Ohio-Valley-Veneer-Grows-From-Passion-and-Wise-Equipment-Choices

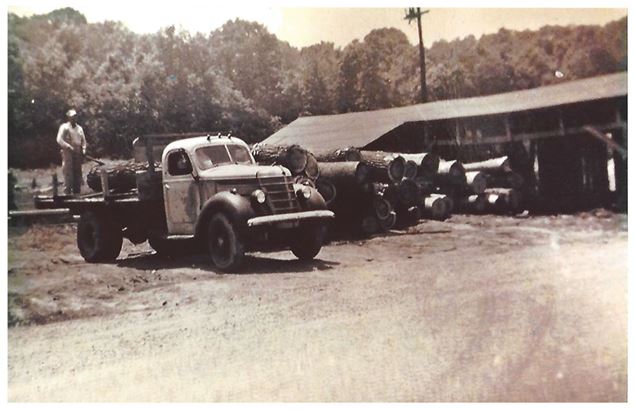

As it is with most successful lumbermen, Ohio Valley Veneer had humble beginnings. Starting out in 1986 with a two man logging crew and the passion to excel, Ed Robbins was on a mission. That mission, mostly unknown to him at the time, was going to revolutionize the forest products industry in Southern Ohio and beyond. Being a fourth generation lumberman provided Ohio Valley Veneer with a deep appreciation for the people and understanding of the tradition and the lifestyle, but most of all it prepared Ed by instilling what was most important: hard work, honest dealing, quality products and the vision to excel.

Founding Ohio Valley Veneer in 1990 to buy, sell and export logs, Ed soon found himself hiring mills to custom saw where it fit market conditions. In 1992 he was able to purchase the land where his father and grandfather had operated sawmills since 1958 and in ‘94 built his first mill on that hallowed ground. The heart of that mill was an eighteen year old Cleereman Model 36 purchased at auction and they ran it every day until 1998 when it was replaced with a Cleereman 36 Proportional carriage. Now Ohio Valley Veneer mills produce more than a million board feet of lumber monthly as well as exporting lumber and some of the world’s finest hardwood veneer logs from the hills and hollers of rural southern Ohio. Those mills now include five linear positioning carriages, four LP42’s, one LP48, and a HS36 Proportional.

Ed’s original mission to bring passion and professionalism to the lumber business now directly employs over four hundred and shows no sign of slowing down. He credits a portion of his success to making sound decisions when it came to major equipment purchases, and he’s proud to say that Cleereman carriages have been instrumental in that growth because, as he puts it, “they just run”. Now purchasing an average of one million dollars in new machinery annually, Ed shared why he continues to run only Cleereman carriages. “A company’s salesman can sell you the first of anything, be it a sawmill, loader or whatever, but that company’s service and parts departments will sell the second one”. Over the course of his career Ed has purchased sawmills from numerous manufacturers and one thing is constant, if that mills stays in production for Ohio Valley Veneer, it gets upgraded to a new Cleereman. It’s that simple.

According to Ed, choosing Cleereman has been one of the greatest moves of his career and credits Cleereman’s low cost of ownership as instrumental in his ability to continue to grow Ohio Valley Veneer. As he often says, “they just run, they seldom break down and when they do the parts are reasonable AND AVAILABLE WITHIN 24 HOURS”. In addition to a superior sawmill carriage, low cost parts and fast breakdown service, the one thing that most impressed Ed was how Cleereman does business when a Cleereman mill experiences a fire and Fran Cleereman and the entire team do whatever is necessary to get that mill owner back in production. In many cases saving the company and hundreds of jobs with it. That kind of dedication to insure family businesses thrive is one of the many things that separate our industry from so many others. In any other industry, whoever put their deposit down first would be ahead of the burnt mill, but doing what is right – not what is expedient is what separates companies like Ohio Valley Veneer and Cleereman from hundreds who produce similar products.

Growth at Ohio Valley Veneer shows no sign of slowing down as the proven formula of efficiency, superior quality and passion to produce the very best lumber and timber products continues. Aggressive, but patient, acquisition is part of Ohio Valley Veneer’s growth plan and Ed is targeting areas known for quality logs such as East Tennessee, Southern West Virginia and Indiana. Following the efficiency path, Ohio Valley Veneer is scheduled to take delivery of their first Cleereman Lumber Pro. Chosen specifically because of its proven low cost of ownership due to reduced electrical consumption, thin kerf, low maintenance requirements, double cut capacity, modular design and its ability to serve as both headsaw and resaw. The Lumber Pro, with its single operator, is expected to replace three or four thin kerf narrow band sawmills greatly reducing overhead and allowing those employees to move into more productive positions.

715-674-2700

Cleereman Industries offers a wide range of sawmill equipment from Carriages to Track Frames to Trim & Grading Lines and everything in between. We are proud to be a leader in innovative and cutting edge sawmill equipment.

.gif)