704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

Woodworking

1696 Results Found

704-841-2001

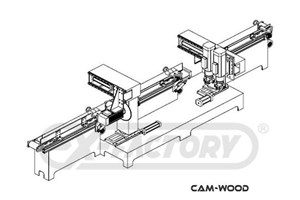

CAM-WOOD MRS-340-1M Dip Chain Gang Ripsaw with one Shifting Blade:Specifications: -- Cutting width up to 13”; machine will pass thru 25-1/2” -- 3” Maximum depth of cut with 12” diameter blades. - Will cut 4” thick with 14” blades (optional). -- With 70 mm saw spindle; accepts 90 mm bore sawblades -- With air-loaded pressure rolls, standard fence, and feed chain. -- Urethane Chain Pads and Pad Holders optional -- With (1) powered moveable blade and fixed blades. -- Moveable blade controlled with a joystick. -- With (10) push buttons for pre-programmed selective ripping -- The shifting blade moves at 20 to 80 mm/second (up to 3” per second). -- Moveable saw blade traverses from 0.59" thru 13.38" -- 50 HP Saw arbor motor; -- 3 HP Feed motor with feed speeds from 15 to 130 FPM -- (2) 1/2 HP Lift motors for pressure rolls and saw arborOptional Equipment when ordered with the machine: -- TRS-FT AUTOMATIC INFEED CONVEYOR SYSTEM, with Movable Fence with Digital Display and Shifting Laser Light for Rip Width Setting: .. -- Hydraulic Quick Lock Spindle Assembly. The hydraulic locking spindle assembly is designed to provide for quick changeover between various ripping requirements. Simply turn the locking knob to pressurize the arbor and lock the blades in position. Turn it in the opposite direction to unlock the blades. The sawblades are mounted to solid steel blade collars: ... -- Additional Quick Set Mechanically-Locked Saw Collars for fast, accurate, sure holding of saw blades in any stationary position ... -- 60 HP Saw Arbor Motor: -- Additional 30 MW Laser Unit with Bracket & Wiring: ... -- Pneumatic Pressure to Hold Down Feed Rollers (In lieu of spring pressure). Provides better control of the product being fed. Each pressure roll is controlled by an individual pressure regulator: .. -- Short stock feeding device for 14” blades (see specifications for cutting capacity information): -- Feed Chain with (69) Easily Replaceable Bolt in Cast Iron Pads. Allows for changing chain pads as they wear or get cut into rather than replacing the complete chain assembly. NOTE: Specially ground down to 0.06” square tip for optimum hold with virtually no marking: ... -- Feed Chain with (69) Easily Replaceable Urethane Non-Marking Strip Inserts. Urethane is vulcanized to metal backing bars and bolted in place: ... -- 12" Dia. carbide tipped ripsaw blades, cuts up to 3" material: ... -- 14" Dia. carbide tipped ripsaw blades, cut's up to 4" material: ...NOTE: Foot Pedal seen in the photo is only used with a powered Infeed Table and is designed to release boards from the Feed Table.

CAM-WOOD XL300/5116 DIP CHAIN GANG RIPSAW12" Width cap.; 5-5/8” max. cutting depth; 14” min. stock length; Designed to meet the exacting standards required for high quality production line use. CAM-WOOD’s Rip Saws are manufactured to precise tolerances, and feature the newest designs for operator safety and volume productionSpecifications: -- Accepts saw blades from 12” to 16” diameter. -- Arbor is 70mm dia. with (2) keyways -- Saw arbor is powered by a 60 HP motor driving the spindle at 3,200 RPM; Soft start starters and low voltage controls are standard equipment. -- Feed chain is powered by a 2 HP motor with variable chain speeds from 8 to 80 FPM; feed chain is 12” wide -- Table is 28” wide x 67” and 12” between the column and the 1st saw blade. -- (2) Integrated 6” dia. dust extraction connections.Complete With: -- (1) 70 mm ID saw sleeve with (2) keyways and the following spacers: (4) 15 mm, (4) 10 mm, (18) 1 mm, (10) 0.5 mm, and (8) 0,25 mm (see drawing after the "literature link). -- Two (2) rows of anti-kickback fingers mounted on the top and one (1) row from the bottom (total 3 rows) provides maximum safety protection. Equipped with: -- Precision fence ensures absolute accuracy between blade & fence, equipped with measuring ruler gauge. -- Power raise and lower to the arbor. -- Heavy-duty industrial motor for powerful cutting capacity. -- Ruggedly constructed cast iron frame for durability usage. -- Variable feed speeds enables the machine to meet different work requirements. -- V-way track and chain block surface are heat-treated for long wear resistance. -- Automatic lubrication to V-Way track facilitates chain longevity smoothness -- Automatic chain lubrication device equipped with an alarm that sends signals upon a lack of lubrication oil. Features: -- Precision built saw head ensures accuracy for straight line rip saw operations. -- Four (4) bearing spindle ensures rigidity & long life. -- Saw arbor is manufactured from NI-Cr-MO alloy steel for durability and anti-fatigue; spindle is heat treated, precision ground and balanced to provide the utmost in precision cutting performance -- Four (4) pressure rollers & two (2) hold-down plates for precise cutting of large and small workpieces. -- Ten (10) groove pulley and V-Belt arrangement ensures maximum motor output, excellent HP delivery to the saw spindle, and guarantees proper power transmission for heavy-duty multiple rip cutting. -- Adjustable guide rollers make cutting straight for slight radials material; they also secure glue joint at short pieces or long stacks.Options when ordered with machine: -- Additional saw sleeves (sleeve only), each, $315 -- Additional saw with spacer set consisting of: -- (2) 50 mm -- (3) 25 mm -- (4) 10 MM, -- (18) 1 MM -- (10) 0.5 MM -- (8) 0.25 MM -- Add per Sleeve with Spacer Set, $685 -- Laser Light with Mounting Bracket, each $980 -- Power raise & lower

CAM-WOOD TRS-3200 SLAT RIPPER - (1) Horizontal Bottom Saw or Moulder Spindle Bottom;The machine can rip extremely narrow parts. Ideal for shutters, louver slats, yardsticks, etc.Features & Equipped with: -- Designed to meet the exacting standards required for high-quality production line use. -- CAM-WOOD’s Slat Rip Saws are manufactured to precise tolerances and feature the newest designs for operator safety and volume production. -- All of these features combine to show what true value these machines are in today’s highly competitive market. -- Precision fence assures absolute accuracy and is equipped with measuring gauge. -- Double anti-kickback fingers mounted at the infeed end of the machine provided maximum safety protection. -- Heavy-duty industrial TEFC motor ensures full-depth cutting capacity in all materials. -- Ruggedly constructed steel frame for durability and extended machine life. -- The variable speed feed works allow the machine to meet the cutting requirements of different materials. -- Saw head built to precise tolerances assures accuracy for all straight-line ripping operations and provides stellar cut quality. -- Top & bottom powered pneumatically tensioned feed rolls for precise feeding and cutting. -- Saw arbor is manufactured from alloy steel for dependability and anti-fatigue, heat-treated, precision ground, and balanced providing precise cutting performance.Specifications: -- 12” Max. Cutting Width. -- 4-3/4” Max. Cutting Depth. -- 10” Min. Workpiece Length. -- 10” to 16” Dia. Sawblade Size. -- 4,000 RPM Spindle Speed. -- 12” Spindle Length -- 70 mm Arbor Diameter (with 2-keyways). -- 30 HP Rip Saw Motor -- 3 HP Feed Motor. -- 12 to 60 FPM Feed Speed (Variable). -- 1 HP Feed Roll Elevating Motor. -- 1/2 HP Saw Arbor Elevating Motor.Footprint: 81" long x 40" wide x 60" high.

CAM-WOOD - XL 300, ...Dip Chain Gang Rip Saw: (...Typically in stock for immediate delivery!)12" Width cap.; 3/8" min. to 4-3/4” max. cutting depth; 14” min. stock length.Specifications: -- 70 mm Dia. saw sleeve (one is included) with (2) keyways and the following spacers: (4) 15 mm, (4) 10 mm, (18) 1 mm, (10) 0.5 mm, and (8) 0.25 mm (see drawing after the "literature link); with 12” usable cutting width. -- Accepts saw blades from 12” - 14” dia.; arbor is powered by a 50 HP motor driving the spindle at 3,200 RPM. -- Feed chain is powered by a 2 HP motor with variable chain speeds from 30 - 100 FPM; feed chain is 12” wide. -- Table: 30” Wide x 62” with 12” between the column and the 1st saw blade. - Integrated 6” dia. dust extraction connection.General Description: -- Designed for high quality Production Line use. CAM-WOOD’s Rip Saws are manufactured to precise tolerances and feature the newest designs for operator safety and volume production. -- Precision fence ensures absolute accuracy between blade & fence; equipped with: Measuring ruler gauge. -- Triple anti-kickback fingers mounted at the infeed side provide max. safety protection; (2) rows from the top and (1) row from the bottom. -- Heavy-Duty industrial motor for powerful cutting capacity. -- Ruggedly constructed cast iron frames for durability usage.Feed System: -- Variable feed speed enables the machines to meet different requirement of work. -- V-way track and chain block surface are heat-treated for long wear resistance. -- Automatic lubrication to V-Way track facilitates chain running smoothly. -- Auto lubrication device is equipped with an alarm that sends signals upon a lack of lubrication oil to increase the durability of the machines. Features & Equipped with: -- Precision built saw head ensures accuracy for straight line rip saw operations. -- (4) Bearing spindle assembly ensures rigidity & long life. -- Power raise & lower to the arbor. -- (4) Pressure rollers & (2) holddown plates for precise cutting of large and small workpieces. -- 10-Piece V-Belt for max. motor power output and guarantees Heavy-Duty multiple rip cutting. -- The saw arbor is manufactured from NI-Cr-MO alloy steel for durability and anti-fatigue, heat treated, precision ground and balanced providing precise cutting performance. -- Adjustable guide rollers make cutting straight or slight radial rip cuts. They also firmly secure lumber to the feed chain for glue joint work on short parts or longer length boards. Options when ordering with machine: -- (1) Set spare feed chain link, please add ...$ 86. -- (1) Set of arbor drive belts consisting of (6) matched belts, add ...$ 600. -- Additional saw sleeve with spacer set consisting of: (2) 50 mm, (3) 25 mm, (4) 10 mm, (18) 1 MM, (10) 0.5 mm, (8) 0.25 mm, Please add... $ 685.

CAM-WOOD MODEL TRS-1200TB SLAT RIPPER - (1) Top & (1) Bottom Rip Spindle.The machine can plane or shape the wood on two surfaces and then rip it. Ideal for shutters, louver slats, yardstick blanks, etc.Features: -- Special profile hold down & groove table for slat ripping, optional -- Designed to meet the exacting standards required for high-quality production line use. -- CAM-WOOD’s Slat Rip Saws are manufactured to precise tolerances and feature the newest designs for operator safety and volume production. -- All of these features combine to show what a true value these machines are in today’s highly competitive market. -- Precision fence assures absolute accuracy between cutterheads & fence and is equipped with a measuring gauge. -- Double anti-kickback fingers mounted at the infeed end of the machine provided maximum safety protection. -- Heavy-duty industrial TEFC motor ensures full-depth cutting capacity in all materials. -- Ruggedly constructed steel frame for durability and extended machine life. -- The variable speed feed works allow the machine to meet the cutting requirements of different materials. -- Saw head built to precise tolerances assures accuracy for all straight-line ripping operations and provides a stellar quality of cut. -- Top & bottom powered pneumatically tensioned feed rolls for precise feeding and cutting. -- Saw arbor is manufactured from alloy steel for dependability and anti-fatigue, heat treated, precision ground, and balanced providing precise cutting performance.SPECIFICATIONS: -- 8” Max. Cutting Width -- 5” Max. Cutting Depth -- 10” Min. Workpiece Length -- 4” to 6” Dia. Top Spindle Sawblade Size -- 8” to 12” Dia. Bottom Spindle Sawblade Size -- 6,000 RPM Top & Bottom Moulder Spindle Speed -- 8” Spindle Length -- 40 mm Rip Saw Arbor Diameter (with key) -- 10 HP Top Rip Saw Motor -- 15 HP Bottom Rip Saw Motor -- 12 to 60 FPM Feeding Speed (Variable) -- 1/2 HP Feed Roll & Top Head Elevating Motor -- 1/2 HP Rip Saw Arbor Elevating Motor -- 3 HP Feed Motor

$92,900

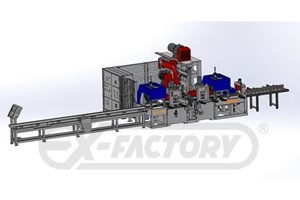

CAM-WOOD CS-650SCC Double End Matcher For Herringbone and Chevron FlooringNC Controlled Trough Feed Type End Matcher for Chevron and Herringbone flooringSpecifications: -- Working Width 1-1/2” to 6” -- Working Thickness 1/2” to 1” -- Working Length 8” to 50” -- Feed Speed 70 FPM with inverter -- Cycle time can be 4 to 8 second per piece1st Saw Station: -- Saw Blade Diameter 10” -- Saw Motor 7-1/2 HP -- Feed Motor 1 HP with Gear Reducer & Inverter. -- Auto Stop & Align2nd Feeding Station: -- Feed Motor 1 HP with Gear Reducer & Inverter. -- Auto Stop & Align3rd Tennon Station: -- High Frequency HSD Routers with HSK63 Spindle, 11 kW (15 HP) x 2 units -- Forward and Reversed Direction at each spindle. -- Feed Motor 1 HP with Gear Reducer & Inverter. -- Auto Stop & AlignFeatures: -- Special Design CHEVRON & HERRINGBONE Double End Tenoner -- Servo control for 45° and 90° cutting. -- The automatic high-speed through feed device allows for perfect finishing at speeds ranging from 45 ~ 70 FPM by inverter -- Suitable for mass production of woodworking factory for processing of double-end cutting, tenoning, grooving, moulding, and sanding. -- Scoring Saw, Trim Saw, Jump Coping shaper, and Coping Shaper: Total 4 stations at each side. -- HMI plus PLC controller for easy setting and operation. -- It is a powerful machine great for heavy-duty production. -- In addition to the double-end cutting, all the settings and other processing can also be executed with high accuracy. -- The specially designed numeric controller allows quick setting of sizes for tolerance within 0.004”. -- Variable speed, through feed, wide rubber pad, spring-loaded dogs conveyor for the best finish selections. -- Heavy-duty pressure rolls at top of a wide conveyor to hold the material tight to prevent sliding during the cutting process. -- Shaper heads can be adjusted to move up & down, forward & backward. -- Features industrial motors for full power cutting capacity.Optional equipment: -- Total sound enclosure add: ...$ 7,900 -- Infeed magazine add ...$ 4,900

CAM-WOOD SET-49DET CKX Double End Tenoner for Click SystemFeatures: -- (9) Heads total as Scoring, Trim Saw, Jump shaper X 3, plus free space -- Configured for click lock System application -- Special design for Click Lock System project with 31” extra Outfeed Conveyor Space. -- HMI / Touch Screen Plus PLC controller for easy and quick setting -- The automatic high-speed through feed device allows for perfect finishing at speeds ranging from 20 ~ 76 FPM. -- Suitable for mass production processing of double-end cutting, tenoning, grooving, moulding, and sanding. -- Powerful machine great for heavy-duty production. • In addition to the double-end cutting, all other settings and processes can also be executed with high accuracy. -- Since the machine is so versatile, we believe it should be one of the highest pay-back investments for lumber-processing factories' with volume production. -- The specially designed numeric controller allows quick setting of sizes, for tolerance within 0.004”. -- Variable speed through feed, wide rubber pad, and spring-loaded dogs conveyor for the best finish selections. -- Heavy-duty powered pressure rolls at top of wide-width conveyor to hold the material tight to prevent sliding during the cutting process. -- Equipped with industrial motor for full power cutting and sanding capacity. -- Trim saw heads can be tilted for different angular setups. -- Heavy cast iron base for durability and heavy-duty usage.Specifications: -- Maximum working thickness 2 1/4" -- Maximum working length 50" (optional for 96") -- Minimum working length: 9" -- (2) Scoring Saw motors, 7.5 HP each -- (2) Trim/hogging saw, motors 7.5 HP each -- (5) Shaper motors with jump servo controlled, 7.5 HP rotation 6,200 RPM, arbor 40 mm dia., spindle tilting 0 - 90° -- Feed speed 20 to 72 FPM, servo drive motor 7.5 HP -- Motorized opening with 1 HP motor -- Control with color touchscreenAvailable option: -- SET-2TRAN two-stage transfer line Additional: ...$86,900 -- Hopper feed magazine additional ...$86,900 -- Sound enclosure additional ...$14,900 -- Infeed extension 48" additional ...$12,600

$259,900

CAM-WOOD SET-88-DET CKX Double End Tenoner for "Click System"Features: -- (9) Heads total as Scoring, Trim Saw, Jump Shaper X 5, and Free Space -- Configured for click-lock System application -- Special design for Click Lock System project with 31” extra Outfeed Conveyor Space. -- HMI / Touch Screen Plus PLC controller for easy and quick setting -- The automatic high-speed through feed device allows for perfect finishing at speeds ranging from 20~76 FPM. -- Suitable for mass production of woodworking factory for processing of double-end cutting, tenoning, grooving, moulding, and sanding. -- It is a powerful machine great for heavy-duty production. • In addition to the double-end cutting, all the settings and other processing can also be executed with high accuracy. -- Since the machine is so versatile, we believe it should be one of the most satisfactory equipment for volume production lumber-processing factories. -- The specially designed numeric controller allows quick setting of sizes, for tolerance within 0.004”. -- Variable speed, through feed, wide rubber pad, and feed chain with spring-loaded dogs for the best finish selections. -- Heavy-duty powered pressure rolls at the top of the wide-width conveyor to hold the material tight to prevent sliding during the cutting process. -- Equipped with industrial motor for full power cutting and sanding capacity. -- Trim saw heads can be tilted for different angular setups. -- Heavy cast iron base for durability usage.Specifications: -- Maximum working thickness 2-1/4" -- Maximum working length 98" -- Minimum working length: 9" -- (2) Scoring Saw motors, 7.5 HP each -- (2) Trim/hogging saw, motors 7.5 HP each -- (5) Shaper motor with jump servo-controlled 7.5 HP at 6,200 RPM, arbor 40 mm diameter, spindle tilting 0 - 90° -- the (2) shaper head on the 4th station will have a special motor with 90-degree spindles for the toe notch -- Feed speed 20 to 72 FPM, servo drive motor 7.5 HP -- Motorized opening with 1 HP motor -- Control with a color touchscreenAvailable options: -- SET-2TRAN two-stage transfer line Additional: ...$86,900 -- Hopper feed magazine additional ...$86,900 -- Sound enclosure additional ...$14,900 -- Infeed extension 48" additional ...$12,600

$18,750

CAM-WOOD - SET-5SA, ...Double End Trim Saw (Tenoner) Capacity: -- Length of cut: 12" to 60". -- Max. width of cut: 24". -- Max. clamping thickness: 4-1/2". -- Saw blade dia.: 8" to 12"; saw arbor dia.: 1"; saw blade speed: 3,400 RPM; saw head swivels: 360°. -- Moulder (Shaper) Spindle: 1" Dia. x 5" long; spindle speed of 6,000 RPM; spindle swivels: 360°. -- Vertical travel: 17". -- Carriage cross travel: 24".Equipped with: -- Saw motors: (2) Each, 3 HP motors. -- Moulder spindles: (2) Each, 3 HP motors. -- Outfeed Conveyor drive: 1 HP Motor. -- Powered length setting: 0.5 HP.Features: -- With the Double End Miter Saw setup, you can cut off stock faster or consider it a Double End Miter Saw combined with moulding head. It cuts off stock & moulding pattern in a single feed that saves time, space, and cost. -- Air-operated Clamp comes down holding sticks firmly in place. After workpiece is clamped, the table starts to feed, perform trims, and shape operations. -- Trim Saw allows cutting stock accurately with a clean-cut. -- Moulding (Shaper) spindle mounted at the rear of saw head enables the machine to perform edge moulding after stock is cut off. -- The entire cutting cycle, cut off, shaping/tenon or mortise is automatically operated at single pass of stock feeding. -- The table travels on a precision linear motion guide for stability. -- The table traverse is driven by power system, ensuring very stable, smooth workpiece feeding. -- Variable feed speed permits proper feed selection for hardwood or softwood materials. -- Big hand wheel adjusts depth of cut. -- All controls are grouped in a Control Panel. -- Industrial motors for optimal cutting results. -- Material transport through machine powered by variable speed inverter drive for (10 - 20) Sec/cycle. Machine Stations: -- 1: Trim Saws powered by: (2) 3 HP Saw arbor motors for trimming to length. -- 2: Shaper Spindles powered by: (2) 3 HP Spindle motors for applying tenons & grooves. -- Floor space requirement: 94" x 40" x 54" high. -- Cycle time: (10 - 20) Sec/Cy.Options Included: -- Auto. Outfeed device. -- CSA Electrics.

CAM-WOOD Continuous in-line Long Board Vertical Finger Joint System, Model "UCT-200"Up to 200 mm (7.87") Wide x 75 mm (2.95")4-1/4" Thick x Unlimited Assembled Length System Specifications: -- Incoming board lengths from 39” to 236" (1,000 mm - 6,0000 mm). -- Board widths from 2” to 7.87” (50 mm - 200 mm). -- Board thickness from 1" to 2.95” (25 mm - 75 MM). -- Board out-feed length unlimited (Conveyor to be quoted separately) -- Glue type to be used: PVAC. with Standard pneumatic pump and spreader included ( For different glue then PVAC Glue pump and applicator not included) -- Board species: SOFTWOOD and HARDWOOD. -- Board moisture content: 8% to 12%. -- Infeed board qualities: Lumber runs best on Finger Jointers when surfaced on (4) sides (S4S) (Tolerance +/- .2 mm (.008"). System prefers straight boards with 90-degree corners. UCT-305 Mechanical Specifications: -- Top infeed feed rolls powered with (2) 2HP motors. -- Bottom infeed feed rolls powered with (2) 2 HP motors. -- In-feed Inverter with (2) 7.5 HP motors. -- Auxiliary conveyor wheel with 2.6 HP servo motor. -- Top Shaper Spindle powered with a 30 HP motor. -- Bottom Shaper Spindle powered with a 30 HP motor. -- Maximum Cutterhead length, 12“(305 mm). -- Maximum Cutterhead diameter, 6.3“(160 mm). -- Typical cutter pitch, 4.0 mm. Length, 10 mm - 12 mm (Other sizes available). -- Shaper spindle moving power by 2.6 HP Servo Motor. -- In-feed speed from 32 to 295 FPM (10 ~90 m/Min). -- Outfeed cut-off saw motor, 10 HP. -- Cut-off sawblade, 24“ dia x 120 teeth (included). -- Cut-off sawblade speed, 2,850 RPM. -- Hydraulic pump power, 30 HP. -- Top outfeed feed rolls powered with (2) 2 HP motors. -- Lower outfeed feed rolls powered with (2) 2HP motors. -- Out-feed Inverter with (2) 7.5 HP motors. -- Glue injection Glue Applicator for Standard PVAC glue. -- Hydraulic oil tank with 150-gal capacity (oil not included)Outfeed options: -- Outfeed roller conveyor 20'' X 8' long Additional: $ 4,890 per sectionNot included with the machine: -- Cutter heads for finger jointer (we can provide quote) -- Gluing system with pump and nozzle if different then PVAC glue Optional Cross Infeed Conveyor System: -- 8’ X 19’ Lateral Long Infeed Conveyor System To Meet Production Requirement. -- Working size accepts inbound boards from 39"40” to 236" long x 2” to 12” wide x 1” to 4-1/4” thick. -- Cross feed system 3 HP drive motor. -- Feed speed 48.75 FPM. (15M/Min) -- 8’ (2,500 mm) Buffer Chains.Additional: $28,990NOTE: Training, installation & tooling not included TO BE PROVIDED LOCALLY -- Electric power supply to Motor Control Center -- Constant voltage (voltage deviations max.: 5%) -- Temperature range for computer control should not exceed 95°F. -- 65% Maximum relative air humidity for computer control system --Dust exhaust system: (V=30M/S at a low pressure of 12M BAR) --Compressed air connection to machinery:

CAM-WOOD AC-7580 Piston Air CompressorCompact unit with a 7.5 HP induction motor.Features & Specifications: -- 22 CFM @ 90 PSI, Splash lubricated cast iron 2-stage pump. -- Automatic start/stop operation. -- 80-Gal. vertical tank that meets ASME standards. -- Manual tank drain & pressure gauge. -- Deep finned after-cooler. -- Fully enclosed belt guard and ON/OFF pressure switch. -- Deep finned cylinder head for cooling and replaceable air filter/silencer. -- Durable painted finish for years of service under the worst conditions.

CAM-WOOD AC-5080 Piston Air CompressorCompact unit with a 5 HP induction motor.Features & Specifications: -- 18 CFM @ 90 PSI, Splash lubricated cast iron 2-stage pump. -- Automatic start/stop operation. -- 80-Gal. vertical tank that meets the ASME standards. -- Manual tank drain & pressure gauge. -- Deep finned after-cooler. -- Fully enclosed belt guard and ON/OFF pressure switch. -- Deep finned cylinder head for cooling and replaceable air filter/silencer. -- Durable painted finish for years of service under the worst conditions.

CAM-WOOD AC-100120 Piston Air CompressorHeavy Duty unit with a 10 HP induction motor.Features & Specifications: -- 34.2 CFM @ 90 PSI, Splash lubricated cast iron 2-stage pump. -- Automatic start/stop operation. -- 120-Gal. horizontal tank that meets the ASME standards. -- Manual tank drain & pressure gauge. -- Deep finned after-cooler. -- Fully enclosed belt guard and ON/OFF pressure switch. -- Deep finned cylinder head for cooling and replaceable air filter/silencer. -- Durable painted finish for years of service under the worst conditions.

CAM-WOOD DC-102 Dust CollectorSmall radial-finned Dust Collector mounted on wheels for portability.Features & Specifications: -- Large 13-1/2" fan that produces 2,100 CFM. -- Heavy Duty 3 HP motor pre-wired at 230 Volts. -- Large capacity dual station cloth top bags of 31.2 sq. ft. total cloth filter area. -- Low sound level of 75 - 90 dB.

CAM-WOOD DC-8075 Dust Collector Radial-finned type impeller for the best efficiency with large 15-3/4" dia. fan that produces 5,800 CFM.Includes: -- Heavy Duty 7.5 HP motor pre-wired at 220 V. -- (4) Large top filter bags and (4) lower collection bags with 48 cu. ft.capacity. -- Standard steel spring clamps to secure bags without leakage.Features: -- Low sound level of 75 - 90 db. keeps the work area quiet. -- Optional connection for using barrels.

Call for Price

CAM-WOOD IAT 620-150H INVERTER DRIVEN FINGER JOINT SYSTEM 3" X 6":Lay-Up and Block-Staging Infeed Conveyor: -- 24" Wide x 31.5" long belt conveyor powered with 1/2 HP motors. Conveyor is controlled by the operating and system. Feeds at a constant rate of 180 FPM. Block delivery is controlled by the operator and machine system criteria to feed the Shaper. The conveyor facilitates keeping the system full and productive. FSR-62I Right Hand Inverter Type Finger Joint Shaper: -- Feed table is 24" wide and accepts blocks from 6" wide x up to 31.5" long x 5/8" to 6" wide. Shaper spindle is driven by a 20 HP motor and is equipped with provisions for vertical adjustment of 20 mm up and 20 mm down. Spindle diameter is 50 mm and runs at 6,600 RPM. 8-1/4” maximum shaper cutterhead diameter - without knives. 10 HP - 4,800 RPM Cutoff and trim saw; accepts 10" dia. x 100 tooth x 5 mm blades. 2 HP - 2,850 RPM Scoring saw, accepts 7" dia. x 50 tooth x 5 mm blades. Table movement is Inverter driven; powered by a 3 HP + 3 HP inverter motor with cycle speeds from 1 to 4 cycles/Min. Motor senses load and varies travel speed as needed. Speed is also controlled by system criteria STC-62A Single Table Transfer Conveyor to the 2nd (Left Hand) Shaper: -- 24" Wide x 31.5" long belt conveyor. Powered with (1) 1/2 HP motor. Controlled by system criteria. Feeds at a constant rate of 180 FPM. FSL-62I Left Hand Inverter Type Finger Joint Shaper with Glue Extruder: -- Feed table is 24" wide and accepts blocks from 6" up to 31.5" long x 5/8" to 6" wide. Shaper spindle is driven by a 20 HP motor. Spindle diameter is 50 mm and runs at 6,600 RPM. 8-1/4" maximum shaper cutterhead diameter - without knives. 10 HP - 4,800 RPM Cutoff and trim saw; accepts 10" dia. x 100 tooth x 5 mm blades. 2 HP motor powers a top and a 2nd 2 HP motor powers a bottom scoring saw, both running at 2,850 RPM; accepts 7" dia. x 50 tooth x 5 mm blades. Conveyer powered by 1/2 HP motor. Table movement is Inverter driven; powered by a 3 HP + 3 HP inverter motor with cycle speeds from 1 to 4 cycles/Min. Motor senses load and varies travel speed as needed. Speed is also controlled by system criteria Injection Type Glue Applicator: -- Extrudes adhesive into the fingers without the messy runoff associated with glue rollers. 6" Comb height is standard. Finger pitch 4 mm, 10 - 12 mm finger length is standard equipment (special sizes available as optional equipment) STC-62A Single Table Conveyor Belt to the Assembly Section: -- 24" Wide x 31.5" long belt conveyor. Powered with (1) 1/2 HP motor. Controlled by system criteria. Feeding at a constant rate of 180 FPM. FJ-500A (198") Assembly Press with Cut-Off Saw: -- Capacity from 1" to 6” wide x 1/2" to 3" high x and from 6' to 16-1/2' long. A 2 HP motor powers the upper and a 2nd 2 HP motor powers lower pre-assembly/crowder rolls. With 5 HP infeed inverter drive. In-feed speed from 30 to 230 FPM. Speed is controlled by system criteria. 5

CAM-WOOD FSM-460AX Finger Joint ShaperSingle Finger joint Shaper with 8" min. and unlimited max. block length; 4" max. block thickness, maximum timber height to feed into assembly press is 3"; 18" max. block width (horizontal joint only); 18" table working width.Equipped with: -- Shaper spindle powered by 10 HP belt drive motor with 50 mm dia. spindle turning at 5,500 RPM; 160 mm (6.3") max. dia. cutter. -- Trim-saw powered by 5 HP direct drive motor at 2,850 RPM and a 1" dia. saw spindle; swings 180 mm (7") max. blade dia. -- Table cycles 2 to 4 per Min via the hydraulic system with a 2 HP hydraulic power unit. Includes 5" dia. dust outlet.Features: -- Manual Fingerjointer performs end trimming and shaping functions on right and left end of blocks. -- Air-operated clamp holding blocks firmly in place. After the workpiece is clamped, the table feeds past the saw and shaper spindles to perform trimming and finger-joint operations; trim saw cuts blocks exactly 90° ends. -- Shaper spindle is precision-constructed for cutting fingers accurately; swings up to 6" dia. tooling. -- Spindle height adjustment is displayed on the dial readout for easy adjustment. -- Table travels on a precision linear guide for stability; table traverse driven by hydraulic power system smooth and accurate block feeding. -- Variable feed speed permits proper feed for hard or soft wood. -- Cast iron frame and table for durability.

CAM-WOOD MODEL FSG-150 Manual FINGER JOINT GLUE APPLICATOR -- Manual operation of sliding table ; Specification: -- Glue roller type -- Working width 24" maximum -- Working thickness 6" -- Glue roller drive 1/2 HP with reducer -- Standard clus height 4"

CAM-WOOD UTC 305 Servo Compound Finger Jointer SystemCONTINUOUS IN-LINE LONG BOARD VERTICAL FINGER JOINT SYSTEM MODEL "UCT-305"Up to 12" Wide X 4-1/4" Thickness X 85' Assembled Length SYSTEM SPECIFICATIONS: -- Incoming board lengths from 1,500 mm to 6,100 mm (55" to 240") --Board widths from 2" to 12"; (50 mm ~ 305 mm) --Board thickness from 1" to 4.3" (25 mm ~ 110 mm) --Board out-feed length 26,000 mm or unlimited (85' or unlimited) --Glue type to be used: PVAC --Board species: SOFTWOOD and HARDWOOD --Board moisture content: 8% to 12% --Infeed board qualities: Lumber runs best on Finger Jointers when surfaced on (4) sides (S4S) (Tolerance +/- .2 mm (1/16"). The system prefers straight boards with 90°corners. UCT-305. MECHANICAL SPECIFICATIONS: --Top infeed feed rolls powered with (2) 3 HP motors --Bottom infeed feed rolls powered with (2) 3 HP motors --In-feed Inverter with (2) 7.5 HP motors --Auxiliary conveyor wheel with 3 HP servo motor --Top Shaper Spindle powered with a 30 HP motor --Bottom Shaper Spindle powered with a 30 HP motor --Maximum Cutterhead length, 12“ (305 mm) --Maximum Cutterhead diameter, 6.3“ (160 mm) --Typical cutter pitch, 4.0 mm. Length, 10 mm - 12 mm (Other sizes available) --Shaper spindle adjustment power by 3 HP Servo Motor --In-feed speed from 32 to 295 FPM (10 ~90 m/Min) --Outfeed cut-off saw motor, 10 HP --Cut-off sawblade, 24“ dia x 120 teeth (included) --Cut-off sawblade speed, 2,850 RPM --Hydraulic pump power, 30 HP --Outfeed conveyor, (2) 2 HP drives --Top outfeed feed rolls powered with (2) 2 HP motors --Lower outfeed feed rolls powered with (2) 2HP motors --Out-feed Inverter with (2) 7.5 HP motors --With injection Glue Applicator for PVAC glue --Hydraulic oil tank with 150 gal capacity (oil not included)HIGH-SPEED INFEED: --10'; X 19' Lateral Long Infeed Conveyor System To Meet Production Requirement --Working size: accepts inbound boards from 55" to 20' long x 2" to 12"wide x 1" to 4-1/4" thick --Cross-feed system 3 HP drive motor --Feed speed 10 to 90 Meter/min -- 8' (2,500 mm) Buffer Chains85' OUTFEED: --12" Wide X 85' Long Non-Powered Outfeed Conveyor, heavy-duty (unloading conveyor to be determined)Capacity of the Shaper (90 mm X 90 mm X 6000 mm long) -- (7) TIMES/Min -- X 6000 mm Average Infeed Length = 42 M/Min -- X 480 Min / 8 Hrs Shift -- X 0.8 RATE OF UTILIZATION =16128 M /SHIFT=130.63 M³/ 8 HOURS SHIFT (52,416 BF/shift)NOTE: Training, installation & tooling not included -- Operator training is available at $850 a day plus travel expenses. Expect (5)days in plant.Option: -- Tilt hoist for feedingTo be provided locally: --Electric power supply to Motor Control Center --Constant voltage (voltage deviations max.: 5%) --Temperature range for computer control should not exceed 95°F --65% Maximum relative air humidity for the computer control system --Dust exhaust system: (V=30M/S at a low pressure of 12M BAR) --Compressed air connection to machinery: 7~8 kG/cm² – 8 BAR --Elec

CAM-WOOD TYPE F1, MODEL FAH 8" X 30’ HORIZONTAL FULLY AUTOMATIC FINGER JOINT SYSTEM - SINGLE CHAIN TYPEMECHANICAL SPECIFICATIONS FOR THE FEED SYSTEM: -- Operating speed: 120 to 150 lugs/Min -- Intermittent feed motor: 2 HP + 1:25 -- Feed chain motor: 30 HP (20 kW) Servo Drive (C2) MECHANICAL SPECIFICATIONS: RIGHT-SIDE SHAPER: -- Cutterhead Motor: 25 HP -- Spindle size: 2-3/4” (70 mm) -- Maximum cutter head body diameter: 10” -- Cutterhead speed: 5,500 RPM at 60 Hz -- Trim Saw Motor: 15 HP -- Trim Saw blade size: 12” (305mm) x 80 Tooth x 5mm kerf -- Cut-off saw Speed: 4,300 RPM -- Scoring saw motor: 3 HP -- Scoring saw blade: 7” (180mm) x 50 Tooth x 5mm -- Scoring saw spindle speed: 4,200 RPM -- Holddown rise and lower motor: 1/2 HP (C3) MECHANICAL SPECIFICATIONS: LEFT-SIDE SHAPER: -- Cutterhead Motor: 25 HP -- Spindle size: 2-3/4” (70 mm) -- Maximum cutter head body diameter: 10” -- Cutterhead speed: 5,500 RPM at 60Hz -- Trim Saw Motor: 15 HP -- Trim Saw blade size: 12” (305 mm) x 80 Tooth x 5 mm kerf -- Cut-off saw Speed: 4,300 RPM -- Scoring saw motor: 3HP -- Scoring saw blade: 7” (180 mm) x 50 Tooth x 5 mm -- Scoring saw spindle speed: 4,200 RPM -- Holddown rise and lower motor: 1/2 HP -- Glue Application by GLUE COMB -- Standard glue height: 6” High, 3.8 mm pitch 3.8 mm. Finger lengths from 10 to 12 mm (Other lengths available) (K) MECHANICAL SPECIFICATIONS: SHAPER OUT-FEED: -- Speed: 230 FPM -- Feed Motor: (1) 3 HP -- Vacuum device blower with 3” Vacuum port: 5 HP (G) MECHANICAL SPECIFICATIONS: PRE-JOINT ASSEMBLY: --Feed chain drive: (2) 3 HP motors --In-feed Inverter: (1) 7-1/2 HP --Chain type: Flat top double chain --Feeding speeds from 30 to 300 FPM (H) MECHANICAL SPECIFICATIONS: 30’ (9.3M) ASSEMBLY PRESS: --Working dimension: 1” to 8” wide x 0.60” to 2 3/8” high x up to 30’ long --Upper & lower roll power: (2) 2 HP motors --In-feed Inverter: 7-1/2 HP --In-feed speed: 30 to 300 FPM --PROGRAMMABLE Cut-off saw power: 5 HP --Cut-off Blade dimensions: 14” Dia. x 120 Tooth x 1” bore --Cut-off saw speed: 2,850 RPM --Hydraulic power: 5 HP (With high speed oil tank) --Cycle Speed: 1 to 8 Cy/MinPRODUCTION CAPACITY - PARAMETERS: -- Based on a 480-minute shift -- Finger length to customer’s specifications -- Average infeed length at the shaper section is 20” --A verage block cross section is 2” x 4” -- Chain speed at the Shaper sections is 150 lugs/Min -- Press capacity is (8) 30’ loads per minute (maximum) CAPACITY OF THE SHAPERS WHEN FINGER JOINTING 2” X 4” x 20" BLOCKS -- (120) Blocks per minute -- x 20” Average infeed length -- x 480 Minutes per shift -- x 0.8 Rate of utilization = 76,800 lineal feet per shift CAPACITY OF THE PRESS ASSEMBLING 30’ LENGTHS: -- (8) Assembled lengths per minute -- x 20’ Per minute -- x 480 Minutes per shift -- x 0.8