LUMBERMENOnline.com’s Latest Industry News & Articles

Submit your company’s latest news or articleTimberwolf Firewood Processing Equipment, a subsidiary of Automated Biomass Systems, has officially released its newest model: the Pro-LP Firewood Processor. Designed to offer professional-grade performance in a compact, user-friendly platform, the Pro-LP fills a crucial gap in the market and delivers dependable output for small businesses, homeowners, and rental operations at an accessible price point.

Built with American precision and engineered for durability, the Pro-LP combines Timberwolf’s hallmark toughness with a design tailored to the needs of light-commercial users.

At the heart of the Pro-LP is a 22 HP Honda GX-700 EFI engine and an 18 GPM high-pressure hydraulic gear pump, which ensures a consistent and reliable cycle which is critical in high-throughput processing scenarios. Logs up to 16 inches in diameter are securely stabilized by the new top-roll clamping plate—a simple yet highly effective design that minimizes bounce and vibration during cuts without relying on complex hydraulics. The Pro-LP also utilizes an hourglass-shaped back roller to increase forward traction, making log advancement smoother and more reliable, even with irregular stock.

The unique design of the processor's 4-foot-wide log lift allows operators to pick up uncut logs directly from the ground, eliminating the need for a tractor or other equipment to load the machine, and making firewood production an easy, one-man operation.

Despite its robust capability, the processor maintains a lightweight footprint. Weighing in around 3,300 pounds, the Pro-LP is towable with nearly any vehicle. For operations that need mobile flexibility, such as firewood delivery services or rural landowners with multiple processing sites, this ease of transport is a major advantage.

The machine includes manual autocycle, hydraulic wedge lift, and intuitive manual valve controls that make it both powerful and user-friendly—no computer diagnostics or steep learning curves involved.

Users can also opt to add a 10-foot integrated conveyor—a chain-driven, paddle-style belt with a built-in fines deflector. This conveyor efficiently loads split wood into piles, bins, or truck beds, reducing physical labor, speeding up operations, and dramatically improving workflow and output.

A single-man operation with average wood cut to 12' long should be able to produce a cord of firewood every 45 minutes, as long as the operator has the physical capability to move! This machine will provide years of reliable service, producing in excess of 10 cords of firewood every 8 hours of operation.

In the growing firewood market, where efficiency, mobility, and low maintenance are more important than ever, the Timberwolf Pro-LP is a high-performance, low-friction solution for users who want real results without a massive learning curve or budget.

For more details, specs, pricing, or to request a quote, visit:

https://www.timberwolfequip.com/products/pro-lp-firewood-processor

Pro-LP at a Glance

| Feature | Specification |

|---|---|

| Engine | 22.1 HP Honda GX-700 EFI |

| Hydraulic Cylinder | 4 inches |

| Stroke | 26 inches |

| Max Log Diameter | 16 inches |

| Max Log Length | 12 feet |

| Trough Length | 9 feet |

| Cycle Time | ~5 seconds |

| Splitter Wedge | 4-way included, 6-way available |

| Output | ~1 cord every 45 minutes |

| Weight (Base) | ~3,300 lbs |

| Towing | Half-ton truck towable |

About Timberwolf

Timberwolf Firewood Processing Equipment is based in Marathon, New York. Proudly designed, manufactured, and built in America, Timberwolf's equipment lineup includes residential and commercial-grade log splitters, firewood processors, conveyors, and other biomass handling equipment.

Follow Timberwolf on Facebook:

https://www.facebook.com/TimberwolfEquipment/

Learn more:

https://www.timberwolfequip.com/

Forest Products EXPO 2025 Largest Show Since 2000

EXPO 2025: Fine Tune Your Strategy. That was the agenda for the 38th Forest Products Machinery & Equipment EXPO from August 6-8, 2025, at the Music City Center in Nashville, and early feedback shows exhibitors and attendees alike were able to successfully collaborate to drive their operations forward.

“The Southern Forest Products Association (SFPA) hosting the Forest Products EXPO in Nashville for a second time continued to far surpass our expectations,” said Eric Gee, SFPA’s executive director. “Seeing and talking with so many members of the forest products industry was truly energizing. I’m beyond proud of our exhibiting companies, whose creativity and hard work transformed the exhibit hall into an outstanding hub of innovation, connection, and opportunity.”

The final floorplan topped out at 243 exhibiting companies, a record number of exhibitors since 2000, representing 185 product categories spread over 61,440 square feet of machinery, innovation, and solutions to meet with nearly 1,000 attendees. EXPO 2025 also welcomed 60 first-time exhibitors.

Early survey responses from attendees were positive, with many lauding the location and Music City Center, the opportunities for networking with industry colleagues and meeting new vendors, and the variety of exhibits.

“Forest Products EXPO is a specialized trade show, and while attendance may have been down in 2025 after a near-record-breaking show in 2023 because of various economic conditions, it continues to attract the highest-quality decision-makers from sawmills throughout North America,” Gee said. “More than one-third of attendees at EXPO 2025 serve in a president and/or owner capacity, representing nearly 100 sawmills.”

Since 1950, Forest Products EXPO has provided a place for both hardwood and softwood sawmillers to gather, celebrate new technology, network, and learn about the industry’s latest machinery and equipment. And as the industry and workplace evolve, so does EXPO, Gee said.

“The SFPA and EXPO teams are always soliciting and reviewing feedback from exhibitors and attendees to ensure Forest Products remains the premier forest products industry event and that it provides plentiful opportunities for growth among that industry.”

The three-day tradeshow provided attendees with solutions for nearly every stage of manufacturing. From raw material handling to crane operations; metal detection and scanning technologies; log optimization; lumber drying, grading, sorting, packaging, and distribution; engineering and AI solutions.

Onsite Activities

SFPA announced the 2024 John Edgar Rhodes Sawmill Safety Excellence Awards during the Sawmill Safety Awards & Summit, sponsored by SFPA associate member and EXPO 2025 exhibitor GAPCO, on Thursday, August 7. For the fourth year in a row, at least seven mills receiving Sawmill Safety Awards with zero incidents among them. Click here to learn more about the 2024 recipients.

EXPO 2025 was also the location for the inaugural SFPA Safety Summit, moderated by Dale Bracken with National Assessment, who is a management consultant and former consumer products division manager with the world's largest pulp and paper maker.

Bracken led a conversation with 2024 Safety Awards recipients Vince Almond of Almond Brothers Lumber Co., Stephen Peskar of Weyerhaeuser, and Johnny Sauls of West Fraser. Topics covered all things safety, from discussing each mill’s safety culture, how they approach safety training and address safety issues to tactical strategies that helped them and their teams achieve zero incidents.

“In an industry where worker safety is paramount, achieving a record with no reportable incidents is truly remarkable,” Gee, said.

“To be able to bring these safety leaders together to share expertise and help other mills improve safety cultures is an amazing opportunity for SFPA to deliver on its mission of being better, together so that all mills, members or not, can learn from each other and grow with safety at the forefront.”

Another first in 2025 was the SFPA Women’s Leadership Summit, held Thursday, August 7.

“We all know leadership has looked a certain way for a long time. But the truth is, we’re changing that with events such as the Women’s Leadership Summit,” Gee said. “We’re not waiting around for change. By showcasing successful women leaders, we’re not just clapping for achievements — we’re lighting the way for others to follow. We’re creating space for mentorship, for connection, and for the kind of career growth that breaks down old barriers.

Donna Whitaker, former vice president with Interfor and former board chair with SFPA, served as moderator as Dr. Heidi Adams, associate professor and Frank Merritt Endowed Professor of Forestry at Louisiana Tech University; Heidi Danbrook, sales manager with Gilbert, an SFPA associate member and EXPO 2025 exhibitor; and Kim Drew APR, president of Drew Public Relations discussed mentorship, education and advancing women in the forest products industry, sales and marketing excellence strategies, and strategic communications and public relations, respectively.

“This amazing panel didn’t just discuss theory,” Gee said. “They shared real-world strategies – what they’ve lived and experienced out there – and gave attendees inspiration, empowerment, and practical tools to lead with confidence.”

SFPA will post recordings of the Safety and Women’s Leadership Summits in the coming weeks on the association’s YouTube channel, which you can access by clicking here

.

What’s Next?

Stay tuned to SFPAexpo.com for future host city and dates to be announced in the coming weeks. Booth sales for the 39th Forest Products Machinery & Equipment EXPO are scheduled to open in June 2026, while registration is scheduled to open in March 2027.

EXPO 2025 By the Numbers

SFPA has conducted a thorough audit of the registration report and found the following:

- Attendees

- 1,041 registered

- 957 confirmed

- Exhibitors

- 243 exhibiting companies

- 1,059 exhibitor personnel

- 61,440 square feet of displays

- International Component

- 300 international attendees and exhibitors

- 18 countries represented

- Attendee Demographics

- Key Category

- 70% – Manufacturing/Processing

- 19% – Non-Exhibiting: Equipment Manufacturing/Dealer/Distributor

- 10% – Forestry/Logging/Harvesting

- 1% – Academia/Student

- Job Title

- 33% – Company Officer/Owner

- 22% – Marketing/Sales

- 14% – Engineering/Operations

- 10% – General manager

- 7% – Purchasing/Maintenance

- 6% – Production manager

- 3% – Superintendent/Foreman

- 1% – Research and development

- 2% – Student

- Key Category

One Name. One Team. Powered By Trust.

To Our Customers,

Fourteen years ago, Michigan CAT and MacAllister Machinery came together as one company. You might not have noticed, and that’s okay—we kept the names separate, but behind the scenes, we merged two hard-working, customer-first teams that share the same values, and have been working as one ever since.

On our 80th anniversary – today June 2, it’s time to make it official on the outside what has been true on the inside since 2011: Michigan CAT and MacAllister Machinery are uniting under one name — MacAllister Machinery Company.

My family’s history with Caterpillar goes way back to before 1945, when my great-grandfather, E.W. MacAllister, made a handshake deal to become the authorized Cat® dealer for 68 counties in Indiana. Around that same time, Jerrold “Jack” Frost and H.O. Penn started Michigan Tractor & Machinery Company, which grew into the Michigan CAT so many of you have come to know and trust.

I’ve been around this business all of my life. As a kid, I used to go to the office with my dad on Saturdays, I repainted our buildings, cut the grass at our main shop during the summer, spent time working the parts counter and turning wrenches in the shop, and rode along on machine deliveries. Over the years, I’ve worked in nearly every division across our locations in Indiana and Michigan. Those experiences gave me real appreciation for the work we do and the people we serve: you!

What does this change mean for you?

Not much, really. And that’s the point. The same folks you count on will still pick up the phone, show up at your jobsite, and have your back when it matters most. The change will enhance coordination and efficiency and eliminate confusion.

Trust isn’t a slogan—it’s how we do business. We build that trust by:

- Showing up when it matters. Not when it’s easy. Not when it’s convenient. We’re there when you need us.

- Doing what we say we’ll do. No excuses, no runaround—just straight answers and solid work.

- Doing it right the first time (DIRTFT). If it’s not good enough for our name, it’s not good enough for you.

- Standing by our price, quality, and turnaround. Because doing good work, at a fair price, on a timeline we agree on—that’s the MacAllister way.

When our customers win, we win. And when you trust us with your business, we treat it like our own.

We’re proud to stand with you—and now, we’re proud to do it under one name: MacAllister Machinery Company.

Thanks for being part of our story. We’re 80 years in, and we’re just getting started.

All the best,

Alex MacAllister

Senior Vice President of Operations

MacAllister Machinery

The 79th Annual Great Lakes Logging & Heavy Equipment Expo will roll into Escanaba, Michigan September 4-6, bringing more than 5,000 people to the area. The Great Lakes Logging & Heavy Equipment Expo is the largest Cut-to-Length Forest Products trade show in the Midwest, drawing internationally from Canada, and across the U.S. We are honored that Fabick Cat will once again be the major sponsor of the Expo. The show will be located at the U.P. State Fairgrounds, and we are thrilled to back in Michigan for 2025!

Henry Schienebeck, GLTPA Executive Director, explains that the Expo provides the opportunity for everyone to learn about new technologies in forestry and heavy equipment while networking with fellow members and colleagues. Exhibitors can showcase their products and services to a variety of interests including professional loggers, truckers, firewood cutters, landowners, students, and families.

This year the Expo is excited to welcome the Wisconsin & U.P. Chainsaw Racing Association to the show. They will run a chainsaw racing contest on Saturday morning, September 6th from 8am – noon. Another new addition to this year’s show will be a Logger’s Breakfast, offered by the Gladstone Knights of Columbus on Saturday morning beginning at 8am.

In addition to viewing the exhibits, attendees and families can enjoy their time together by participating in all the activities that the Expo has to offer. The Komatsu and Roland Machinery Forwarder Operator Challenge demonstrates the skills of experienced operators through a challenging course while competing side by side. The BARKO Loader Contests will once again time the skill and accuracy of log construction by the participants. Favorites including the tug-of war and bowling pin toss will also welcome willing participants during the Expo. And let’s not forget about the annual Kickoff Event on Thursday evening beginning at 6pm in the Miracle of Life Building, offering dinner, drinks, and raffles to raise funds for CMN Hospitals through Log A Load for Kids.

The Great Lakes Logging & Heavy Equipment Expo is open to the public and all are encouraged to attend. The Expo officially opens at noon on Thursday, September 4th, and ends at 1p.m. on Saturday September 6th. Admission is $20 and is good for all 3 days. Children under 18 are free!

For more information contact Great Lakes Timber Professionals Association at 715-304-2681 or find us on the web at www.gltpa.org.

McDonough Manufacturing Company is pleased to announce the appointment of Bob Bell as Director of Sales and Service, effective May 19, 2025.

In this role, Bell will be responsible for leading the company’s sales initiatives, overseeing customer service operations, and supporting McDonough’s continued growth across North America.

Bell brings extensive experience in the sawmill and industrial machinery sectors, along with a strong track record of performance at McDonough. His appointment reflects the company’s ongoing commitment to leadership and customer-focused service delivery.

This strategic promotion supports McDonough’s broader efforts to strengthen relationships, enhance responsiveness, and deliver long-term value to its customers throughout the industry.

Indianapolis, IN – Wood-Mizer, a global leader in the portable sawmill industry, is excited to announce the launch of the LX30 portable sawmill, the most affordable Wood-Mizer sawmill ever made.

Designed for hobbyists and woodworking enthusiasts, the LX30 brings industry-leading precision and performance at an unbeatable price point of $2,495 USD, making it easier than ever for anyone to transform logs into valuable lumber. The LX30 sawmill is a game-changer for those who have always dreamed of owning a high-quality, durable sawmill but were held back by cost. With its compact design, reliable engine, and user-friendly features, the LX30 delivers exceptional value without compromising on performance.

Key Features of the Wood-Mizer LX30 Portable Sawmill:

Unmatched Affordability: The LX30 is the most budget-friendly sawmill ever offered by Wood-Mizer, providing a cost-effective solution for DIY and woodworking projects.

Reliable Engine: A Command Pro 9.5HP gas engine powers the sawmill, ensuring optimal sawmilling performance.

Precision Sawing: Engineered for accuracy and reduced sawdust waste with a 1/8” thin-kerf sawmill blade, the LX30 produces up to 30% more lumber than the 1/4” thick kerf of a chainsaw mill.

Versatile Sawmilling: Capable of sawing hardwood and softwood logs up to 22 inches in diameter with a 21-1/2 inch width of cut, the LX30 has plenty of capacity to produce smooth, clean lumber, boards, and slabs for the hobby sawyer.

User-Friendly Operation: With intuitive controls including rev & run blade action and simple maintenance, the LX30 is designed to be easy for beginners.

Premium Quality Manufacturing: Made by the Wood-Mizer owned and operated factory in Poland provides for the best combination of premium quality equipment at a low cost. Wood-Mizer employees in Poland have been manufacturing high-quality Wood-Mizer equipment for global markets since 1990.

“We’ve always strived to make high-quality sawmill equipment accessible to more people, and with the LX30, we’ve succeeded in bringing the Wood-Mizer lifestyle to an even broader audience,” said John Smith, Wood-Mizer CEO. “The LX30 combines the performance, reliability, and innovation Wood-Mizer is known for with an affordable price tag, opening the door for woodworking enthusiasts and homeowners to start sawing their own lumber.”

Backed by Wood-Mizer’s industry leading 30-day money back guarantee, a reassuring two-year warranty, and legendary customer service throughout ownership, the LX30 portable sawmill is now [DB1] available for purchase online and through Wood-Mizer’s established network of authorized dealers. For more information about the LX30, visit woodmizer.com or contact your local Wood-Mizer dealer.

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a world-leading wood processing equipment manufacturer with a strong legacy from its innovative sawmilling products. Serving more than 100,000 customers throughout the world From Forest to Final Form®, Wood-Mizer offers an extensive line of equipment including narrowband portable and industrial sawmills, wideband sawmilling equipment, band resaws, board edgers, wood kilns, planer/moulders, firewood processing equipment, pallet recycling equipment, material handling equipment, sawmill blades, and blade maintenance equipment for woodworking and forestry hobbyists and professionals all over the world. Visit woodmizer.com for more information.

With over 46 years of experience in the forest products industry, Robert J. Bauer has

dedicated his career to advancing forestry practices and the wood products sector. He

holds a BS Degree in Forestry from the University of Kentucky and began his career as

a Forest Products Utilization Forester with the Kentucky Division of Forestry. There, he

worked on improving efficiency and utilization within the forest industry.

After two years, Bauer transitioned to a role as a service forester, offering guidance on forest management and

timber sales. He then spent six years at Morehead State University, focusing on expanding and improving the

wood industry in Eastern Kentucky through economic development projects and marketing assistance.

Bob Bauer’s three-decade leadership with the Kentucky Forest Industries Association (KFIA) is truly

remarkable. His passion and dedication are evident in his role managing operations, member services, and

organizing major events like the KFIA Annual Meeting and the Kentucky Wood Expo.

The Kentucky Chapter of Log a Load for Kids, founded in 1997 under Bauer’s guidance, has made an incredible

impact by raising $1 million for the Kentucky Children’s Hospital. This charity reflects Bauer’s commitment to

“Kentucky’s most precious resource – Our Children.”

Bauer’s involvement with the Kentucky Tree Farm Committee further showcases his deep connection to nature

and the woods. Judging tree farms nationwide and visiting active logging sites to determine Loggers of the Year

finalists have been incredibly fulfilling for him.

In addition to these roles, Bauer’s work in government affairs, advocating for the wood industry and addressing

regulatory and legislative issues at both state and federal levels, demonstrates his commitment to the industry's

future. His career is a testament to his passion, dedication, and tireless efforts to benefit the community and the

environment.

Throughout his career, Bauer has been actively involved in various professional organizations, including the

American Forest Foundation, Society of American Foresters, National Council of Forestry Association

Executives, and the Southern Forestry Association. His leadership roles in these groups have allowed him to

forge valuable professional relationships and learn from others in the field.

Bauer’s primary goal has always been to help KFIA members navigate industry challenges, improve their

business operations, and provide valuable networking opportunities. Reflecting on his career, Bauer expresses

gratitude for the friendships he has made and the opportunities to contribute to the growth and sustainability of

the wood industry. Robert J. Bauer will be retiring in April 2025, leaving behind a legacy of dedication to the

industry and its future.

Effective January 1, 2025, the Woodtech division of WINTERSTEIGER Inc. has become its own entity, WINTERSTEIGER Solutions LLC. A subsidiary of WINTERSTEIGER Woodtech in Austria, WINTERSTEIGER Solutions is dedicated to serving customers in the wood processing industry across North America. WINTERSTEIGER Solutions offers a comprehensive range of wood processing solutions, including thin-cutting band saws and frame saws, timber repair and cosmetics machines, saw blades and saw blade sharpening, automation plants, and mobile and stationary sawmills from SERRA Sawmills. As a full-service provider, the company offers tailored solutions with convenient access to the full range of WINTERSTEIGER and SERRA products and improved local support and service. Brent Fischmann has been appointed the Managing Director of WINTERSTEIGER Solutions LLC. In this role, he will oversee all North American business activities. Fischmann brings extensive experience in industrial sales with a focus on highly engineered products and advanced processes. He will be instrumental in driving growth and expanding market share for both brands in the North American market. We are thrilled to welcome Brent to the WINTERSTEIGER team said Andreas Doubrava, Managing Director of Division Woodtech at WINTERSTEIGER in Ried im Innkreis, Austria. His leadership and strategic vision will be invaluable as we continue to strengthen our presence in North America and provide our customers with innovative solutions. Fischmann will be based out of the WINTERSTEIGER Solutions LLC headquarters located at 1031 Parkway Dr. Bldg. 24B, Spring Hill, Tennessee 37174. Additional warehousing, saw blade sharpening, and service operations will continue from the WINTERSTEIGER, Inc. location in Salt Lake City. Sales and service team as well as all contact information remains the same, with the addition of a new general office email address: [email protected].

Industry professionals gathered for three days of networking, education, and social activities at the 87th Annual Oregon Logging Conference, held February 20 – 22, 2025 at the Lane Events Center and Fairground. This year, there were more exhibitors, both inside and outside, and greater attendance at the OLC. The OLC thanks this year’s sponsors, many of whom support the conference every year, who without their support, this conference would not be possible.

2025 Oregon Logging Conference President Jayme Dumford said, “The 2025 Conference was excellent. The show continues to grow and has become the place to be for industry professionals,” he added. He expressed his appreciation to everyone who did their part to make such a huge event so successful.

Saying it was an honor to be invited and share his message with the Oregon Logging Conference, Keynote speaker Chris Evans, President of Timberlab, based on Portland, OR, talked about the environmental advantages of using mass timber building materials rather than concrete and steel. He said using mass timber instead of concrete and steel will result in a 60% reduction in greenhouse gases “Using wood helps reduce carbon emissions,” Evans said. “If you put this product into a building where it’s going to be stored for 100 years,” he added, “that really is a deferment of having that carbon released into the atmosphere.” Evans also said the typical mass timber building is half the weight of a concrete building. “It’s hard to fathom how much a building weighs when you look at it, but when you think about the impact that has to the local community, as that building is being built, that’s half the trucks on the road,” he said.

Evans holds a Master of Science in internal construction management from the University of Florida and a Bachelor of Science in mathematics from the University of Oregon.

Desserts for Dreams Fundraiser Benefits Every Child Lane County

More than $30,000 was raised at the 21st Annual Desserts for Dreams luncheon, held Friday Feb 21st at the Graduate by Hilton Eugene hotel. It was the most successful of all events held since it began in 2004.

OLC First Lady Maria Dumford selected Every Child Lane County as this year’s charity to benefit from the annual fundraiser. Every Child Lane County is a non-profit organization that provides assistance for children and families in the foster care system.

“Dessert for Dreams was an overwhelming success with the largest attendance ever!” Dumford said. “Thank you to everyone who came and gave generously,” she added.

The luncheon included salads and delicious desserts donated by local bakeries and restaurants, and a special sock drive, with all donations given to the charity’s Brighter Side Giving Store.

Future Forestry Workers Career Day

More than 700 students, educators and industry professionals participated in the 7th Annual Future Forestry Workers Career Day, held on Friday February 21st, in conjunction with the Oregon Logging Conference.

The high school students from more than 32 Oregon schools attended this interactive and hands-on career day, learning about logging, forestry, reforestation, sawmills, wildland firefighting, diesel mechanics, and operating heavy equipment.

Some of the students had an opportunity to operate a small excavator with one student saying, “That’s the most fun I’ve ever had,” and adding, “that was so cool.” One of the educators accompanying her students described the event as a “one-stop shop” for learning about current job opportunities and careers in natural resource-related industries, adding how much she and her students look forward to coming to this event every year.

One of the activities at Future Forestry Workers Career Day was the high school forestry skills relay.

With 100 students from 12 Oregon schools competing, Waldport High School teams took first and second places, finishing within seconds of each other. Third place was captured by La Pine High School and Taft High School took fourth place.

The teams competed against each other in the four-skills relay, which included hose lay, choker setting, crosscut sawing. and chainsaw use.

This event is coordinated by Future Natural Resource Leaders and Executive Director Rex Lowther said, “Overall the event went great with no issues. The kids did a great job of being ready to go and properly equipped,” he added.

Log Loader Competition Winners

Demonstrating their skills at operating a 4040-B Link-Belt, the top three winners in the 15th Annual Oregon Logging Conference Log Loader Competition were within 20 seconds of each other.

First place was Jeremy Staats of Bryant Logging with a time of 3:24:44. Second place was a familiar name in this annual contest, Bryan Chipps of Green Diamond Resource Company, with a time of 3:35:91, and third place was Layne Walker with a time 3:43.16.

Guess the Net Scale

Oregon Logging Conference attendees gave their guesses for the net scale of two loads of logs, with the winner of each receiving a $250 Cabela’s gift card.

The winner of the load of alder chip and saw logs was Thomas Fox of Ethel, WA. He was one of four who were ten feet off the total of 4,690 board feet. All four names were put into a hat and Thomas was the winner drawn.

The net scale of the load of logs was 6,660 net. The lucky winner is Jack Miller from California guessed it to the foot.

Thank you sponsors; Swanson Bros. Lumber and Southport Lumber Co. Log trucks provided by Leonard Masser Logging and Bracelin Trucking Co.

Family Day and OLC Open to the Public Day

Forest families and other members of the public turned out in large numbers on Saturday, February 22nd, as the rain held off until late afternoon, and the weather was good for those who built wooden bird houses just outside the Wheeler Pavilion.

Other popular Family Day activities included live wildlife, free seedling giveaways, face painting, balloons, art projects, and other hands-on forestry-related opportunities.

“The final day of the conference is an opportunity for families to attend the OLC and for the public to learn more about who we are and what we do and meet many of the professionals who make their living in our industry,” said Rikki Wellman, OLC Manager.

The dates for the 88th Annual Oregon Logging Conference are February 19, 20, and 21, 2026.

For more information visit: www.oregonloggingconference.com (OLC website)

www.forestnet.com/oregon-logging-conference-official-show-guide/ (2025 TimberWest Magazine OLC Show Guide)

Cooper Machine Company, Inc. is proud to celebrate 60 years of dedicated service to customers and continuous innovation to the sawmill industry, including the Overhead and Sharp Chain Scraggs.

In addition to Cooper Machine celebrating 60 years, we also celebrate Company President Robert Cooper’s 60-Year commitment and service to our customers and this industry. Cooper Machine was started by Billy and Mary Cooper in 1965 and was run by Robert and Bill Cooper until Bill retired in 2008. The company is currently run by Frances Cooper, who is a third generation Cooper.

Since its founding, starting with Billy Cooper and the first Overhead Scragg, the company has focused on the needs of their customers and making the equipment to fit those needs. Cooper Machine is deeply committed to continuing that tradition.

Over the last several years, the employees at Cooper Machine have continued this innovation by expanding our product offerings with an Optimized Merchandising and Sorting System for the post and pole industry. We created an updated design of the VSA for cutting pallet boards for our pallet customers using circle saws instead of bands, as well as expanding our sawmill product offerings by including EWD sawmill equipment and added Ledinek equipment to our cooperage offerings.

“I want to express my gratitude to the employees of Cooper Machine, without whom this company would not have been successful, as well as our customers and partners for their support over the years. We want to continue to earn that support and strive for the company’s continued commitment to service and adapting to market needs in the future,” states CEO Frances Cooper.

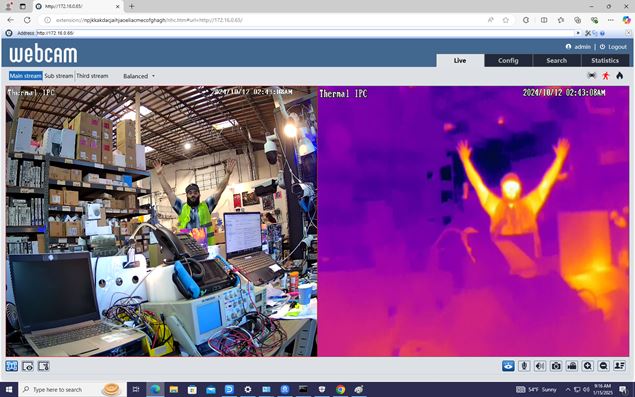

Opticom Tech, a leader in industrial video monitoring solutions, announced the release of its new thermal monitoring camera that detects hot spots and fire hazards in sawmills. The cutting-edge fire prevention solution is designed to safeguard sawmills from catastrophic fire events. Using advanced AI-driven thermal imaging and analysis, the camera provides early detection so operators can mitigate fire risks before they escalate.

“Sawmill operators face a constant challenge when it comes to fire prevention, and our new monitoring system provides a proactive solution,” said Heidi Schmidt, Global Sales Manager at Opticom Tech. “By integrating intelligent thermal imaging and real-time alerts, we’re giving sawmills a plug-and-play system to detect potential fire hazards, taking facility safety to another level.”

Opticom Tech’s thermal monitoring camera, the MIB-5141T, comes with the quality and durability the brand is known for. The camera continuously monitors for temperature anomalies in sawmill operations. When a hotspot is detected, the system triggers alerts via multiple channels—chosen by the sawmill—including on-site alarms, visual indicators, email notifications and text messages. With immediate notification, operators can act on-the-spot to prevent fires.

Key features of the thermal monitoring camera include:

- AI-Powered Thermal Detection: Identifies heat anomalies—based on your custom temperature parameters—before they turn into fires

- Real-Time Alerts: Notifications via alarm, email, text, and on-screen warnings for rapid response, plus a hardwired I/O for integration into existing fire system alarms

- High-Resolution Imaging: 5-megapixel visible spectrum camera captures clear footage for AI to analyze

- Durability: IP67 rating, with IP66 ingress protection, to withstand harsh sawmill environments

- Flexible Integration: Supports DC 12V and PoE (power over ethernet) for easy installation

- Customizable Thermal Palettes: Various display modes, including black hot, white hot, and iron oxide red to customize alert sensitivity

This new thermal monitoring camera stands out among competitors by delivering a powerful combination of high-resolution thermal detection and AI-driven alerts, helping sawmills reduce downtime, protect assets, and improve worker safety. Designed to operate seamlessly in demanding environments, this system provides the fire prevention capabilities that sawmills need at a price that doesn’t break the bank.

“With the MIB-5141T thermal monitoring camera, we’re redefining what’s possible in fire prevention technology for industrial operations,” added Schmidt. “Our goal is to help sawmills run safer and more efficiently by providing a proactive, intelligent monitoring solution.”

The system is now available to purchase through Opticom Tech and its network of distributors. For more information, visit www.opticomtech.com.

About Opticom Tech

Founded in 1973, Opticom Tech provides integrated video monitoring solutions for industrial applications, including sawmills, mines, food processing facilities, and more. Built to withstand harsh environments, Opticom Tech’s rugged cameras and equipment stand the test of time. For more information, visit www.opticomtech.com.

Wood-Mizer, a global-leading sawmill and woodworking equipment manufacturer, is pleased to announce a new Authorized Sales Center in Linden, Michigan. Located an hour from Detroit and Lansing, Wood-Mizer Michigan is the 17th sales location in the United States and reflects the company’s ongoing commitment to sell, support and serve the sawmilling and forest industry throughout the world.

Managed by an experienced representative Chuck Schultz, Wood-Mizer Michigan will provide sales and service of Wood-Mizer sawmill, woodworking, and firewood processing products to customers throughout Michigan and surrounding areas. Products provided include the popular LX50, LT15, and LX150/LX250 model portable sawmills, woodworking equipment, log splitters, as well as sawmill blades and common parts.

“I am excited to serve sawyers and woodworkers by providing Wood-Mizer’s premium quality sawmill equipment and products to hobbyists and professionals throughout the Great Lake State,” shared Wood-Mizer Michigan Manager, Chuck Schultz.

Wood-Mizer Michigan is now open and located at 8392 Argentine Rd, Linden, MI 48451. For more information about Wood-Mizer Michigan, visit woodmizer.com or contact Chuck Schultz at +1 810-255-1153 or [email protected].

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a global-leading sawmill and woodworking equipment manufacturer. From Forest to Final Form®, Wood-Mizer offers an extensive line of equipment including portable and industrial sawmills, resaws, board edgers, wood kilns, planer/moulders, firewood processing equipment, pallet recycling equipment, material handling equipment, sawmill blades, and blade maintenance equipment. For more than 40 years, Wood-Mizer remains committed to serving sawmilling and woodworking hobbyists and professionals all over the world throughout an established and growing distribution network.

.gif)