Articles, Contributed Resources & LUMBERMENOnline's Blog

Submit Your Article & Valued ContentWhen you ask a sawmill manager to name the most expensive word in the plant, the answer is usually: “downtime.” Paused processing operations can bleed tens of thousands of dollars per hour in idle labor, increased holding costs, and missed deliveries.

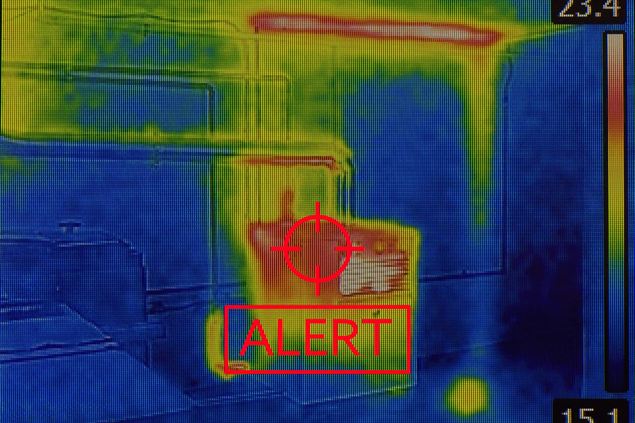

Thermal video monitoring is already a proven first line of defense against one of the biggest downtime risks—fire—but the same cameras that watch for ignition sources can do double duty as a 24/7 condition-monitoring system.

By turning a fire-monitoring asset into a predictive-maintenance tool, mills can schedule repairs on their own terms, cut unplanned outages, and stretch the life of critical equipment.

Let’s explore how thermal cameras can be part of a sawmill’s maintenance team.

Heat: The Earliest Symptom of Mechanical Distress

Excess heat is rarely a good thing, and it’s rarely meaningless. It is the by-product of worn bearings, unbalanced rotors, inadequate lubrication, overloaded drives, and dozens of other failure modes.

Because abnormal heat often appears days or even weeks before vibration or noise suggest a problem, infrared (IR) thermography has become one of the must-have predictive maintenance technologies.

Why Preventative Maintenance in Sawmills Is Different

Most industrial plants fight heat in a few motors and gearboxes; a sawmill fights it everywhere. High-RPM planers shave boards in milliseconds. Kilns, debarkers, chippers, and conveyors all push mechanical and electrical components to their limits—usually in proximity to combustible dust and shavings.

Heat from unexpected friction is an invisible sign that sawmill processes are vulnerable to fire. If a friction-generated hotspot is from a gear about to start sparking, the risk multiplies.

Traditional point-temperature sensors or handheld IR guns can spot problems, but they see only the exact spot they’re aimed at and only when someone happens to walk by.

Fixed thermal video cameras, on the other hand, cast a wide field of view over the entire planer room, debarking process, carriage line, and other areas of the mill. They capture not just the hottest pixel but the complete thermal signature of every moving part, every second of every shift.

Turning Thermal Data into Maintenance Intelligence

You know thermal imaging can help, but where should you start? At Opticom Tech, we help sawmills use industrial video monitoring in a variety of ways—so we know about key areas of the mill to watch.

- Motors and Gearboxes – Localized heating can flag bearing wear, shaft misalignment, or impending lubrication failure.

- Planer Heads – Heat can indicate resin buildup, worn cutter heads, or other issues, which can degrade surface quality and raise ignition risk at the same time.

- Electrical Cabinets – Overheated breakers or busbars can suggest loose connections or overloaded circuits.

- Conveyors and Debarkers – Excess friction on idlers or chain drives can point to mis-tensioned belts or debris accumulation.

For example, an area that normally runs at 60°C (140°F) but drifts upward to 75°C (167°F) within a week may not trip a fuse or start a fire, but it is sending a clear early-warning signal.

With continuous thermal video feeds, these anomalies appear as bright spots long before smoke, vibration, or noise betray the fault. Alerts can be customized to come through the mill’s fire alarm system, text message, on-screen alert, or email based on customized temperature thresholds chosen by the mill.

Planned Vs. Unplanned Maintenance: The ROI

The financial argument is straightforward. Several Opticom customers have quantified the payoff in three areas:

- Downtime Avoided – Every minute saved on the critical path adds finished board-feet to the day’s tally.

- Component Life Extended – Bearings that run cooler last longer; motors that stay within design temperature avoid insulation breakdown.

- Incident Reduction – Fewer seized rollers and overheated knives translate into fewer fires and injury incidents.

- Insurance Savings – Many sawmill insurance companies offer discount incentives for facilities with Opticom’s Thermal Imaging solutions.

- Two In One – Our dual-sensor camera has both thermal and normal video feeds so there’s no need to buy two cameras to monitor the same location.

In addition to the dollar ROI, there’s also increased safety, proof for insurance purposes, and other benefits. Read more about the role of video monitoring in planned maintenance.

Final Thoughts

Fire detection alone justifies thermal cameras in a sawmill. But using that same video monitoring equipment to expose hidden wear, misalignment, and overloads multiplies the return on investment. Thermal video monitoring transforms maintenance from a reactive scramble to a scheduled, planned process that happens when the mill—not the machine—decides it is needed.

Not sure whether our thermal cameras are ideal for your sawmill? Get in touch with our experts and we’ll help you decide whether thermal cameras are the right approach for you.

Kindling Growth: Low-Cost Marketing Strategies for Firewood Businesses

When you're up to your elbows in sawdust and your days revolve around processing timber, marketing probably isn't the first thing on your mind. Most firewood operations focus their energy on production, equipment maintenance, and logistics. Yet even the best firewood business can struggle without effective marketing to connect with potential customers.

The good news? You don't need a marketing degree or a massive budget to promote your firewood business effectively. With some strategic thinking and practical approaches, you can build a steady customer base without diverting precious time and resources from your core operations.

Understanding Your Customers and Building Your Digital Presence

Before diving into specific tactics, it's worth considering who's buying your firewood and why. Some folks need it for primary home heating, others for occasional ambiance, and some for specific purposes like smoking meat or outdoor fire pits.

Your typical residential firewood customer falls into one of these categories:

The Practical Burner: This customer relies on wood heat and cares primarily about BTU output, seasoning quality, and value. They often buy in bulk and early in the season.

The Weekend Warrior: This casual user wants convenience and cleanliness for occasional fires. They're often willing to pay more for small quantities of premium wood that's ready to burn.

The Specialty User: Pizza oven enthusiasts, meat smokers, and restaurant owners seeking specific wood varieties for flavor profiles or consistent performance.

Understanding these different customer types helps you tailor both your products and marketing messages appropriately.

Establishing an online presence doesn't require complex websites or elaborate social media campaigns. Creating a Google Business Profile should be your absolute first step. It's free, takes less than an hour to set up, and dramatically improves your visibility when people search for firewood in your area.

Include accurate business information, hours of operation, and high-quality photos of your firewood products. Most importantly, list your service area clearly so you appear in local searches. Add seasonal updates about inventory availability, and encourage satisfied customers to leave reviews.

While social media gets a lot of attention, a basic website gives you more control and professional credibility. Website builders like Wix or Squarespace offer templates specifically for small service businesses that require minimal technical knowledge. Focus on including clear pricing, delivery policies, photos of your products, service area details, and prominent contact information.

Make sure your business appears in online directories where customers look for local firewood suppliers. FirewoodLink.com is a specialized directory that connects consumers directly with local firewood suppliers in their area. Creating a profile on such directories can drive highly targeted traffic your way since these visitors are actively searching for exactly what you sell.

Community Marketing and Building Your Reputation

Some of the most effective marketing for firewood businesses happens offline, right in your community. Form relationships with businesses that share your customer base but aren't competitors. Chimney sweeps, fireplace stores, wood stove installers, and even hardware stores can become valuable allies. Offer them a referral fee or reciprocal arrangement for sending customers your way.

Local tree services generate mountains of potential firewood. Approaching them about processing their logs can create a win-win situation, giving you raw materials and them a waste disposal solution.

Community events provide excellent marketing opportunities, particularly in rural areas. Consider donating firewood as raffle prizes at fundraisers, setting up booths at fall festivals, or providing wood for community bonfires with your business sign prominently displayed.

Never underestimate the power of a well-placed sign. If your processing yard is on a visible roadway, invest in clear, professional signage. For rural operations, consider placing seasonal "Firewood for Sale" signs at key intersections during peak buying seasons. Magnetic vehicle signs are another low-cost option that turns your daily driving into mobile advertising.

In the firewood business, reputation is everything. Word-of-mouth remains the most powerful marketing tool, particularly in rural and suburban communities. The surest way to build a positive reputation is through consistency. Deliver exactly what you promise in terms of wood species, volume measurements, seasoning level, and delivery timing. Customers remember and talk about reliable service, especially for a product that directly impacts their comfort at home.

Consider creating a simple referral program that rewards existing customers for sending new business your way. A discount on their next order or a free bundle of kindling can motivate satisfied customers to spread the word.

Seasonal Marketing and Low-Cost Digital Strategies

Firewood sales follow predictable seasonal patterns. Aligning your marketing efforts with these natural cycles maximizes impact while minimizing effort. August through October represents prime firewood buying season for planning-ahead customers. Ramp up your marketing efforts during this period with early-bird specials, customer reminders, increased signage, and updates to your online profiles.

Keep some inventory available for emergency needs during winter storms or cold snaps when demand spikes. A small premium can be charged for this "emergency service," and these situations often convert to loyal customers if you can help when others can't.

Use slower seasons for relationship building rather than direct sales. Visit potential commercial accounts like restaurants, reach out to tree services about partnerships, and update your marketing materials.

Beyond your basic online presence, consider digital marketing approaches that require minimal investment. Platforms like Nextdoor and Facebook community groups are perfect for firewood businesses. These hyperlocal forums allow you to reach people specifically in your service area without paying for advertising.

Collect email addresses from your customers (with permission) and send occasional updates about seasonal availability, special offers, weather-related reminders during cold snaps, and helpful tips for wood burning. Email marketing services like Mailchimp offer free plans for small customer lists, making this a no-cost option for staying connected with past buyers.

Product Presentation and Implementation

How you present your product influences perceived value and can justify premium pricing. Certain presentation elements signal quality to customers: neatly stacked wood (rather than dumped in a pile), consistent sizing, clean delivery vehicles, and professional appearance. These details require little additional cost but significantly impact customer perception.

Small extras can make your service memorable: including a small bundle of kindling with large orders, providing a simple instruction sheet for new wood burners, or following up after delivery to ensure satisfaction. These thoughtful additions encourage repeat business and referrals at minimal cost.

The key to successful marketing for busy firewood operations is simplicity and consistency. Create a basic seasonal calendar outlining when to implement specific marketing tactics. Dedicate small, regular time blocks for marketing rather than occasional major efforts. Track what brings in customers by simply asking how they found you. Start with one or two approaches and add more as you determine what works.

Remember that effective marketing doesn't require perfection or complexity. Even implementation of a few basic strategies consistently will yield better results than sporadic, elaborate campaigns.

Conclusion

Running a successful firewood business requires balancing production efficiency with effective customer outreach. By implementing these straightforward, low-cost marketing strategies, you can build a loyal customer base without diverting significant resources from your core operations.

The most successful firewood businesses recognize that quality products combined with consistent, targeted marketing create a sustainable operation that weathers seasonal fluctuations and builds equity in your business name.

With these approaches, you'll not only move more product but also potentially command better prices and build a more stable, profitable firewood business for years to come.

This article was contributed by FirewoodLink, an online directory connecting consumers with local firewood suppliers. Suppliers can create profiles that make them easily discoverable by customers searching for firewood in their specific area.

The Ultimate Guide to Preparing and Storing Firewood for Winter: Expert Tips for Efficiency and Longevity

When the cold months of winter approach, there’s nothing quite like the warmth and comfort of a crackling fire in your wood stove or fireplace. However, the key to enjoying that cozy ambiance all season long lies in proper firewood preparation. As experts in wood processing and outdoor heating, we're here to share some best practices on how to prep and store firewood for the winter, ensuring that your firewood is dry, seasoned, and ready for use when you need it most.

Step 1: Starting with the Right Tools

To efficiently cut, split, and process your firewood, you need the right equipment. For those looking to streamline the process, a high-quality firewood processor is an indispensable tool. One of the best on the market today is the Timberwolf Pro-MP firewood processor. This versatile machine is designed to make the entire process—from cutting to splitting—more efficient.

The Timberwolf Pro-MP stands out for several reasons:

Speed and Efficiency: The Pro-MP is engineered to handle logs wide as 24" in diameter and 32' long with ease, cutting through even the toughest wood. With a powerful saw and a built-in splitter, it can process 2+ full cords of firewood in just one day, saving you hours of labor.

Versatility: It accommodates logs of various lengths and diameters, making it perfect for homeowners, hobbyists, and even small commercial operations. Whether you’re working with hardwoods like oak and hickory or softer woods like pine and poplar, the Pro-MP is up to the task.

Safety: With safety features such as hydraulic controls, the Timberwolf Pro-MP allows for controlled operation, reducing the risk of injury when handling large logs. Safety is always a priority, especially when working with heavy machinery and sharp blades.

Long-Term Durability: Timberwolf is known for its build quality. The Pro-MP is built to last, meaning you can rely on it for years of efficient firewood processing.

With a firewood processor like the Timberwolf Pro-MP, you can begin the firewood preparation process with minimal effort and maximum results.

Step 2: Cutting and Splitting Logs

Once you've got the right equipment, the next step is to cut and split your logs. The key here is to select the right wood species and prepare it properly.

Cut the Logs to the Right Length: Most stoves and fireplaces require firewood in lengths ranging from 16 to 18 inches. The Timberwolf Pro-MP can automatically cut logs to your preferred length, making it easy to prepare firewood that fits your heating appliance perfectly.

Split for Efficient Burning: After cutting, the logs must be split to increase their surface area, which helps them burn more efficiently. Hardwoods, like oak and ash, require more force to split, while softer woods, like pine, split easily. The Pro-MP features a hydraulic splitter that can easily handle different wood types, so you’ll be able to split logs with minimal effort.

Seasoning the Wood: Freshly cut wood, also known as "green wood," contains a lot of moisture, and burning wet wood is inefficient. The goal is to season your firewood, which means drying it out to a moisture content of 20% or less. Seasoning typically takes six months to one year, depending on the species of wood and the climate. Split wood dries much faster than un-split logs, so splitting wood right after cutting will accelerate the seasoning process.

Step 3: Storing Firewood Correctly

Once your firewood is split and seasoned, the next challenge is storing it properly. Firewood needs to be kept dry to ensure it burns efficiently. Storing wood incorrectly—such as stacking it directly on the ground or in a damp area—can lead to mold growth, rot, and difficulty in lighting your fire.

Here are some expert tips on storing your firewood for the winter:

Stacking the Firewood: Use a well-ventilated area to stack your firewood. Create a pile off the ground using wooden pallets or similar materials to allow air to circulate beneath the stack. Stack the wood in a way that promotes airflow—cross-stacking is a good method where you alternate the direction of each layer of logs.

Covering the Firewood: Protect the top of your firewood stack from rain and snow, but avoid covering the entire pile with plastic or tarps. While you want to shield the top from precipitation, covering the sides will trap moisture and inhibit drying. Use a breathable tarp or firewood cover designed for ventilation.

Choosing the Right Location: Store firewood close to your home but away from walls or direct exposure to snow. Keeping your firewood too far away from your house can result in the logs freezing during extreme cold. Ideally, store it in a dry, shaded location with good airflow.

Rotation: If you have several years’ worth of firewood stored, be sure to rotate your stock. Always use the older wood first, ensuring that it is properly seasoned before burning.

Step 4: Regular Maintenance and Inspection

Even with the best firewood processor and proper storage techniques, it’s essential to inspect your firewood regularly. Look for signs of mold, rot, or pests. Wood-eating insects like termites and carpenter ants can damage firewood, so it’s important to check your pile for these issues before bringing the wood inside.

You should also monitor the moisture content of your firewood. A moisture meter is a small and inexpensive tool that can help you check if the firewood is sufficiently dry. Wood that is too wet will not burn well, produce more smoke, and can create dangerous creosote buildup in chimneys.

Conclusion

Properly preparing and storing firewood is an essential task for anyone who relies on wood for heating during the winter months. Using the right equipment, such as the Timberwolf Pro-MP firewood processor, can make the process faster, safer, and more efficient. By following these expert tips—choosing quality wood, cutting and splitting it to the right size, seasoning it properly, and storing it correctly—you can ensure that your firewood is ready to burn efficiently when the cold sets in.

Not only will this make your home feel cozy and warm all winter long, but it will also save you time and effort in the long run, so you can spend less time chopping wood and more time enjoying the fire.

Stay warm, and happy wood processing!

Improve Mill Safety And Quality

Video monitoring is a valuable tool for sawmill safety. It can help identify hazards before they become serious problems, and it can also be used to investigate accidents after they occur.

By now, most sawmills have some form of video monitoring in place to watch for potential problems. It may be through a live feed that someone is watching in real-time, via recorded footage that is reviewed later, or a combination of live and recorded video.

For all these reasons, sawmills should make sure that their video monitoring systems are up to date, working properly, and can withstand the harsh sawmill environment.

Install Video Equipment Built for Sawmills

Sawmills are unique environments, with a lot of noise, vibration, and debris. Off-the-shelf cameras from big box stores, or even those made for other industrial applications, don’t cut it in the sawmill. When sawmill video monitoring systems use standard equipment, it isn’t reliable and has to be replaced frequently.

At Opticom, we have video monitoring equipment designed specifically for the sawmill environment. They have been tested and are proven to perform and outlast other systems.

Opticom cameras optimized for sawmills includes:

- CC02 Industrial Analog Camera

- CC02-TVI Industrial HDTVI Camera

- CC03 Explosion Proof Camera

- CC04-IP2MV Industrial IP Network Camera

In addition to an industrial, vibration-resistant camera, sawmills should use mounts that are designs for high-vibration environments. The Opticom VM-1 Vibration/Shock Mount further protects the rugged CC02 camera from vibration. Most of our customers have to replace the vibration mount long before they have to replace the cameras—and often years after initial install.

Improve Safety With Remote Video Monitoring

We all know how dangerous the sawmill floor is. Remote video monitoring lets operators keep an eye on the line without being in dangerous proximity to logs and debris. By installing rugged video cameras and routing footage to a central monitoring area, operators can observe from a safe distance. They’re close enough to troubleshoot issues but far enough away to keep safety a top priority.

Just like the cameras, the monitors in a sawmill’s video system need to be able to withstand the hard environment. We offer sawmill CCTV monitors in a variety of sizes, definitions, and connectivity options. We also offer the MVM-LCD-1 Vibration Mount that helps extend the life of video monitors inside sawmills.

With safety being a high priority, a video system with remote monitoring capabilities is a surefire way to keep operators far from danger.

Store Video Footage to Troubleshoot Issues

In addition to remote monitoring, sawmills can record and store video footage. By watching footage of the sawmill process, operators can identify potential problems and make corrections before they cause damage or downtime. In addition, video footage can be used to track production rates and identify areas where improvements can be made. By constantly monitoring the sawmill process, operators can ensure that the mill is running smoothly and efficiently.

We offer sawmill video recorders from 4 to 64 channels and with recording via DVR, NVR, and/or POE.

At Opticom, we’re more than an equipment vendor—we’re a partner. We’ll help you evaluate your options for sawmill video monitoring, networking, and storage to set you up with a complete system that meets your needs. For a no-obligation review of your sawmill video needs, contact us.

There’s a better way to monitor sawmill operations with the right video systems.

TRACK RECORD ON SAW DEVIATION

Interest in tracking saw deviation has continued to grow in

the forest products industry as limited resources,

expensive stumpage, and keen competition have driven

mills to look for ways to increase yield and bring more

dollars to the bottom line.

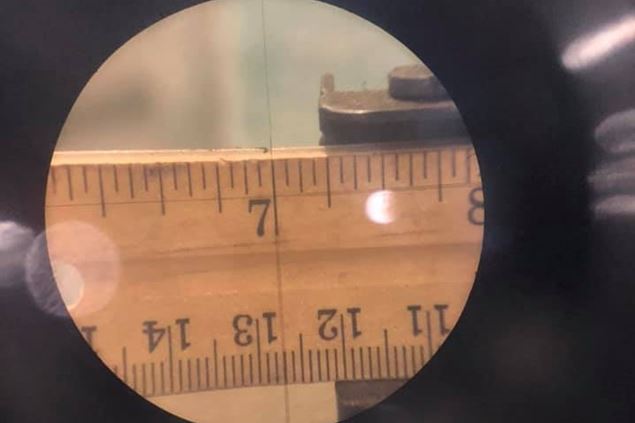

Tracking devices or detectors can sense when a saw is deviating

from the set tolerances and warn the operator, who in tum can slow the

feed speed to avoid miscutting lumber. It’s a simple concept, but the

benefits of such monitors can be quite substantial.

There are plenty of problems that can cause a saw to deviate and a

number of variables have to be evaluated before pinpointing the cause

of mis-cut lumber once the monitor indicates a problem. There could be

a problem in the initial setup of the mill or the sharpness of the saw

itself, but generally; it’s caused by wood characteristics and varying

densities of the wood being cut.

Saw deviation detectors provide real-time feedback of the exact

position of the blade relative to the expected position. Any deflection

of the blade, whether caused by too high a feed speed, knots, frozen

lumber, dull or damaged blade, trash between the blade and guide

block, or simple guide wear will instantly be detected by the monitor

allowing the operator to correct the situation before lumber is mis-cut or

the saw is damaged. Equally important, by monitoring the blade

position and ruling out blade deviation as the source of mis-cut lumber,

it becomes much easier to effectively zero in on other issues, such as

track misalignment or head blocks out of adjustment, that might be

causing production problems.

All deviation detectors include a sensor that is placed next to the

bandsaw guide. These sensors actually “feel” where the saw is running

in the cut.

The advantage of real-time information is largely what makes the

increased production possible. With a real-time look at what the blade

is doing, operators can actually see night away if they’ ve cut irregular

lumber, versus finding out when they measure the lumber later on.

DETECTOR DETAILS

Our monitor, which can measure deviations of only a few

thousandths of an inch, uses a proximity sensor, a controller display

unit, and a data cable that connects the two together, to indicate

deviation and sometimes vibration when it actually occurs in the saw.

The “real-time” aspect of the process discourages unplanned downtime.

You don’t have to wait until you get downstream and measure the

lumber to see you have a problem. We can see it while it’s happening-

that’s the real-time aspect of the process.

CONSIDERING A MONITOR?

The monitors can serve in a teaching capacity for first-time

operators. If you've got a new guy in the sawyers cab, it helps him

know how much wood he can push through, and it helps him learn

tolerances. It’s kind of like a speedometer in that the deviator becomes

a good way to gauge how fast you can go and stay within tolerances.

The Sawblade Deviation Detector provides real time feedback from

the proximity sensors, with a visual display that indicates varying

degrees of deflection. The display box is set in the operator’s line of

sight, and contains a series of light bulbs. Green lights indicate a safe

rang, yellow lights warn of deviation out of good operating range, and

red lights indicate deviation beyond acceptable tolerances.

Many industry experts say monitors are tools that give operators and

filer’s insight on saw behavior as well as assuring the correct operation

of the equipment. Every operation, even the most sophisticated sawmill

equipment with the very best in people, as the day goes on, will produce

less than the best lumber.

The payback period is relatively quick. The SD40 model] often has

a payback in little more than 60 days.

A system of lights on the SD-40 display box indicates the saw’s

behavior, a safe operating range is reflected by three green lights in the

center of the display, a slight deviation is reflected by two yellow lights.

which may also indicate the blade is getting dull; red lights and the

sound of an alarm to warn the operator of an unsafe deviation. It lets

you know exactly how fast you can travel through the cut without

“getting stopped” for speeding. On the other hand if you’ve been

traveling “45 and the conditions are such that you could have been

traveling “55”, the deviator lets you know that you are well within

limits, go ahead —go faster!

With only 2+ hours installation time, the Sawblade Deviation

Detector can be purchased for approximately $2,750. The Model SD-

40 comes complete with controller/display module, sensor unit, and

cabling and operates from a standard 110V outlet. It offers an

adjustable setting for sensitivity and allows remote centering of signal

for display.

We are selling one of the lower-priced units on the market. It is our

belief that the maximum benefit is obtained from Deviation Detection

units when they are rugged, simple to install, intuitive to operate, and

inexpensive enough to use on every saw in the mill.

The Deviation Detector can help sort out problems with guide wear

or set works performance. It can help determine proper feed speeds and

aid in calculating the optimum time between blade sharpening. Most

importantly, the Deviation Detector allows the sawyer to push his

equipment to the limit in pursuit of maximum production with full

confidence that he’s not exceeding the capability of the blade.

574-370-5050

AUTOMATION & PROCESS CONTROL

P.O. BOX 3 SHIPSHEWANA, IN 46565

Hoosier Hardwood Expo

Aug 27th - 29th · Indianapolis, IN

Website: www.hoosierhardwoodfestival.com

Great Lakes Logging & Heavy Equipment EXPO

Sep 9th - 11th · Escanaba, MI

Website: https://www.gltpa.org/gltpa/Expo.asp

Kentucky Wood EXPO

Sep 17th - 18th · Lexington, KY

Website: https://www.kfia.org/Page.ign?title=55-kentucky-wood-expo-kfia-wood-expo

Mid-South Forestry Equipment Show

Sep 17th - 18th · Starkville, MS

Website: www.midsouthforestry.org

Northeastern Forest Products Equipment Expo

Sep 24th - 25th · Bangor, ME

Website: https://northernlogger.com/2021-northeastern-forest-products-equipment-expo-or-loggers-expo/

Paul Bunyan Show

Oct 1st - 3rd · Cambridge, OH

Website: https://www.ohioforest.org/page/PBSShowFacts

If you’ve been patiently waiting for the labor market to improve, it’s time to quit procrastinating and take action. Experts predict that finding new workers will only get harder for U.S. manufacturers over the coming years, and so it is high time to consider how investing in equipment can help lessen your dependency on employees in your production process.

According to a new report from Deloitte and the Manufacturing Institute, manufacturing job openings have been growing at double-digit rates since mid-2017, and are nearing the historical peak recorded in 2001. As many as 2.1 million manufacturing jobs will be unfilled through 2030, according to a study. The report warns the worker shortage will hurt revenue, production and could ultimately cost the US economy up to $1 trillion by 2030. Seventy-seven percent of surveyed manufacturers anticipate there will be ongoing difficulties in attracting and retaining workers in 2021 and beyond. US manufacturing executives surveyed believe that finding the right talent is now 36% harder than it was in 2018.

Pallet companies are also feeling the pinch of not having enough people. While there are various approaches available to attract and retain labor, one important area of consideration is to strategically expand investment in plant equipment. Equipment can replace the need for labor for some activities, and for others, it can make workers more productive. Whether you measure your output by pallets per labor hour or board feet per labor hour, having the right equipment can help increase productivity so that you can expand your business without adding a commensurate proportion of employees.

Here are some examples of how pallet companies can ease their dependency on employees through the strategic deployment of equipment.

Move from a cell-based manufacturing process to an in-line process

Many smaller pallet shops still rely on a variety of workstations. In new manufacturing operations, for example, stringers might be stacked, then forklifted to the notching machine, and then restacked again before being moved yet again - this time to the pallet nailing department. To stick with this analogy, by moving the notcher in line with the stringer production line, stacking and forklift requirements are reduced, resulting in labor savings.

Eliminate bottlenecks in your production process

Is there a piece of equipment in your process that is causing you to under-utilize your other machinery? For example, is your splitting capacity a constraint? By adding a high-speed thin kerf unit such as the HY400, companies can enjoy a significant boost to their lumber production operation, thus significantly increasing the number of board feet per employee. Keep in mind, however, that increasing capacity on the front end of the cut-up line means that you may find yourself with a new bottleneck on the back end, such as stacking. An investment in automated stackers can help fully optimize your line. Or if you have an automated stacker already, you might require a shift to higher capacity stackers, for example from 8 rows per minute to 25 per minute. Keep in mind that wood is half or greater of pallet cost, and your processing efficiency can be a source of competitive advantage.

What about banding wood and pallets?

People tend to accept the manual banding of lumber or finished stacks of pallets as a necessary evil. It is often performed by forklift drivers, but while they are banding, they aren’t driving. That means you are under-utilizing your forklift as well as your driver. By installing an inline automated banding machine that tedious task can be eliminated, allowing your forklift operator to be more productive.

What about other opportunities

Look around your plant for opportunities to eliminate employee touches, steps, and physical exertion. There are many mature machinery options that have not been fully leveraged by pallet shops such as automated stackers, tippers, flippers, and conveyors. Do you lose production waiting for material to arrive, or for the finished product to be removed? Infeed and outfeed conveyors can ensure that production is maintained and that the number of pallets per employee is maximized.

Consider the other employee benefits of machinery investment

Investing in machinery doesn’t just directly boost your production per employee. It can offer other benefits as well. A well-designed equipment layout can help improve consistent quality, eliminate defects, rework and waste. It can also provide a safer workplace, meaning fewer injuries to further strain employee availability. And ultimately, automation results in a more pleasant and rewarding work experience, ultimately helping to improve worker retention.

Looking ahead

Even in machinery-intensive pallet operations, there continue to be further opportunities for equipment to boost productivity. For example, design for automatic feed is an opportunity to eliminate the manual labor associated with placing boards in automated assembly lines. Likewise, scanning technologies continue to be developed that will help automate grading, improving accuracy, and reducing the need for human decision making.

In automated shops, we can look forward to getting better productivity per employee, better quality, and better working conditions. Of course, there is more to retaining a superior workforce than just equipment alone. Employee benefits, engagement strategies, second chance hire programs for ex-convicts, high school affiliation programs, and more can all play important roles in ensuring that you have the people you need to do the work. Investment in equipment, however, can make sure the people you have are as productive as possible, by eliminating the heavy lifting. Why not contact PMG to see how you can do more with less?

Are you starting a firewood operation or considering the upgrade from a splitter towards a full-featured firewood processor or maybe you're just looking for useful tips for your current firewood operation? Then this guide is for you!

Download our free "How to build a successful firewood business?" guidebook here: Hakki Pilke — How to build a successful firewood business?

Here at Hakki Pilke we have over four decades of experience with firewood processing and the workings of the industry. Whether you’re just getting started or aiming to develop your firewood operation further, we hope this guide gives you valuable insight on the things you need to take into account when planning your operation.

We’ve divided this guide into four sections:

1. Getting started

2. Before processing

3. During processing

4. After processing

In the first section we look at all the features and variables that you need to consider when you are getting started and choosing the right processor for your needs. We also cover the reasons for making the jump from a splitter to a processor.

The second section covers things you need to know before you start processing firewood. We shed light on how to sort and feed the logs into your processor. We also discuss the importance of choosing the right log deck for your operation.

We then in third section discuss firewood processor features that come in handy during processing. In this chapter we touch upon user ergonomics and safety, chainsaw maintenance and distribution of work.

Lastly, in the fourth section we take a look at what you need to do to your firewood after processing – storing, drying and packaging. Also included are ideas on how to sell and market your firewood product.

This year, EXPO Richmond returned after last year’s break due to the pandemic. The event was held in it’s regular location, the Richmond Raceway Complex on May 21st - May 22nd, providing ample space for attendees, exhibitors, contests, and workshops. EXPO Richmond 2021 was sponsored by the Virginia Forest Products Association & The Cooperative Extension Service at Virginia Tech. The COVID-19 precautions were expertly organized and helped drive attendance from enthusiastic attendees. Over 200 exhibitor companies gathered with attendees; the complex offers over one-half million square feet of exhibit space, so it was easy to observe distancing guidelines.

This year’s theme was no different from previous events - a spectacular showcase of forest products, equipment, & services for sawmills, kiln drying, harvesting, biomass, trucking, pallet/manufacturing/recycling, optimization/scanning, material handling, firewood production & related equipment, commercial equipment finance, and other forest industry supplies and services.

Since EXPO Richmond is one of the first events of the year that our team attended since the shut-downs of last year, we reached out to a few of the exhibitors to get their perspective on the event.

Q: How is the event going, and what’s your overall impression of the forestry and logging equipment market?

A: “We’ve been coming to Expo Richmond since we’ve been in business, but this is the first industry trade show that we’ve attended since October 2019—and it’s a great show for the first one back,” said Noah Carr, President of Lumbermen Online. ““Last spring was extremely uncertain… and unfortunately, advertising is usually the first expense to get cut. When the manufacturing plants shut down, they pulled back on their advertising. Since then, things have improved significantly and are on a positive, upward trajectory. People are looking to buy more equipment than usual right now. Used equipment is in high demand because of long manufacturing lead times, which has resulted in more business for us.”

Q: How was the turnout this year? Are you glad you made the effort to be an exhibitor?

A: “It’s been a great show for us… people were actually waiting at our booth for us this morning! It’s a much more successful show than we thought. We weren’t sure what to expect with the gas shortages and prices in Virginia. A lot of companies didn’t show up for the event but we’re sure glad we did,” shared Kevin Weisner, Go Fast Manufacturing. “We sell very little at the tradeshows, but it’s really about the connections you make. Today’s been a bit different than previous events; however, the industry is hot, and we’re expecting a lot of orders to come in after the show.”

If you didn’t attend this year’s event, we hope you’re encouraged by those remarks to add next year’s event to your calendar!

Here’s are the highlights from the 2021 event:

Notable Demonstrations

Rotochopper

MC-226 Horizontal Grinder, a highly portable yet full-featured grinding solution that brings “perfect in one pass” convenience for diverse feedstocks.

Baker Products

Blue Streak™ Portable Band Sawmill 3638G, heavy-duty, portable sawmill designed to give high production with little effort. Powered with a 38-HP gasoline engine and hydraulic log controls for loading, turning, clamping, fence arms, and leveling.

Ransome Attachments

Black Splitter, a hydraulic wood splitter attachment series that has earned acclaim for its superior quality in all types of log splitting, firewood & wood fuel production, biomass harvesting, forestry, land clearing, and landscaping.

Rayco Industries

Pallet PRO, a two operator pallet system with collated nail and pneumatic non-stop nailing. The two operator pallet system is capable of producing between 800-1200 pallets/shift.

Smith Sawmill Service

TurboSawmill Automated Warrior swing-blade with proven swing-blade technology with electric start, power feed, allows for any diameter log.

On to EXPO Richmond 2022!

Next year’s conference dates haven’t been announced yet, but the website https://www.exporichmond.com/ is a dedicated conference website. Check back soon for 2022 dates and registration information.

Moving with the markets is something we’ve always tried to do. So when local markets in Mississippi tightened up back around 2000, we got in the mulch business, then added a hardwood circle mill in Oakland and a scragg mill Winona. After eight years running three operations, in three locations we decided that the time had come to merge into one location, update and modernize our milling operations.

Once we made the decision to build a state of the art hardwood sawmill to replace the multiple smaller mills we were running, the search began. And it was a long one. I traveled for a year and a half across the eastern United States and Canada visiting sawmills. The goal from the beginning was to build a mill that would efficiently produce a wide variety of materials so Fly Timber could move with the markets. The mix included cross ties, long timbers, crane mat material as well as hardwood grade lumber. This flexibility would insure that we could always produce what the hardwood lumber market sought and operate with an eye toward maximum return per log. Getting’ the squeal out of the pig as the old-timers called it.

We found out early in the planning phase that to meet this goal, we would have to deal with multiple machinery manufacturers and find a way to smoothly connect everything from the debarker to the main production machines like the Cleereman carriages, McDonough band headrigs and optimized edger, gang and trimmer. All the way out the back of the mill, not to mention the challenge of processing and flowing cross ties to rail cars.

Why Mellott?

During my many mill visits, whenever the discussion turned toward log or lumber conveyors, Rosserhead debarkers, log turners, lumber stackers and material handling equipment, Mellott was the name that kept coming up. From a very rugged built Rosserhead debarker, stand-alone decks and complete systems – nearly everywhere I went there was Mellott. That convinced me, I needed to see for myself, so I visited their plant in Pennsylvania and that sold me. Dale and Stacy Mellott and the entire staff at Mellott Manufacturing are fine people to do business with. They did an excellent job of working on this very complex job, dealing with multiple suppliers, engineers and deadlines. Each time we asked for something to be beefed up to meet our spec’s or to make something longer to expand our product line, the staff at Mellott stepped up to the challenge. That’s why the first thing a log sees when it arrives is a customized Mellott LMR 48” Heavy Duty Debarker, Mellott Log Haul trough, Mellott log decks, slab conveyors and the last thing is the custom built tie lifting system and lumber decks and rollcases.

Fact is looking back on the project, I can’t see how we could have done it as well without Mellott. They truly became a partner in our new mill and in the future of Fly Timber.

Ricky Fly

Fly Timber

Grenada, MS

When it comes to airborne mold spores, what we can’t see definitely can hurt us. Unfortunately, when the weather gets warm in spring and conditions are right, those spores can quickly colonize surfaces. In days, mold can spread from idle lumber or a pallet to contaminate materials and equipment. As a result, employee health and safety, as well as sensitive products, can be compromised.

What is lumber mold and why does it matter?

A mold is a fungus that grows in the form of multicellular filaments called hyphae. There are more than 100,000 mold species, which play an important role in helping to decompose wood and other plant matter. They become problematic, however, when they take root on lumber, pallets, and other unintended surfaces.

To successfully colonize a surface, mold requires a combination of oxygen, adequate temperature, a food source (your wood pallets), and free or liquid water. The most common approach to controlling mold is to limit wood moisture. Experts recommend that the moisture content of wood be kept below 19% for best results.

One common misconception is that the ISPM 15 heat treatment of lumber will prevent mold. The application of heat treatment is (a minimum of 30 minutes at a core temperature of 56 degrees Celsius) is designed to kill insects living in the treated wood. The intention is to prevent the inadvertent transport of wood pests internationally, where they could attack forests in other countries. In fact, heat treatment can make matters worse by drawing moisture and sugars to the wood surface. Once removed from the heat chamber, a convenient surface environment has been created for mold spores to colonize.

Product manufacturers, distributors, and retailers in hygiene-sensitive supply chains are becoming increasingly sensitive to the problem of mold. The presence of mold not only presents a food safety and quality risk but is also a concern from an occupational health and safety standpoint. Pharmaceutical and food supply chains are particularly vigilant in preventing exposure, and the presence of mold has resulted in health and safety complaints by employees in a variety of settings.

Basic steps to limit lumber mold

Basic steps for limiting lumber mold start with keeping them dry. Here are some best recommended best practices:

Make sure that mold is actually the issue. The discoloration you see in your wood pallets might not be mold. Bluestain creates a bluish or greyish discoloration in wood but is not associated with human health concerns or pallet performance issues. According to an NWPCA brochure, “Mold grows on the surface and can be brushed off or smeared, whereas blue stain penetrates deep into the wood and cannot be removed.”

- Keep lumber out of the rain. Even a short exposure to water can be problematic. Such a brief occurrence can be enough for a fungus to start germinating, grow into the wood and produce spores on the surface. By then the wood might be dry, but mold will already be present.

- Elevate stacked pallets and lumber off the ground. By using an elevated surface, you can prevent water from wicking up from any puddles on the floor surface or ground.

- Don’t store lumber in a trailer. Dark, warm, and humid trailers can quickly turn into an incubator for mold growth. Coordinate deliveries with trading partners so that lumber can be quickly unloaded and placed into dry storage.

- Keep lumber in a well-lit, dry, and ventilated environment. Covered storage is critical for keeping lumber dry. For outdoor storage sheds, pallet ends of stringer pallets should be aligned in the direction of the prevailing winds to help improve airflow. For indoor storage, choose a well-lit, ventilated part of the warehouse.

- Ensure row spacing to further promote ventilation. Stacked stringer pallets can act as a barrier to air movement on the stringer side. Circulation can be improved by leaving a gap between pallet rows. Orient the ends of stringer pallets in the direction of air movement.

- Consider KD softwood lumber and pallets. More industries are switching to kiln-dried softwood pallets. While some applications still require the use of hardwood, KD softwood pallets can be designed to deliver comparable service, without the mold challenges associated with pallet heat treatment.

What about traditional chemical treatment options?

In spite of heroic efforts to keep pallets dry in warm weather, pallets far too frequently have exposure to the necessary combination of heat and moisture, and mold results. Even if you keep your pallets under 19% moisture content, small localized wet spots can provide the needed ingredients for mold to colonize.

To improve protection against mold, lumber and pallet providers have relied on hazardous and caustic chemical solutions. These treatment products pose additional challenges for pallet manufacturers and users alike. Boards are either dipped into vats of toxic solution or it can be sprayed onto the boards. Both of these approaches pose a health and safety risk to employees as well as the threat of corrosion damage to plant equipment - even after the mold inhibitor has been applied. Such products are categorized as being toxic to the environment, particularly to marine life. As such, careful attention to handling and disposal is needed to avoid environmental damage.

A new approach to chemical mold prevention

WoodLock Bio-Shield was originally developed as a treatment for construction lumber to inhibit mold growth in homes. Its inventor, Jim Stanley, saw the need for a non-toxic mold inhibitor for lumber and pallets and reformulated the product for that use.

Similar to other mold prevention products, WoodLock is applied by spraying or dipping onto green cut boards, hardwoods, softwoods, pallets, crates, and boxes. It is uniquely effective in preventing mold by utilizing a unique polymer emulsion that forms an ionic bond with the formula’s anti-microbial agent and a mechanical bond with the wood, effectively “locking” out mold spores by stopping gestation. The active ingredients of WoodLock Bio-Shield are bio-available at just 10% humidity with higher availability at higher humidity levels, so the better the conditions are for mold growth, the harder WoodLock works. These ingredients are held on the surface of the wood by the polymer, which softens, allowing the anti-microbial agent to become more bio-available.

This unique formula has a zone of inhibition up to 2-3 mm away, ensuring that nearby areas are protected even if a board is not 100% covered. The polymer seals as it dries so it can work repeatedly, and because WoodLock is not water-soluble, it continues to protect wood from mold growth even after thousands of wet-dry cycles. WoodLock’s performance was validated by Virginia Tech using ASTM D4445 Laboratory Method for Evaluating the Mold Resistance of Wood-based Materials.

In addition to its unique effectiveness, WoodLock is formulated with active ingredients which are on the EPA Safer Alternative List and are listed as FDA GRAS (Generally Regarded as Safe). The formula contains no hazardous materials or carcinogens and is non-flammable and non-corrosive. As a result, WoodLock requires no additional safety precautions and can be used indoors and/or around sparking machinery. The product’s pH of 7.3 (once diluted) is the same as the human body, so it will not damage containers, forklifts, or other equipment. Empty WoodLock containers can be recycled in standard municipal recycling streams, no special disposal protocols required.

.gif)