Woodworking Equipment For Sale

1732 Results Found

Call for Price

The Vantec Veneer Auto Stacker, ELV 1.82B is a Vacuum stacker for 2800 mm Veneer lathe. It is fitted with double stacking system (04 bins), with four veneer transport lines and four 5hp exhausters. with of two stoppers and eight ejecting arms. With drive Panel, VSD for exhaust fans and hydraulics lifting tables. Min veneer sheet length sheet: 2300 mm; • Max veneer sheet length sheet: 2700 mm (or Two sheets of 1350mm); • Min veneer sheet width: 800 mm; • Max veneer sheet width: 1500 mm; • Max height of stacks: 1000 mm; • Exhaust motor: 10 hp 4P (8x); • Inlet conveyor motor: 2hp 8P; • Transport conveyor motor: 6hp 4P; • Hydraulic pump motor: 5hp 4P (3x);

Call for Price

VANTEDGE MM 6.0 9 C-MOTION Edgebander with Pre-milling & Corner Rounding (EVA & POLYOLEFIN adhesive ready).Specifications: -- 10" Color Tough Screen PLC. The PLC controls all work units and the adhesive thermostats with 1-touch Icon Programmable selections, Photo Indicator Alarms to easily troubleshoot, and Swivel Control Panel.Tape and Panel Infeed System: -- 750 mm Coil support table, heavy-duty large solid polished steel panel in-feed fence guide system, Large industrial digital adjustment for the Pre-Mill panel material removal amount. Top Pressure Beam Adjustment: -- Automatic adjustment from the PLC control, Red LED panel feed indicator light for correct panel spacing, Pneumatic Pop Up Stop system -- Working Capacity: Edgebanding thickness, 0.4 - 3 mm capacity. Min. panel width 85 mm (3.3"); min. panel length 125 mm (4.9"); panel thickness 10 - 50 mm (0.39" - 1.96"), Edge Height 55 mm (2.2").Equipped With: -- Dual 3 HP Pre-milling Motors w/Diamond Cutter Heads, Misting Unite w/Large Dual Dust housing ports to help clean the Pre-Milling system, quick change Glue Reservoir and Pressure Section/Infrared Heat Lamp system; consists of Heavy Duty Guillotine to cut 3 mm coil materials, (4) pneumatic polished Pressure Rollers with manual digital adjustment to edge thickness, (1) Rubber Infeed Tape Roller, (1) Metal Infeed Tape Roller; Direct Universal Drive system - NO Chains. Unit with "Auto-set" automatic intervention, Strip & Coil Edge magazine, automatic shear type guillotine. -- Hot-Melt Glue System: Teflon-coated glue pot, digital thermostats with automatic kick-down when the machine is in idle mode.Workstations:End Trimming Unit: -- Dual 0.5 kW (.67 HP) high-frequency End Trim motors on precision "Auto Lube" Linear Guideway. 90 to 10° pneumatic tilt cut adjustment. Electronic sensors to safely monitor motor positions. Thumb screw pneumatic adjustments for simplicity. Tilting Super Finish Top & Bottom Trimming Station: -- Dual High Frequency 0.65 kW (.75 HP) motors with Combi Finish insert tooling, Top Servo-driven positioning of motors for different edge trimming profiles & positions. Corner Rounding Unit: -- Motors on precision billet aluminum swing tracer arms with pneumatic guidance and Face Copy system. The (2) independent motors can be adjusted to match tape thickness via digital scales. Profile Scraping Unit: -- Top, Bottom & Side Copy wheels to properly follow your panels edge, Triple Copy System for panels with blind Dados & Hinge cup holes., digital adjustment for fine-tuning the unit to the proper tape thickness. -- Flat Scraping Unit: Large copy wheels, Insert tooling, adjustable panel spray mist cooling & cleaning system for special materials and composites, adjustable dual Buffing Wheel system, Dual Hot Air Blowers. Buffing Unit: -- Top & bottom Buffing Unit, 0.5 HP (0.37 kW) - 2,800 RPM motors), units tilt 0° - 30°.Complete With: -- Insulated sound enclosure overall trim stations with a split dust hood,

$ 27,000

VANTEDGE MM 6.5 EDGEBANDER (W/PRE-MILL & CORNER ROUNDING) + EVA & POLYOLEFIN adhesive ready. -- Specifications: Working Capacity: Edgebanding thickness, 0.4 - 3 mm coil stock capacity & 10 mm strip capacity.Min. panel width 85 mm (3.3"); min. panel length 125 mm (4.9"); panel thickness 10 - 60 mm (0.39" - 2.36"). -- Tape and Panel Infeed System:750 mm Coil support table, Adjustable Track Feed Speed 14, 16 & 20 MPM (66 FPM).Heavy-duty large solid polished steel panel in-feed fence guide system.Large industrial digital adjustment for the Pre-Mill panel material removal amount. -- Top Pressure Beam Adjustment: Automatic adjustment from the PLC control, Pneumatic Pop Up Stop system.Red LED panel feed indicator light for correct panel spacing, Equipped With: -- Dual 3 HP Pre-milling Motors w/Diamond Cutter Heads. Pneumatic "JUMP In-Out function.Misting unit prior to Pre-Milling. Large Dual Dust housing ports to help clean the Pre-Milling system.Quick change Glue Reservoir for EVA & PO Glues. Pressure Section/Infrared Heat Lamp System.Heavy Duty automatic shear type Guillotine with "Auto-set" automatic intervention for Strip & Coil materials.(4) Pneumatic polished Pressure Rollers with manual digital adjustment to edge thickness.(1) Rubber Infeed Tape Roller, (1) Metal Infeed Tape Roller; Direct Universal Drive system - NO Chains. Teflon-coated glue pot, digital thermostats with automatic kick-down when the machine is in idle mode.Workstations: -- End Trimming Unit: Dual 0.5 kW (.67 HP) high-frequency End Trim motors on precision "Auto Lube" Linear Guideways. 90 to 10° pneumatic tilt cut adjustment. Electronic sensors to safely monitor motor positions. Thumb screw pneumatic adjustments for simplicity. -- Tilting Super Finish Top & Bottom Trimming Station: Dual High Frequency 0.65 kW (.75 HP) motors with Combi Finish insert tooling,Top Servo-driven positioning of motors for different edge trimming profiles & positions. -- Corner Rounding Unit: Motors on precision billet aluminum swing tracer arms with pneumatic guidance and Face Copy system. The (2) independent motors can be adjusted to match tape thickness via digital scales. -- Profile Scraping Unit:Top, Bottom & Side Copy wheels to properly follow your panels edge. -- Panel Nesting System: Triple Copy System for panels with blind Dados & Hinge cup holes.Digital adjustment for fine-tuning the unit to the proper tape thickness. -- Flat Scraping Unit: Large copy wheels. -- Buffing Unit: Top & bottom Buffing Unit, 0.5 HP (0.37 kW) - 2,800 RPM motors), units tilt 0° - 30°. -- Dual Hot Air Blowers:To re-embellish edge materials. Operator Interface10" Color Tough Screen PLC with Swivel Control Panel.The PLC controls all working units & the adhesive thermostats with 1-touch Icon Programmable selections.Photo Indicator Alarms to easily troubleshoot errors/issues. -- Complete With: Insulated sound enclosure overall trim stations with a split dust hood, viewing windows and industrial lights.Pan

$ 59,500

VIET - S2-321-HP/KRT, ...3-Head Planer Sander3-Head Planer/Sander 43" with: Planer, Drum and Combi-HeadSpecifications: -- Max. operating width: 1,100 mm (43") -- Min/Max thickness: 3 mm - 160 mm (1/8" to 6.3") -- Working Height: 900 mm (36") -- Belt sanding dimension: 44" x 103" -- Feed speed: 3 - 16 MPM (9-3/4 - 52 FPM) -- Rubberized drum: 30 HP Motor -- Combination head with drum & platen; driven by the same motor as the sanding drum -- Extended infeed & outfeed roller -- Planer head with helical insert knives: 30 HP Drive motor

$ 19,800

VIET - S1-323, 3-Head Calibrating Wide Belt Sander (53" Capacity)53" Width cap., Steel Drum, Drum, and Combination Head.Head Configuration:1st Head: Steel contact roller, spirally grooved, dia. 190 mm (7-1/2"), 20 HP motor.2nd Head: Steel contact roller, spirally grooved, dia. 190 mm (7-1/2"), 20 HP motor.3rd Head: Combination head with contact roller, electric-pneumatic fine sanding platen, not segmented.Specifications: -- Belt size 53" x 86". -- Pneumatic tensioning of sanding belts and 160 mm (6-5/16") dust hoods. -- Electronic inverter for variable feed speed, 2 HP drive. -- Roller & pressure shoe holddowns. -- Part thickness 3 - 160 mm (1.2" - 6,3"). -- Min working length 250 mm. -- Motorized part thickness adjustment, with digital height readout. -- Pneumatic tensioning of feed conveyor.Equipped with & Features: -- Load meter on main motor; disc brake on main motor. -- Emergency stops front & back. -- Roller table extensions front & back. -- Oversized parts infeed protection. -- Constant Pass Line Sander.NOTE: Some specs need to be verified.

Call for Price

VIET Planer Sander Sander model S2 321 HR/KRT ( 2018 ) !st head planer with helical insert cutter knives 30 HP 460 volts 2nd head drum contact roller 3rd head combination drum rollers with finish platen Both sanding heads run by 30 HP motor 460 volts Adjustable rubber coated pressure rollers Opening capacity range 1/8” to 6” Sanding belt size 44” x 103” Feed speed 19 to 52 FPM Electronic digital readout with auto thickness positioning Disc brakes on each machining station Front and rear emergency push buttons Electro pneumatic sanding belt tracking This machine has low hours as owner only ran half days first year and less after next years

$ 28,300

VIET - S211 R+ KRT, 2-Head Wide Belt Sander43" Width. cap.: Drum and Combination head.Head Configuration:1st Head: 160 mm 6.3″ Helical grooved rubber drum. 25 HP motor2nd Head: 160 mm(6.3") Helical grooved rubber drum with a platen combination head., 25 HP motorSpecifications: -- Each heads are powered by 25 HP motor. -- The heads can be programmed to pneumatically raise & lower along with the platen and do (3) sanding combinations (with the twist of a button). -- Digital height readout along with a calibration unit to the left side of the conveyor. -- Conveyor speed is controlled via a variable frequency drive 2.5 HP . --Max width: 43″. -- Max. height: 6-1/4". -- Variable speed conveyor belt drive from: 3 - 16 MPM (11 - 52 FPM).Equipped with & Features: -- Both heads equipped with: 1,130 x 1900 mm (44-1/2" x 75"). -- Roller & pressure shoe holddowns. -- Pneumatic tension of sanding belts and feed conveyor. -- Load meter on main motor. -- Disc brake on main motor. -- Emergency stops front & back. -- Roller table extensions front & back.. NOTE: This is an extremely low hour 2016 BIESSE Viet S1 dual head 43″ calibrating Wide Belt Sander.

$ 36,000

VIET - S1 211, ...2-Head Wide Belt SanderWidth Cap. 43"; Drum and Combination Head.2-Head with: (1) Contact Roller and (1) Fine Sanding Platen; 1,100 mm (43") working width. Solid wood, veneer & lacquer Sander.Head Configuration:1st Head: Rubber covered contact roll, spirally grooved, dia. 200 mm (7.9").2nd Head: Fine sanding platen, segmented, electronically controlled.Specifications: --Both heads driven by (1) main motor 15 kW (20 HP). -- Both heads equipped with: 1,130 x 2,620 mm (44-1/2" x 103") abrasive belts. -- Roller shoe holddowns, Pneumatic tension of sanding belts and feed conveyor. Feed System: -- Vacuum conveyor system for small and lacquered parts. -- Variable speed conveyor belt drive from 3 - 16 MPM (11 - 52 FPM). -- Part thickness 3 - 160 mm (1.2" - 6.3"). -- Motorized part thickness adjustment, with digital height readout. Equipped with & Features: -- SCS Control panel with storage capacity for multiple sanding programs. -- Load meter on main motor. -- Disc brake on main motor. -- Emergency stops front & back. -- Roller table extensions front & back.

VITAP ALFA 27 CONSTRUCTION BORING MACHINE27-Spindle boring head on 32 mm centers, drills vertically from bottom-up and head rotates to horizontal position for edge boring, head rotation is pneumatic with switch control. -- 2-3/4" Max. drilling depth, 2.5 HP - 2,800 RPM motor, pneumatic drill head advance with speed control; head height adjustment with mechanical digital readout; 34" x 20" table size, max. workpiece width 31-1/2". -- Equipped with: Left & right side fences for construction boring, (3) pneumatic holddown clamps, 118" line boring fence w/ (4)flip-stops, pneumatic foot pedal control.

Call for Price

VITAP ALFA 21 21-Spindle Semi-Automatic Construction/Line Boring Machine21-Spindle Boring Head on 32 mm Centers.Specifications: -- Drills vertically from bottom up, Head rotates to horizontal position for edge boring, Head rotation is pneumatic with Switch control. -- 2-3/4" Max. drilling depth, 2.5 HP - 2,800 RPM Motor, Pneumatic drill head advance with Speed control. -- Head height adjustment with Mechanical digital readout. -- 34" x 20" Table size, Max. workpiece width 31-1/2".Equipped with: -- Left & right side fences for construction boring, (2) Pneumatic hold-down clamps, Line boring fence with flip stops. -- Pneumatic foot pedal control, Magnetic starter & Overload protection, (1) Set of quick-change chucks.NOTE: Sold "As-Is" Without Warranty!

Call for Price

VITAP POINT K2 2.0 CNC MACHINING CENTER (W/ATC/BORING) + Includes "VITAP Bar Nesting System." – Demo Model Never Used in Production -- Specifications: VITAP - K2 2.0 CNC Center is the best and most technically advanced machine for wood processing. The K2 has a patented "Double Dynamic Transport (DDT)" System with a double clamp technology that creates smooth panel movement.With an automatic tool changer and modern software, the programming for this machine is easy and efficient to use. This machine is perfect for companies of all sizes and is the optimal choice for your CNC woodworking needs. -- Working Field:Max. panel size "X" Axis infinite; "Y" axis 49.2" (1,250 mm); "Z" axis 1.97" (50 mm).Min. panel size "X" axis 10" (270 mm); "Y" axis 5.9" (150 mm); "Z" axis 0.1" (3 mm). -- Positioning Speed:"U" Axis Panel feeding speed 82 FPM (25 MPM); "X" & "Y" axes 197 FPM (60 MPM); "Z" axis 49 FPM (16 MPM).Axes positioning by AC drives & brushless motors; the "Panel" moves in "X" axis & the "Machining Units" move in "Y & Z" axis.Max. Panel weight is 176 Lbs (80 kG). -- Work Area: Vitap "DDT" + "Vitap Bar Nesting System":DDT is short for "Double Dynamic Transport", a clamping system for workpieces on CNC Machining Centers, for moving the workpiece in "X" axis.The function of the DDT system consists of: (2) Gripper/clamps that move the workpiece in the same or alternate direction. This allows for a significantly longer travel distance of the workpiece compared to the travel distance of the gripper/clamps. DDT system is a requirement for Bar Nesting."VITAP Bar Nesting" is a special form of combining a Beam Saw & Nesting at the same CNC Machining Center. VITAP Bar Nesting is also designed to combine the advantages of nesting technology with the possibility of horizontal drilling.VITAP Bar Nesting is a technology that has been specially developed for VITAP Machining Centers. The prerequisite is a machine in which the X-axis is generated through the movement of the workpieces. A further prerequisite is the presence of (2) grippers for workpiece movement, known at VITAP as "DDT-System".Bar Nesting is not a complete nesting of the workpieces, as the large-sized (Ripped) panels must still be cross-cut into stripes on a Saw.NC Controlled "Optical Material Sensor" creates a “0“ Panel reference point by reading the panel's ends; this ensures that RH & LH (mirror image) panels will always be symmetrical.Fixed RH ("U" axis) panel clamping device with: Automatic panel adjustment according to the programmed information; LH side pressure clamp with automatic adjustment & pneumatic locking according to the panel width; scratch resistant idle rollers for panel positioning from the bottom & sides. -- Boring Unit: (1) 2.2 HP (1.7 kW) - 3,600 RPM motor; (12) independent vertical spindles on 32 mm centers with 6-spindles in "X" axis & 6-spindles in "Y" axis.(8) Horizontal Spindles with: (2 + 2) spindles in "X" axis & (2 + 2) spindles in "Y" axis.(1) "X"

Call for Price

VITAP SMART Hot Melt Contour EdgebanderDesigned for straight, curved (contour) or beveled edgebanding, Unique design to allow banding of strips or rolled edging.Specifications: -- 0.3 - 3 mm (0.01" - 0.12") PVC Edgebanding thickness. -- 3/8" - 2-3/8" Edgebanding height. -- 20 mm (0.79") Minimum radius with concave curve.Equipped with: -- Hot Melt glue system applies adhesive to banding for softer flexible applications. -- Automatic advance of banding material by foot pedal activation. -- Digital temperature control for precise & easy temperature setting. -- Small glue pot for quick heat-up.NOTE: Sold "As-Is" Without Warranty!

Call for Price

VITAP RC 92 Semi-Automatic Top & Bottom Edge TrimmerFor straight & curved edgebanded panels; (2) spindles (one top & one bottom) 0.75 HP - 12,000 RPM ea.Features: Large dia. guide bearings to ensure precise trimming of edges; panel thickness from 10 - 60 mm., Up to 3mm thick PVC banding material. Complete with precision ground table, table size of 31" x 27".NOTE: Sold "As-Is" Without Warranty!

$ 52,500

VITAP - ECLIPSE 2.0, ...Semiautomatic Contour (Curved Panel or Round Tables) EdgebanderSemiautomatic Contour Edgebanding and Trimming for Panels including: -- Concave shaped panels. -- Convex shaped panels. -- Straight panels.(3) Methods of Operation: -- Manual: Via the use of a foot pedal control for the guillotine. -- Laser: By entering the length of the desired dimension into the PLC, the guillotine will engage automatically. -- Smart Laser: Guillotine engages automatically when the high-definition laser detects the starting point of the applied edgeband with no need to measure/enter the length.Standard Specifications: -- High productivity and flexibility. -- Application for big and small shaped panels. -- Reinforced hinged holding arm with vacuum table to hold large pieces for edging and trimming. -- Color touch screen HMI 7”.(4) Control Pedals: -- Pedal to start the automatic feeding and manually engage guillotine. -- Pedal for slowing down the feed to process tight radii (turtle speed). -- Pedal for opening/closing the trimming head. -- Pedal to engage suction table vacuum.Glue Station: -- Teflon coated glue pot with 1 kG / 2.2 Lbs capacity. -- Quick disassembly system. -- Supports PUR or EVA Hotmelt Glue. -- Amount of glue applied is adjustable., -- Programmable glue temperature. -- Automatic guillotine for edgebands up to 3 mm x 45 mm. -- (2) Side rollers to follow the contour of the workpiece. -- Bottom support roller tilts after edgebanding for easy release of the panel. -- Variable speed for turtle speed adjusted by potentiometer.Laser for an automatic speed adjustment for complex panel shapes with the help of a potentiometer. -- Utilizes 2 x 800 W heating elements with a thermoregulator and electronic temperature control.Trimming Station: -- Trimming unit with: (2) Motors, approx. 0.5 kW / 0.7 HP high frequency, 15,000 RPM motors. -- Upper, lower, and front contour copy rollers, -- Auxiliary working table that can be raised for trimming small pieces. -- (2) Brazed cutters: R=3, Z = 6. -- Trimming Station with: Pneumatic tilting to allow trimming of big pieces.Technical Data: -- Dimensions of the machine: 2,000 mm (6’-6”) x 2,000 mm (6’-6”) x 1,700 mm (5'-7”). -- Weight: 600 kG/1,323 Lbs. -- 10 - 60 mm Panel thickness range. -- 1 - 3 mm Band thickness range. -- 13 - 64 mm Band height range. -- Connection data: 230 V, 3-Phase, 60 Hz.

Call for Price

VITAP BC-91 Contour Edgebander – Demo Model Never Used in ProductionDesigned for straight or curved (contour) edgebanding.Specifications: -- 0.3 - 3 mm (0.01" - 0.12") Edgebanding thickness. -- 10 - 60 mm (0.39" - 2.36") Panel thickness & Edgebanding height. -- 20 mm (0.79") Minimum radius with concave curve. -- 280 mm (11.02") Min. panel length.Equipped with: -- Compact "Quick heat-up" underneath worktable glue pot. -- Double roller glue applicator. -- Magazine for coil material or solid strips. -- Manual feeding of straight and/or contoured panels. Complete with: -- Program-controlled end cutoff for coil material, Coil dispensing table, Digital thermo-control for glue temperature. -- Single motor end trim with 1 HP - 10,500 RPM Motor. -- Magnetic push button starter.NOTE: Sold "As-Is" Without Warranty!

Call for Price

VITAP SMART Hot Melt Contour EdgebanderDesigned for straight, curved (contour) or beveled edgebanding, Unique design to allow banding of strips or rolled edging.Specifications: -- 0.3 - 3 mm (0.01" - 0.12") PVC Edgebanding thickness. -- 3/8" - 2-3/8" Edgebanding height. -- 20 mm (0.79") Minimum radius with concave curve.Equipped with: -- Hot Melt glue system applies adhesive to banding for softer flexible applications. -- Automatic advance of banding material by foot pedal activation. -- Digital temperature control for precise & easy temperature setting. -- Small glue pot for quick heat-up.NOTE: Sold "As-Is" Without Warranty!

$ 1,500

For pre-glued PVC, veneer, & melamine laminate coil stock; 0.4 - 1.2 mm edge thickness and up to 35 mm panel thickness cap., automatic coil feed. -- Equipped with: Electronically controlled temperature setting for hot air blower, 3,000 watts for up to 650° F temperature, (1) Min heat-up time. -- Guillotine type front & rear end trim (with fast speed, flying knife), top & bottom flush trims with single motor drive to cutterheads. -- Overhead belt type feeder, 16 FPM feed speed. - Mounted on machine base with panel support table.

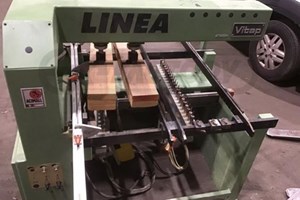

VITAP LINEA 42 Line Boring SystemSpecifications: -- (2) Drill heads of (21) spindles ea., drills from bottom up, ea. support with 2 HP motor and (21) spindle boring block w/panel support mounted on top; -- Drills panels from 100 - 3,000 mm in length, and 100 - 950 mm in width. Complete with: -- Digital readouts for boring blocks, 2,000 mm bar scale fence with (5) adjustable flip stops. -- (2) Moveable overhead pneumatic holddown cylinders, foot pedal for clamping & boring cycle.

VITAP - ALFA 21, ...Construction Boring MachineSpecifications: -- 21-Spindle boring head on 32 mm centers; drills vertically from bottom-up & head rotates to a horizontal position for edge boring; head rotation is pneumatic with switch control. -- 2-3/4" Max. drilling depth, 2.5 HP - 2,800 RPM motor, pneumatic drill head advance with speed control. Left & right flip stops mounted onto a custom-made sliding back fence (see photos for details). Details: -- (4) Pneumatic hold-down clamps; pneumatic foot pedal control. -- Complete with: Magnetic starter & overload protection.

.gif)