704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

2069 Results Found

704-841-2001

$1,500

For pre-glued PVC, veneer, & melamine laminate coil stock; 0.4 - 1.2 mm edge thickness; up to 35 mm panel thickness cap., automatic coil feed. -- Equipped with: Electronically controlled temperature setting for hot air blower; 3,000 Watts for up to 650° F temperature; (1) Min heat up time. -- Guillotine type front & rear end trim (with fast speed, flying knife); top & bottom flush trims with single motor drive to cutterheads. -- Overhead belt type feeder; 16 FPM feed speed. -- Mounted on machine base with panel support table.

VITAP ALFA - 27: Construction/Line Borer27-Spindle boring head on 32 mm centers; drills vertically from bottom-up and head rotates to horizontal position for edge boring; head rotation is pneumatic with switch control. -- 2-3/4" Max. drilling depth; 2-1/2 HP - 2,800 RPM motor; pneumatic drill head advance with speed control; head height adjustment with mechanical digital readout; 34" x 20" table size; max. workpiece width 31-1/2". -- Equipped with: Left- & right-side fences for construction boring; (2) pneumatic holddown clamps; 118" line boring fence w/flip stops; pneumatic foot pedal control; magnetic starter; overload protection.

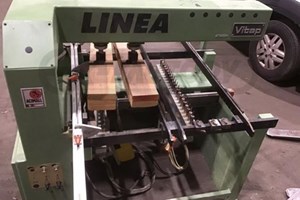

VITAP LINEA 42 Line Boring SystemSpecifications: -- (2) Drill heads of (21) spindles ea., drills from bottom up, ea. support with 2 HP motor and (21) spindle boring block w/panel support mounted on top; -- Drills panels from 100 - 3,000 mm in length, and 100 - 950 mm in width. Complete with: -- Digital readouts for boring blocks, 2,000 mm bar scale fence with (5) adjustable flip stops. -- (2) Moveable overhead pneumatic holddown cylinders, foot pedal for clamping & boring cycle.

$4,500

VITAP RC 92 Semi-Automatic Top & Bottom Edge Trimmer, New, Never Used!Specifications: -- For straight & curved edge banded panels. -- Max. edge thickness 3 mm (0.12"). -- Panel thickness 10 - 60 mm (0.39" - 2.36"). -- Table size 27" x 31".Equipped with: -- (2) 0.55 kW (0.7 HP) - 12,000 RPM Spindle motors. -- Large dia. guide bearings to ensure precise trimming of edges.NOTE: Sold "As Is" without Warranty!

$41,500

VITAP BLITZ CNC BORE, GLUE & DOWEL INSERTER: -- Specifications:(1) CNC Controlled head assembly with rapid (side-to-side) traverse, assembly with boring, gluing & insertion unit, This Flexible machine is IDEAL for JIT or high production runs. -- Working Area:Useable working area "X" axis 36.2" (920 mm), "Y" axis 3.14" (80 mm), "Z" axis up to 1.57" (40 mm) material thickness with digital readouts -- BG & D Unit(1) 1 HP - 6,000 RPM horizontal drill motor; 0.47" (12 mm) Maximum drill bit dia. (1) Glue injector & (1) dowel Inserter with 1.57" (40 mm) Max. dowel lengthMachine is capable of processing dowel diameters from 6 mm dia x 25 mm long - 10 mm dia x 40 mm long dowels (currently setup for 8 mm dia dowels); -- Operator & Machine Control:CNC "Color Touch-Screen" Controller for function & simple part programming and program storage. -- Complete with: (1) 12" Dia. vibratory feed hopper, totally sealed electronically metered glue system with "Automatic" injector flushing; (1) 4.75 G (18 L) Glue tank & (1) 2.37 G (9 L) water tank;(4) Inclined vertical pneumatic hold-down clamps; Function selector control for boring only or doweling; Anti-slip table surface, Rack & pinion drive and centralized dust collection manifold.

Call for Price

VITAP - POINT K2 2.0 : CNC Machining Center (w/ATC/Boring) + Includes: "VITAP Bar Nesting System." -- SpecificationsVITAP - K2 2.0 CNC Center is the best and most technically advanced machine for wood processing. The K2 has a patented "Double Dynamic Transport (DDT)" System with: Double clamp technology that creates smooth panel movement.With an automatic tool changer and modern software, the programming for this machine is easy and efficient to use. This machine is perfect for companies of all sizes and is the optimal choice for your CNC woodworking needs. -- Working FieldMax. panel size "X" Axis infinite; "Y" axis 49.2" (1,250 mm); "Z" axis 1.97" (50 mm).Min. panel size "X" axis 10" (270 mm); "Y" axis 5.9" (150 mm); "Z" axis 0.1" (3 mm). -- Positioning Speed"U" Axis Panel feeding speed 82 FPM (25 MPM); "X" & "Y" axes 197 FPM (60 MPM); "Z" axis 49 FPM (16 MPM).Axes positioning by AC drives & brushless motors; the "Panel" moves in "X" axis & the "Machining Units" move in "Y & Z" axis.Max. Panel weight is 176 Lbs (80 kG). -- Work Area: Vitap "DDT" + "Vitap Bar Nesting System":DDT is short for "Double Dynamic Transport", a clamping system for work pieces on CNC Machining Centers, for moving the workpiece in "X" axis.The function of the DDT system consists of: (2) Gripper/clamps that move the workpiece in the same or alternate direction. This allows for a significantly longer travel distance of the workpiece compared to the travel distance of the gripper/clamps. DDT System is a requirement for Bar Nesting."VITAP Bar Nesting" is a special form of combining a Beam Saw & Nesting at the same CNC Machining Center. VITAP Bar Nesting is also designed to combine the advantages of nesting technology with the possibility of horizontal drilling.VITAP Bar Nesting is a technology that has been specially developed for VITAP Machining Centers. The prerequisite is a machine in which the X-axis is generated through the movement of the workpieces. A further prerequisite is the presence of (2) grippers for workpiece movement, known at VITAP as "DDT-System".Bar Nesting is not a complete nesting of the workpieces, as the large-sized (Ripped) panels must still be crosscut into stripes on a Saw.NC Controlled "Optical Material Sensor" creates a: “0“ Panel reference point by reading the panel's ends; this ensures that RH & LH (mirror image) panels will always be symmetrical.Fixed RH ("U" axis) panel clamping device with: Automatic panel adjustment according to the programmed information; LH side pressure clamp with automatic adjustment & pneumatic locking according to the panel width; scratch resistant idle rollers for panel positioning from the bottom & sides. -- Boring Unit (1) 2.2 HP (1.7 kW) - 3,600 RPM motor; (12) independent vertical spindles on 32 mm centers with: 6-Spindles in "X" axis & 6-spindles in "Y" axis.(8) Horizontal Spindles with: (2 + 2) spindles in "X" axis & (2 + 2) spindles in "Y" axis.(1) "X" Axis grooving saw: 7,000 RPM with 100 mm m

VITAP - 27-Spindle, ...Boring MachineSpecifications: 27-Spindle boring head: On 32 mm centers; drills vertically from bottom up, and head rotates to horizontal position for edge boring; head rotation is pneumatic with switch control. -- 2.5 HP - 2,800 RPM Motor; pneumatic drill head advance with speed control; head height adjustment with mechanical digital readout; 14" x 42" table size.Equipped with: (4) Pneumatic holddown clamps; 118" line boring fence with: (4) Flip stops; pneumatic foot pedal control.

$46,900

VALPATO LBK-150-ST 1 Feed Through Profile SanderTECHNICAL FEATURES: An added small needle type drum sander can be fitted with drum sanding aggregates of 25, ­30, ­35,­40, ­45 ­50 mm diameters which can be used for tighter curves and smaller radius sanding requirements. Storage compartments (2 in total) are located on each machine extremities, these are easily accessible and can be used for sanding belts and various tooling storage. Sanding belt motor power: 3 Kw Abrasive head motor power: 1.5 Kw Oscillation motor power: 0.38 Kw Feed motor power: 0.75 Kw Motor power for electrical adjustment of sanding group: 0.19 Kw Machine voltage: 480/3/60 Full Load Amps @ 480V: 15A Compressed air: Not required Dust collection requirement one (1) only 6" (150mm) port: 950 CFM Sanding belt speed: 14 Mt/sec Variable speed of the belt: from 5 to 25 m/min Sanding belt dimensions: 150 x 2640 mm Height of working table: 930 mm Dimensions of front working table: 1980 x 250 mm Machine dimensions: 2500 x 900 x 1600 mm Net weight: 1000 KMAIN FEATURES: User friendly PLC touch screen control panel is accessible from 360° by the operator, the control panel is centrally located on the infeed end of the machine. Factory installed variable feed drive (VFD), enables machine to run from 5 M/Min to 25M/min (+/­ 80 ft/Min). The entire sanding plenum rise and fall is motorized, it can be adjusted vertically in height to utilise the full height/width of the sanding belt. An oiling unit ensure long life of sanding plenum rise and fall master cylinder.

Call for Price

Volvo L90H Wheel LoaderSpecifications: Static tipping load at full turn: 22,265 lbs Bucket capacity: 2.9 - 9.2 yd³ Log grapples: 1.6 - 2.9 yd² Operating weight: 31,968 - 38,140 lbs Breakout force: 31,470 LBF Engine: Volvo D6J Max power: 1,400 - 1,900 RPM, ISO: 14,396 gross, 184 HP, ISO: 9,249, SAE J1349 Net, 184 HP Max torque: at 1,400 RPM, ISO 14,396 gross 689 LBF Ft., ISO 9249, SAE J1349 Net 689 LBF Ft. Tires 20.5R25 600/65R25