704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

2043 Results Found

704-841-2001

JLT 79F-12-PC Multi Level Panel Clamp12' Wide, free-standing or wall mount Clamp Rack unit.Equipped with: -- (5) Levels for mounting clamps; -- (6) clamps per level (a total of 30) manually adjusted - side-to-side and manual open-and-close for all clamps. -- Clamps have a 40" opening with a 3-1/2" high x 4" wide jaw.Available Options: -- Pneumatic panel flattener with single lever valve operation, 40" reach and flatten up to 1-1/2" thick material, additional: ...$1,500 -- Glue applicator Redi spreader 6" x 27" grid capacity, additional ...$ 1,200 -- Glue applicator Plate spreader 8" x 48" grid capacity, additional ...$2,350 -- Clamp 3 1/2" X 40" opening ... $ 149 -- 79-1680-Handle $110 for use with 1/2" drive impact gun (adjustable torque preferred with setting of 50-55 ft/lbsFloor space requirement: 144" x 78" x 52" high

Call for Price

JOHN DEERE 470G LC Large Hydraulic ExcavatorSpecifications: -- Max. digging depth: 27'-2" to 29'-11" -- Engine: JOHN DEERE 6135HT997 -- Displacement: 13.5 L -- Cylinders: 6 -- Fuel type: Diesel -- kW: 560 -- Transmission: Hydrostatic 2-speed travel -- Tracks Width: 35-1/2" -- Stick length: 12'-5" -- Quick coupler: Hydraulic -- Bucket width: 60" -- Hours: 4,602Equipped with: -- TOPCON 3DMC Control -- Operators station: EROPS -- AC and Heat -- Grade control -- Counterweights -- Auto lube -- Cutting Edge: Weld-On -- Grouser Pads: Triple

Call for Price

JOHN DEERE 210G ExcavatorSpecifications: -- Engine: 159 HP at 1,900 rpm -- Max. Travel Speed Low 2.2 mph / High 3.4 mph -- Bucket size: 42" -- Fuel Tank: 06.5 gal -- Undercarriage: 85% -- Hours: 2,540Equipped with: -- Hydraulic thumb -- Quick coupler -- Back-up camera -- Pre-emissions -- Heat / AC -- Recent service -- New batteries

Call for Price

JOHN DEERE 550K Crawler DozerThe John Deere 550K is a crawler dozer with a Power-Angle-Tilt (PAT) blade.Specifications: -- Engine: PowerTech PWS 4045 engine (turbocharged) -- Displacement: 4.5L (276 cu. in.) -- Net Rated Power: 92 HP at 2,200 rpm (69 kW) -- Transmission: Hydrostatic -- Blade Type: Power-Angle-Tilt (PAT) -- Blade size: 105" (2.67 m) -- Maximum Travel Speed: 8.0 km/h (5.0 mph) - Maximum (optional) 9.7 km/h (6.0 mph) -- Operating Weight (with standard equipment): 7718–8279 kg (17,016–18,252 lb.) -- Fuel Tank Capacity: 234 L (61.9 gal.). -- Hours: 1318Equipped with: -- Air conditioning and heated Cab -- Power-Angle-Tilt (PAT) blade -- Rock guards

Call for Price

JOHN DEERE 85G Mid-Sized ExcavatorNeither too big nor too small, these right-size excavators are the perfect solution for a wide varietyof tasks.Specifications: -- Engine: Net Power 56.9 HP at 2,000 rpm ( (ISO 9249) 42.4 kW) -- Engine Cylinders: 4 -- Powertrain: 2-speed propel with automatic shift - Low 3.1 km/h (1.9 mph) - High 5.0 km/h (3.1 mph) - Drawbar Pull 6650 kgf (14,661 lb.) -- Swing Speed: 10.5 rpm -- Fuel Tank 31.7 gal -- Hours: 710Equipped with: -- AC and Heated Cab -- Front blade -- Multifunction, color LCD monitor -- 2-speed propel with automatic shift -- Electronic engine control -- Reduced-drift valve for boom down, arm in -- Auxiliary hydraulic valve section -- Work lights: Halogen / 1 mounted on boom / 1 mounted on frameThe 85G comes equipped with an independent-swing boom that enables work close to curbs, parallel to structures, or alongsidetraffic. We can provide financing and also the most economical delivery to your location.

Call for Price

JOHN DEERE 324K Compact Wheel LoaderProductive for tight turns and extra agility in close quarters.Specifications: -- Engine Power: 70 HP -- Engine type: YANMAR Diesel -- Full-turn tipping load: 9,766 Lbs -- Bucket capacity range: 1.4–2.0 cu. yd -- Bucket breakout force: 2,364 Lbs -- Operating weight: 14,087 Lbs

Call for Price

50 HP JORDAN - MS4220: Dual Shaft Shredder with Infeed ConveyorSpecifications -- Overall length: 141". -- Overall width: 56". -- Overall height: 98". -- Cutting chamber size: 42" x 20". -- Hopper size: 1-1/2 - 2 Cubic yard. -- Cutter assembly height: 13-1/2". -- Motor horsepower: 50 HP. -- Approx chamber weight: 4,570 Lbs. MS-4220 is a most popular midrange Shredder with: Power to handle tougher jobs; cost that can fit into your demanding budget. MS-4220 can be used to Shred: Paper, plastic, passenger tires, carpet, and an many other materials. Shredder is designed with: Counterrotating dual speed shafts; cutting group continuously changes knife tip position. This helps the knives grab & pull through hard to hold materials. MS-4220 Industrial Shredder offers: Midsize chamber capacity; horsepower to handle many of the most demanding applications. For a cost-effective Shredder, this unit cannot be beat for volume reduction & material shredding. The MS-4220 Industrial Shredder is a "Workhorse."

Call for Price

JV MANUFACTURING MODEL - CC-02: Stationary CompactorSpecifications: -- Charge box capacity: 2 Cu/Yards. -- Clear Top opening: 40" x 58-1/2". -- Average cycle time: 63 Sec. -- Total normal force: 56,500 Lbs. -- Max. total force: 67,900 Lbs. -- Normal ram pressure: 33 PSI -- Max. ram pressure: 39.7 PSI.Equipped with: -- Standard 3-button controls. -- Heavy-Duty structural steel components and welded by AWS Certified Welding Technicians.Designed for: ● Retailers ● Hospitals ● Hotels ● Distribution Centers ● Manufacturing Centers ● Recycling Centers ● Home Centers

Call for Price

JV MANUFACTURING - HE-60 BIG MOUTH: Closed-Door Horizontal BalerSpecifications: -- Cylinders: (2) 6". -- Main motor: 20 HP. -- Bale size: 60"; x 30"; x 48";. -- Cycle Time (No Load): 47 Seconds. -- Platen Force:120,600 Lbs normal; 140,800 Lbs max. -- Hydraulic Cylinder Bore Diameter: 8";. -- Hydraulic Cylinder Stroke: 84";.Equipped with: -- Conveyor hopper. -- Heavy-Duty operator controls.NOTE: Back cover is included.

Call for Price

JV MANUFACTURING - PH-04, ...Pre-Crusher CompactorSpecifications: -- Hydraulic Cylinder: 7" -- Charge Box Capacity: 4 Cu.yd -- Cycle Time: 56 Sec -- Total Force: 77,000 Lbs -- Ram Face Dimensions: 60" x 35" -- Motor: 20 HPEquipped with: -- Rear Deck

(2) JV MANUFACTURING - VB-60-B & VB-72-B, ...Vertical Balers Lot: (2) Vertical Balers in great working condition!Specifications: -- Cylinder: 6" -- Main motor: 10 HPEquipped with: -- ANSI Z245.5 Compliant -- Key operated controls -- Quiet operating Vane Pump -- Gas spring assisted Loading Door

JV MANUFACTURING - HE-60 BIG MOUTH, ...Closed-Door Horizontal BalerSpecifications: -- Cylinders: (2) 6" -- Main motor: 20 HP -- Bale size: 60"; x 30"; x 48"; -- Feed opening: 18,000 LbsEquipped with: -- Conveyor hopper -- Factory infeed conveyor -- Full penRefurbished work. New: Guides, press head cover, main door hinge pin, main door patch pin, oil & filters, hoses as required, seals in control manifold, belt on conveyor, drive chain, and sprockets on conveyor.Rebuilt: Cylinders, door latch cylinder, shear blades sharpened and adjusted. - Gear oil changed in conveyor drive.

Call for Price

JV MANUFACTURING SC-T2-34 Self-Contained Compactor with Cart TipperSpecifications: -- Feed opening: 58" x 41" -- Cylinder: (2) 4" -- Main motor: 10 HP -- Capacity: 34 yd.Equipped with: -- Rear hydraulic Cart Tipper -- Universal rails

Call for Price

KAESER - SX 5: Air Compressor5 HP TEFC Motor - 1,800 RPM: Single-stage; oil injected rotary screw air end; 21 CFM at 125 PSI; high efficiency air & oil cooler; 4-micron air intake filter with: Replaceable, cleanable cartridge. -- Approx (2,994) hours; complete with: Automatic dual control allowing unit to run fully loaded or unloaded at reduced power consumption.Control panel displays: Air pressure & lubricant discharge pressure' operating hours; start/stop switch; power on light; & E-Stop button. -- KAESER Control Safety System: monitors motor overload, high air & lubricant temperature, reverse rotation; loss of drive with indicator lights & shutdown upon alarm. -- Features: KAESER soundproof enclosure with durable powder coated finish; easy access locking panels; Compressor mounted on solid base frame with a solid steel floor and anti-vibrating mounts.

KAESER KCF 200 Oil/Water Separator Specifications: Cap. for Screw Compressors: 900 SCFM for Mineral/Turbine oil (Additive free), 600 SCFM for Diesters PAO, & 450 SCFM for Polyglycol. Cap. for Piston Compressors: 600 SCFM for Mineral/Turbine oil (Additive free), 450 SCFM for Synthetic oil. Filling volume 19.2 Gallons. Max. operating pressure 232 PSIG. Equipped with: 30.5 Gallon Container. 4.9 Gallon Pre-filter, 5.4 Gallon Main filter. CURRENCY NOTE: Negotiable Price is listed in U.S. Dollars.

KAESER - ASD 40 T, ...40 HP Rotary Screw Air Compressor, with Integrated Dryer & 17,702 Run & 3,775 Load Hrs (as of 2/16/24)Specifications: -- Rated capacity: 191 CFM. -- Max. pressure: 125 PSIG. Equipped with: -- 40 HP - 3,570 RPM TEFC Direct drive motor; IE3 (Premium Efficiency). -- "SIGMA PROFILE" Air end. -- 1:1 Motor-air end coupling. -- Wye-Delta reduced voltage magnetic starter. -- Electronic Thermo-Management (ETM) system. -- 2-Stage 4 micron air intake filter with Cyclone pre-separation & replaceable element. -- Safety pressure relief valve. -- Anti-vibration mounts. -- Sound enclosure. -- KAESER "SIGMA CONTROL 2" PC-Based controller with LCD Display & Touchpad.Complete with: -- Integrated Refrigerated Dryer. -- Compressor Operator Manual & Controller User Manual.Dimensions for this Specific Machine: 70" x 36" x 61" H.Weight for this Specific Machine: 750 kG (1,650 Lbs).

KAESER KCF 200 Oil/Water SeparatorSpecifications: -- Cap. for Screw Compressors: 900 SCFM for Mineral/Turbine oil (Additive free), 600 SCFM for Diesters PAO, & 450 SCFM for Polyglycol. -- Cap. for Piston Compressors: 600 SCFM for Mineral/Turbine oil (Additive free), 450 SCFM for Synthetic oil. -- Filling volume 19.2 Gallons. -- Max. operating pressure 232 PSIG.Equipped with: -- 30.5 Gallon Container. -- 4.9 Gallon Pre-filter, 5.4 Gallon Main filter.

KAESER - ASD 40 T: .40 HP Rotary Screw Air Compressor w/Integrated Dryer & TankSpecifications -- Rated cap.: 191 CFM; max. pressure: 125 PSIG; 40 HP - 3,570 RPM TEFC Direct drive motor; IE3 (Premium Efficiency). -- "SIGMA PROFILE" Air end; 1:1 motor - air end coupling; WYE-DELTA reduced voltage magnetic starter; electronic Thermo-Management (ETM) system. -- Equipped with: -- 2-Stage 4 micron air intake filter with: Cyclone preseparation & replaceable element; safety pressure relief valve; anti-vibration mounts; sound enclosure. -- KAESER "SIGMA CONTROL 2" PC-Based controller with: LCD Display & Touchpad; KAESER ABT "60" Integrated Refrigerated Dryer. -- Includes -- Vertical Accumulator Tank (approx. 400 gal.); KAESER, KCF 100, Oil/Water Separator.

KAESER ASD 40 T 40 HP Rotary Screw Air Compressor, with Integrated Dryer & 17,702 Run & 3,775 Load Hrs (as of 2/16/24) Specifications: Rated cap. 191 CFM. Max. pressure 125 PSIG. Equipped with: 40 HP - 3,570 RPM TEFC Direct drive motor, IE3 (Premium Efficiency). "SIGMA PROFILE" Air end. 1:1 Motor-air end coupling. Wye-Delta reduced voltage magnetic starter. Electronic Thermo-Management (ETM) system. 2-Stage 4 micron air intake filter, with Cyclone pre-separation & replaceable element. Safety pressure relief valve. Anti-vibration mounts. Sound enclosure. KAESER "SIGMA CONTROL 2" PC-Based controller, with LCD Display & Touchpad. Complete with: Integrated Refrigerated Dryer. Compressor Operator Manual & Controller User Manual. Dimensions for this Specific Machine: 70" x 36" x 61" H. Weight for this Specific Machine: 750 kG (1,650 Lbs). CURRENCY NOTE: Negotiable Price is listed in U.S. Dollars.

Call for Price

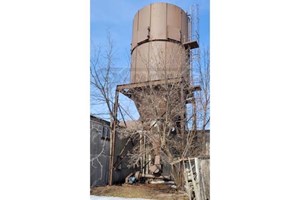

MACDONALD STEEL 65 ST Dust Collector System with Shaker filter cleaning, Rotary Air Lock, and 18' dia. housing. -- Specifications: Capacity for 65,000 CFM, 18' dia. shell, with 8,199 sq-ft. of filter area for an air-to-cloth ratio of 7.7:1. T-150 polyester bags 14 oz. with a 30 - 40 CFM.@ 1/2" WG permeability. -- Current Fan configuration: System 1: Fan inlet of 33" at 32,500 CFM; System 2: .Future capacity for a second fan as per System 1. Return air duct is 42" x 72". -- Filter Cleaning: Top mounted electrically operated & timed mechanical shaker, approx. 2 HP motor which will automatically operate on all shutdowns. -- Equipped with: MACDONALD 18" Rotary Air Lock (RAL) with bottom eductor/T-section for connection to a relay/transfer fan (not included.). -- Complete with Fire Damper, Summer/Winter Damper with Silencer, Explosion doors, safety ladders, and access platform. -- Features: 13" MH/HT 20 HP Transfer/Transport fan -- Overall height is currently 57'-3" with 12' clearance under RAL. Weight of filter with structural steel is 29,000 Lbs plus fan is about 3,000 Lbs. -- Shell panelized construction (made of separable panels allowing for road/Hwy travel).Professional rigging, loading and transportation are available at extra cost; quote upon request.