trim block belts, green chain and stacking carts. Great planermill, ran 120,000fbm per shift when in production. 600V, 3phase, 60Hz system. Call/text for more details

$ 5,000

SALE PENDING Baxter Whitney "No. 32A" Planer - 30" Machine is in full working order. We will provide services for power disconnect as well as loading onto any transport vehicle provided.- Call 800-459-2148 for more info.

$ 2,500

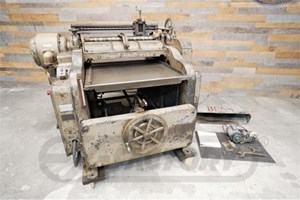

Baxter Whitney & Sons Planer model 32-A manufactured in mid 1940s. This planer was taken out of service in good working order about 8 years ago. I have not used it. There is one pulley that has a broken edge as seen in photo 9319. This was broken in transit and should not affect its function . This planer has a 15 hp, 3 ph main motor with a 3 hp feed motor. Dust hood included. It will need to be picked up with a roll body truck. It comes with the knife sharpener and the sharpener box. Call 800-459-2148 for more info.

$ 5,000

Baxter Whitney "No. 32A" Planer - 30" Machine is in full working order. We will provide services for power disconnect as well as loading onto any transport vehicle provided.

$ 5,000

Berlin 4 head planer. Manufactured pre WW1. Electric motor with each head individually powered. Cap 14" x 20" surface. Call 800-459-2148 for more info.

Call for Price

Call for Price

Call for Price

16” Width Capacity Approx 15 HP Top Head Approx 10 HP Bottom Head Feed 23-65 FPM 220 Volt 3 Phase

$ 4,950

20" Width cap., 1/4" - 9" opening, 7.5 HP motor (3-phase) with 1.5 HP feed motor, both made in the USA, variable feed speed 20 - 32 FPM.Complete with: Segmented infeed roller, cast iron chipbreaker and adjustable bed feed rollers; 3-knife cutter with jack screw adjustment. - Includes (2) sets of knives.

$ 9,750

Buss Type 44 36" Wide Top Planer ready to go still hooked up to run yourself. Motivated seller says let's go! 3 phase 440/480 Volt Call Amy 928-723-9449. 931-797-6284

$ 8,750

BUSS - 44, ...36" PlanerSpecifications: -- 36" x 8" Cap. -- 20 HP - 3,600 RPM Direct drive single Top Head. -- Spiral cutterhead with grinding attachment. -- Top sectional infeed rolls, sectional chip breaker. -- 1/16" Min. to 8" max. manual opening with indicator. -- Min. stock length of 14" and 4" butted.Equipped with & Features: -- Manual table raise-and-fall. -- Infeed variable speed from 28 - 85 FPM. -- Knife Grinding/Jointing equipment. -- Pressure lubricator. -- Push button magnetic control & shaving hood.

$ 10,200

BUSS DL 30" X 8" Heavy Duty Wood Planer with GrinderModel DL, , Bed Capacity 30" W x 65" L x 8" H ,Specifications: -- (2) Large steel support rollers on bed, upper area: (1) steel roller -- One (1) cutter-head with (4) knives, one (1) grip-thru roller. -- Heavy duty spring tension adjustment on top of machine. -- Two (2) 15 HP, 3-PH motors; one connected to 20-ratio gear reducer variable feed speed drive and the other connected to the cutter head system. -- Upper cross frame attachment for knife grinder system ( Comes with grinder )Equipped with & Features -- Oil cup & grease fitting lube system. -- Power Raising and lowering of the Planer bed.

$ 7,200

BUSS - 44, 26" PLANERSpecifications: -- 25" x 8" Cap. -- 20 HP - 3,600 RPM Direct drive single Top Head. -- Spiral cutterhead with grinding attachment. -- Top sectional infeed rolls, sectional chip breaker. -- 1/16" Min. to 8" max. manual opening with indicator. -- Min. stock length of 14" and 4" butted.Equipped with & Features: -- Manual table raise-and-fall. -- Infeed variable speed from 28 - 85 FPM. -- Pressure lubricator. -- Push button magnetic control & shaving hood.

$ 18,200

BUSS DL TYPE Heavy Duty 50" x 8" Single Sided Wood Planer:Specifications: -- Belt-Driven 50" Straight Knife Cutter Head. -- 25Hp Cutter Head Motor. -- Dust hood with 12" Port. -- Chip Breakers -- Grooved Feed Rolls -- Smooth Pressure Roll After Cutter HeadEquipped with & Features -- Top Mounted Grinding Bar -- Manual Height Adjustment -- Leeson SpeedMaster - Adjustable Feed Speed Controller -- Push Button Controls -- Safety Guards

$ 19,750

BUSS 44-40 STRAIGHT KNIFE PLANER40" x 8" Cap., 30 HP - 3,600 RPM direct drive single top head,Specificatioins: -- 4-knife cutterhead w/high speed steel knives, top sectional -- infeed rolls, sectional chip breaker. -- 1/16" Min. to 8" max. material thickness. Manual opening with indicator. -- Min. stock length 14" and 4" butted, manual table raise-and-lower; variable speed infeed 28 - 85 FPM. via REEVES power transmission -- Complete with: Knife grinding/jointing equipment, pressure lubricator, push button magnetic control & shaving hood.

Call for Price

$ 30,990

CAM-WOOD PL-18 18" Wide Top & Bottom Straightening Planer. -- 18" Planer with straight knife heads with HSS knives for accurate and powerful two-sided planning in one pass.ADD for Spiral Heads with Carbide Insert Knives... $4,000.00Replacement Knives:CT-SCH-14T 14 mm wide x 2.0 mm thick Spiral Knives - $2.90 EACHCT-SCH-15T 15 mm wide x 2.5 mm thick Spiral Knives - $3.60 EACHSpecifications: -- 17-3/4” Max. Planning Width. -- 3/8 to 8" Max. Planning Thickness. -- 1/4” Max. Cutting Depth. -- 10” Min. Planning Length. -- 15 to 70 FPM Feeding Speed (Inverter Driven). -- 4,200 RPM Cutter Straight Knife Head Speed. (6,000 RPM for Spiral Cutter Head). -- (4) Knife Cutterheads. -- 15 HP Upper Motor. -- 10 HP Bottom Motor. -- 2 HP Feed Motor. -- 1/2 HP Elevation Motor. -- Table Size (L x W) 88" x 16". -- N.W. 6,500 Lbs.Features: -- Standard equipped with automatic thickness controller, easy, accurate and quick setting for the cutting thickness. -- Upper & lower straight knives or spiral cutterheads for accurate and powerful two-sided planing in one pass. -- The worktable surface is precision ground and then electric chrome-plated and polished to a smooth mirror finish. The durable wear resistance surface is easy to clean and maintain. -- A heavy-duty feed conveyor with metal spikes firmly holds stock securely to the worktable and feeds positively giving a smooth finish for rough or final planning. -- Stepless variable speed control for smooth adjustment of feed rate depending on the material hardness, depth of cut & width to provide the best finish surface and fast cutting performance. -- The infeed conveyor is fitted with numerous pressure pins so the feeding process can be firmly stabilized. It will moderately press the stock, and then accurate planing of the surface can be performed to prevent jumping during processing of narrow or bent material. -- The (4) power feed rollers are driven with a geared transmission box linked with heavy-duty drive chains and gears to provide a smooth even feeding during rough or finish planning. -- A twist torsion anti-kickback device provides additional safety. It’s designed to work in conjunction with the built-in conveyor stop. It safeguards mechanical parts in case of overload. -- The heavy-duty rigid cast iron frame supports the worktable, helps dampen vibration and ensures years of dependable service. -- Powerful industrial motor for maximum cutting capacity. -- All precision sealed long-life bearing for durability -- A swivel stand is designed for convenient knife changing on the bottom cutterhead. -- Changing the knife on the upper cutterhead only requires removal of the upper dust chute. -- The optional spiral insert head design allows for fast, accurate insert changes and minimum down time. -- Setup time is minimized to set cutterhead height using the auto material thickness device. -- The top and bottom cutterheads are precision balanced to provide consiste

$ 7,990

CAM-WOOD WP-2400 Single Sided PlanerFeatures & Specifications: -- Solid cast iron construction. -- Precision ground cast iron table w/manual adjustment by hand wheel via (2) large lead screws. -- Scale & pointer readout for accurate thickness adjustments. -- solid steel 3 knife cutter head -- Fixed feed speed setting for consistent stock removal. -- Sectional steel infeed roller & segmented chip breaker. -- Independently adjustable feed rollers. -- (2) Externally adjustable bed rollers. -- Hinged top for easy access to cutterhead & gear assembly. -- Self-braking motor 5 HP. -- Magnetic starter & thermal overload switch. -- Emergency stop. -- Operations manual, parts list & tool kit..

$ 77,990

CAM-WOOD PL-38 TOP & BOTTOM STRAIGHTENING PLANERIncludes (1) set of Spiral Insert Cutterheads with (1) set of 15 x 15 x 2.5 mm Insert Carbide Knives with (4) Cutting EdgesReplacement Knives: CT-SCH-15T 15 x 15 x 2.5 mm Spiral Knives - $3.60 EACHDeduction for HSS Knives in lieu of Carbide Insert Spiral Heads - Deduct $8,000Specifications: -- 3" to 38” Max. Planning Width -- 3/8" to 7” Max. Planning Thickness. -- 1/4” Max. Cutting Depth. -- 12” Min. Planning Length. -- 15 to 52 FPM Feed Speeds (Variable). -- 4,000 RPM Cutter Head Speed. -- Spiral Carbide Insert Cutterheads with 15 x 15 x 2.5 mm carbide insert knives with (4) cutting edges 40 HP Top Head Motor. -- 20 HP Bottom Head Motor. -- 5 HP Feed Motor -- 2 HP Elevation Motor. -- Net weight 9,800 Lbs. Equipped with: -- Standard equipment includes Automatic Thickness Controller for quick, accurate thickness adjustments. -- Top and bottom Spiral Carbide Insert Cutterheads with 15 x 15 x 2.5 mm Insert Knives for accurate and powerful two-sided planing in a single pass. -- The Planer’s table surface is precision ground then chrome-plated and polished to a mirror finish; wear resistance, easy to clean and maintain.Feed System: -- Heavy-duty upper feed carpet (conveyor) with spring-loaded steel “fingers” holds stock firmly against the Planer’s table; prevents stock splitting while providing positive feed and smooth finish for rough and finish planing. -- The conveyor (carpet) is fitted with numerous pressure pins, or fingers, which firmly holds and stabilizes stock during the planing process. Fingers apply moderate pressure to the stock and provides accurate planing while preventing wide cupped boards from splitting and feeding problems while planing narrow material. -- (4) Powered feed rolls are driven via a gearbox linked to heavy-duty chains and sprockets; provides smooth even feeding during rough and finish planing. -- Stepless variable speed control (Inverter driven) for smooth adjustment of feed speed depending on the material hardness, depth of cut & width; allows for the best finish and feed speed. -- Anti-kickback device provides safety and is designed to work in unison with a conveyor stop. Safeguards mechanical parts in case of overload situations.Features: -- The heavy-duty CAST IRON frame supports the worktable, helps dampen vibration, and ensures years of dependable service. -- Powerful industrial motors for maximum cutting capacity. -- All precision sealed-for-life bearings for long and durable use. -- A built in cutterhead stand is designed for convenient knife changing at the bottom cutterhead. -- Changing knives on the upper cutter head only requires removal of the upper dust chute. -- Setup time is minimized to set cutter head height using the auto material thickness device. -- The top and bottom cutter heads are precision balanced to provide smooth, chatter-free planing regardless of the feed rate or har

$ 199,900

CAM-WOOD WP-4S-500-2C 4-SIDED, 19-5/8" WIDE X UP TO 20" HIGH PLANER SPECIFICATIONS FOR 6” X 19-5/8” HEAVY-DUTY PLANER: -- Width Capacity from 2-3/4" to 19-5/8" -- Thickness Capacity from 3/4" to 6” (see options for taller side spindles) -- Variable Feed Speeds from 18 to 75 FPM (higher on request) -- 20 HP Top and Bottom Spindle Motors -- 15 HP Left and Right Vertical Spindle Motors -- (2) 1/2 HP Left & Right Chamfer Motor -- (2) 7-1/2 HP Feed Motors -- Belt-driven, high speed, 7,000 RPM spindle speeds. -- TEFC motors with sealed-for-life ball bearings provide accurate, vibration-free spindle vibration. -- Top & Bottom Cutterhead Dia. 5" -- Right & Left Cutterhead Dia. 5" or 6" -- Top & Bottom Spindle Dia. 60 mm -- Right & Left Spindle Dia. 40 mm (1-13/16" available) -- Chamfer Spindle Dia. 30 mm -- Insert Cutter Size 15 x 15 x 2.5 mm -- (4) 6" Diameter Dust Hood -- Machine Size 110" x 86" x 94" x net 15,200 Lbs. Additional Equipment and Options: -- Right side fixed fence (no charge) -- Change side head spindle rotation to rotate with the direction of feed (no charge) -- 1-13/16" side spindle dia. (no charge) -- Top & bottom spindle rotation against the direction of feed (standard) -- Wired for 480-Volt operation (no charge). -- Pair Auto-Set and Power Raise/Lower of right and left side spindles (included). -- Pair Spindle Brake on right and left side spindles (included). -- 12” High side spindle with outboard bearing, add $19,000 -- 16” high side spindle with outboard bearing, add $25,500 -- 20” high side spindle with outboard bearing, add 30,700. FEATURES: -- Compact construction, huge moulding or planing capacity, extremely flexible and high-performance design. -- Digital controller automatically sets thickness & width adjustment -- Rigidly mounted alloy steel spindles with outboard bearing support provide accurate vibration-free power transfer. -- Spindle height adjustment by precision rack & gear sets -- Beds and fences are precision ground then chrome-plated and polished to a smooth mirror finish. The wear resistant surfaces are easy to clean and maintain -- Variable speed invertor controls for smooth adjustment of feed rate depending on the material hardness, depth of cut & width will provide the best finish surface and fast cutting performance -- The floating powered feed rollers are driven by geared transmission boxes linked to the feed rolls by heavy-duty universal joint axels while firmly holding stock securely to the bed; feeds positively to provide a smooth, even feed rate during rough or finish planning -- The heavy-duty welded and heat treated steel frame supports the beds and helps dampen vibration while safeguarding future years of dependable service -- Industrial rated motors for maximum stock removal and feed rates -- Precision sealed, long-life bearings throughout -- Removable cutter heads are designed for convenient knife changing even on the on the b

.gif)