Woodworking Equipment For Sale

1736 Results Found

$ 87,750

HEESEMANN - LSM 8, ...3-Head Wide Belt Sander53" Width cap. Crossbelt, Combination , and DrumHead Configuration:1st Head: Cross Belt Sanding Unit, 2-speed motor - 19/24 kW (26/33 HP). - Abrasive belt speed: 12/24 MPS (39/78 FPS); Cross Belt (Cloth), 4,800 x 150 mm (189" x 6").2nd Head: Combination Longitudinal Sanding Unit Front retractable roller for light calibrating and segmented pad system for fine sanding; bi-directional sanding; Door-in-Door viewing; 2 speed motor - 31/37 Hp, abrasive belt speed 10/20 mps (33/65 fps3rd Head: Longitudinal Sanding Unit Internal pressure segment belt for finer sanding Inner chevron belt; Inverter driven motor: 26 kW (34 HP); abrasive belt speed: 0.5-16 MPS (1.6-52 FPS); Longitudinal Belt: 2,620 x 1,350 mm (103" x 53").Unit 4: Panel Cleaning Brush, Fiber trimming.Specifications: -- HEESEMANN's LSM-8 Sanders are designed for heavy (2 - 3) shift operations; this Sander is ideal for: Whitewood sanding of veneered panels and panels coated with various sealers. -- The crossbelt removes tape, cuts short fibers that contribute to grain rising, and sands panels with "book-matched" veneer. -- The last sanding unit is equipped with an internal pressure segment belt for an extra smooth finish.Enhanced 16 mm control roller spacing with (3) rollers per segmented pad. -- CSD® Segmented pad system is equipped on all (3) sanding units. -- Pneumatic conveyor belt cleaning. -- Infeed extension with non-driven rollers. --Electronic variable feed speed from 5 - 25 MPM (16-82 FPM). --Workpiece thickness 3 mm - 140 mm (1/8" to 5-1/2").Equipped with & Features: -- Vacuum Table: Only HEESEMANN builds it into the frame for superior holddown! -- Industrial PC controller, Windows® Operating System.Width Capacity: 53"

$ 90,000

HEESEMANN - LSM 8-5 RRRL, ...53" Wide Belt Sander53" Width cap.: Drum, Drum, Drum, and CSD® Pad.Head Configuration:• Unit 1 - Longitudinal Sanding Unit: Steel contact roller, helically grooved. - Single-speed 48 HP motor, electronic braking.• Unit 2 - Longitudinal Sanding Unit: Rubber-covered contact roller, helically grooved. - Single-speed 35 HP motor, electronic braking.• Unit 3 - Longitudinal Sanding Unit:- Rubber-covered contact roller, helically grooved. - Single-speed 35 HP motor, electronic braking, bi-directional drive.• Unit 4 - Longitudinal Sanding Unit: CSD® Segmented pad system, 2-speed 20/26 HP motor, electronic braking.• Unit 5 - Panel Cleaning Brush: Fiber trimming, 2.3 HP Motor.Specifications: -- Working height: 880 mm (34.64"). -- Workpiece thickness: 3 mm to 150 mm (1/8" to 6"). -- Working width: 1,300 mm (51-1/8"). -- Longitudinal belt: 1,350 x 2,620 mm (53" x 103"). -- Machine voltage: U.S. Electrics 480 Volts, 3-Phase, 60 cycles.Constant Pass LineController: -- Industrial PC. -- TFT Color touchscreen. -- Windows® Operating System. -- (100) Memory addresses for: • CSD® sanding pressure. • Sanding start/stop. • Sanding belt speeds. • Grit sequence indication. • Sanding belt selection - "ON/OFF". • 1-Button sequenced starting for all motors.RS-232 Serial port.RJ-45 LAN Port.Modem with software licenses.For All additional, detailed specs, select the "View Literature" link .

$ 55,000

HEESEMANN LSM-8/3-OSR Wide Belt Finishing Sander, 52" and (3) Heads; Equipped with: (1) longitudinal segmented platen head. and (2) Orbital Platens -- 1st Head: Longitudinal segmented platen head. Segmented Polishing Platen, 20 & 27 HP dual speed motor. electronically controlled segments to conform to panel size,.2620 x 1350 mm (91.4 x 53.2") Sanding belt. - Equipped with HEESEMANN's patented "CSD" selective pressure adjustment system, sensors placed every 16 mm (5/8") sense part configuration; pressure for each segment, to eliminate sand through, can be pre-programmed to provide less pressure on the outer edges or more in the center if desired. The "CSD" computer control will hold a maximum of (20) programs. -- 2nd & 3rd Heads: OSR Dual orbital action head with (1) high-speed orbit on sanding pad, powered by 3 kW (4.5 HP) motor.Secondary oscillation movement of platens powered by 1.5 HP motor. Upstream and downstream vacuum chutes on each head for dust localized dust pickup.- Platens feature "quick change" abrasive material; Both orbital heads with variable speed inverter drives. -- Outfeed Rotary Brush with cleaning brush loading with single end adjustment , 6" max. dia., 3.4 HP motor. -- Variable feed speed from 13 to 82 FPM, 6.5 HP feed drive. -- Infeed and outfeed Ssissor Lift and Control box shown are not included. -- Motorized thickness opening 1/4" to 3-5/32" max. - -- Power Consumption: 63 KW, 75 Amps. -- Separate display console for CSD control.

Call for Price

Heian CNC Router This was used at a particle board plant that has been shut down for approx 10 years.

Call for Price

Hemple CL-8 Wood Turning Lathe 20” capacity will turn to 1/4” diameter manyal feed but auto cycle up to 400/hour 220 volt 3- phase

Call for Price

Hemple CL-8 Wood Turning Lathe 20” capacity will turn to 1/4” diameter manyal feed but auto cycle up to 400/hour 220 volt 3- phase

Call for Price

Hemple CL-8 Wood Turning Lathe 20” capacity will turn to 1/4” diameter manyal feed but auto cycle up to 400/hour 220 volt 3- phase

$ 1,450

HENDRICK PETS Overhead Rail Panel Saw -- 8' Max. cutting cap.; 7.5 HP saw motor; 5-1/4" cutting capacity and 1" Dado Capacity. -- Carriage rides on 2" dia. hardened steel precision ground rails; 16" dia. blade capacity. -- 0 to 50 FPM infinitely variable D-C carriage drive; push button control console including separate controls for forward and reverse carriage drive.

Call for Price

Single Head Horizontal Band Re-saw System Model : HP-11P-SMART • Single saw head configuration. • Motor powered set works for accurate saw wheel elevation. • Digital position controller permits accurate saw wheel height positioning. • Automatic blade tension is controlled by hydraulic cylinder. • Variable feed speed by hydraulic motor drive. • The big pressure roller is air cylinder loaded to hold wood down firmly. Specifications HP- 11P-SMART 1. Saves Time and labor costs 2. Pneumatic pressure roller infeed 3. Digital position controller permits accurate saw wheel height 4. Easy to operate and set up Feed speed: 4-27m/min (13-90FPM) Max. cutting height: 250mm (10”) Max. cutting width: 300mm (11 3/4”) Min. workpiece length: 400mm; 205mm with extension set Max. workpiece length: 580mm Distance from blade to conveyor: 4-125mm Saw wheel Diameter: 711.5mm (28”) Saw wheel width: 22.7mm (1”) Saw blade size: 4265 x 27mm (168” x 1’) Blade speed: 2816m/min (9240FPM) Saw Motor: 15kW(20HP) Feed unit: 0.75kW(2HP) gearbox motor with frequency converter Cooling system Oil mist Blade tensioning Hydraulic system Motor for blade positioning: 0.18kW(1/4HP) Dust post: Ø4” x 4 Table height: 902.5mm Machine weight: 951kgs Machine dimensions: 2835 x 2052 x 1678mm (LxWxH)

Call for Price

$ 3,000

Hitachi Band Resaw. 7.5 HP motor with feed, 3 phase. New 4" carbide tipped blades. Ready to go to work. Call 800-459-2148 for more info.

Call for Price

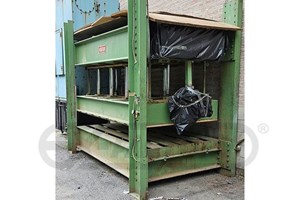

HOFER HOP 160 K Hydraulic Door/Veneer Heavy Duty Cold PressSpecifications:Platen size 63" deep x 98" long, Total Daylight/Opening 32".available. Currently set at about 13" opening. Top platen is hydraulically powered by a 2.2 KW power pack. and has (10 sets) of bolt holes for manual adjustment of daylight opening.Equipped with:(8) 3-1/4" Diameter Hydraulic cylinders, Rack & pinion platen leveling adjustment.Front and back loading (access on all sides).Heavy duty steel structural beams. Bolted top and bottom platens.Features:Pneumatically loaded 3 +1 rows of idle rollers on bottom platen for ease of feeding the load in and out front of press. Air valve for up/down selection of bottom platen rollers.Hydraulic closing speed adjustment.Electrical controls on right hand side.Dimensions/Weight: 124" x 72" x 122" H. Approx. 12,000 Lbs.

Call for Price

Call for Price

HOFFMANN PU 2 DOVETAIL ROUTER (SINGLE SPINDLE) Pneumatic Dovetail Routing Machine - Dovetail routing machine for use with HOFFMAN dovetail butterfly connectors. - Maximum routing height 4", Max. workpiece height 5-3/4" - Table size 15-1/2” x 27-1/2” x 36-1/2” H - Production speed: Approx. 16 SPM (2 Complete rectangular frames) - (1) HOFFMANN "UAD 33 F" 33,000 RPM 1,000 W Router motor - 45° Fence, Accurately positions material with guide in table keyway, Quick adjustments made by adjusting fence plate - Pneumatic hold-down, Pneumatic foot pedal Includes: - Extra HOFFMANN "UAD 33 F" 33,000 RPM 1000 W Router Motor - 2007 HOFFMANN "FM1000" 35,000 RPM 1,000 W Router Motor - (2) 16” x 48” x 35” H Left-Hand & Right-Hand Aluminum Frame Tables, with 3/4” Thick Top, & 2” x 2” Aluminum frame - Palletized Dimensions: 42” x 42” x 60” H

$ 21,500

HOLYTEK HK 610 Double-Sided Strato Planer -- 24" x 8" Cap. Double Surface Planer, spiral carbide cutterheads belt driven by 20 HP top and 15 HP bottom motors at 5,000 RPM. -- Spriral cutter head 125 mm diam. with 96 inserts 30 mm X 12 mm X 1.5 mm -- Variable feed motor delivers a range of 6 M./min to 25 M./min. (9.5 FPM to 82 FPM), -- Feed motor 3 HP, corrugated sectional infeed rollers and (4) table rollers provide superior feeding regardless of the type of wood being processed; -- Hard-chromed table surface precision ground to provide smooth performance and maximum wear resistance at high speeds.Technical Specifications:• Maximum width 635 mm (25")• Minimum length: 300 mm (11.9")• Maximum thickness 200 mm (7.87")• Minimum thickness 10 mm (.39")• Table size: 686 mm x 2616 mm (27" x 103")Features: ● Dovetailed slideways on the table elevation ensure stability and rigidity; Mechanical readout provides accurate details of table positioning adjustment; ● Thickness limit guard is provided at the infeed end as a safety feature. ● Machine weight 6,600 Lbs

$ 33,500

HOLYTEK MHB 242 Top/Bottom Wide Belt SanderHeavy-duty and powerful double surface sander providing significant time saving and improved productivity.Smooth and quiet oscillation. Belts oscillation controlled electronically by an infrared system which resists dust.Pneumatic sanding belts tensioning ensuring fast and easy belt replacement.Independent motor for each sanding belt.Pneumatic disc brake system automatically activated if power supply is interrupted, thus preserving the sanding belts from being damaged. Top and bottom 24" wide belt sanderFeatures: -- Spiral grooved 8" (D) rollers (R) and 3-1/2" (D) rollers (K) keep the sanding belts cool. -- Sanding belts: 75" Long. -- Elevation of table with digital readout and activated by independent motor. -- Control panel with: Ammeters indicating main motors current. Specifications: -- Upper Drum motor: 15 HP; 600 V; 60 Hz - 3-Ph. -- Upper Combination head motor: 10 HP; 600 V; 60 Hz - 3-Ph. -- Lower Drum motor: 15 HP; 600 V; 60 Hz - 3-Ph. -- Lower Combination head motor: 10 HP, 600 V, 60 Hz - 3-Ph. -- Feeding motors: 2 HP (x2). -- Table elevation motor: 0.5 HP. -- Electrical intensity: 53 A. -- Drums: 8" (D) - 75 DUROS. -- Max. working width: 24". -- Min. working length: 13-3/4". -- Working thickness: 3/16" ~ 5" -- Sanding belts dimensions: 25" x 75". -- Variable feeding speed: 8 - 16 MPM. -- Dust hoods Top: 4 x 4"(D); Bottom: 3 x 4"(D). -- OAL 127" x 70" x 75" high. -- Weight: 9,460 Lbs.

$ 19,100

HOLYTEK - HK 400, ...Top & Bottom PlanerSpecifications: -- 16" x 8" Cap., top & bottom helical insert knife heads, 4,000 RPM cutterhead rotation. -- 15 HP Top & 10 HP bottom; 10" min. stock length. -- 2 HP Variable feed speed from 23 - 65 FPM; sectional feed rolls & chipbreaker. -- 0.5 HP Motorized opening w/micro-adjustable table. Complete with: -- Heavy swing-out carriage with a built-in micro-dial; supports bottom cutterhead, pulled out for "quick & easy" replacement of knives.

$ 28,900

HOLYTEK - KL-36PC, ...2-Head Sander 2-Head Planer Sander 36" with planer head & combination head.Description: -- Planing Head (P): 6'' Dia. made of steel with spiral design for heavy stock removal. 228 TCT Tips: 15 x 15 x 2.5 mm; each disposed on (6) rows. Each knife has: (4) Usable cutting edges; easy access to planing head for tips rotation or replacement. -- Precise dial indicator showing the exact positioning of the sanding pad; quiet & smooth oscillation! Pneumatic oscillation system controlled electronically by an infrared system, which is not affected by dust. -- Combination Head: (1) Drum & (1) sanding pad (C) for superior quality of finishing. Sanding belt with: 120 or 150 Grit; allows finishing sanding in a single pass. -- Elevation Table: (4) Screws. -- Infeed roller table extension: 15-3/4". -- Outfeed roller table: 15-3/4" with (2) Rollers. -- Centralized Control Panel with: Electronic digital readout (Metric or Imperial) for elevation; precise positioning at the elevation requested. -- Ammeter indicating: Electrical intensity on the spiral cutterhead and the combination head motors. -- Electrical box with: CSA Approved electrical components ensuring maximum dependability and an outstanding long-lasting performance.Specifications -- Spiral cutterhead motor: 20 HP - 600 V; 60 Hz - 3 Ph. -- Combination head motor: 15 HP - 600 V; 60 Hz - 3 Ph. -- Table elevation motor: 1/4 HP - 600 V; 60 Hz - 3 Ph. -- Feed motor: 2 HP - 600 V; 60 Hz - 3 Ph. -- Spiral cutterhead dia.: 6''. -- TCT Tips dim.: 15 x 15 x 2 mm (228); (6) rows. -- Max. working width: 36". -- Min. working length: 12". -- Max. working thickness: 5". -- Sanding belt dim.: 37" x 75". -- Dust hoods dia.: 4'' x 2 & 5" x 2. -- Machine dim.: 71" L x 76" W x 77'' H. -- Net weight: 1,450 kG or 3,190 Lbs.

$ 5,500

$ 32,500

HOLYTEK HK 610 Double Sided Planer with THOMAS MANUFACTURING Return ConveyorHOLYTEK HK 610 Double Sided Planer specifications - -- 24" x 8" Cap. Double Surface Planer, spiral carbide cutterheads belt driven by 20 HP top and 15 HP bottom motors at 4,000 RPM. -- Spriral cutter head 125 mm diam. with 96 inserts 30mm X 12 mm X 1.5 mm -- Variable feed motor delivers a range of 7 M./min to 20 M./min. (19.5 FPM to 82 FPM) -- Feed motor 3 HP, corrugated sectional infeed rollers and (4) table rollers provide superior feeding regardless of the type of wood being processed; hard-chromed table surface precision ground to provide smooth performance and maximum wear resistance at high speeds. -- Machines are currently wired for 220 Voltage.Technical Specifications:• Maximum width 610 mm (24")• Minimum length: 300 mm (11.9")• Maximum thickness 170 mm (6.69")• Minimum thickness 8 mm (.31")• Table size: 686 mm X 2616 mm (27" X 103")• Dovetailed slideways on the table elevation ensures stability and rigidity; a mechanical readout provides accurate details of table positioning adjustment; thickness limit guard is provided at the infeed end as a safety feature. • Machine Dimensions - 109" Long x 46" Wide x 68" High, Machine weight 7,280 lbsTHOMAS MANUFACTURING Return Conveyor specifications -37" Wide x 144" Long Receiving Table that transfers to a 20" Wide x 240" Long Return Conveyor1 HP - 3 Phase Variable-Speed DrivePhotoelectric SensorRemote ControlSolid State TimerSwing-Out Section that is 20" Wide x 90" Long

.gif)