704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

2033 Results Found

704-841-2001

Call for Price

EZ CAR - (Used) Model A: Car Crusher Approx: 6,200 hours.New in: 1988.System Pressure: 2,500 PSI.Port Reliefs set at: 2,650 PSI.Cylinders: 10" Bore.Travel: 78".Shaft: 4" rod.OpeningSize: 20" x 8'-1" x 7'-7".OverallWeight: 61,000 Lbs.Length: 43'-1/4."Travel & operating height: 13'-1/4'.

Call for Price

EZ SANDER EZ-3760 Wide Belt SanderEZ-Sander's are built to with the ability to hold very tight tolerance (+/-.003) side to side when set up properly.Specifications: -- The sanding head is a combination head that consists of a 5" rubber-covered contact drum for the more aggressive sanding and then followed by an adjustable 2-1/2" graphite-covered felt polishing platen for doing very fine finishing sanding using a 37" X 60" abrasive belt. -- The conveyor belt speed is set to run at 10 - 30 FPM and is controlled via AC variable speed unit mounted in the main control panel. Simply adjust the dial setting to your desired feed speed. -- Double infeed and outfeed hold-down rolls are provided to help ensure proper part feeding through the Sander. -- The conveyor table/bed opening has a 0" to 5" opening allowing the operator to sand some parts as thick as 5" and the ability to sand very thin parts as well. -- Power raising and lowering of the conveyor bed is standard. -- Digital thickness display is standard.Complete with & Features: -- EZ Sander is equipped with a state-of-the-art electronic tracking system for the abrasive belt. -- Emergency stop heavy-duty caliper disc brakes bring the sanding head to a stop within 4 to 5 Sec when activated by the machine's safety interlock system. -- Limit Switches on both sides of the abrasive belt to keep the belt from over-travel. NOTE: -- Available in single phase with a 7.5 HP or 10 HP 3-Phase main drive motor. -- Voltage change to 440 Volt ...$275.

Cabinet Door Finishing System --4 Air Spray Guns --3 different lines and pumps --Paper feed belt with various speed options --Infrared sensors detect exact measurements of cabinet doors or mouldings and spray only the pieces being sent through. --System includes: (1) Dry Room and fan for air movement. --System is in great condition and works well. Our shop got to the point where we were really only using it to prime doors and it is capable of so much more than that.

Call for Price

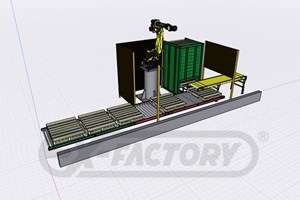

FANUC M410/160 iB ROBOT PALLETIZING SYSTEM Specifications: -- Complete with R-30iA Controller All Refurbished -- Pillow Bag Tooling -- 4-Axis control -- Mounted to a heavy-duty base -- 10 Feet Long Rubber Belt Conveyor -- (2) 5 Feet Motorized Pallet Conveyor -- (3) 10 Feet Motorized Pallet Conveyor -- Automatic Pallet Dispenser -- up to (14) 50 Lbs bags per minute -- Machine weight 4500 LbsAUTOMATIC PALLET STRETCH WRAPPING SYSTEMWULFTEC or LANTECH Stretch Wrapping System or Equivalent Not INCLUDED

Call for Price

FANUC 165 Complete Palletizing SystemEquipped with and includes: -- FANUC 165 Complete with R-2000iA Controller with 600mm stand -- Pick-Up Arm Gripper Arm for pillow bag type -- 5 Feet x 24" Motorized In-feed Belt Conveyor -- (1) 10' Motorized Pallet Conveyor -- Automatic Pallet Dispenser -- Price includes Loading on your Truck

Call for Price

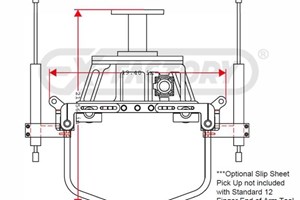

END ARM TOOLING FOR FANUC ROBOT -- Gripper Finger Type End Arm Tooling -- Design for Fanuc Robot Model S-430iW -- Loaded on your truck

Call for Price

COMPLETE FANUC 125I ROBOTIC PALLETIZING SYSTEM --System Includes the following: --FANUC M-410IB/160 Palletizing Robot with Controller and Stand --Robot will be tested --End of Arm Tooling to Pick, Fork Style, Picking 94 Lbs Concrete Bags --Master System Control Panel, 480 VAC 3PH & 24VDC Controls with HMI --Allen-Bradley Light Curtain with Safety Controller --Infeed Chain Drive Roller Conveyor 10 Feet --Pallet Hopper --Safety Fencing COST --20 Feet Exit CDLR Pallet Conveyor 52" Wide --System Integration / Programming

Call for Price

FANUC - S430iW, ...RobotFANUC Robot for palletizing rectangular compressed bags.Specifications -- (6) Axes. -- Payload: 165 kG (255 Lbs). -- H-Reach: 2,643 mm (104"). -- Robot mass: 1,300 kG (2,860 Lbs). -- Complete with: Pendant control. -- Complete with: Gripper type arm and pallet gripper. -- Refurbished with (90) days Warranty. -- Buyer to install safety guards.NOTE: Machine was rebuilt is 2021.

Call for Price

FANUC - M-410I, ...Palletizing RobotFANUC M-410iC/110 Robot is a Palletizing Robot. It runs on the FANUC "R30iB" and "R30iB Plus" controller platform. With lighter payload, this Robot is designed to run faster than its bigger variants.This Robot was ordered and never installed, so it is "new" old stock.Max. payload: 110 kG (242 Lbs). -- Reach: 2,403 mm (94"). -- Axes: 4. -- Repeatability: +/- 0.5 mm. -- Robot Mass: 1,030 kG (2,270 Lbs). -- Floor mounted.

Call for Price

FARR GOLD GS4 DUST/FUME/MATERIAL COLLECTOR: 3,000 CFM Rated cap., 1,300 sq. ft. filter area from (4) cartridge filters, approx. 2.3:1 air: cloth ratio . -- Equipped with: 5 HP Pull thru motor; dirty air is pulled into the filter area at bottom of filter media section allowing gross dust particles to fall into collector barrels located beneath pyramidal hopper discharging to a sealed drum (not included) -- Fine dust is pulled up thru the cartridge filters; dust filter cartridges are cleaned by automatic pulse jet with minimum compressed air consumption; cleaned air continues thru blower and is returned to the building air supply thru a silencer.. -- Includes: Cyclone with slide gate discharging into a sealed barrel (not included), electrical control panel, support stand with clearance under hopper, discharge for a waste bin,. access door, some pipe as pictured.

$6,940

Large table size, extendable in all three directions by up to 39" (1,000 mm) without the requirement of tools. Comfortable one-handed lever operationHeavy-duty eccentric clamp, usable on the left and right-hand side.Specifications: -- 3 HP motor, tilting head, manual hand lever control for mortise length and depth; 13" x 22" table with eccentric clamp -- 3000 RPM, reversible motor that caters for left and right cutting bits and a solid quad-jaw chuck with clamping range from 0–20 mm -- Lateral range of motion is 250 mm, cut depth is 160 mm, available height adjustment is 130 mm and there are solid locking stops in all three directions for setting precise stops.Features: 2-Jaw chuck with 5/8" capacity, Dust control collection tray below the cutter out to an 80 mm outlet,Complete with (2) adjustable and removable extension wings; fence for 90° & 45° mortises, extended stop bar on each side of table.

FELDER - FORMAT KAPPA 450: Sliding Table SawSpecifications -- 126" (3,200 mm) Cutting length w/scoring; anodized 14-3/4" x 126" aluminum sliding table with tracking by roller bearings; locks for easy panel loading in any position; 450 mm dia. main saw blade. -- Motorized: Raise, lower, and tilting (0° - 45°) of the blade with digital readout. Equipped with: -- 7-1/2 HP Main motor; 1.0 HP scoring motor unit w/external adjustment; square crosscut fence with: (2) Stops; standard rip fence with: 1,250 mm (49") Rip cap. w/digital readout; extension table with: Miter fence and sliding outrigger support. Includes: -- (2) 4" Dia. dust outlets; swing away overarm saw guard.Also available for an extra fee: 30 KVA; 208 - 380 Volt 3-Phase Transformer.

Call for Price

FELDER RL-350 Dust CollectorFelder clean-air extractors filter the air so that the dust remaining is less than 0.1mg/m cu. These exceptional air quality values are achieved by the position of the impeller. In other extracting systems, the impeller works by creating pressure between the machine and filter; with the Felder systems, the impeller is located on the clean-air side creating negative pressure throughout the system so no dust can escape. Specifications: -- 15 HP blower with 13-3/4" in-let -- Max. airflow 4,705 CFM, nominal air flow capacity 4,072 CFM -- Static pressure 9.4" WG -- Compressed air connection for automatic cleaning function. -- Dust emission quality less than mg/m cu. -- Filter surface area 71 m/sq. -- Acoustic pressure 75 dB -- Chip volume 2 x 55 gal. -- Dimension / Weight: 104" L x 45" W x 89" H, 1,785 lbs.

Call for Price

FELDER FORMAT4 PROFIT H08 16.31 FLAT TABLE MACHINE (W/ATC) -- Specifications5' x 10' "MATRIX" Phenolic Flat Table design for "Nested Base" Manufacturing. -- Working Capacity"X" Axis is 121.6" (3,090 mm); "Y" axis is 60.2" (1,530 mm);"Z" axis stroke is 11.8" (300 mm); max. material thickness is 4.3" (110 mm). -- Positioning Speed"X" & "Y" Axis at 197 FPM (60 MPM); "Z" axis is 49 FPM (15 MPM). -- WorktableThe working area is subdivided into (8) vacuum fields (H08 16.31) to ensure the best holding force for the most varied board sizes. The vacuum fields are controlled manually by means of hand levers on the front side of the machine.Prepared for (optional) elevated pods that allow profile & horizontal machining. -- Machining(1) 13.4 HP (10 kW) Vertically mounted electro-spindle router with: HSK F63 Adaptor; inverter driven 1,000 - 24,000 RPM with max. torque from 12,000 RPM.(1) 11-Position ATC tool rack mounted at the end of the machine. -- Operator & Machine ControlPC Based User-Friendly, icon driven control housed on the main machine base + "WOODFLASH" Operating System. -- Complete with:(1) 250 cbm/Hr Vacuum pumps; handheld terminal with: Potentiometer & emergency stop; automatic measuring system of the tool length.Sound absorbing protective head enclosure with debris curtain around bottom edge. -- Actual model: FELDER FORMAT4 - PROFIT H08 16.31

Call for Price

FELDER FORMAT4 PROFIT H08 FLAT TABLE MACHINE (W/LOADING, UNLOADING): -- Specifications5' x 10' "MATRIX" Phenolic Flat Table design for: "Nested Base" Manufacturing. -- Working Capacity"X" Axis is 121.6" (3,090 mm); "Y" axis is 60.2" (1,530 mm);"Z" axis stroke is 11.8" (300 mm); max. material thickness is 4.3" (110 mm). -- Positioning Speed"X" & "Y" Axis at 197 FPM (60 MPM); "Z" axis is 49 FPM (15 MPM). -- WorktableThe working area is subdivided into (8) vacuum fields (H08 16.31) to ensure the best holding force for the most varied board sizes.The vacuum fields are controlled manually by means of: Hand levers on the front side of the machine. Prepared for (optional) elevated pods: Allows profile & horizontal machining. -- Boring Unit(1) DH 8-Spindle Vertical Drill block on 32 mm centers. -- Machining(1) 13.4 HP (10 kW) Vertically mounted electrospindle Router with: HSK F63 Adaptor; inverter driven 1,000 - 24,000 RPM; max. torque from 12,000 RPM.(1) 15-Position ATC Tool Rack: Mounted at the end of the machine. -- Operator & Machine ControlPC Based user-friendly; icon driven control housed on the: Main machine base + "WOODFLASH" Operating System. -- Complete with:(2) 250 cbm/Hr Vacuum pumps; handheld terminal with: Potentiometer & emergency stop; automatic measuring system of the tool length.Sound absorbing protective head enclosure with: Debris curtain around bottom edge. -- Options Include: Automatic unloading unit with: Electromotive offloading pusher. This addition allows finished workpieces to be automatically pushed off the table after processing: Reducing manual handling & speeding up production cycles. -- Actual model: FELDER FORMAT4 - PROFIT H08 16.31

$4,750

FELDER - G-330: Edgebander0.4 - 3 mm Edge thickness cap.; 40 mm panel thickness; 3" min. width; 4-3/4" min. panel length.Equipped with: -- Quickmelt TEFLON coated glue pot for granular hot-melt adhesive. -- Heavy-Duty Guillotine: Up to 3 mm thick PVC. -- Integrated Operator PLC controls and an LCD display. -- "Anti-slip" rubberized surface chain pads.Workstations -- Single motor; Double Blade End Trim with: HF Motor; 12,000 RPM. -- Top & Bottom Flush/Bevel Trim: Bevels 0° - 15°; 1/2 HP motor - 12,000 RPM each. -- Open space at outfeed. -- Single feed speed: 26 FPM.Complete with: -- Sound & Safety enclosure over trim stations; outrigger panel support; used tooling.NOTE: Seller states that the equipment has less than (500) hours of use!

$55,000

FELDER FORMAT4 - Profit H08: Flat Table Machine Specifications -- 4’ x 8‘ Flat Table Working Capacity: X: 2,500 mm (98.4";); Y: 1,250 mm (49.2";); Z: 85 mm (3.3";).Gantry Outrigger: (2) synchronized Servo drivers in the X-direction; max. speed rate: 25 MPM (985 IPM). -- (1) Servo Driver: Y-Direction; max. 25 MPM (985 IPM); (1) Servo driver: Z-Direction max.; 15 MPM (590 IPM); power transmission in X. -- Y Via rack & pinion ball bearing spindle on: Z Axis; axis runs on ground linear guides. -- Automatic Centralized Lubrication of all axes -- Nesting Table: (2) Stops in X-direction: (1) Stop in Y-direction, left rear side; (6) manual switches situated in front of the machine; heavy valve system. -- Phenolic Vacuum Table with: (6) Vacuum fields and manual field choice. -- Stop cylinder at: Rear left; (2) in X, (1) in Y direction; electric box front left with light barrier. -- 1 ST 305-01004. -- Configuration package "Professional" H08 13.25 10 kW (S6) main spindle: HSK F63 Left/right rotation; 1,000 - 24,000 RPM controlled by inverter. -- Drilling Head "DH8": (8) Vertical drills; 1,000 - 6,000 RPM; controlled by inverter; 8-position tool changer. Extraction Hood: (22) Separate connections -- Software: Compact; standard PC with Windows 7 Controller; control for the use of ISO-Code; WOODFLASH programs on the machine.Includes: 210 cbm/Hr BECKER Vacuum Pump.

$3,950

FESTO - DSS3: Push Feed MoulderSpecifications -- 4-Head; -- 3-1/4" x 2" max. cap.; 3/32" x 3/16" min. cap.; min. length 10". -- Equipped with: (2) Side heads; 7 HP - 9,500 RPM motor; top & bottom heads 3 HP - 8,500 RPM motor each; 3/4" dia. spindle. -- 4-Feed rollers steel & urethane. -- Top head tilts both directions.

$11,950

FIN - ST 1600, ...Top/Bottom Cleaning Brush.62" Width and 3-1/8" max. thickness opening, thickness adjustment by handwheel via worm gear with dial indicator.Equipped with: -- Top & Bottom nylon brushes driven by 3 HP drive motor (only 1-brush with machine). -- Separate variable speed feed motor with magnetic controls driving 3" dia. rubberized infeed & outfeed pinch rolls. -- Full fabricated sheet metal enclosure for efficient dust collection, dust enclosure hood with central 6" dia. dust outlet connection.

FLETCHER EZ-DOOR Raised Panel Door MachineThis freestanding machine can produce an entire 5-piece door in a matter of minutes. Easy to operate, the E-Z Door has a 4-position configuration to produce raised panels, cope/stile profiles and mullions for glass doors. Cathedral doors are produced by using a quick change template system.Specifications: -- Select cutter and material stop with the press of one button. -- Simple four position one spindle design. -- PLC controlled pneumatics. -- Rigid lubricated spindle assembly. -- Re-circulating ball bearing slides. -- 10 HP 230 or 460V/60HZ spindle motor – (460V/3PH=17FLA) – (230V/3PH=33FLA) -- 6,500 RPM spindle speed. -- 62 inch travel length standard with circulating ball bearing slides, cut rails to 59"; and panels to 55"; -- Includes: (4) Standard cutters (shape to be decided), others optional. -- Includes: one template of customers choice. -- 1-¼"; Arbor. -- CFM requirement is 392.Made in North Carolina, USA!