704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

1794 Results Found

704-841-2001

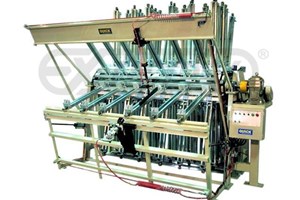

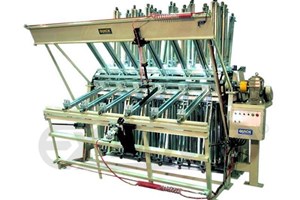

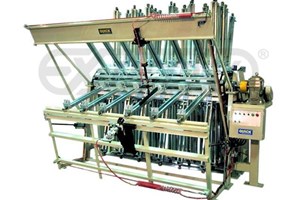

QUICK 20 Section Heavy Duty Pneumatic Clamp Carrier: -- Clamp Carrier: (20) Sections with 8-1/2' width cap., (6) heavy duty zinc plated clamps per section (120 clamps total), 44" opening on clamps (other lengths available). -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- For face gluing, Rocking Plates available as optional equipment. -- Equipped with: Panel Flattener with easy to use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation: Push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time! -- Complete with & Includes: Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: 20 Section machine can produce up to (500) panels per shift!

Quick Hydraulic Clamp Carrier with 20-sections and 12-1/2' width capacity.This special "thick stock" frame accepts (12) Heavy Duty zinc plated clamps per section. Includes: -- 240 clamps with 36" openings and 6" high x 4-3/4" wide jaws with 1° inward draft. -- Integral hydraulic overhead panel flattener. -- Automatic hydraulic clamp tightener with adjustable torque limiter. -- Single button automatic electric motor rotation cycle with indexing. -- The machine automatically flattens panels, tightens clamps, rotates, and loosens clamps. -- Heavy Duty frame with 3" diameter shafts and 6" I-beam legs. -- Includes foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating and tool box with spare parts & tools.

QUICK 20 Section 16.5' Heavy Duty Clamp Carrier Specifications: -- 20-Section Thick Stock Pneumatic Clamp Carrier; 16-1/2' width cap.; -- (12) Clamps, each with 3 1/2" high jaws and 44" clamp opening for a total of (240) clamps. -- All clamps are heavy duty type; zinc plated and with 1° inward draftEquipped with: -- Dual operator package with (2) pneumatic overhead panel flatteners, -- (2) Pneumatic clamp tighteners. -- Semi-automatic rotation via electric motor drive and separate buttons for Front Rest Out, Rotate Reverse, Rotate Forward and Front Rest In.Standard features: -- Heavy-duty thick stock frame with 3" dia. shafts and 6" I-beam legs; -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high-quality urethane finish coating, and toolbox with maintenance tools.

QUICK 20-Section Heavy Duty Pneumatic Clamp Carrier with 10-1/2' width capacity -- With (8) Standard zinc plated clamps per section (160 clamps total), 38" opening on clamps.Standard Features include: -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Panel Flattener with easy to use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation 2 HP; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time!Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: A 20-Section Clamp typically produces 500 panels per shift.OAL Dimensions are 163" W x 182" D x 125" H

Quick Heavy Duty Pneumatic Clamp Carrier with 20-sections and 12-1/2' width capacity. -- (8) Heavy Duty zinc plated clamps per section for 10 section, clamp opening 44" -- (10) Heavy Duty zinc plated clamps per section for 10 section, clamp opening 44" -- Includes 180 clamps with 44" openings and 3.5" high x 4-3/4" wide jaws with 1° inward draft. -- Pneumatic overhead panel flattener along with tightener -- Pneumatic panel flattener for second operator -- Semi-Automatic Pneumatic clamp tightener . -- Semi-Automatic panel tightener for second operator -- Single button automatic electric motor rotation cycle with indexing. -- Heavy Duty frame with 3" diameter shafts and 6" I-beam legs. -- Includes foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating and tool box with spare parts & tools.

Call for Price

Quick Pneumatic Clamp Carrier with 20-sections and 12-1/2' width capacity. -- (8) Heavy Duty zinc plated clamps per section with 52" opening. -- Includes 160 clamps with 52" openings and 3.5" high x 4-3/4" wide jaws with 1° inward draft. -- Pneumatic overhead panel flattener riding along with tightener -- Semi-Automatic Pneumatic clamp tightener . -- Single button automatic electric motor rotation cycle with indexing. -- Heavy Duty frame with 3" diameter shafts and 6" I-beam legs. -- Includes foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating and tool box with spare parts & tools.

QUICK 20-Section Pneumatic Clamp Carrier with 10-1/2' width capacity -- With (8) Standard zinc plated clamps per section (160 clamps total), 38" opening on clamps. Standard Features include: -- Clamps jaws are 2-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Panel Flattener with easy to use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time!Complete with: Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: A 20-Section Clamp typically produces 500 panels per shift.

$21,600

QUICKWOOD CD2-300 Moulding & Profile Sander or Denibber;4-Head Brush Loading Sander, 12" width and 4" height cap., for 3-sided sanding & denibbing. Head Configuration: -- (2) "BH300" Overhead rotating abrasive/brush heads, both arbors equipped with a combination of abrasive and brush loadings, 12" long arbors, 12" max. dia. sanding discs. -- 0.75 HP Motor drives each arbor with inverter for 200 - 1,200 RPM arbor rotation speed. -- Right & Left ("BH-140" & "BH-100" respectively) side mounted rotating abrasive/brush heads. -- Tilting heads and adjustable in-and-out, 6" long arbor, 8" dia. sanding discs, 0.5 HP motor each head. -- 0" - 4" Max. manual part height adjustment via hand wheel; 57-1/2" long roller conveyor with PVC covered rollers, variable feed speed 10 - 60 FPM. -- Infeed & outfeed overhead holddown rolls and (1) between the top heads. Includes centralized control panel, hubs, abrasive, & brush. -- Can also be ordered with just (2) top heads or (3) heads, ie. Left or Right. Call for separate prices.

QUINCY - QMT15 ACA, ...Air Compressor (Rotary Screw) w/DryerSpecifications: -- 15 HP - 54.9 CFM @ 125 PSIG; 120-Gallon tank mounted with Refrigerated Dryer & Filters. Equipped with: -- 15 HP TEFC Motor; air-cooled aftercooler; high efficiency inlet filter; upward package air discharge; vibration isolation; Wye-Delta start. -- 54.9 CFM @ 125 PSIG; 69 dBA; 120-gal horizontal tank; refrigerated air dryer.Total operating hours: (29,407).Specifications subject to verification

$23,500

SELCO EB 120 FRONT LOAD, AUTO. PANEL SAW: -- Specifications:173" (4,400 mm) Overall cutting length & 169" (4,300 mm) pull back, 4.8" (122 mm) max. saw blade projection,Main saw blade projection is automatically adjusted according to the stack height selected, ensuring optimum cutting quality. 24 HP (18 kW) main & 3.5 HP (2.6 kW) scoring motor. -- Saw Carriage:Variable saw carriage travel speed from 0 - 427 FPM (0 - 130 MPM), 427 FPM (130 MPM) return speed,Travel speeds obtained by a brushless Servo motor with digital technology ensures a real CNC control without the use of sensors or micros switches. -- Pusher Fence:Electronically controlled overhead program fence, rack & pinion driven, forward speed of 0 - 263 FPM (0 - 80 MPM), return speed of 263 FPM (80 MPM). Equipped with: (7) Self-leveling gripper/clamps (open up to 4.8" / 122 mm), of which (4) are closely spaced in crosscut area and the other (3) are at equal distance in rip cut area.Design of structure and machine logic allow the total ejection of the cut stack of panels beyond the cutting line which facilitates the removal of the trim cuts produced. AC Brushless Servo motor with digital technology under direct monitoring of numerical control drives the pusher fence. -- Operator & Machine Control:Front-end PC controlled with: Color monitor integrated into high-tech look operator control panel (displays cutting dimensions & patterns), virtually unlimited cutting pattern storage capacity.Self-diagnostic, data input by keyboard or possible direct downloading from office PC. -- Machine equipped with:90" (2,300 mm) Long crosscut fence, (2) side/crosscut aligners (automatically positioned & monitored by the numeric control according to the width of the panels to be aligned).(4) Front mounted air float tables with rounded front for moving panel from rip to crosscut position 24" x 79" (609 x 2,000 mm) each;Rear of machine with Modular rollers and (2) longitudinal aligners to accurately position book of panels on rear saw table prior to cutting; partially enclosed with fencing for safety. -- Actual Model is SELCO EB 120L

$21,500

SELCO - EB 70 L, ...CNC Front-Load Horizontal Beam CNC Panel SawSpecifications & Features -- 126" (3,200 mm) Overall cutting length, 2-3/4" cutting height (80 mm saw blade projection); 10 HP main & 3 HP scoring motor. -- Modular roller rear machine table; side aligning device for squaring ripped strips out to 59". -- Variable saw carriage travel speed from: 0 - 164 FPM (0 - 50 MPM). -- Electronically controlled overhead program fence; rack & pinion driven; forward speed of 80 FPM, 131 FPM return speed.Equipped with: -- (6) Clamps (open up to 70 mm - 2-3/4"); (3) are closely spaced in crosscut area & (3) are at equal distance in rip cut area; AC Servo motor drives on both saw carriage & pusher fence. -- PC Controller with: Graphics color monitor & "Assist Line"; LED readout integrated into "high tech" look operator control panel (displays cutting dimensions & patterns), (400) cutting patterns with (50) different dimensions for ea. pattern, self-diagnostic. Machine Features -- 1,500 mm (59") Long crosscut fence (front-to-back); (1) side/crosscut aligner. -- (1) Front mounted air flotation table in the crosscut area (24" x 80"), and (2) front mounted air flotation tables with patented rounded front for moving panel from rip to crosscut position (24" x 59" each). -- 36" Working height; rear of machine partially enclosed for safety.

Call for Price

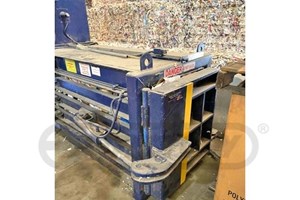

SELCO - HLO-608-A40, ...Wide Mouth Auto-Tie Horizontal BalerSpecifications: -- Bale size: 48"; x 40"; x 72"; -- Main motor: 50 HP -- Cylinder: 8" -- Twister motor: 2 HP -- Cooler motor: 2 HP -- (4) Tension cylinders: 5" BoreAvailable NOW!

SELCO - HLO-608-A40, ...Wide Mouth Auto-Tie Horizontal BalerSpecifications: -- Bale size: 48"; x 40"; x 72"; -- Main motor: 40 HP -- Cylinder: 8" -- Twister motor: 2 HP -- Cooler motor: 2 HP -- (4) Tension cylinders: 5" BoreEquipped with: -- Conveyor controls -- Shear bar (tapered & serrated)Available NOW!

Call for Price

SELCO HSO-128A50 HORIZONTAL AUTO-TIE BALER -- Open end type -- 8" Cylinder -- 50 HP motor -- Infeed opening 36" x 28.5" -- Bale size 30" x 40" x variable -- Bale weight up to 1,200 lbs. (OCC) -- Production capacity 2 to 4.5 tph -- Shear blade -- Hopper size 36" x 28.5" -- Ram face pressure 103 psi -- System pressure 2,400 psi -- Platen force 120,637 lbs -- cycle time 11.5 sec. ( no load)

SELCO - HS0-128A, ...Horizontal Auto-Tie Baler -- Motor: 50 HP -- Cylinder: 8" -- Feed Opening: 36" x 28" -- Conveyor NOT included -- Loaded onto your Truck

Call for Price

SELCO HL50 Horizontal Closed Door BalerSpecifications: -- Large corrugated wide-mouth baler. -- Horizontal closed – door. -- Max amps draw 48 amp – max motor amp 39 amp. -- Max motor HP: 30 HP – 60 hz – 3 phase. -- Bale size: 72″ x 36″ x 48″. -- Feed opening: 50″ x 46″ . -- Main pump @ 800 psi. -- Hydraulic pump capacity: 54 GPM. -- Oil reservoir capacity: 180 Gal. -- Cycle time – 20 Sec. -- Ramface pressure : 68 PSI. -- Baling material weight – 1500 – 1800 Lbs. -- Bale volume – 72 cu.ft. -- Main cylinder: 7″ bore, 62″ stroke. -- Door cylinder: 4″ bore, 12″ stroke.

SELCO HL60-M Horizontal Closed Door BalerSpecifications: -- Full Penetration. -- Motor: 30 HP. -- Cylinder: 8". -- Feed Opening: 60" x 45". -- Shear Blade. -- Bale Size: 48" x 40" x 72". -- Max: 2,100 Lbs OCC. -- Feeding Cleated Motorized Belt Conveyor: 20' L x 36" W. -- Loaded onto your Truck.

Call for Price

SELCO Model HL-12-LH HORIZONTAL BALER With Infeed Conveyor• 20 HP Motor • 6"; Main Cylinder• Hopper Opening: 50";x 28";• Cycle Time (No Load): 15 seconds• System Pressure: 2,000psi•Total Compression Force: 56,556 lbs

Call for Price

SELCO WNT 7/730 REAR LOAD, AUTOMATIC PANEL SAW -- Specifications: 177" (4,500 mm) Overall cutting length, 5" (127 mm) max. saw blade projection, 29 HP (22 KW) main & 3.5 HP (2.6 KW) scoring motor. -- Saw Carriage:Variable saw carriage speed from 0 - 606 FPM (0 - 185 MPM), return speed 600 FPM (185 MPM); Rack & pinion drive, driven by AC brushless Servo motors. -- Pusher Fence:Electronically controlled overhead program fence with (8) pneumatic gripper clamps (open up to 5" / 128 mm).Forward speed of 295 FPM (90 MPM) & return speed of 295 FPM (90 MPM); rack & pinion drive, driven by AC brushless Servo motors. -- Operator & Machine Control:PC front end with Selco "OSI" + WINDOWS "7" operating system with easy programming of very complex cutting patterns.15" Flat screen monitor displays REAL-TIME graphics of cutting dimensions & patterns, program cutting list, manual cuts, diagnostic & on-line help.Data input by industrial keyboard & mouse, floppy disk or CD; direct downloading from office PC is possible.OSI (Open Selco Interface) guarantees fully automatic management of cutting patterns by optimizing all machine movements (pressure beam, saw carriage and side aligner pusher positioning, etc.).The numerical control adjusts the optimum saw blade projection for the stack of panels being cut and sets the most appropriate cutting speed, in relation to the stack itself and, when necessary, to the width of trim cut too. -- Rear Load Lift Table:Automatic lift table 173" x 87" (4,400 x 2,200 mm), 12,000 Lbs (5,455 KG) lift capacity.4 HP (2.3 kW) Motor for raise-and-lower, encoder-controlled guide rods for automatic book height adjustment; 28.7" (730 mm) max book height w/o a pit or risers. -- Rear of machine:(3) Lateral aligners to accurately position book of panels on rear table prior to cutting.Rear modular roller support rails with 80 mm dia rollers; rear of machine enclosed for safety. -- Front of machine:Automatic side/crosscut aligning device located inside the pressure beam aligns the panels against the right angle fence prior to cross-cutting, 2.4" - 87" (60 - 2,200 mm) stroke.90" (2,300 mm) Long crosscut fence (front-to-back); (4) Front mounted air flotation tables with rounded fronts 26" x 81" (650 x 2,050 mm). -- Complete with: "Quick Change" saw blade system; "DIGISET" electronic scoring adjustment; Selco "Quick-Opti" optimizing software; CP link. -- Options Include:173" x 87" (4,400 x 2,200 mm), LH facing, rear in-feed/out-feed conveyors with fork cut-outs that allow for staging/loading/unloading from the Rear LH side of the machine. -- Actual Model is SELCO WNT 7/730/4500.

SEVEIN - 12KVA, operates on 50 - 60 Hz, ...Transformer with Neutral wire (on 400 V side). -- General-purpose enclosed, European made, 12 KVA, 3-Phase ventilated Autotransformer. -- Primary 400 V, Secondary 208 - 220 V, 50 - 60 Hz.