Articles, Contributed Resources & LUMBERMENOnline's Blog

Submit Your Article & Valued ContentLooking to upgrade your equipment, but need to sell your skidder, sawmill, or pallet nailer first? Or maybe you acquired a few items for a specific job that need to be liquidated, but you aren’t sure what to do? Truth is, there are many different ways, from listing it on LumbermenOnline.com to sitting it out by the road. Each way can fit different types of people and have their own place in the market, but carry pros and cons as well. Assuming you're not one of those lucky guys that are always approached by a deep pocketed offer to help you part ways, here are the main four options in no particular order:

Auctions

Pros - Assuming the process goes well it's a "quick sale." You have a defined date of item being liquidated, therefore, removes uncertainty. Auction companies have an interest in your items selling for high value and foot the bill for most of the promotion around the sale.

Cons - Uncontrolled variables including attendance on auction date due to outside factors, previous items sold, and inability to display equipment’s ability (if applicable). Additionally, other risks are items not exceeding reserve and having to pay a stocking fee, auctioneer’s fees can become very lofty with expensive equipment, transportation of equipment to and from auction, just to name a few.

Who does this option work for? Sellers who have numerous items to liquidate, end of business liquidation, or those who want an exact date of sale to plan accordingly.

Brokers

Pros - There is little time invested by the equipment owner. Generally speaking, there are no fees if your equipment doesn't sell. Utilizing a wide range of contacts from the brokering company. Good brokers are experts at selling equipment, they’ve sold 100s of items, and your item will be nothing they can’t handle.

Cons - The most common percent of fees for brokered items is 10% (moving the decimal one place on $100,000 = $10,000). Many brokers have numerous clients and many obligations, you could potentially be one of 100 -200 customers they’re servicing at a particular time. You will not directly know the interest of your equipment to the market and could make for a long selling process. Bad brokers. There are many reputable brokering companies that are worth 10% or more of any item, but there are just enough brokers that talk the buyer up and the seller down to give everyone a bad taste. Not sure where to start looking for a dependable contact to represent your equipment, check out our Online Edition for a solid line up.

Who does this option work for? Equipment owners who would like an expert to act on their behalf, while saving time that takes away from what their everyday responsibilities.

Marketplaces, i.e., LumbermenOnline.com

Pros - Direct control of entire selling process, from price, terms, and transportation. No pressure or obligation to continue to sell your equipment, if the decision is reverted, for example, a new job gets pushed through and that equipment is now needed. Selling your equipment directly carries the minimum number of people involved, by default will simplify the process. Sellers will avoid the previously mentioned high fees versus brokers or auction companies. Solid marketplaces and buy/sell/trade outlets will advise you on tips to help make the process go as smoothly as possible. Advertising in outlets, like LumbermenOnline.com, get your items in front of all potential buyers, including dealers, other brokers, and end-users.

Cons – Selling your own equipment can potentially be time-consuming by taking calls, following up, showing equipment, etc. Finding a reasonable asking price can be cumbersome in some circumstances, not all machines are equal - however, your account representative can help advise you on a target price. Just like brokers, selecting valuable outlets to use can be risky – focus on similar equipment listed (if there’s just one or two like items, you’re in the wrong spot), gauge their online services, 84% of adults use the internet, and reach out to past advertisers for reference, even if their item didn’t sell, they can give insight on the process. Prepaying for services, that is any less than 100% success rate always, carries a risk of being out the advertising cost. Logistics of a potential buyer can be a headache.

Who does this option work for? People who want to sell their own equipment efficiently, control the process, retain the selling amount in full and get their equipment in front of as many prospective buyers as possible. Get started now!

FREE! - Local/Roadside/Craigslist/Facebook

Pros – By far the cheapest option to utilize. 90% of potential buyers will be local, therefore, transportation of equipment won’t be a hurdle. You’re still selling the equipment yourself, so you will have complete control of selling process. No pressure from others in the selling process make for a stress-free experience.

Cons – If this option worked more often than not, this article would be two sentences long and the above options wouldn’t exist. Furthermore, low number of eyes on your equipment reduces response greatly. Let me explain, parking a Ford F-150 on a busy highway is a good idea. Everyone that drives by is a potential customer because they’re a driver. However, not every driver has a need for a used feller buncher or other heavy equipment. This route is a time killer, if your equipment is parked on the road for 2 months with no interest, that’s two months of no use and time that could’ve been advertised on a larger scale.

Who does this option work for? Sellers who aren’t in a hurry for any reason, don’t need to use the equipment during the selling process, and have a solid local market for their equipment for sale.

Overview

All options have ups and downs, that’s why they all exist. Your goals of selling your equipment will help determine which option fits you. Overall, selling your equipment isn’t hard, like many things, you just have to start. Many potential sellers put off liquidating tens of thousands of dollars in equipment because it seems overwhelming or time-consuming. However, that equipment is at its peak value today (assuming no upgrades or repairs are needed) and there’s a cost even for items that are paid for and not used. If I were selling my equipment, I’d use a couple options that are able to ensure I got my item in front of as many potential buyers as possible. The real winner here, is the buyer of your equipment – you just have to find him!

By: LumbermenOnline.com

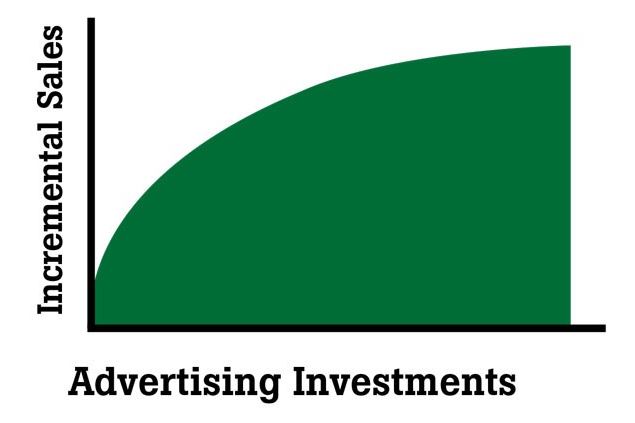

I’ve heard it thousands and thousands of times and its well documented and reported that ‘print’ is DEAD! From local newspapers, to national magazines, industry related rags and many others have collapsed or barely holding on – I get it! It’s a popular thing to say, “Print is Dead,” it can make you feel innovative, forward thinking and even trendy. BUT, take one step back to the headline, replace “Print” with any advertising outlet you’re a customer of and the statement may still be true… if you don’t evaluate your chosen advertising channels.

As an advertiser and a customer, you’re paying for the audience that the magazine, newspaper, website, app, radio, television, billboard, racecar, trade show, or any other advertising investment reaches. That’s it, the audience. Are they reaching your perspective customers? How do you know? In some cases, you won’t know until you try it.

It’s simple! No really, it is. To at least check the basics of any advertising option, but in this case, let’s stick with print. There’s 3 key requests you should ask for, before advertising with any print media or if you haven’t in a while (or ever), your current print advertising outlets:

Can you send me your most recent audit statement or postal receipt?

How do you grow your audience?

How do you scrub your audience?

If these don’t get answered truthfully with proof, don’t donate your money – even if it is ‘cheap.’

Online advertising is popular for many reasons, but the one that is most overlooked is that every specific paid for ad directly tells you how many eyes were reached. Great! Now, apply that to all other advertising focuses, including print.

In short, don’t group all ‘print’ all in one – there’s plenty of print media that wasn’t worth advertising with in the 80’s and 90’s, and that’s still true today. Vet your advertising, ALL ADVERTISING.

By: LumbermenOnline.com

The family-owned and operated L. Garbers & Sons Sawmill in Northwest Ohio was established in 1997 by Luther and Kathryn Garbers and their two sons David and Marty. What started out as a side business with a portable sawmill has grown into a full-time operation with a high-production industrial sawmilling system producing pallet material, cut stock, blocking, and grade lumber in Wauseon, Ohio.

L. Garbers & Sons Sawmill

During the formative years of the business, Luther, David and Marty both farmed and worked separate full-time jobs so they were only able to help their father at the mill on weekends and holidays, but their interest in sawing started at a young age. “We both love sawing lumber and it’s a joy to run the mill,” said David. “It all started when we were kids running our grandfather’s mill. We’ve grown up with it in our blood.” When Luther passed away in 2002 and farming profits started to decline, the brothers turned their focus to sawmilling and began working full-time at the family mill. “Our dad always told us to produce quality material and you will always have work,” said David. “That’s been true and we’ve held to that since the start.”

In addition to having decades of experience running sawmill equipment, L. Garbers & Sons has relied on Wood-Mizer equipment for more than 20 years to produce accurate, consistent material by maintaining thickness, reducing waves or variation, and minimizing wane. “We’ve always received comments about the quality and consistency of our material and Wood-Mizer contributes a great deal to our quality,” said Marty. “The quality of how they construct their mills and their engineering help you maintain your production as well as your quality of cutting.”

In addition to providing quality material, L. Garbers & Sons has grown throughout the decades by sawing a variety of material and taking smaller jobs to get their foot in the door with a potential for securing larger jobs with clients. For example, the business entered the pallet board business by first doing trailer planking for a trucking company who eventually started a steel coil shipping business and contracted all pallet work to L. Garbers & Sons. “If one product is a little slower, another product will pick up,” said David. “We try to keep our eggs in different baskets.” The business processes and sells material to a range of clients including pallet stock to the pallet industry, blocking to the railroad and steel industry, and grade lumber to clients throughout Michigan, Wisconsin, Indiana, and Missouri.

Upgrading to a WM4500 Industrial Sawmilling System

While L. Garbers & Sons has remained flexible to produce whatever the market demands, one constant has been operating with Wood-Mizer sawmilling equipment. The company started with a Wood-Mizer LT40 hydraulic portable sawmill before securing a large contract for producing pallet stock. This led to an upgrade to an LT40 super hydraulic portable sawmill to meet production demands. After more than 1 ½ million board feet on the LT40 super portable sawmill in just a few years, the operation upgraded again to an LT300 sawmill – Wood-Mizer’s largest industrial mill at the time. Sixteen years later, the company operates today with an industrial sawmilling system that includes a Wood-Mizer WM4500 sawmill, EG400 board edger, and material handling equipment. They also maintain their own blades on-site with Wood-Mizer blade sharpening and setting equipment. “The WM4500 was huge for us, kind of like a present for paying our dues and working our way up,” said David.

The installation of the WM4500 was completed in approximately three days and David and Marty were both trained by Wood-Mizer technicians how to operate the new machinery. “What I like most about the WM4500 is the powered toeboard rollers,” said Marty. “It is much nicer shifting the log back and forth on the deck how you want and the dual chain turners are able to handle the logs so much easier.”

L. Garbers & Sons fits their sawmill equipment with Wood-Mizer Turbo 7 blades. “We’ve always had the best results with Wood-Mizer blades. We are running the 2” wide Turbo 7 blades with the 1-1/4” tooth spacing and we really like them for the ability to cut faster with the same surface quality,” said Marty. “We’ve tried other blades but didn’t see the quality like we do with Wood-Mizer.”

The company also sharpens their blades daily in-house with Wood-Mizer blade sharpening and setting equipment which has helped reduce costs and provide consistent cut quality. “Maintaining our blades in house tends to save money when you don’t have to worry about shipping them out,” said Marty. “We can also control the quality of blades that we are using and we can change the tooth set based on the species we are sawing.”

Processing Grade and Pallet Material

The sawmill business runs eight hours a day, five days a week with five employees doing a variety of work including milling, edging, running the chop saw, and sharpening blades. "The WM4500 is a lot heavier built which makes it a lot easier handling bigger and longer logs,” said Marty.

A variety of grade and pallet quality logs are supplied from Ohio and nearby states including Michigan and Indiana. Grade quality logs tend to come from longer distances because there is more money in the finished material than pallet quality logs that generally come from shorter distances. “We primarily saw walnut, red and white oak, cottonwood, cherry, maple, sassafras, and hickory,” said Marty.

First, logs are unloaded and scaled for board footage before being sorted for grade or pallet quality. If they are grade quality, logs are also sorted by species. On the WM4500 sawmill, logs are milled into various sized cants and boards depending on the customer needs and sent to a transfer deck. For boards that need to be edged, the transfer deck sends material to a green chain that goes to the EG400 board edger. “The EG400 edger has a larger width capacity, laser lines, and presets for quickly setting the right board width. Plus cutting speed is a lot faster which has sped up production,” shared Marty. For straight edged material off the mill, the transfer deck sends material to a large chop saw to cut to the correct length. Material is then stacked and prepared to send out to clients.

David’s advice for start-up sawmill operations is to work hard, market your business to grow your customer base, and to be patient during good times and bad. For the future, the company is looking to invest in a log debarker, a second sawmill, or even a grade resaw system in order to improve efficiency. For now, L. Garbers & Sons continues to focus on quality and consistency in everything they do. “Do a quality job and you will always have work,” said Marty. “We’ve heard from many different customers that they buy from places with good quality and consistency. That’s something we always try to strive for and is a pride of ours. That philosophy has kept us work in even some of the leanest times.”

By: Wood-Mizer Products, Inc.

Sims Forest Products: Southern sawmill shifts focus from low-grade hardwoods to sawing pine, installs new equipment. Operates equipment from some of the biggest names in sawmill and resawing sector, including Cooper Machine.

By Tim Cox

Date Posted: 4/2/2018

Sims Forest Products

Southern sawmill shifts focus from low-grade hardwoods to sawing pine, installs new equipment. Operates equipment from some of the biggest names in sawmill and resawing sector, including Cooper Machine.

TUSCUMBIA, Alabama — When Sims Forest Products started up a new sawmill in 2015, it was all set up to cut low-grade hardwood logs into pallet components and other industrial lumber products. About a year later, however, the company transitioned to sawing pine for the same markets and also added some new products for other markets.

A key partner in launching this mill has been Cooper Machine, which manufactures a wide range of sawmill machinery. Cooper supplied the Tuscumbia mill with two new machine centers, including a Cooper log merchandising and sorting system in the log yard and a Cooper auto edger.

Sims Forest Products operates several manufacturing facilities and has two sawmills operating in Alabama. The company specializes in cutting industrial lumber products.

The company’s pine sawmill is located in Tuscumbia in northwest Alabama, adjacent to Muscle Shoals, where Sims Forest Products has its corporate headquarters.

Changing the Mill Focus

Last year, Sims management transitioned the facility to pine as low-grade hardwood logs became increasingly difficult to obtain. Pine is much more abundant and has made it easier to keep the mill supplied with logs, and many pallet manufacturers have been moving their customers to pallets made of softwood lumber.

During this plant evolution, Sims added some new equipment, including a second scragg mill — a Baker Products system — to increase production. The company’s operations are equipped with other well-known names of pallet and sawmill machinery manufacturers.

The Tuscumbia plant is comprised of four buildings with a combined 30,000 square feet. Forty employees produce 1.4 million board feet of finished lumber products per month. Cutting all low-grade pine logs, the mill manufactures pallet parts, fence pickets, and it also has operations to produce fence posts, a new product line. About 50% of the mill’s production is pallet components, 25% fence pickets, and 25% fence posts.

The mill can cut “whatever a customer wants” for pallet stock, said assistant mill manager Jeff Lindsey, from 7/16-inch deck boards to 3-inch stringers with lengths ranging from 36 to 72 inches. Most stringers coming out of the plant already are notched for four-way pallets.

The mill, which began operating in 2014, transitioned to pine as low-grade hardwood logs became increasingly difficult to obtain. Sims Forest Products has pallet manufacturing customers in such states as Mississippi, Georgia, Tennessee, and Kentucky.

Exploring the Mill Process

The mill buys tree-length pine logs down to a 4-8-inch top. The company gets most of its logs locally, but it buys from contractors up to 200 miles away, which includes southern Tennessee and Mississippi. In the log yard, a knuckleboom loader unloads and stacks incoming logs. A front-end loader is used to feed logs to either scragg mill.

For fence post production, the logs are fed first to a Cooper merchandising system that was added last year. It bucks the logs to lengths of 6, 7, or 8 feet. Logs continue along a trough and are automatically kicked out into bins according to length and diameter and then can be picked up and staged at the pole operations.

The Baker Products scragg mill, acquired used and added in early 2017, is a sharp chain system and runs two 48-inch circle saws to remove two sides of the log. The two-sided cant then is turned on its side 90 degrees.

The two-sided cant then goes to another Cooper addition, a 6-inch, two-saw auto edger. The Cooper machine, with automated infeed, replaced an older edger that required a worker to manually feed it material. The Cooper auto edger centers the cant, and two saws are adjusted automatically and remove the remaining sides to produce a four-sided cant.

The Cooper auto edger has been a good addition to the mill, noted Jeff. “It has worked out well,” he said.

The other production line, in place when the mill first began operating, starts with a Big Jake scragg system originally built by Timberland Machinery, which later was acquired by Brewco. It is a four-saw system with sharp chain infeed that processes the log into a four-sided cant. After twin circular saw blades remove the first two sides, the log continues along to a set of rollers and is turned on its side 90 degrees. The two-sided cant is clamped, measured and centered for the next two saws and exits the machine as a four-sided cant.

Cants produced by both scragg mills are conveyed the length of the building to a cant dumper, then stacked with a forklift, banded, and put in storage until they will be resawn.

The mill relies entirely on gang saws for resawing the pine cants. They are housed in the other mill building and put on a deck feeding to a Timberland double-end trimmer before being resawn.

The company has three gang saws and is in the process of adding a fourth. It has a Brewer, a Brewco, and a Quality Machine, and it will be adding a second Brewer. All the machines have been purchased used — except for the Brewco — and rebuilt by the Sims maintenance staff. The additional Brewer will be a used machine that is being refurbished.

Each gang saw has a planer head sizer on the front to trim the top of the cant down to the correct height. Of the three gang saws, one normally is set up to cut stringers and one for fence pickets. The third machine usually cuts deck boards or other material.

Material exiting the gang saws is graded by a couple of workers and fed to one of four stackers, two AIT lumber stackers and two Timberland Machinery stackers.

The company has a Timberland Machinery double-head notching machine for notching stringers and is getting ready to add a second machine, a West Plains two-head notcher. Profile Technology cutting tools are used for the notching heads.

Fencing Operations & Other Markets

Sims Forest Products is equipped with a Holtec package saw that is mainly used to cut material to length that is manufactured into fence posts. It also may be used to cut cants to length if needed.

The pole operations, contained in a shed, produce 6- and 8- foot fence posts that are perfectly round, without any taper.

The mill has one customer for whom it makes a small quantity of pallets; they’re assembled by hand with pneumatic nailing tools.

All slabs from the Cooper auto edger and the Big Jake scragg system are routed to a Montgomery hog grinder along with other scrap material. The grindings and sawdust are supplied to the nearby affiliated parent company and is processed into mulch.

Most stringers are 48 inches long by 1-1/4x3-½, and nearly all of them are notched before leaving the plant. The company cuts some custom dunnage, too. It also is equipped to cut banding grooves and supplies some grooved dunnage, but most of it is done for its own shipments of fence pickets.

Fencing is sold to markets in Florida, Georgia, Ohio, and Kentucky, and most of it ends up being treated before eventual sale to building contractors and homeowners.

The mill relies on two suppliers for saw blades and service, a local company, Miner Saw, and also Superior Saw Service in Tennessee.

Sims Forest Products is a family business, and the owners treat their employees like family, according to Jeff. “We try to get as many local people as possible. We try to help our community around here grow.”

Growing with Cooper Equipment

Although the cut-up system and auto edger are the first two Cooper machines at the Tuscumbia mill, Sims Forest Products has been no stranger when it comes to turning to the machinery manufacturer for equipment. Cooper has supplied machine centers to the company’s other Alabama mill, including an overhead scragg, a MIT 4-inch vertical band head rig, and a 3-inch edger.

Cooper Machine, in Wadley, Georgia, manufactures a wide range of machinery and equipment for the sawmill industry and also is a distributor of some lines of sawmill machinery.

For more information, visit www.coopermachine.com or call (478) 252-5885.

By: Cooper Machine Company, Inc.

”A new generation is taking the lead”, managing director Anssi Westerlund summarizes this autumn’s brand new Hakki Pilke 38 Pro firewood processor and the Hakki Pilke Pro series being announced now.

”The Hakki Pilke Pro series takes firewood processors to a new age and level. We provide professionals with the output and speed of a new processor generation. We bring productivity-enhancing innovations and market-leading performance to firewood manufacturers”, Westerlund promises.

First introduced in the KoneAgria exhibition in Finland on October 12th-14th, the Hakki Pilke 38 Pro is a result of our development work based on close cooperation with customers – careful listening and responding to wishes. Hakki Pilke delivers thousands of processors to more than 30 countries on five continents each year; a lot of information about the requirements of different markets and conditions is accumulated.

”We know professional firewood manufacturers and professionals know us. For example, 38 Pro’s HakkiCut cutting control, where cutting takes place with optimized speed just by pressing a button, and AC10’s automatic chain tensioning are responses to distinct customer needs. This is the direction where we will increasingly steer our operation and R&D”, says Hakki Pilke’s R&D chief Timo Jussila.

Hakki Pilke is the world’s leading firewood processor manufacturer, who has revolutionized the market with several innovations and processor models in three decades. 38 Pro’s cut-enhancing HakkiCut™ and patented AC10 are unique solutions not available from other manufacturers. Furthermore, 38 Pro includes many new functionalities and improved features.

”The splitting power has been increased compared to the previous Easy 38 and it’s easily sufficient for even the hardest wood species in different parts of the world. The cycle time is 3 seconds, making the processor even faster with small and big logs. The enlarged hydraulic oil tank cools temperature and extends the operating life of the parts and oil. The reverse valve of the outfeed conveyor is also one of the new features”, Jussila lists.

Apart from power, speed, and productivity, professionals making a lot of firewood demand ergonomics and ease of use as well as uninterrupted operation from their processors.

”In 38 Pro, cutting and splitting take place by pressing a joystick button. All other essential functions are also at hand, delivering top-class usability. With 38 Pro, you can make firewood faster than with competing processors in the same size class”, Jussila says.

Hakki Pilke 38 Pro in a nutshell

- Max log diameter 380 mm

- Max log length 600 mm

- Power source PTO, electric, combi

- Splitting power 10 t

- Splitting blade 2/4, 6 and 8 -way

- HakkiCut™ cutting control

- Outfeed conveyor speed control and reverse

- AC10 automatic chain tensioner

- Minimal maintenance needs

- Hydraulic oil tank volume 72 liters

- Reinforced frame

- Updated hydraulics

About Hakki Pilke

Hakki Pilke produces the best firewood processors in the world with more than 30 years of expertise. We know professional firewood manufacturers and professionals know us. We deliver thousands of processors to our customers on five continents in over 30 countries every year. The international operation and local service network of Hakki Pilke offer the world’s best support and after sales service to processor owners. The manufacturer of Hakki Pilke processors, Maaselän Kone Ltd, is part of the Terra Patris group. www.hakkipilke.fi

By: Maaselän Kone Oy

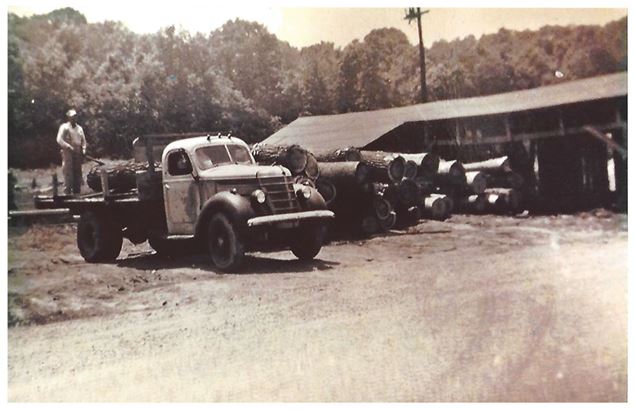

As it is with most successful lumbermen, Ohio Valley Veneer had humble beginnings. Starting out in 1986 with a two man logging crew and the passion to excel, Ed Robbins was on a mission. That mission, mostly unknown to him at the time, was going to revolutionize the forest products industry in Southern Ohio and beyond. Being a fourth generation lumberman provided Ohio Valley Veneer with a deep appreciation for the people and understanding of the tradition and the lifestyle, but most of all it prepared Ed by instilling what was most important: hard work, honest dealing, quality products and the vision to excel.

Founding Ohio Valley Veneer in 1990 to buy, sell and export logs, Ed soon found himself hiring mills to custom saw where it fit market conditions. In 1992 he was able to purchase the land where his father and grandfather had operated sawmills since 1958 and in ‘94 built his first mill on that hallowed ground. The heart of that mill was an eighteen year old Cleereman Model 36 purchased at auction and they ran it every day until 1998 when it was replaced with a Cleereman 36 Proportional carriage. Now Ohio Valley Veneer mills produce more than a million board feet of lumber monthly as well as exporting lumber and some of the world’s finest hardwood veneer logs from the hills and hollers of rural southern Ohio. Those mills now include five linear positioning carriages, four LP42’s, one LP48, and a HS36 Proportional.

Ed’s original mission to bring passion and professionalism to the lumber business now directly employs over four hundred and shows no sign of slowing down. He credits a portion of his success to making sound decisions when it came to major equipment purchases, and he’s proud to say that Cleereman carriages have been instrumental in that growth because, as he puts it, “they just run”. Now purchasing an average of one million dollars in new machinery annually, Ed shared why he continues to run only Cleereman carriages. “A company’s salesman can sell you the first of anything, be it a sawmill, loader or whatever, but that company’s service and parts departments will sell the second one”. Over the course of his career Ed has purchased sawmills from numerous manufacturers and one thing is constant, if that mills stays in production for Ohio Valley Veneer, it gets upgraded to a new Cleereman. It’s that simple.

According to Ed, choosing Cleereman has been one of the greatest moves of his career and credits Cleereman’s low cost of ownership as instrumental in his ability to continue to grow Ohio Valley Veneer. As he often says, “they just run, they seldom break down and when they do the parts are reasonable AND AVAILABLE WITHIN 24 HOURS”. In addition to a superior sawmill carriage, low cost parts and fast breakdown service, the one thing that most impressed Ed was how Cleereman does business when a Cleereman mill experiences a fire and Fran Cleereman and the entire team do whatever is necessary to get that mill owner back in production. In many cases saving the company and hundreds of jobs with it. That kind of dedication to insure family businesses thrive is one of the many things that separate our industry from so many others. In any other industry, whoever put their deposit down first would be ahead of the burnt mill, but doing what is right – not what is expedient is what separates companies like Ohio Valley Veneer and Cleereman from hundreds who produce similar products.

Growth at Ohio Valley Veneer shows no sign of slowing down as the proven formula of efficiency, superior quality and passion to produce the very best lumber and timber products continues. Aggressive, but patient, acquisition is part of Ohio Valley Veneer’s growth plan and Ed is targeting areas known for quality logs such as East Tennessee, Southern West Virginia and Indiana. Following the efficiency path, Ohio Valley Veneer is scheduled to take delivery of their first Cleereman Lumber Pro. Chosen specifically because of its proven low cost of ownership due to reduced electrical consumption, thin kerf, low maintenance requirements, double cut capacity, modular design and its ability to serve as both headsaw and resaw. The Lumber Pro, with its single operator, is expected to replace three or four thin kerf narrow band sawmills greatly reducing overhead and allowing those employees to move into more productive positions.

By: Cleereman Industries

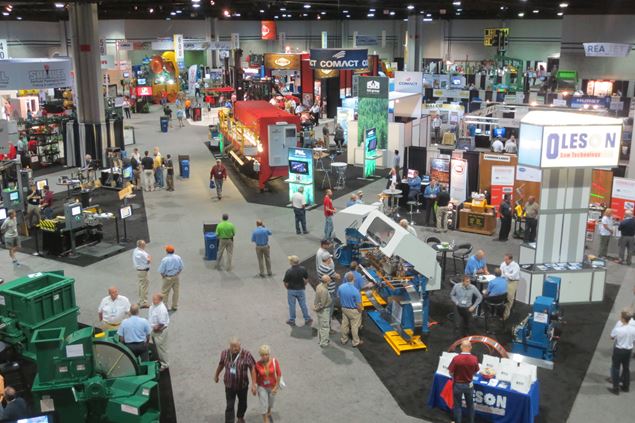

The 34th Forest Products Machinery & Equipment Exposition – Expo 2017 – opens its doors June 14 for three days of exhibits housed at Atlanta’s Georgia World Congress Center. More than 180 exhibitors will display the very latest in technology and equipment that advances the wood products industry into the 21st Century.

“This international show promotes the sawmilling industry as high-tech, providing the tools and machinery needed to produce quality products that help build global economies,” notes exposition director Eric Gee. “Like our show two years ago, Expo 2017 is a sold-out showcase of mill upgrades for both softwood and hardwood operations,” he adds.

A visit to the show is enhanced this year with the debut of a new app for handheld devices. The app provides full coverage of the event’s exhibitors, the floor plan, special events during the show, with links to social media. It’s available for Android and I-phones – download on the Goggle play or I-Tunes App Store; search: FOREST EXPO.

“Here is a handheld tool to manage your show schedule in real time,” noted SFPA exposition director Eric Gee. “Visitors can schedule appointments with exhibitors and take notes about what they see at the show,” he added. They can also connect with other attendees and exhibit personnel, making for a more interactive networking experience. “This app is the latest in exposition event technology and provides the user with a wealth of information in the palm of their hand,” commented Gee.

Sponsored and conducted by the Southern Forest Products Association (SFPA) every two years since 1950, this event has traditionally included many of the biggest names in the business displaying everything from sawmill machinery to materials handling equipment, attracting key representatives from the nation’s largest wood products manufacturers.

By: Southern Forest Products Association

Hakki Pilke firewood processors are built in Haapajarvi, Finland with over 30 years’ experience. Every year thousands of machines are shipped to five continents around the world. Customers are using the products in varying conditions but mainly for producing firewood professionally for sale. For a manufacturer it is a challenge to fulfill different customer needs with the product, which is why Maaselan Kone listens international Hakki Pilke users and dealers carefully in order to understand the market needs and challenges. All product development is based on customer feedback and extensive testing. Testing is done in close collaboration between the factory, importers and experienced customers.

The latest model in the lineup, Easy 43, is designed for professional wood processing. It is a successor of very popular and globally well-known model Easy 42. Most of the inventions and new features of the new model derive from the requests and suggestions made by Hakki Pilke users. Hakki Pilke distributors were already involved in early prototype testing phase to help the factory to find the right direction in the project. Maaselan Kone finds this kind of close collaboration highly rewarding and successful.

New Key Features Requested by International Customers

Hakki Pilke Easy 43 raises the bar for firewood processing by many world’s first features such as the new cutting mechanism only seen before in forestry harvesters and the delay-free splitting system designed to make processing as effective with both small and big sized logs. “After comprehensive testing in 6 different countries and over 20.000 cubic meters (5.500 cords) of hardwood and softwood species processed, we have developed many long-awaited solutions for international Hakki Pilke users. New ergonomically designed interface and other features such as log landing plates, automatic log infeeding and the patented AC 10 automatic saw chain tensioner are all solutions for the industry’s existing problems,” says Timo Jussila, Development Manager, Maaselan Kone Ltd.

NEW TYPE OF CONTROL

All the main functions are ergonomically positioned on the joystick. Sawing button performs following functions:

- log clamp activates

- saw is activated and lowered

- log landing plates are raised

- log measuring device is retracted

HYDRAULICALLY RETRACTING LOG MEASURING DEVICE

The hydraulic log measuring device retracts automatically during sawing to allow the cut log to fall freely into the splitting groove. The firewood is measured precisely to ensure right sized final product.

LOG LANDING PLATES

The log landing plates ensure that the logs land into the splitting section in a controlled manner. Landing plates can be used in automatic or manual mode. Manual operation enables the controlled dropping of the last piece of log.

HYDRAULIC AC10 – Saw chain tensioner

The AC10 maintains optimal chain tension, preventing it from coming loose or breaking. The correct chain tension notably increases the service life of the chain and bar. The chain can be replaced effortlessly without any tools.

LOG INFEED ASSIST MECHANISM

The infeed assist mechanism feeds in a new log during every splitting motion, ensuring that a log is always ready for sawing at the right time. When infeed assist is turned on processing a log requires using only two joystick buttons.

Resulting productivity and satisfied customers

The new Hakki Pilke Easy 43 is an example of a product boasting many features the end users have requested from the manufacturer. It is very easy to use and reliable in all conditions. It is flexible in terms of processing different type of raw materials from small timber to big knotty logs. Processing is continuous and has no disruptions with cycle time below 3 seconds for cutting and splitting. Improved ergonomics in processor control and log handling enable the operator to work longer without getting tired. Further development will be done in collaboration with professional heavy users.

“Thanks to the new features of Easy 43, processing firewood is now easier and more efficient than ever before”, praises Anssi Westerlund the Managing Director of Maaselan Kone. “In addition, appearance of the new machine follows the modern and user friendly Hakki Pilke design”, he adds.

About Maaselan Kone Ltd

Maaselan Kone Ltd has been manufacturing world leading firewood processors since 1984, and exports 80 % of its products to over 29 countries worldwide, being market leader at many of its markets. Hakki Pilke firewood processors are renowned by professional users around the world for high productivity and fast investment payback time. International Hakki Pilke users are always at the heart of the product development process. For more information, see www.hakkipilke.fi We are expanding our distribution network in the US, contact us for more details.

By: Maaselän Kone Oy

Moving with the markets is something we’ve always tried to do. So when local markets in Mississippi tightened up back around 2000, we got in the mulch business, then added a hardwood circle mill in Oakland and a scragg mill Winona. After eight years running three operations, in three locations we decided that the time had come to merge into one location, update and modernize our milling operations.

Once we made the decision to build a state of the art hardwood sawmill to replace the multiple smaller mills we were running, the search began. And it was a long one. I traveled for a year and a half across the eastern United States and Canada visiting sawmills. The goal from the beginning was to build a mill that would efficiently produce a wide variety of materials so Fly Timber could move with the markets. The mix included cross ties, long timbers, crane mat material as well as hardwood grade lumber. This flexibility would insure that we could always produce what the hardwood lumber market sought and operate with an eye toward maximum return per log. Getting’ the squeal out of the pig as the old-timers called it.

We found out early in the planning phase that to meet this goal, we would have to deal with multiple machinery manufacturers and find a way to smoothly connect everything from the debarker to the main production machines like the Cleereman carriages, McDonough band headrigs and optimized edger, gang and trimmer. All the way out the back of the mill, not to mention the challenge of processing and flowing cross ties to rail cars.

During my many mill visits, whenever the discussion turned toward log or lumber conveyors, Rosserhead debarkers, log turners, lumber stackers and material handling equipment, Mellott was the name that kept coming up. From a very rugged built Rosserhead debarker, stand-alone decks and complete systems – nearly everywhere I went there was Mellott. That convinced me, I needed to see for myself, so I visited their plant in Pennsylvania and that sold me. Dale and Stacy Mellott and the entire staff at Mellott Manufacturing are fine people to do business with. They did an excellent job of working on this very complex job, dealing with multiple suppliers, engineers and deadlines. Each time we asked for something to be beefed up to meet our spec’s or to make something longer to expand our product line, the staff at Mellott stepped up to the challenge. That’s why the first thing a log sees when it arrives is a customized Mellott LMR 48” Heavy Duty Debarker, Mellott Log Haul trough, Mellott log decks, slab conveyors and the last thing is the custom built tie lifting system and lumber decks and rollcases.

Fact is looking back on the project, I can’t see how we could have done it as well without Mellott. They truly became a partner in our new mill and in the future of Fly Timber.

Ricky Fly

Fly Timber

Grenada, MS

By: Mellott Manufacturing Co., Inc.

The paths to success in the lumber business are as varied as the patterns on an oak leaf. So was the foundation and growth of Copiah Lumber Company of Crystal Springs, Mississippi. Founded by Craig Pyron in 1986, this prosperous and growing hardwood mill grew out of a small short pulpwood trading operation. Ever the forward thinker, Craig began buying standing timber, with brother, John Pyron, taking charge of harvesting operations.

Always seeking ways to maximize utilization, the brothers installed a Hurdle Portable sawmill in 1990 and began producing ties, cants, matts and lumber. Successful by any measure, by 1996 the ever increasing cost of standing timber and gate logs ushered in the next major growth phase. To improve yield by reducing kerf loss. Bob Rose, of Rose Machinery, a well-respected sawmill equipment dealer who represented Cleereman in the Southeast, assisted with the design and installation of a Cleereman LP-42 with the latest linear positioning and seven foot McDonough band headrig. Over two decades later that original Cleereman carriage is still sawing lumber every day.

Not one to shy away from innovation, other efforts were made to realize the ever expanding benefits of thin kerf technology, Copiah Lumber installed a West Plains 660 Resaw system and at one time even attempted primary breakdown with 1 ½” thin kerf systems. These proved incapable of producing the quality and volume of lumber required. So when Cleereman Industries of Newald, Wisconsin, introduced the first modular double cut Lumber Pro ST 54 the die was cast. But there was one thing missing, size of band to maximize capacity. Craig’s experience with smaller band systems made him skeptical of smaller sized band saws, so after several discussions with Fran Cleereman and Rod Chitko both companies agreed to create the largest Lumber Pro mill ever built with a LP-42 lineal positioning carriage and 62” double cut McDonough head. In addition to the larger carriage and headrig, the Lumber Pro at Copiah is also capable of sawing up to thirty foot timbers, offering Copiah Lumber another avenue of maximizing profit with the added capability of sawing the very longest matt and crane pad timbers of any high production mill in the southeast.

The Cleereman Lumber Pro design is unique in many ways, from the speed and efficiency of its thin kerf double cut moving head, to drastically reduced electric requirements that have proven to cut long-term overhead costs. The compact modular design coupled with the Lumber Pro’s moving saw head reduce the footprint required and installation time. This deeply reduces installation expense by delivering a truly modular machine that installs in just a few days, not weeks or months. In Copiah’s case their maintenance team worked with the Cleereman staff to handle the installation. Every Lumber Pro comes complete with an infeed log deck built to the customers required length, smooth log charging system that greatly reduces carriage wear by gently placing logs with a minimum of inertia, integrated off-bearer belt, dust and scrap conveyor, multiple setworks choices that includes several optimization selections, set shaft or LP carriage and a comfortable and spacious sawyers control cab that allows for a clear uncluttered view of the log during the entire sawing process.

Mill manager, Pee Wee Smith, described the Lumber Pro as a “log eating machine” that line for line was consistently producing the same, if not more, lines per day than the original conventional Cleereman running a shotgun feed and 7’ band headrig. Pee Wee attributed the impressive production rate to the Lumber Pro’s double cut design that eliminates back gigging to load logs onto the carriage, turn the log and setting for the next cut, all of which can be accomplished from either end with the Lumber Pro. In addition to the double cut headrig’s efficiency, production has also been enhanced by well-designed downstream material handling and nearly zero downtime.

Within two weeks head sawfiler, Lee Stockton had the double cut saws under control and operating at peak performance. Lee stated that it really isn’t any more difficult, as long as both sides are set to cut straight lines there’s not a problem. Craig and Pee Wee Smith agreed that the combination of properly prepared saws and a mill that came aligned and ready to saw put the ST 62 Lumber Pro in full production immediately. Transitioning periods for the sawyer proved just as smooth as the install, within days Copiah Lumber had trained a resaw operator to assume sawyer duties on the Lumber Pro and within just a few weeks he was up to 85-90 percent of capacity.

As with any major mill innovation or expansion there really is only one question that matters, would you do it again? Co-owner Craig Pyron firmly stated, “Absolutely, absolutely…over the long-haul with the cost of logs and cost of production we’re going to be way ahead, way ahead.”

By: Cleereman Industries

It’s easier to decide you need a sawmill than it is to make good choices about the mill you eventually buy. Ask me. I almost made the common choice of going non-hydraulic when I bought my first Wood-Mizer.

Actually my first mill was an old “portable” circle sawmill a friend had stored “out behind the barn.” It didn’t take long operating it to realize portable band sawmilling was clearly the superior option for me.

Today, about five million or more board feet later, I’ve learned a little about what you should and should not consider when choosing a sawmill.

I started with that old circle mill because it didn’t cost me anything beyond milling a few boards in trade but for most of us, cost is important once the decision to purchase is made. But don’t make the mistake of thinking cost is all-important. I’ve seen plenty of my fellow sawmill owners regret the emphasis they put on the initial cost of their mill without considering other things that are just as important over the long term.

An important question to ask before signing on the dotted line is, “What do I intend to use this mill for and, beyond that, what am I likely to use this mill for?”

Research done at Auburn University a few years ago showed me some important things anyone looking to buy a sawmill should consider. The study found, for example, that nearly half of the people buying a portable sawmill were replacing another mill because, “My previous sawmill had limited production capacity and I needed a more productive sawmill.” Another important finding of the study was that nearly 1 out of 3 mill owners might have intended to use their mill mostly for hobby use but, by the time they’d had the mill for awhile they ended up earning all or part of their income with the machine. It’s inevitable. Start milling a few sticks for your own use and pretty soon people will start showing up and asking, “Hey, can you do that for me?”

It’s been my observation that whether you are buying a portable mill strictly for hobby use or, to earn all or a part of your living, you are almost sure to find you end up using the mill a lot more often and for milling a wider variety of lumber, timber, and other products than you imagined when you first decided you wanted a mill. My advice is, you’ll almost never go wrong buying a little more mill than you think you need but you will certainly regret not buying enough mill.

Do some thinking about the type of product you intend to mill.

If you intend to make a full or part-time living with your portable sawmill you will definitely need a mill with full hydraulics to be successful. On the other hand if you’re going to be milling long length boards or timber for your own contracting company you may be more concerned with easily cutting long lengths. You might not need hydraulics and want to focus on something like an LT15 that can easily be extended using bed extensions.

Another element to consider is cost and production over the long term instead of the short.

When I began to mill, I quickly learned that if I wanted to make good wages from portable sawmilling I needed to have high production and charge by the board foot instead of by the hour. With my LT70 and EG200 twin blade edger I usually average $200+ per hour charging 35 - 40 cents per board foot. I could never charge that much an hour to custom sawmill but because I have the right equipment (especially an edger) and charge for production, not by the hour, I have been financially successful. In my 15 years of portable sawmilling, I have never had my Wood-Mizer not carry its own weight in a month, even when making payments on it.

Last, reliability and service are all important.

I remember looking at other, and often cheaper, brands when I was looking for my first thin-kerf portable sawmill. I ended up buying a Wood-Mizer and now many years down the road I am so thankful I made the decision to spend a little more for a higher quality machine; and especially for the legendary customer support that comes with every Wood-Mizer.

My LT70 is currently 7 years old. It has a remote station and many electrically controlled features. Combine staying outdoors year round in the rainy Pacific Northwest, along with the sawdust, dirt, and dust every operation will have and you will eventually need to do some maintenance on your machine no matter how much you try to baby your mill.

My mill is way out of warranty but I still have free access to Wood-Mizer’s troubleshooting service. One phone call and a person that can walk you through a problem to a solution is available. Believe me, having an expert to help you use a voltmeter to figure out wiring issues when you truly do not understand wiring and electronics is HUGE! The troubleshooters know you are stressed and broke down. They are experts at walking someone like me through the diagnostics needed to fix problems both mechanical and electric.

You get what you pay for in the sawmill world but by considering your sawmill purchase carefully you can help make sure you are getting what you need to be successful over the many years your machine will serve you.

By: Wood-Mizer Products, Inc.

A cold and rainy October day did not dampen Baker Products’ spirits (or performance) in this year’s Sawmill Shoot-Out at the Paul Bunyan show in Cambridge, Ohio. The team of sawyer Hank Somer and tailman Clay Hedrick operated a Baker Blue Streak 3665D mill and a KASCO Maxx-7 blade to out-shoot the completion at this year’s event. Baker Products and KASCO blades earned first place honors in the hydraulic mill category by sawing their way to an impressive production rate of 1,273 BF/hr and a production overrun of 1.07.

For the competition Hank Somer brought his new Baker Blue Streak Model 3665D from New Hampshire where he runs a one-man sawmill business. The Baker Blue Streak Model 3665D is a 65 HP Cummins diesel powered band mill that offers a cutting capacity of 36 in. x 20 ft. (D x L). His blade of choice was KASCO’s Maxx-7 blade. KASCO’s high-performance Maxx-7 blade features an aggressive 7-degree hook angle and 7/8” tooth spacing. Hank runs this blade on a daily basis and claims he hasn’t found any other that outperforms the Maxx-7 blade from KASCO.

Ask your distributor for KASCO WoodMaxx blades and their new Maxx-7 profile . Contact Baker Products for more information on their complete line of equipment.

By: Kasco/Sharptech

.gif)