704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

Woodworking

1855 Results Found

704-841-2001

ELGI EN07-125 10 HP ENCAP Rotary Screw Compressor w/Tank & Dryer; 38 CFM @ 125 PSIG.ELGI's 10 HP Rotary Screw Air Compressor w/20 CFM Refrigerated Dryer mounted on a 120 gal. receiver tank. -- Equipped with: 10 HP motor operation up to 115°F ambient temperature; "Neuron" controller that has been custom designed and engineered to monitor and control overall performance. -- Service indicators, fault alarms, safety shutdowns and a service / operational log feature for real-time feedback. -- Phase monitor, auto re-start and the ability to hook up to a RS 485 connection to monitor system remotely. -- Includes: 120 Gal. receiver tank, 40 CFM Refrigerated Air Dryer; single-door access to routine maintenance points. -- Spin-on oil filter and separator elements for fast and easy routine service.6-Year Air End Warranty. - UL/cUL certified to ensure high levels of safety.Recommended option: -- [F10104 / MICRO 50] Clean Resources F10104 / Micro 50, Clean Resources F10104 Oil/Water Condensate Separator - Add $ 305Designed for smaller compressed air systems. This system was designed as an economical solution for small compressed air systems, up to 125 psi. Theproduct offerings also include a factory-installed and plumbed wall bracket, reducing installation time. Replacement cartridges provide easy, no messmaintenance and offer the lowest life cycle cost in the industry.

ELGI EG75-125 Rotary Screw Air Compressor; 100 HP - 453 CFM @ 125 PSIG100 HP Rotary Screw Compressor, 450 CFM @ 125 PSIG(Direct Drive); Air-End equipped with "eta-V" profile rotors. -- Equipped with: -- 4/5 Lobe combination designed to run at optimum speeds; low operating speeds for extended life, low maintenance and a reduced sound level; Intake Valve System with integrated blow down unit, solenoid controls & actuators designed for low losses. -- Optimal Capacity Control results in a direct saving on power consumption; air-oil separation with OSBIC process means oil-free air (1 PPM), per ISO standards and increasing the life of the separator element. -- Features: -- Efficient air cooling system; "Smart" cooling system maintains a lower temperature which increases the motor life, enables easy maintenance and the ducting is completely insulated internally from the other zones. -- Robust, reliable and able to perform at extreme temperatures - from cold to hot and from dry to extreme humid conditions. -- Complete with: -- Performance Control System's user-friendly intuitive backlit display for easy reading; remote monitoring through an RS485 connection; optimal pressure sensors monitor compressor internal pressure differences to optimize compressor maintenance. -- Includes: -- Phase Monitor, Auto Restart; custom designed, centrifugal type moisture separator with an automatic timer control drain which removes over 99% of bulk water from the compressed air.LIFETIME Air-End Warranty: Lifetime warranty subject to adherence to conditions outlined below. The scope of lifetime warranty will cover replacement of parts and free of cost labor for 120 months from date of start-up or 126 months from date of shipment from an ELGi warehouse, whichever occurs first. Parts only thereafter.Optional: [F10501 / CRP-500] Clean Resources F10501 / CRP-500 CRP-500 CFM Oil/Water Separator System (Includes DC Plus Manifold Installed) Order Number: 553-12-0047 The Next Generation Molecular Filtration System Compression-fit manifold for precise filtration control Timer drain for improved flow of condensate through the media bed Antimicrobial sanitation of discharge hose to prevent algae growth Twelve available inlets (increased from six) No maintenance or messy bag change-outs Cradle-to-grave warranty System monitoring services - Add ...$ 2,650

ELGI EN11-125 Tank Mounted Rotary Screw Compressor w/Refrigerated Dryer, 15 HP - 55 CFM @ 125 PSIGENCAP Series Screw Compressors:120 Gallon Tank Mounted with refrigerated dryer and filters - are designed to encapsulate all functional components and compressor within a common housing. With its small footprint, high reliability and low maintenance requirements, the compressors are ideal for all industrial applications where size, efficiency and cost matter.Equipped with & Features: -- 6 Year Airend Warranty -- Low Sound Enclosure -- Premium Efficiency NEMA motor w/F insulation -- TEFC Drive and Fan Motor -- High Ambient Oil Cooler for low operating temperature -- UL/cUL Certified Control Panel -- Controls & Indications: Microprocessor Controller includes -- Maintenance Schedules -- Pressure Transmitter -- Temperature Transmitter -- Auto Restart -- Remote Start / Stop -- Modulation and Load / Unload Controls -- Phase Monitor -- DCS Connection through Rtu/RS 485 PortRecommended option: F10105 / MICRO 100 Clean Resources F10105 / Micro 100 Clean Resources F10105 Oil/Water Condensate Separator - add $ 775

ELGI EGRD 500 Refrigerated Air Dryer (480 CFM)The ELGi EGRD 500 refrigerated dryer is designed to provide a constant 41ºF dew point and utilizes the latest advancements in refrigeration technology to provide low operating cost and years of trouble-free performance.The advanced “ALU Dry"; aluminum heat exchanger module enables the packaging of the pre-cooler, evaporator, separator, and reheater all in one compact unit. This reduces the size, weight and pressure drop associated with conventional exchangers and optimizes the overall performance and reliability of the dryer which ensures effective removal of condensed liquids regardless of flow.Features: -- Microprocessor Controls with Dew Point Display Indication -- All-In-One Aluminum Design Exchanger -- Low-Pressure Drop -- Ozone Friendly Refrigerant -- De-Mister Type Moisture Separator -- Environmentally Friendly Refrigerant -- Hot Gas Bypass for Constant Dew Point -- Extended Service Life -- Timer Drain Options Include: ELGI Pre-filter AF 0520P rated at 520 SCFM, 1-1/2" NPTPremium Filter Series is constructed from premium materials and features with ease of installation and service in mind. Filter elements have a unique push-fit, double O-ring design to ensure no contaminants get down stream. Features: -- High Quality Aluminum Construction -- Automatic Internal Float Drain -- Pop-up Filter Change Indicator

Call for Price

ELIO VALERI ELVAP 120 Copy Lathe. -- General data: 48" max. length cap., 7" max. dia. without steady rest, 3.93" max. dia. with steady rest, and up to 2.5" x 2.5" dia. with steady rest for square pieces; 0 - 39 FPM forward and 0 - 52 FPM return speed, 5.5 HP motor, 1,300 - 3,500 - 5,000 RPM; -- Features: Air/oil feed and copier, chain head stock drive, gate loading, pattern; pneumatic tail stock, automatic pneumatic control program.

Call for Price

EMC GIANT 1350 2WR Abrasive Planer with (2) Heads, Planer Head and RollerTop of the line Heavy Duty Abrasive Planer from EMC. The series of GIANT machines are available in many configurations. Abrasive Planer has a helicoidal head with insert tooling.Useful working width 1,350 mm (53"). Working thickness min/max mm 3 - 170 (1/8" - 6-5/8").Head configuration: 1st Head: Planer Head "W" -- Cutter head knifes diameter 180 mm. -- Shaft for helicoidal position knifes with (512) Interchangeable knifes with 4 cutting edges, 14 x 14 x 2 mm. -- Sectioned pressure bars in 24 independent segments. -- Anti kickback protection made of 72 independent elements. -- On-Off pneumatic cylinder for planer group in working position. Working pressure adjustment. Motor power 30 kW (40 HP), Star-delta starterSpeed rotation: 35 m/Sec (115 FPS).2nd Head: Roller "R" Belts dimensions: 3,250 x 1,370 mm (128" x 54"). -- Roller diameter: 320 mm (12-5/8"). -- Roller rubber hardness 45 Shore. Constant control to any position with accuracy 0.02 mm. -- On-Off pneumatic piston, controlled from the electrical panel. -- Rotation: Against feed (clockwise). -- Motor power: 22 kW (30 HP) Automatic star-delta starter. Rotating cutting speed: 21 m/Sec (99 FPS). Blower for the roller unit.Feed system: -- Constant pass line, 900 mm (35.4") from floor (In line machine). -- Vacuum bed, 4 kW (5,5 HP) for hold down of smaller parts, mounted inside of the machine base. -- Idle table rollers support in infeed and outfeed. -- Rubber covered presser rollers, grooved. -- Variable feed belt speed, adjustable from 3 to 20 m/Min (9.8 - 65.6 FPM). Inverter Controlled. -- Large diameter screws on machined guides with columns and pistons. -- Automatic feed belt centering device.General Machine Features: -- Independent main motors. -- Analog ammeters, for each motor, on main control cabinet. -- Electronic motorized grit set system, control from touch screen for each working group.Electronic programmable color TOUCH SCREEN display, 7" widePLC with micro-processor of latest generation, modular and expandableConnection USB, RS232, Ethernet 10/100/1000Memory capacity: 100 working programs or moreGraphic synoptic to facilitate programmingSoftware facilities: -- Automatic motor sequence starting. -- Command, programming and display for all electronic pad functions. -- Command, programming and display for thickness. -- Command, programming and display for feeding. -- Command, programming and display for all inverters. -- Command, programming and display for selected groups. -- Command, programming and display for blowers, including compressed air saving function. -- Display report and reset of alarms (self diagnostic) with memory records.Options Included: -- Vacuum bed, 4 kW (5,5 HP) for hold down of smaller parts, mounted inside of the machine base. -- Rotating blowers for part and feed belt cleaning. -- LED light inside the machine. -- Telemetry for remote computer assistance

Call for Price

EMC GIANT 1350 3WRF Abrasive Planer with (3) Heads, Planer Head, Roller and Superfinishing PadTop of the line Heavy Duty Abrasive Planer from EMC. The series of GIANT machines are available in many configurations. Abrasive Planer has a helicoidal head with insert tooling.Useful working width 1,350 mm (53"). Working thickness min/max mm 3 - 170 (1/8" - 6-5/8"). Head configuration:1st Head: Planer Head "W" -- Cutter head knives diameter 180 mm (7-1/16"). -- Shaft for helicoidal position knives with (512) Interchangeable knifes with 4 cutting edges, 14 x 14 x 2 mm. -- Sectioned pressure bars in 24 independent segments. -- Anti kickback protection made of 72 independent elements. -- On-Off pneumatic cylinder for planer group in working position. Working pressure adjustment. -- Motor power 30 kW (40 HP), Star-delta starter.Speed rotation: 35 m/Sec (115 FPS).2nd Head: Roller "R" Belts dimensions: 3,250 x 1,370 mm (128" x 54"). -- Roller diameter: 250 mm (9-13/16"). -- Roller rubber hardness 60-65 Shore. Constant control to any position with accuracy 0.02 mm. -- On-Off pneumatic piston, controlled from the electrical panel. -- "Grit-set system". -- Rotation: Against feed (clockwise). -- Motor power: 22 kW (30 HP) Automatic star-delta starter. Rotating cutting speed: 21 m/Sec (99 FPS). Blower for the roller unit.3rd Head: SUPERFINISHING PAD "F" Electronic PAD segmented in (75) sections. -- Belts dimensions: 3,250 x 1.370 mm (127-15/16" x 54"). -- Width of a single element (section): 18 mm (11/16"). -- APC - Automatic Programmable Control and setting of the air pressure. -- Electronic motorized roller pressure adjustment "grit-set system". -- Rotation: Against feed (clockwise). -- Timed oscillating abrasive belt "air jets" cleaning. -- Motor power: 18,5 kW (25 HP) with electronic inverter variable abrasive belt speed 3 to 18 m/Sec (9.8 - 59 FPS).Feed system: -- Constant pass line, 900 mm (35.4") from floor (In line machine). -- Vacuum bed, 4 kW (5,5 HP) for hold down of smaller parts, mounted inside of the machine base. -- Idle table rollers support in infeed and outfeed. -- Rubber covered presser rollers, grooved. -- Variable feed belt speed, adjustable from 3 to 20 m/Min (9.8 - 65.6 FPM). Inverter Controlled. -- Large diameter screws on machined guides with columns and pistons. -- Automatic feed belt centering device.General Machine Features: -- Independent main motors. -- Analog ammeters, for each motor, on main control cabinet. -- Electronic motorized grit set system, control from touch screen for each working group.Electronic programmable color TOUCH SCREEN display, 7" widePLC with micro-processor of latest generation, modular and expandableConnection USB, RS232, Ethernet 10/100/1000Memory capacity: 100 working programs or moreGraphic synoptic to facilitate programmingSoftware facilities: -- Automatic motor sequence starting. -- Command, programming and display for all electronic pad functions. -- Command, program

$121,500

EMC FLEXY 1350 3WRK Abrasive Planer / Wide Belt Sander with (3) Heads; Knife Head, Roller, Combination Head Roller/Pad.Useful working width 1,350 mm (53"). Working thickness min./max. 3 - 190 mm (1/8" - 7-1/2").Head configuration: 1st Head: Knife Planer Head "W" -- Cutter head knives diameter 140 mm (5-1/2"). -- Shaft for helicoidal position knives with (380) Interchangeable knifes with 4 cutting edges, 14 x 14 x 2 mm. -- Sectioned pressure bars in 24 independent segments. -- Anti kickback protection made of 70 independent elements. -- On-Off pneumatic cylinder for planer. group in working position. -- Working pressure adjustment. -- Motor power 15 kW (20 HP). -- Automatic Star-delta starter. -- Speed rotation: 35 m/Sec (115 FPS).2nd Head: Steel Roller "R", Belts dimensions: 2,620 x 1,370 mm (103" x 54"). -- Roller diameter: 250 mm (10"), spirally grooved. -- Electronic motorized roller pressure adjustment "Grit-set system". -- Constant control to any position with accuracy 0.02 mm. -- Rotation: Against feed (clockwise). -- Motor power 15 kW (20 HP). -- Automatic star-delta starter. -- Abrasive Belt cutting speed: 18 m/Sec (59 FPS). -- Air Jet Blower for abrasive belt cleaning.3rd Head: Combination Head "K", Belt dimensions: 2,620 x 1,370 mm (103" x 54"). -- 3° roller diameter mm 150, Roller rubber covered, hardness 45 shores, Roller pressure adjustment control and "grit-set system" -- ON-OFF selector switch control for 3° roller, including pneumatic piston -- PNEUMATIC aluminum pad, lamina 40 mm, ON-OFF -- Quick changing system; extractable blade with felt, rubber and graphite -- Abrasive belt motor power 15kW (20hp) • Soft starter for slow starting 15kW• Rotating cutting speed 18 m/sec. -- Air Jet Blower for abrasive belt cleaning.Feed system:Constant pass line, 900 mm (35.4") from floor -- Idle table rollers support in infeed and outfeed. -- Rubber covered presser rollers, grooved. -- Variable feed belt speed, adjustable from 3 to 18 m/Min (9.8 - 59 FPM) Inverter Controlled. -- Large diameter screws on machined guides with columns and pistons. -- Automatic feed belt centering device.General Machine Features: -- Independent main motors. -- Analog ammeters, for each motor, on main control cabinet. -- Electronic motorized grit set system, control from touch screen for each (head) working group. Electronic programmable color Touch Screen display, 10" wide -- PLC with micro-processor of latest generation, modular and expandable. -- Connection USB, RS232, Ethernet 10/100/1000. -- Memory capacity: 100 working programs or more. -- Graphic synoptic to facilitate programming.Software facilities: -- Automatic motor sequence starting. -- Command, programming and display for all electronic pad functions. -- Command, programming and display for thickness. -- Command, programming and display for feeding. -- Command, programming and display for all inverters. -- Command, programming and display for selected groups

Call for Price

EMC EXPLORER 1100 SUPER WK Abrasive Planer / Wide Belt Sander with (2) Sanding Heads; Planer Head, Combination head roller/pad.TECHNICAL DATA: -- Useful working width 1,100 mm (43"). -- Working thickness min./max. mm 3 - 170 (1/8" - 6-11/16"). -- Abrasive belt dimension (length) 2,200 mm (86.6") x (width) 1,120 mm (44"). -- Feed belt speeds adjustable by electronic inverter from 3 to 19 m/Min (10 - 63 FPM). Head configuration:1st Head: Planer Head "W" -- Cutter head knives diameter 142 mm (5-9/16"). -- Shaft for helicoidal position knives with (316) Interchangeable knifes with 4 cutting edges, 14 x 14 x 2 mm. -- Sectioned pressure bars in 20 independent segments. -- Anti kickback protection made of 60 independent elements. -- On-Off pneumatic cylinder for planer group in working position. -- Working pressure adjustment. -- Motor power 15 kW (20 HP). -- Automatic Star-delta starter. -- Speed rotation: 30 m/Sec (97.5 FPS).2nd Head: Combination Roller & Pad. -- Roller diameter 142 mm (5-9/16"). Rubber covered hardness 45 Shore. Automatic abrasive belt grit compensation with "Grit-Set System". On Off Selector control for 2° roller incl. pneumatic piston -- Pneumatic elastic pad high resistance with quick changing system; extractable felt, rubber & graphite. . Complete with On-Off Selector and Quick Change System for removable pad with felt, rubber and graphite. Rotating cutting speed 18 m/Sec (59.1 FPS). -- Motor power 15 kW (20 HP). Belt blowers, oscillating, for cleaning of abrasive belt. Abrasive belts oscillation by means of electronic photocell sensor. -- Cleaning Brush: -- Tampico brushing unit for panel cleaning, at outfeed, 150 mm diameterFeed system: -- Working thickness min./max. mm 3 - 170 (1/8" - 6-11/16"). -- Motorized table lifting including fine adjustment, on 4 precision screws. Natural rubber conveyor belt machined. -- Automatic feed belt centering device. Electronic digital display for working thickness; resolution 0.1 mm (0.004"). -- Feed belt speeds adjustable by electronic inverter from 3 to 19 m/Min (10 - 62 FPM). -- Idle table rollers support in infeed and outfeed.Centralized Control Cabinet: Analog ammeters on main control cabinet. Table lifting-lowering thickness system electrically controlled. AUTOMATIC Delta - Star starter on main motors and IP 54 protection against dust & moisture. Centralized independent pneumatic control cabinet: Pneumatic air filter with automatic water-drain system. Pneumatic adjustment for "Grit set system". Pneumatic plant working without lubrication. Compressed air pressure 6 bar (85 PSI). Features: -- Control panel with self-diagnostics alarm control unit. -- Telemetry computer remote diagnostics control. Direct connection with EMC via internet for assistance.USA UL or Canada CSA Safety Features

Call for Price

EMC MERCURY 1350 3WRK Abrasive Planer / Wide Belt Sander with (3) Heads; Planer Head, Contact Roller, and Combination Head.Useful working width 1,350 mm (53"). Working thickness min./max. 3 - 170 mm (1/8" - 6-11/16"). The machines uses abrasive belts 2,620 x 1,370 mm (103" x 54") for longer life of the sanding belts.Head configuration:1st Head: Planer Head "W" -- Cutter head knives diameter 140 mm (5-1/2"). -- Shaft for helicoidal position knives with (380) Interchangeable knives with 4 cutting edges, 14 x 14 x 2 mm. -- Sectioned pressure bars in 20 independent segments. -- Anti kickback protection made of 72 independent elements. -- On-Off pneumatic cylinder for planer. group in working position. -- Working pressure adjustment. -- Motor power: 15 kW (20 HP). -- Automatic Star-delta starter. -- Speed rotation: 32 m/Sec (115 FPS). -- Soft starter for slow starting2nd Head: Steel Roller "R", Belts dimensions: 2,620 x 1,370 mm (103" x 54"). -- Roller diameter: 180 mm (7"), spirally grooved. -- Electronic motorized roller pressure adjustment "Grit-set system". -- On-Off selector switch control for roller. -- Constant control to any position with accuracy 0.02 mm. -- Rotation: Against feed (clockwise). -- Motor power: 11 kW (15 HP) with Automatic star-delta starter. -- Abrasive Belt cutting speed: 18 m/Sec (59 FPS). -- Timing oscillating cleaning abrasive belt blower located at the bottom 3rd Head: COMBINATION Unit "K", Belt dimensions: 2,620 x 1,370 mm (103" x 54"). -- Roller diameter: 140 mm (5-1/2"). -- Roller rubber hardness 45 Shore, Constant control to any position with accuracy 0.02 mm. -- On-Off selector switch control for 3rd roller including pneumatic piston -- Pneumatic Aluminum PAD , lamina 40 mm, On-Off. -- Quick changing system, extractable blade with felt, rubber and graphite. -- Rotation: Against feed (clockwise). -- Motor power: 11 kW (15 HP) with automatic star-delta starter. Abrasive Belt cutting speed:18 m/Sec (59 FPS).Feed system: -- Idle table rollers support in infeed and outfeed. -- Rubber covered presser rollers, grooved. -- Variable feed belt speed, adjustable from 3 to 17 m/Min (9.8 - 55 FPM) Inverter Controlled. -- Automatic feed belt centering device. General Machine Features: -- Large diameter screws on machined guides with columns and pistons. -- Independent main motors. -- Analog ammeters, for each motor, on main control cabinet. -- Electronic motorized grit set system, control from touch screen for each (head) working group. Electronic programmable color TOUCH SCREEN display, 7" wide -- PLC with micro-processor of latest generation, modular and expandable. -- Connection USB, RS232, Ethernet 10/100/1000. -- Memory capacity: 100 working programs or more. -- Graphic synoptic to facilitate programming.Software facilities: -- Automatic motor sequence starting. -- Command, programming and display for all electronic pad functions. -- Command, programming and display for thickn

Call for Price

EMC VENUS 1300 1K ... Finishing Sander with (1) Sanding Head: Combination Head.Useful working width 1,300 mm (51"). Working thickness min/max mm 3 - 170 (1/8" - 6-5/8").Working Unit: Combination Roller & Pad. -- Roller diameter 142 mm (5-5/8"). Rubber covered hardness 85 Shore. Roller pressure adjustment control & "Grit-set system". Main Motor On Off Selector control with pneumatic piston to select roller, 22 kW (30 HP) Automatic star-delta starter Rotating cutting speed: 18 m/Sec (59 FPS). -- PNEUMATIC Controlled Flexible Sanding Pad Including On-Off Selector: Quick Change System: Removable pad with felt, rubber and graphite. Rotating cutting speed 18 m/Sec (55.8 FPS). Abrasive belts oscillation by means of electronic photocell sensor.Feed system:CONSTANT PASS LINE - fixed infeed height 900 mm (35") from floorIdle table rollers support in infeed and outfeedRubber covered presser rollers, groovedVariable feed belt speed, adjustable from 3 to 19 m/Min (9.8 - 62 FPM). Inverter ControlledLarge diameter screws on machined guides with columns and pistonsAutomatic feed belt centering deviceElectronic digital display for working thicknessGeneral Machine Features: -- Analog ammeters on main control cabinet. -- Electronic motorized grit set system, control from touch screen.Electronical Panel: -- Check Control Self Diagnostics with Alarm Control. -- Analog Ammeter on the main control cabinet. -- Infeed table thickness system electrically controlled. -- Independent Overload protection.Safety: -- Infeed front emergency swinging bar for oversized panels. -- Infeed protection pressing blade to avoid pieces to go back to operator. -- Rear and front emergency push buttons. -- Automatic brake on abrasive belts motors. -- Automatic emergency stop and alarm display in case of: ● Low Air Pressure. ● Doors opened ("easy maintenance and inspection"). ● Electric motors overloading. ● Emergency detector for over thickness material cut. ● No tension on abrasive belt. ● Abrasive belt lateral mistracking. ● Abrasive belt broken.Idle table rollers support in infeed and outfeedCentralized Control Cabinet: ● IP 54 protection against dust & moisture. ● Analog ammeter on main control cabinet. ● Table lifting-lowering thickness system electrically controlled. ● AUTOMATIC Delta - Star starter on abrasive belts motors. Centralized independent pneumatic control cabinet: ● IP 54 protection against dust & moisture. ● Pneumatic air filter with automatic water-drain system. ● Pneumatic adjustment for "Grit set system". ● Pneumatic plant working without lubrication. ● Compressed air pressure 6 bar (85 PSI). Options Available: Tampico Brush natural fiber brush for cleaning of the pieces, diameter 150 mm (6"). Motor Power 1.1 kW (1.5 HP). $3,950

$13,900

EMC PIONEER 2RK Wide Belt Sander, (2) Head: 37" Width capacity. Drum, Combination Head.Head Configuration: 1st Head: -- Rubber covered contact roll 180 mm diameter.2nd Head: -- Combination Head, rubber covered roller with padSpecifications: -- Useful working width: 950 mm (37"). -- Working thickness min/max: 3 - 170 mm. -- Abrasive belts length: 1,900 mm. -- Abrasive belt width: 975 mm. -- (2) Feed speeds: 5 - 10 m/min. -- Electronic digital display for working thickness. -- Abrasive belt oscillation by electronic photocell. -- Main drive motor 15 HP -- Feed drive 2 to 19 Meter/min.

$37,500

Heesemann MFA6 (3) Head Wide Belt Sander, 53" width cap. Drum Drum, Segmented platenHead configuration1st Head: Steel contact roll, 30 HP motor2nd Head: Rubber covered contact roll, 20 HP motor3rd Head: Segmented polishing platen, electronically controlled segments to conform to panel size, 20 HP motor4th Station: Outfeed rotary panel cleaning brush, 2 HP motor.Specifications -- Platen head equipped with: HESSEMANN's Patented "CSD-32" selective pressure adjustment system; sensors placed every (32 mm) sense part configuration, pressure for each segment can be pre-programmed to provide less pressure on the outer edges or more in the center if desired. -- Both contact rolls with NC positioning and auto grit compensation, automatic line control for platen independent of feed speed determines automatically the correct part in time for the pressure segmentEquipped with & Features -- Outfeed rotary panel cleaning brush, 2 HP motor. -- 55" x 103" Abrasive belts on all heads with abrasive belt air cleaners, "ICP" control for all sander functions, (20) programs storrage. -- Variable feed speed from 10 - 49 FPM, 3 HP feed drive with inverter control. -- Vacuum conveyor bed assembly with suction fan and )motor mounted in machine base, motorized thickness opening 0" - 5-7/8" w/digital readout, constant passline of conveyor bed assembly 35" height.NOTE Some Spec's need to Varified

$193,320

Heesemann MFA Impression 4-Head Wide Belt SanderSpecifications -- Working Width: 53" (1350mm) -- Workpiece Thickness: 0.118" to 6" (3mm to 160mm) -- Working Height: 36.2" (880 mm) -- Wide Belt Size: 103" x 55" (2620mm x 1400mm) -- Cross Belt Size: 189"x6" (4800 x 150mm) -- Variable Feed Speed: 10-50 FPM (3-15 mpm) -- Vacuum Bed for Safe Movement -- os Workpieces Shorter than 19.7" (500mm)Head Configuration1st Head: Cross Sanding Unit Heesemann's Cross Sanding Head Unit Removes Fiber from Solid Wood or can be used to Remove Tape from VeneerSanding Belt Speed:6.5 - 65 FPS (2-20 m/s)Drive Motor: 23HP (17kW)2nd Head: Longitudinal Sanding Unit Sanding Belt Speed: 6-60 FPS (1.8-18 m/s) Drive Motor: 23HP (17kW)3rd Head Longitudinal Sanding Unit Sanding Belt Speed: 6-60 FPS (1.8-18 m/s) Drive Motor: 23HP (17kW)4th Head: Lef Head w/ Internal Pressure Belt Enhanced Finish Let Head Features an Inner Chevron Belt to Allow for Fine Sanding of Workpiece Sanding Belt Speed w/o Pressure Belt: 6-60 FPS (1.8-18 m/s) Sanding Belt Speed w/ Pressure Belt: 6-30 FPS (1.8-9 m/s) Drive Motor: 23HP (17kW)Equipped with & Features --All Heads Variable Speed Belt equipped with Inverter Motor -- CSD® segmented pad system on all Heads -- A pinch roll system, rubber covered and adjustable -- An automatic infra-red belt control -- Servo cross belt tracking adjustments, for quick and easy belt centering when loading -- Workpiece Blasting Device -- Rotating Compressed Air Nozzles for Blasting Workpiece Surface -- LED Lights on Belt Change Side -- Ionization Bar from Above that Helps Reduce Static Charge -- Pneumatic Conveyor Belt Cleaning -- Dust Extraction: Approx 6000 CFM -- Compressed Air: 100 cfm @ 100 psi -- Power: 480 Volt, 3 Phase, 60HZ

$90,000

HEESEMANN - LSM 8-5 RRRL, ...53" Wide Belt Sander53" Width cap.: Drum, Drum, Drum, and CSD® Pad.Head Configuration:• Unit 1 - Longitudinal Sanding Unit: Steel contact roller, helically grooved. - Single-speed 48 HP motor, electronic braking.• Unit 2 - Longitudinal Sanding Unit: Rubber-covered contact roller, helically grooved. - Single-speed 35 HP motor, electronic braking.• Unit 3 - Longitudinal Sanding Unit:- Rubber-covered contact roller, helically grooved. - Single-speed 35 HP motor, electronic braking, bi-directional drive.• Unit 4 - Longitudinal Sanding Unit: CSD® Segmented pad system, 2-speed 20/26 HP motor, electronic braking.• Unit 5 - Panel Cleaning Brush: Fiber trimming, 2.3 HP Motor.Specifications: -- Working height: 880 mm (34.64"). -- Workpiece thickness: 3 mm to 150 mm (1/8" to 6"). -- Working width: 1,300 mm (51-1/8"). -- Longitudinal belt: 1,350 x 2,620 mm (53" x 103"). -- Machine voltage: U.S. Electrics 480 Volts, 3-Phase, 60 cycles.Constant Pass LineController: -- Industrial PC. -- TFT Color touchscreen. -- Windows® Operating System. -- (100) Memory addresses for: • CSD® sanding pressure. • Sanding start/stop. • Sanding belt speeds. • Grit sequence indication. • Sanding belt selection - "ON/OFF". • 1-Button sequenced starting for all motors.RS-232 Serial port.RJ-45 LAN Port.Modem with software licenses.For All additional, detailed specs, select the "View Literature" link .

$39,700

HEIAN FP-151-MC-2113 5-Axis CNC MachineFor high speed & precision routing/trimming & sizing wood and composite parts.Equipped With: -- (2100 mm) x (1,300 mm), moving table, fixed bridge style machining center; mahogany vacuum table. -- 3.7 kW, NT 30 Type ATC spindle, variable speed from 2,000 - 18,000 RPM with 8-position tool carousel. -- FANUC "16i CNC Control, 10.4" LCD , RS-232C/PCMCIA (memory card). Features: -- 5-Axis simultaneous motion, M & G code programming, inch or metric operation. -- Working Axes Stroke & Speed: X-Axis (2,600 mm) 60 m/Min; Y-axis (1,600 mm) 40 m/Mn; Z-axis (800 mm) 20 m/Min -- C-axis +/- 270°; B-axis +/- 110°; C-axis travels at 4,000°/Min and B travels at 4,000°/Min. -- Complete with assorted tool holders.

HENDRICK - PRO-V HP3: Automatic Vertical Panel SawSpecifications & Features -- 96" Cutting length (cuts vertically top to bottom); adjustable depth of cut up to 2-3/8"; 14" blade dia. with: 1" Dia. bore; single blade scoring; 7.5 HP main motor. -- Equipped with: -- Heavy-Duty precision machined squaring fence; Formica laminated back table surface; full length pneumatic holddown bar with: Sensitive safety tape on both sides of holddown; 1 HP drive; 2-speed automatic saw carriage; travels 30 & 60 FPM (saw travel/return adj. to cut length). -- Complete with: -- (5) Adjustable flip stops on: (3) Positioning bars; ready for Dust Collector hookup. Actual model: Pro-V HP3

$32,500

HMC 2-Saw Trimmer Model ET-10,;Complete with the following features: --16′ capacity. --Push Button Setworks. --Left hand (feeds from left to right). --Cuts up to 8″ thick. --Belt Conveyor for waste.NOTE: Removed from service and it was running just fine at the time of removal. Stored outside.

Call for Price

HOCKER POLYTECHNIK - MultiStar Series: Pulse Jet Baghouse 33,000 CFM (56,000 cbm/Hr) based on 5.2 to 1 Air-to-cloth ratio (FPM: Average air velocity thru filter media) with: 6,345 Square feet of filter area. -- Filtration: Filters are automatically cleaned by Pulse-Jet system based on supply of: 1" Dia. dried clean compressed air line from Plant. Cleaning automatically controlled via timed cycles or by the Delta P, which is the differential pressure across the filter bags. -- Supplied with: (4) HOCKER DER - 040/45022 Radial BI fan; each directly driven by: 30 HP - TEFC 3,600 RPM High efficiency motors; mounted on the clean air side. Rated for a total of: 33,000 CFM at 16" SP (4,000 Pa). Fan inlets are: 18" (450 mm) Dia. each. Non-return flap camper on the outlet side. -- Includes Electrical panel with: PLC Controls; explosion relief panels; sprinkler heads in the clean air plenum; ATEX approved construction with 11-gauge electroplated galvanized steel shell with: Clean air outlet not returned to plant. -- Equipped with: (1) HP Rotary Air Lock. -- Control - SIEMENS - SIMATIC TPI200. PLC Controller housed in a floor-mounted central control panel with: Modem module for allowing HOCKER online access to assist in program changes; 12" TFT color, touchscreen display.All starters & contacts for included motors.Pictorial guided navigation and fault messages are displayed in text.Graphic images, curves, bar diagrams, parameter adjustment settings, and fault report.FI MF 22.0 kW SPS Ctrl.: Allows startup of several fans, one after the other. -- VFD Drives on each motor with: Automatic motor tuning; automatic startup; min./max. speed limits; DC brakes; operating hours meter. -- Includes: Access ladder to upper catwalk and exterior pipe; Heavy-Duty galvanized for outdoor operation. -- Professional dismantling & transportation available upon request.

Call for Price

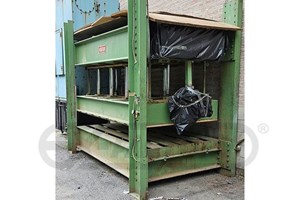

HOFER HOP 160 K Hydraulic Door/Veneer Heavy Duty Cold PressSpecifications:Platen size 63" deep x 98" long, Total Daylight/Opening 32".available. Currently set at about 13" opening. Top platen is hydraulically powered by a 2.2 KW power pack. and has (10 sets) of bolt holes for manual adjustment of daylight opening.Equipped with:(8) 3-1/4" Diameter Hydraulic cylinders, Rack & pinion platen leveling adjustment.Front and back loading (access on all sides).Heavy duty steel structural beams. Bolted top and bottom platens.Features:Pneumatically loaded 3 +1 rows of idle rollers on bottom platen for ease of feeding the load in and out front of press. Air valve for up/down selection of bottom platen rollers.Hydraulic closing speed adjustment.Electrical controls on right hand side.Dimensions/Weight: 124" x 72" x 122" H. Approx. 12,000 Lbs.