704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

33 Results Found

704-841-2001

Call for Price

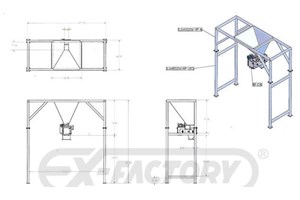

MCRS is a Bagging System for mulch, compost, rock, or sand. This system is complete with a 2-yard product surge hopper, a 20' X 24" wide troughed incline product delivery conveyor with a cleated belt, an 8' bag closing conveyor, and a custom 7.5 HP Elec/hydraulic power unit. The system can fill bags by time and depth of stream or digitally with load cells.Standard construction carbon steel Powder Coated Industrial Gray(RAL 7046).The MCRS operation has been designed for one man to bag fill, bag close, and stack three bags per minute continually. -- The operator hangs bag #1 on the scale, hits the palm switch to close the CG spout, and automatically fills it. -- Bag #1 will drop once the timer times out onto the moving conveyor and hangs bag #2 into position, hits the palm switch, and starts the filling. -- The operator steps to his left. Bag #1 contact a wand switch and is in position underneath the impulse sealer. --The operator starts the bag into the impulse sealer. Once completed, bag #1 is then manually stacked. -- Bag #2 filled and waiting for the operator's return. -- Bag #2 is then released, and bag #3 hung. -- The process is then repeated.The Front End loader feeds the system. Consists of the following --infeed hopper --incline conveyor --dosing system --bag closing system:Bag Closing System Consists of a (CON 508) 8' long x 1' wide smooth top belt to take bags into aposition where a wand switch manually stops them. The bags are then prepared and enteredinto theImpulse Sealer (31103737610) Programmable Impulse Sealer for the repeated sealing of thermoplastic films such as polyethylene and polypropylene. This automatic single-impulse heat sealer is controlled by a plug-in transistorized circuit board and electronic timers. The timed closure ensures an even and consistent seal. --THE PRICE REFLECTS AN UPGRADE FROM THE IMPULSE SEALER TO A SEWING SYSTEM.The operator has hands free to handle the product quickly. This type of machine generally increases workers' productivity.The electric foot pedal is included for manual operation. -- Seal Length: 24" -- Seal Thickness: 8 mil -- Seal Width: 10 MM

Call for Price

SPECIAL FEEDER FOR HAMER 2080FFS BAGGER -- Hopper 37 Cubic Feet and Support -- With Scale Support System -- Belt Feeder with Discharge to Existing Hamer Form-Fill and Seal -- Brand New -- Loaded on your Truck

Call for Price

LOOSE BAGGING SYSTEM "MCSRE"System includes and is supplied with: -- Hopper BF 87 Cu/Ft. and Support, Charging Hopper to Integrate with product Delivery Conveyor -- CON PD 24X24: 24 Feet Product Delivery Conveyor -- Hopper Stand BF: Hopper and Support 37 Cu/Ft. Surge Hopper for 5 GV Duplex Net Weight Bagging System -- GV-52 - DUPLEX GRAVITY/VIBRATORY TRAY: Duplex unit for (20) Bags/Minute -- Spout to Meet Customer's Bag -- CON 512: Bag Closing Conveyor. 12 Feet Long -- PACKRITE XROL: Heat Sealer with Extra Set of CO.Loaded on your Truck

Call for Price

COMPLETE LOOSE BAGGING SYSTEM System includes: -- Feed Hopper 3 Yards Capacity. ( 87 Cu.Feet) -- 24 feet Incline Conveyor. -- GB Mechanical Bagging Scale -- Feeding Hopper 37 Cu.Feet with Stand. -- Packrite Xtrol Impulse Sealer. -- Motorized Bag Conveyor. -- Loaded on your Truck.

Call for Price

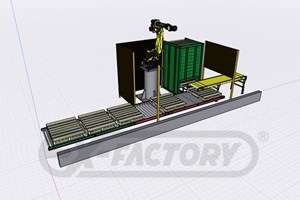

FANUC 165 Complete Palletizing SystemEquipped with and includes: -- FANUC 165 Complete with R-2000iA Controller with 600mm stand -- Pick-Up Arm Gripper Arm for pillow bag type -- 5 Feet x 24" Motorized In-feed Belt Conveyor -- (1) 10' Motorized Pallet Conveyor -- Automatic Pallet Dispenser -- Price includes Loading on your Truck

Call for Price

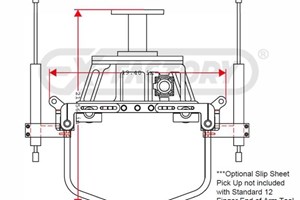

END ARM TOOLING FOR FANUC ROBOT -- Gripper Finger Type End Arm Tooling -- Design for Fanuc Robot Model S-430iW -- Loaded on your truck

$73,630

COMPLETE FANUC 125I ROBOTIC PALLETIZING SYSTEM System Includes the following: -- FANUC M-410IB/160 Palletizing Robot with Controller and Stand -- Robot will be tested -- End of Arm Tooling to Pick, Fork Style, Picking 94 Lbs Concrete Bags -- Master System Control Panel, 480 VAC 3PH & 24VDC Controls with HMI -- Allen-Bradley Light Curtain with Safety Controller --Infeed Chain Drive Roller Conveyor 10 Feet -- Pallet Hopper. ÷ Safety Fencing COST -- 20 Feet Exit CDLR Pallet Conveyor 52" Wide -- System Integration / Programming.

Call for Price

FANUC - M-410I, ...Palletizing RobotFANUC M-410iC/110 Robot is a Palletizing Robot. It runs on the FANUC "R30iB" and "R30iB Plus" controller platform. With lighter payload, this Robot is designed to run faster than its bigger variants.This Robot was ordered and never installed, so it is "new" old stock.Max. payload: 110 kG (242 Lbs). -- Reach: 2,403 mm (94"). -- Axes: 4. -- Repeatability: +/- 0.5 mm. -- Robot Mass: 1,030 kG (2,270 Lbs). -- Floor mounted.

Call for Price

FANUC - S430iW, ...RobotFANUC Robot for palletizing rectangular compressed bags.Specifications -- (6) Axes. -- Payload: 165 kG (255 Lbs). -- H-Reach: 2,643 mm (104"). -- Robot mass: 1,300 kG (2,860 Lbs). -- Complete with: Pendant control. -- Complete with: Gripper type arm and pallet gripper. -- Refurbished with (90) days Warranty. -- Buyer to install safety guards.NOTE: Machine was rebuilt is 2021.

Call for Price

FANUC M410/160 iB ROBOT PALLETIZING SYSTEM Specifications: -- Complete with R-30iA Controller All Refurbished -- Pillow Bag Tooling -- 4-Axis control -- Mounted to a heavy-duty base -- 10 Feet Long Rubber Belt Conveyor -- (2) 5 Feet Motorized Pallet Conveyor -- (3) 10 Feet Motorized Pallet Conveyor -- Automatic Pallet Dispenser -- up to (14) 50 Lbs bags per minute -- Machine weight 4500 LbsAUTOMATIC PALLET STRETCH WRAPPING SYSTEMWULFTEC or LANTECH Stretch Wrapping System or Equivalent Not INCLUDED

Call for Price

FLEXICON HOPPER/FEEDERSpecifications: -- Flexible Screw Approximately 12 Feet -- 7" Diameter -- Flights 6-1/2" -- Tube Diameter 7-1/2" -- Discharge Height 86 Inches -- Discharge Diameter 10 Inches -- 10 HP Motor -- Dimensions; 72" Long x 48" Height x 7-1/2" Depth -- Loaded on your Truck

Call for Price

KAWASAKI FS030L E Palletizing RobotArticulating arm type Palletizing Robot.Specifications: -- Suction cup type "pickup". -- PENDANT 6 AXIS -- Controller Model "D32FD001" -- Capacity: 30 kG (66 Lbs) bags. -- Complete with pendant control station. -- Includes control panel Cabinet. -- Dimension; 98" H x 42" W x 98" L (wooden crate); weight approx. 3,190 Lbs.Loaded on your truckNOTE: (2) Units available!

Call for Price

KCB BAGS BIG SACKS BULK TOTES "NEW"Bulk Bags, never used. -- Bag size: 35" x 35" x 25" S/S. -- 2,200 Lbs, SWL (1,000 kg), Safety factor 5:1. -- Document pouch. -- Fill spout top inlet. -- Bottom discharge chute with flap, liner. -- Min. purchase quantity is 500 bags. -- Special Price for Higher Quantities -- Loaded on your truck

Call for Price

MATH-EX - SUCTION CUP END TOOLING ARM FOR FANUC ROBOT -- Suction Type Pick Up Tooling Arm. -- Specially Designed for FANUC Robot. -- To Palletize Pillow Type Bag up to 75 Lbs. -- This Tooling will be Installed on a FANUC Robot. -- Loaded onto your truck.

Call for Price

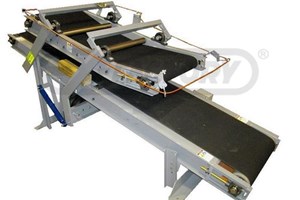

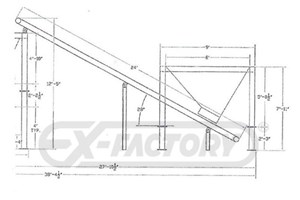

MATH-EX Bag FlattenerSpecifications: -- Standard Bag Flattener conveyors are 10' in length with a 15° incline. -- The system has an opposed 5-1/2 foot conveyor with parallel linkage and adjustable spacing for various bag thicknesses. -- The standard unit has a 12" inlet and 42" discharge. -- The lower conveyor has a 1-1/2 HP motor and the top conveyor has a 1 HP motor both with a speed of 90 FPM. -- Both conveyors come with 24" wide Roughtop black belt.Custom length bag flatteners are available in 2' increments from 10 feet to 24'. Mild steel construction with industrial powder coat finish is standard, however all stainless steel, corrosive resistance packages and hazardous location components are available as option.

MATH-EX BAG TURNER WITH CONVEYORSpecifications: -- Bag Turner/Knockdown Conveyor -- 5' Long x 24" Wide Smooth Top Belting -- Includes Turn Wheel -- 30" Stainless Steel Turn Plate and Adjustable Knockdown Bar -- 1/2 HP Motor at 90 FPMLoaded on your truck

Call for Price

JM-FF-ED-DT BAG FILL MACHJM-FF-ED-DTMild steel construction, dust-tight spoutJM Electronic digital gross weigh scale for free-flowing products with 880 Digital Programmable Controller, air-operated dust tight spout, recommended for use with dry, free-flowing products that do not require auto adjustments from the digital controller. 21", 25", or 31" circumference spout available. Dust Collection Port: 1-1/2" dust port (upper left corner LH side of scale) 100 CFM regulated by customer dust collection system - metered.HOPPER STANDHOPP & SUPT 37 CU' MS37 Cu' Surge Hopper and Scale Support system with Upper and Lower Level Sensors to control feederCON 510-LPCONV 510 Bag Closing Conveyor10' overall length, 1/2 HP motor, 12"-wide 3-ply neoprene smooth top belt, 110V variable speedmotor mounted internally, adjustable conveyor height 13.5" to 18.5" and adjustable back plate,electrical controls include on/off switch. Powder Coated Industrial Gray (RAL #7046)Dwg: CON 510-LPPACKRITE XROLHEAT SEALER W/ EXTRA SET OF COBAND SEALER - BAND SEALER - Model 6000 Bandrite Band Sealer is the result of innovative sealing technology and 60 years of packaging experience at Packrite. It has been and will be continually upgraded and enhanced. This machine is a workhorse! It is made for multi shift operations. Bandrite, R-L, 3/4 Seal, StSt, ~~ Adjust to height, stainless steel & pressure rollersincluded.CON 8INCCONV INCL 8'Incline Conveyor 8' long, fixed speed, specify 90' or 120' FPM, 24" wide rough top belt. Roll Over plates are included on all incline conveyors that have an inline bag closing conveyor. Mild steel construction coated with gray powder coating.ROLLER TABLE BGRAVITY ROLLER ACCUMULATION TAGravity conveyor 3'-6" long with 1.9 x 16 gauge rollers set high on 2" centers 30"EFF. 30" BF feeding to 18" radius adjustable top. "H" type support legs 36" to 42" height. Half moon table to stop bag from rolling.PALLET POSITIONP3-AA All Around Pallet PositionAll Around Pallet PositionerLift Capacity 400 lbs to 4,500 lbs - Base Size W / L 36-1/4" x 36-3/4"Lowered Height 9-1/2" - Raised Height 27-3/4"Turntable 43-5/8" diameter - Pressure relief valve StandardFork Pockets 6-3/8" W x 1-3/4" H on 29-3/8" Centers

MATH-EX Bag FlattenerSpecifications: -- Standard Bag Flattener conveyors are 12' in length with a 15° incline. -- The system has an opposed 6 foot conveyor with parallel linkage and adjustable spacing for various bag thicknesses. -- The standard unit has a 12" inlet and 42" discharge. -- The lower conveyor has a 1-1/2 HP motor and the top conveyor has a 1 HP motor both with a speed of 90 FPM. -- Both conveyors come with 24" wide Roughtop black beAlt.Custom length bag flatteners are available in 2' increments from 10 feet to 24'. Mild steel construction with industrial powder coat finish is standard, however all stainless steel, corrosive resistance packages and hazardous location components are available as option.There is a $250 crating fee that must be added to the price Standard Delivery 8 weeks

Call for Price

HOLDING BIN WITH CONVEYOR -- Made to order Holding Bin for Free Flowing Material -- 87 Cubic Feet Capacity -- Top Feeding of 8 Feet Wide -- Total Height 7'11" -- Complete with Support Legs. -- Motorized Incline Belt Conveyor 24 Feet Long @ 12'5" Discharge Height -- Loaded on Truck

MATH-EX Bag Flattener with 8 foot conveyorSpecifications: --Bag Flattener conveyors are 8' in length with a 15° incline. -- The system has an opposed 5-1/2 foot conveyor with parallel linkage and adjustable spacing for various bag thicknesses. -- The standard unit has a 12" inlet and 42" discharge. -- The lower conveyor has a 1-1/2 HP motor and the top conveyor has a 1 HP motor both with a speed of 90 FPM. -- Both conveyors come with 24" wide Roughtop black belt.Custom length bag flatteners are available in 2' increments from 8 feet to 24'. Mild steel construction with industrial powder coat finish is standard, however all stainless steel, corrosive resistance packages and hazardous location components are available as option.