704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

Woodworking

1847 Results Found

704-841-2001

$12,000

JLT CLAMPS 717C-CHBB Double Door Miter ClampAccurately clamp, square and adjust your miter joints with JLT large miter double door clamp. The “CH Big Boy"; Door Clamp has quick changeovers, protects MDF doors, has accurate corner pressure adjustment and with removable center bars. Specifications: -- Dial regulators: “Dial"; pressure A, B, C, D IN or OUT for adjustment of corners. -- Includes (2) vertical and (2) horizontal clamps. -- Maximum capacity: 38"; W x 96"; L. -- Installed center bar: (2) 30";W x 46";L. -- For use on stile and rail doors as well. -- Single lever valve air activation.

JLT CLAMPS 79F-M2-6-1R Single Row Panel ClampEdge Glue and Face Glue a variety of solid wood components. Produce 10+ edge glued panels per day with a Standard Setup. -- Taylor’s Patented and Successful Clamp Arm Design Features: -- 6' Single Row Panel Clamp level. -- Free Standing Unit with 500 lbs. Weight Capacity. -- 100% Complete Tubular Steel Construction. -- Complete 3 Year WarrantyIncludes: -- (6) 3 1/2″ High jaw 40″ Clamps. -- Optional 52″ Clamps Available on Request(Photo Is a Generic of Single Row Panel Clamps)

JLT CLAMPS 180A-M2-52 Pneumatic Panel Flattener. -- Complete with; Air System and Docking attachment with 52" reach and up to 2-1/2" material thickness.Additional Thickness Capacities Available (4" & 6")

JLT CLAMPS 717C-LM Panel and Door Clamp (Miter Doors)Pneumatically operated Cabinet Door Clamp to square & clamp a door in (1) Sec. -- 38" Front-to-back x 97" left-to-right clamping cap. -- Special design for mitered doors. -- Single row Door Clamp with (2) horizontal pneumatic clamp & (2) vertical pneumatic clamps. -- Each clamp includes the JLT Dial Control System for fine adjustments, which is simple and easy to use. -- This innovative Dial Control System allows for adjustments in BOTH directions while the door is under clamping pressure -- Special mount on a 30° angle for ease of loading & less operator fatigue. -- (4) Large diaphram cylinders for quick clamping pressure with single lever operation. -- 40 PSI Air pressure to produce 500 Lbs of force on each clamp. -- Shelf to hold the pieces of the frame before pressing on all squaring components. -- 40 Sq. ft. footprint.Precisely Clamp and Square MDF or HDF Doors too!!

JLT CLAMPS 79F-M2-8-1R Single Row Panel ClampEdge Glue and Face Glue a variety of solid wood components. Produce 10+ edge glued panels per day with a Standard Setup. -- Taylor’s Patented and Successful Clamp Arm Design Features: -- 8' Single Row Panel Clamp level. -- Free Standing Unit with 500 lbs. Weight Capacity. -- 100% Complete Tubular Steel Construction. -- Complete 3 Year WarrantyIncludes: -- (8) 3 1/2″ High jaw 40″ Clamps. -- Optional 52″ Clamps Available on Request(Photo Is a Generic of Single Row Panel Clamps)

JLT CLAMPS 79F-M2-12-1R Single Row Panel ClampEdge Glue and Face Glue a variety of solid wood components. Produce 10+ edge glued panels per day with a Standard Setup. -- Taylor’s Patented and Successful Clamp Arm Design Features: -- 12' Single Row Panel Clamp level. -- Free Standing Unit with 500 lbs. Weight Capacity. -- 100% Complete Tubular Steel Construction. -- Complete 3 Year WarrantyIncludes: -- (10) 3 1/2″ High jaw 40″ Clamps. -- Optional 52″ Clamps Available on Request(Photo Is a Generic of Single Row Panel Clamps)

JLT 190B-M3 Drawer Clamp. Heavy-duty Drawer and Box clamp, maximum capacity 10" H x 24" L x 36" W Specifications & Features: -- Achieve 3,000 Lbs. clamping force at 100 PSI air pressure. -- Easy to use mounted lever valve with intergraded pressure hold kit. -- Pneumatic foot pedal activation. -- 2- Clamp Design provides equal pressure from top to bottom. -- Horizontal aluminum side pressure walls offer a non-marking smooth durable surface. -- Fast, easy changeovers with minimal adjusting. -- The vertical clamping carriage slides smoothly for horizontal width adjustments.Complete with: -- (3) Sets of pressure shoes for added strength also eliminate vertical (drawer depth) adjustments. -- (1) Set of aluminum side plates. -- (1) Lever valve pressure hold kit.

$11,500

JLT CLAMPS 79F-16-PC Panel and Door Clamp. This Clamp for the Custom Woodworker who produces 16' Railing, Long Posts and Face Glue Solid Wood Components up to 6" thick. -- (3) Levels of 16' long x 52"wide x 70" high -- Heavy tubular frame with (36) # 302-40-H-R 3.5" high Jaw 40" Taylor Clamps. Made of solid steel and are manually tightened with a JLT "T" handle. -- Manually adjustable bar clamps that easily set in place and move from side-to-side. -- Heavy Duty Construction with 5000 Lbs. capacity. Great for the big jobs. -- Clamps are aligned perfectly for a straight and precise clamp face. -- 6" High rocker adapter Plates offer consistent clamping pressure throughout the glue joint. -- -- JLT heavy duty clamps offer up to 3000 Lbs of clamping pressure. -- JLT Clamps are guaranteed Never to twist, bow or bend! -- Clamping System Package Includes: (1) #79F-16-PC 16' long multi-level panel clamp. -- (36) #302-40-H-R 3.5" High jaw 40"opening Taylor Clamps. -- (72) #80-1706 Gocker adapter plates for up to 6" thick glue ups. -- (1) Fastener and shim kit for precise clamp alignment.

$10,850

JLT CLAMPS 190C-M2 Drawer Clamp Heavy-duty Upper Box and Case Clamp, maximum capacity 12" H x 48" L x 48" W -- Achieve 3,500 Lbs clamping force at 100 PSI air pressure. -- Easy to use mounted lever valve with intergrated pressure hold kit. -- Pneumatic foot pedal activation. -- (4) Clamp Design provides equal pressure from top to bottom. -- Horizontial aluminum side pressure walls offer a non-marking smooth durable surface. -- Fast, easy changeovers with minimal adjusting. -- Vertical clamping carriage slides smoothly for horizontial width adjustments. -- (5) Sets of pressure shoes for added strength also eliminates vertical (drawer depth) adjustments. -- Includes: (1) Set of aluminum side plates, (1) lever valve pressure hold kit.

JLT CLAMPS 180A-M2 Pneumatic Panel Flattener. -- Complete with; Air System and Docking attachment with 40" reach and up to 2-1/2" material thickness.Additional Thickness Capacities Available (4" & 6")...add $100

JLT CLAMPS 160B-M3 Glue ApplicatorThe Door Stile spreader compliments the JLT Door Clamp for providing a quick simple method of applying glue to cabinet door stiles. -- Foot pedal operation. -- Includes: (2) Pre-cut profiles and UHMW material to produce up to 12 more profiles. -- Virtually no clean up (end of the day spray with water form the provided spray bottle and cover). Minimize potential for squeeze out. Final set up dimensions: 16"; L x 16" W x 38"; H

JLT 190B-M3-48 Drawer Clamp. Heavy-duty Drawer and Box clamp, maximum capacity 12" H x 24" L x 48" W -- Achieve 3,000 Lbs. clamping force at 100 PSI air pressure. -- Easy to use mounted lever valve with intergraded pressure hold kit. -- Pneumatic foot pedal activation. -- (2) Clamp Design provides equal pressure from top to bottom. -- Horizontal aluminum side pressure walls offer a non-marking smooth durable surface. -- Fast, easy changeovers with minimal adjusting. -- Vertical clamping carriage slides smoothly for horizontal width adjustments. -- (3) Sets of pressure shoes for added strength also eliminates vertical (drawer depth) adjustments. -- (1) Set of aluminum side plates. -- (1) Lever valve pressure hold kit.

JLT 720A-8W Face Frame Assembly Table. The JLT CLAMPS Face Frame Assembly System simplifies the assembling process. -- This is to ensure flush alignment of frames regardless of thickness of material. -- Major face sanding is eliminated. -- Total 1"; thick, 5' x 8' clamping surface featuring a high quality UHMW top layer for a flat, sturdy and easy to clean surface. -- Innovative vertical pressure over arm with (5) hold down clamps and squaring bar. (Replaces #78G-5-8)

Call for Price

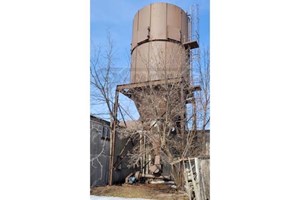

MACDONALD STEEL 65 ST Dust Collector System with Shaker filter cleaning, Rotary Air Lock, and 18' dia. housing. -- Specifications: Capacity for 65,000 CFM, 18' dia. shell, with 8,199 sq-ft. of filter area for an air-to-cloth ratio of 7.7:1. T-150 polyester bags 14 oz. with a 30 - 40 CFM.@ 1/2" WG permeability. -- Current Fan configuration: System 1: Fan inlet of 33" at 32,500 CFM; System 2: .Future capacity for a second fan as per System 1. Return air duct is 42" x 72". -- Filter Cleaning: Top mounted electrically operated & timed mechanical shaker, approx. 2 HP motor which will automatically operate on all shutdowns. -- Equipped with: MACDONALD 18" Rotary Air Lock (RAL) with bottom eductor/T-section for connection to a relay/transfer fan (not included.). -- Complete with Fire Damper, Summer/Winter Damper with Silencer, Explosion doors, safety ladders, and access platform. -- Features: 13" MH/HT 20 HP Transfer/Transport fan -- Overall height is currently 57'-3" with 12' clearance under RAL. Weight of filter with structural steel is 29,000 Lbs plus fan is about 3,000 Lbs. -- Shell panelized construction (made of separable panels allowing for road/Hwy travel).Professional rigging, loading and transportation are available at extra cost; quote upon request.

Call for Price

MACDONALD STEEL 37- 168-132 Pull Thru Type ST Dust Collector with Shaker type bag cleaning. -- 35,000 CFM, 150 HP blower with 37" inlet dia., 4,354 square feet of cloth filter area with 8 to 1 air to cloth ratio, (114) 9" dia. X 168" (14') long bags, 1.5 HP shaker motor. T-150 filter bags. -- MACDONALD 37 AT main fan belt driven by a 150 HP WEG motor. Silencer on fan discharge. 11' dia. baghouse with 2,160 cubic feet storage cap; overall height of approx. 55' -- Includes: Retrofitted hopper with transition to bottom auger to Rotary Air Lock (RAL). Explosion Doors -- Features: Enclosure with SIEMENS Variable Frequency Drive (VFD) for efficient ramp-up control convenient fan speed control as needed.Summer/Winter diverter on return air line. Truck level loading .'Y' branch on inlet with approx. 33" & 16" supply lines. -- Complete with: Electrical control panels with with starters for auger and RAL. All external ducting, and about 100' manifold of 33" dia. steel flanged main trunk supply line. Safety ladders & access platforms.

Call for Price

MACDONAL STEEL - 26 PT: Dust Collector with RAL/Auger and Diverter Gate.Overall data: 16,700 CFM; 1,780 sq/ft. of cloth area comprised of: (85) Bags: 8" Dia. & 120" long; 60 HP blower; 26" inlet dia. with retrofitted Auger/Rotary Air Lock. -- Equipped with: Electrically operated mechanical bag shaker; back pressure damper on inlet manifold; Diverter/Abort Gate. -- Complete with: Safety hoop access ladder; (1) access platform to filter media; (1) top mounted fan/motor; silencer on return air. -- Starter/electrical control panels and disconnects inside/outside for each drive. -- Used 150 HP; rated VFD is available at extra cost.

MAGGI SYSTEM 23 Construction Hole Boring Machine Adjustable 23-spindle boring head on 32 mm centersSpecifications: -- Stops in 0° & 90° with pneumatic positioning in vertical & horizontal. -- 0" - 2-1/2" Adjustable drilling depth with patented setting device. -- (2) Patented material clamps with auto-setting & safety feature. -- Head height fine adjustment with a mechanical digital readout. -- 2 HP - 2,800 RPM Motor. -- 38" x 16" Table with mechanical digital side fences for mirror-image. -- 120" Line Boring fence with (4) repeat stops & spring loaded repeat pin. -- Foot actuated pneumatic clamps & drill cycle. -- Magnetic starter, overload protection and (1) set of "quick change" chucks. -- Dust Outlet: 3".Net weight: 630 Lbs; Dimensions: 51.7" x 37.8" x 50" Tall; Crated Dimensions: 44" x 38" x 42" Tall; Crated Weight: 664 lbs.Available in single phase ... Add $ 600.00

MAGGI SYSTEM 29 CONSTRUCTION/LINE BORERAdjustable 29-spindle boring head on 32 mm centers with position indicator. -- Stops in 0° & 90° with pneumatic positioning in vertical & horizontal. -- 0" - 2-1/2" Adjustable drilling depth with patented setting device. -- (2) Patented material clamps with auto-setting & safety feature. -- Head height fine adjustment with mechanical digital readout. -- 2 HP - 2,800 RPM Motor. -- 45" x 16" Table with mechanical digital side fences for mirror-image. -- 120" Line boring fence with (4) repeat stops & spring loaded repeat pin. -- Foot actuated pneumatic clamps & drill cycle. -- Magnetic starter, overload protection and (1) set of "quick change" chucks. -- Other Accessories also Available!

MAGGI SYSTEM 46 Double Head Line Boring Machine:Heavy Double Head Line Borer with (2) 23-spindle heads; 32 mm spindle spacing.Specifications: -- Drilling from the bottom up and with 5-1/8" - 25-19/32" distance between rows. -- Drilling vertically from the bottom allows the chips to drop down falling out of the holes. -- Drilling depth of up to 2-1/16" (55 mm) max., takes only seconds to set. -- (2) 2 HP - 3,500 RPM Commercial Duty motors; spindles with steel gears & high quality bearings. -- Easy repetition by (2) air index pins for continuous line drilling, left and right roller track supports extend up to 400 mm (15-3/4") for larger panels.Features and Includes: -- 120" Back fence with (4) repeat "flip" stops; includes 27-3/4" (704 mm) fence for quick positioning of flip stops. -- (6) Pneumatic holddowns to automatically actuate when the drill cycle begins. -- (46) "Quick Change" chucks for easy tool change. -- Magnetic motor controls and 1/4" air regulator with filter and oiler; 100 PSI required air pressure.

MAGGI SYSTEM 35 CONSTRUCTION/LINE BORINGAdjustable 35-spindle boring head on 32 mm centers with position indicator. -- Stops in 0° & 90° with pneumatic positioning in vertical & horizontal. -- 0" - 2-1/2" Adjustable drilling depth with patented setting device. -- (2) Patented material clamps with auto-setting & safety feature. -- Head height fine adjustment with mechanical digital readout. -- 2 HP - 2,800 RPM Motor. -- 45" x 16" Table with mechanical digital side fences for mirror-image. -- 120" Line boring fence with (4) repeat stops & spring loaded repeat pin. -- Foot actuated pneumatic clamps & drill cycle. -- Magnetic starter, overload protection and (1) set of "quick change" chucks. -- Other Accessories also Available!