704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

Woodworking

1883 Results Found

704-841-2001

CASADEI (PUTSCH-Branded) EBP-950 PMCR Automatic Edgebander, , New, Never Used, with Pre-Mill & Corner RoundingSpecifications: -- Edgebanding thickness: 0.4 - 3 mm (0.02" - 0.12") Coil, 0.4 - 5 mm (0.02" - 0.20") Strip with Manual feed. -- Panel thickness 8 - 45 mm (0.31" - 1.77"), Min. panel width 95 mm (3.74"), & Min. panel length 110 mm (4.33"). -- Feed speed 9 MPM (29 FPM).Equipped with: -- Pre-Mill Unit, with (2) 0.75 kW (1 HP) - 12,000 RPM - 200 Hz Motors, Counter-rotation, (2) 60 mm Dia. x 52 mm H (2.36"; Dia. x 2.05"; H) Diamond cutterheads, Max. milling adjustment 2 mm (0.08"), & Dedicated extraction system with Blower. -- Anti-Adherence Spray Unit. -- Infrared lamp. -- FLEX Interchangeable gluing system, with Teflon-coated glue pot with (6) 1,315 W Heating elements with (4) in Glue pot, (1) in Turret & (1) in Glue spreading roller, Thermostatic glue control, Automatic standby & Temperature display, and Automatic glue drainage. -- Pneumatically-operated guillotine. -- Pressure section, with (1) Large driven & (2) Small idler rollers. -- Feed chain, with Scratch resistant, non-slip rubber pads. -- Top pressure beam, with (2) Rows of rubber rollers. -- Safety enclosure. -- PLC Control, with ETOUCH 7" Backlit LCD touchscreen display, 99-Program Storage, & Diagnostics.Workstations: -- Front & Rear End Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, & (2) 80 mm (3.15";) Knives. -- Top & Bottom Flush/Bevel/Radius Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motors, 75 mm (2.95") Dia. Cutters with Disposable knives, 2 - 3 mm (0.08" - 0.012") Radii, & 15° Bevel. -- Corner Rounding Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, 50 mm (1.97";) Diamond cutterheads, 50 mm (1.97";) Vertical/Horizontal copiers for profiling straight, curved, & beveled edges, & PLC-selectable front, rear, or complete panel processing. -- Edge Scraping Unit, with 2 mm (0.08";) Cutters, -- Top & Bottom Glue Scraping Unit, with 120 mm (4.72";) Vertical disc copier. -- Top & Bottom Buffing Unit, with (2) 0.13 kW (0.17 HP) - 1,400 RPM Motors. -- Polishing Spray Unit, PLC-Controlled, with (2) Sprayers.NOTE: Sold "As Is" Without Warranty!

CASADEI (PUTSCH-Branded) EBP-950 PMCR Automatic Edgebander, New, Never Used, with Pre-Mill & Corner RoundingSpecifications: -- Edgebanding thickness: 0.4 - 3 mm (0.02" - 0.12") Coil, 0.4 - 5 mm (0.02" - 0.20") Strip with Manual feed. -- Panel thickness 8 - 45 mm (0.31" - 1.77"), Min. panel width 95 mm (3.74"), & Min. panel length 110 mm (4.33"). -- Feed speed 9 MPM (29 FPM).Equipped with: -- Pre-Mill Unit, with (2) 0.75 kW (1 HP) - 12,000 RPM - 200 Hz Motors, Counter-rotation, (2) 60 mm Dia. x 52 mm H (2.36"; Dia. x 2.05"; H) Diamond cutterheads, Max. milling adjustment 2 mm (0.08"), & Dedicated extraction system with Blower. -- Anti-Adherence Spray Unit. -- Infrared lamp. -- FLEX Interchangeable gluing system, with Teflon-coated glue pot with (6) 1,315 W Heating elements with (4) in Glue pot, (1) in Turret & (1) in Glue spreading roller, Thermostatic glue control, Automatic standby & Temperature display, and Automatic glue drainage. -- Pneumatically-operated guillotine. -- Pressure section, with (1) Large driven & (2) Small idler rollers. -- Feed chain, with Scratch resistant, non-slip rubber pads. -- Top pressure beam, with (2) Rows of rubber rollers. -- Safety enclosure. -- PLC Control, with ETOUCH 7" Backlit LCD touchscreen display, 99-Program Storage, & Diagnostics.Workstations: -- Front & Rear End Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, & (2) 80 mm (3.15";) Knives. -- Top & Bottom Flush/Bevel/Radius Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motors, 75 mm (2.95") Dia. Cutters with Disposable knives, 2 - 3 mm (0.08" - 0.012") Radii, & 15° Bevel. -- Corner Rounding Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, 50 mm (1.97";) Diamond cutterheads, 50 mm (1.97";) Vertical/Horizontal copiers for profiling straight, curved, & beveled edges, & PLC-selectable front, rear, or complete panel processing. -- Edge Scraping Unit, with 2 mm (0.08";) Cutters, -- Top & Bottom Glue Scraping Unit, with 120 mm (4.72";) Vertical disc copier. -- Top & Bottom Buffing Unit, with (2) 0.13 kW (0.17 HP) - 1,400 RPM Motors. -- Polishing Spray Unit, PLC-Controlled, with (2) Sprayers.NOTE: Sold "As Is" Without Warranty!

CASADEI (PUTSCH-Branded) EBP-950 PMCR Automatic Edgebander, New, Never Used, with Pre-Mill & Corner RoundingSpecifications: -- Edgebanding thickness: 0.4 - 3 mm (0.02" - 0.12") Coil, 0.4 - 5 mm (0.02" - 0.20") Strip with Manual feed. -- Panel thickness 8 - 45 mm (0.31" - 1.77"), Min. panel width 95 mm (3.74"), & Min. panel length 110 mm (4.33"). -- Feed speed 9 MPM (29 FPM).Equipped with: -- Pre-Mill Unit, with (2) 0.75 kW (1 HP) - 12,000 RPM - 200 Hz Motors, Counter-rotation, (2) 60 mm Dia. x 52 mm H (2.36"; Dia. x 2.05"; H) Diamond cutterheads, Max. milling adjustment 2 mm (0.08"), & Dedicated extraction system with Blower. -- Anti-Adherence Spray Unit. -- Infrared lamp. -- PURE (PUR & EVA) Hot melt gluing system, with Teflon-coated glue pot with (6) 1,315 W Heating elements with (4) in Glue pot, (1) in Turret & (1) in Glue spreading roller, Thermostatic glue control, Automatic standby & Temperature display, and Automatic glue drainage. -- Pneumatically-operated guillotine. -- Pressure section, with (1) Large driven & (2) Small idler rollers. -- Feed chain, with Scratch resistant, non-slip rubber pads. -- Top pressure beam, with (2) Rows of rubber rollers. -- Safety enclosure. -- PLC Control, with ETOUCH 7" Backlit LCD touchscreen display, 99-Program Storage, & Diagnostics.Workstations: -- Front & Rear End Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, & (2) 80 mm (3.15";) Knives. -- Top & Bottom Flush/Bevel/Radius Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motors, 75 mm (2.95") Dia. Cutters with Disposable R1/R2 3"; Knives, 2 - 3 mm (0.08" - 0.012") Radii, & 15° Bevel. -- Corner Rounding Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, 50 mm (1.97";) Diamond cutterheads, 50 mm (1.97";) Vertical/Horizontal copiers for profiling straight, curved, & beveled edges, & PLC-selectable front, rear, or complete panel processing. -- Edge Scraping Unit, with 2 mm (0.08";) Cutters, -- Top & Bottom Glue Scraping Unit, with 120 mm (4.72";) Vertical disc copier. -- Top & Bottom Buffing Unit, with (2) 0.13 kW (0.17 HP) - 1,400 RPM Motors. -- Polishing Spray Unit, PLC-Controlled, with (2) Sprayers. -- Antistatic & Cooling Spray UnitNOTE: Sold "As Is" Without Warranty!

CASADEI (PUTSCH-Branded) EBP-950 PMCR Automatic Edgebander, New, Never Used, with Pre-Mill & Corner RoundingSpecifications: -- Edgebanding thickness: 0.4 - 3 mm (0.02" - 0.12") Coil, 0.4 - 5 mm (0.02" - 0.20") Strip with Manual feed. -- Panel thickness 8 - 45 mm (0.31" - 1.77"), Min. panel width 95 mm (3.74"), & Min. panel length 110 mm (4.33"). -- Feed speed 9 MPM (29 FPM).Equipped with: -- Pre-Mill Unit, with (2) 0.75 kW (1 HP) - 12,000 RPM - 200 Hz Motors, Counter-rotation, (2) 60 mm Dia. x 52 mm H (2.36"; Dia. x 2.05"; H) Diamond cutterheads, Max. milling adjustment 2 mm (0.08"), & Dedicated extraction system with Blower. -- Teflon-coated glue pot with (6) 1,315 W Heating elements with (4) in Glue pot, (1) in Turret & (1) in Glue spreading roller, Thermostatic glue control, and Automatic standby & Temperature display. -- Pneumatically-operated guillotine. -- Pressure section, with (1) Large driven & (2) Small idler rollers. -- Feed chain, with Scratch resistant, non-slip rubber pads. -- Top pressure beam, with (2) Rows of rubber rollers. -- Safety enclosure. -- PLC Control, with ETOUCH 7" Backlit LCD touchscreen display, 99-Program Storage, & Diagnostics.Workstations: -- Front & Rear End Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, & (2) 80 mm (3.15";) Knives. -- Top & Bottom Flush/Bevel/Radius Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motors, 75 mm (2.95") Dia. Cutters with Disposable R1/R2 Knives, Vertical nesting copiers, 2 - 3 mm (0.08" - 0.012") Radii, & 15° Bevel. -- Corner Rounding Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, 50 mm (1.97";) Diamond cutterheads, 50 mm (1.97";) Vertical/Horizontal copiers for profiling straight, curved, & beveled edges, & PLC-selectable front, rear, or complete panel processing. -- Edge Scraping Unit, with 2 mm (0.08";) Cutters.NOTE: Sold "As Is" Without Warranty!

CASADEI (PUTSCH-Branded) EBP-950 PMVR Edgebander, New, Never Used, with Pre-Mill & Vertical RoundingSpecifications: -- Edgebanding thickness: 0.4 - 3 mm (0.02" - 0.12") Coil, 0.4 - 5 mm (0.02" - 0.20") Strip with Manual feed. -- Panel thickness 8 - 45 mm (0.31" - 1.77"), Min. panel width 95 mm (3.74"), & Min. panel length 110 mm (4.33"). -- Feed speed 9 MPM (29 FPM).Equipped with: -- Pre-Mill Unit, with (2) 0.75 kW (1 HP) - 12,000 RPM - 200 Hz Motors, Counter-rotation, (2) 60 mm Dia. x 52 mm H (2.36"; Dia. x 2.05"; H) Diamond cutterheads, Max. milling adjustment 2 mm (0.08"), & Dedicated extraction system with Blower. -- Anti-Adherence Spray Unit. -- Teflon-coated glue pot with (6) 1,315 W Heating elements with (4) in Glue pot, (1) in Turret & (1) in Glue spreading roller, Thermostatic glue control, and Automatic standby & Temperature display. -- Pneumatically-operated guillotine. -- Pressure section, with (1) Large driven & (2) Small idler rollers. -- Feed chain, with Scratch resistant, non-slip rubber pads. -- Top pressure beam, with (2) Rows of rubber rollers. -- Safety enclosure. -- PLC Control, with ETOUCH 7" Backlit LCD touchscreen display, 99-Program Storage, & Diagnostics.Workstations: -- Vertical Rounding End Trim Unit, with Diamond Cutterhead & PLC-selectable front, rear, or complete panel processing. -- Top & Bottom Flush/Bevel/Radius Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motors, 75 mm (2.95") Dia. Cutters with Disposable R1/R2 3"; Knives, 2 - 3 mm (0.08" - 0.012") Radii, & 15° Bevel. -- Edge Scraping Unit, with 2 mm (0.08";) Cutters, -- Top & Bottom Glue Scraping Unit, with 120 mm (4.72";) Vertical disc copier.NOTE: Sold "As Is" Without Warranty!

$23,500

CASADEI (PUTSCH-Branded) EBP-950 EdgebanderSpecifications: -- Edgebanding thickness: 0.4 - 3 mm (0.02" - 0.12") Coil, 0.4 - 5 mm (0.02" - 0.20") Strip with Manual feed. -- Panel thickness 8 - 45 mm (0.31" - 1.77"), Min. panel width 95 mm (3.74"), & Min. panel length 110 mm (4.33"). -- Feed speed 9 MPM (29 FPM).Equipped with: -- Teflon-coated glue pot with (6) 1,315 W Heating elements with (4) in Glue pot, (1) in Turret & (1) in Glue spreading roller, Thermostatic glue control, and Automatic standby & Temperature display. -- Pneumatically-operated guillotine. -- Pressure section, with (1) Large driven & (2) Small idler rollers. -- Feed chain, with Scratch resistant, non-slip rubber pads. -- Top pressure beam, with (2) Rows of rubber rollers. -- Safety enclosure. -- PLC Control, with ETOUCH 7" Backlit LCD touchscreen display, 99-Program Storage, & Diagnostics.Workstations: -- Top & Bottom Flush/Bevel/Radius Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motors, 75 mm (2.95") Dia. Cutters with Disposable R1/R2 3"; Knives, 2 - 3 mm (0.08" - 0.012") Radii, & 15° Bevel. -- Edge Scraping Unit, with 2 mm (0.08";) Cutters.NOTE: Sold "As Is" Without Warranty!

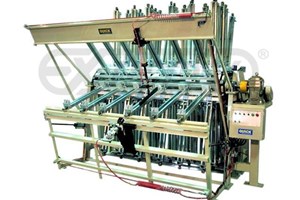

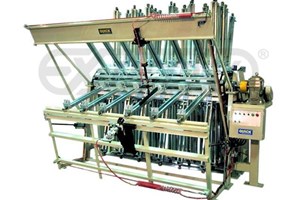

QUICK Clamp Rack 8' -- Description: The QUICK Clamp Rack features a cleanly-designed, exceptionally strong frame, with massive 4" x 4" structural tubing cross beams and feet, and 4" x 6" structural tubing legs.The innovative “two-sided"; frame design allows for either one-sided or two-sided operation, at the shop owner’s discretion. The one-sided configuration allows for placement of the frame tightly against a wall, for maximum compactness. The two-sided configuration doubles the amount of easily-accessible clamping area, for industry-leading “room to work."; The Rack is configured by choosing either of the two available foot mounting positions. -- Specifications:96" Wide (36) Clamps 3.5" X 40" opening

Quick Hydraulic Clamp Carrier with 20-sections and 12-1/2' width capacity.This special "thick stock" frame accepts (12) Heavy Duty zinc plated clamps per section. Includes: -- 240 clamps with 36" openings and 6" high x 4-3/4" wide jaws with 1° inward draft. -- Integral hydraulic overhead panel flattener. -- (2) Hydraulic clamp tightener with adjustable torque limiter. -- (2) Pneumatic panel flattener -- Single button automatic electric motor rotation cycle with indexing. -- Heavy Duty frame with 3" diameter shafts and 6" I-beam legs. -- Includes foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating and tool box with spare parts & tools.Note: Could be order with single tightener and panel flattener

QUICK 20-Section Heavy Duty Pneumatic Clamp Carrier with 10-1/2' width capacity -- With (8) Standard zinc plated clamps per section (160 clamps total), 38" opening on clamps.Standard Features include: -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Panel Flattener with easy to use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation 2 HP; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time!Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: A 20-Section Clamp typically produces 500 panels per shift.OAL Dimensions are 163" W x 182" D x 125" H

QUICK 20-Section Pneumatic Clamp Carrier with 10-1/2' width capacity -- With (8) Standard zinc plated clamps per section (160 clamps total), 38" opening on clamps. Standard Features include: -- Clamps jaws are 2-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Panel Flattener with easy to use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time!Complete with: Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: A 20-Section Clamp typically produces 500 panels per shift.

The 7000 vertical panel saw is a high capacity production machine. This heavy-duty saw offers incredible durability and accuracy at a very affordable price. -- Sporting a 3 HP, 3-Ph motor - (Model 7000M - 2 HP 1-Phase deduct $ 205) this machine will rise to the occasion during the toughest of applications. -- The saw carriage rides on two aluminum anodized extruded beams with integrated linear v-guides allowing the machine to deliver an accuracy of .015". -- The rugged steel frame will handle years of abuse in the most challenging working environments. -- Shipping anywhere in continental U.S.;...$ 649.

Call for Price

SALVADOR - SUPERANGLE 600, ...Pusher Chop Saw. Provides complete chop to length & optimization of wood strips including the elimination of defects. -- Infeed is made of Heavy-Duty steel frame; working height: 1,000 mm (39") from floor level; safety provided by a light curtain. -- Pusher slides on double hardened rails. -- Reading Operation: Uses (2) Sensors: (1) for overall length and the other to read the crayon marks. -- Transmission of power: From motor to the carriage; accomplished by a 50 mm wide steel reinforced toothed belt. -- Part held in place by (2) aligners before & after the blade; insures a square cut. -- Saw box area: Enclosed by interlocking steel cover with a large window for clear view; Saw travels through an aluminum table insert that can be easily changed as needed; High Efficiency motor, IE3 rating, helps keep power consumption at a minimum. -- Technology: Operating software: Customized Windows-based program; designed to be intuitive and specially designed for optimization of the wood. -- Large 19" monitor at operator eye level; PC set up with: SSD Double hard drive with 2nd being a clone to have and be ready to back up in the machine. -- Cut lists: Can be uploaded remotely by network connection or flash drive; chop length optimization can be set for minimum waste priorities. -- Optimizer supports defecting crayons, as well as up to 5-grade qualities. -- Electronics: Multi tap transformer steps down higher voltages; 460 - 600 to the voltage requited by the machine. -- SP 15 Magnetic Strip Measurement: Technology improves positioning from basic encoder standards to absolute measurements of +/- 0.1mm. -- Outfeed: 0° Belt and (1) PC double ejector. For applications of many workpieces cut at angles, it is best to eject the workpieces together with one large rack & pinion ejector. Workpieces are pulled from the Saw on an outfeed belt. - Once the parts are clear of the Saw, the large ejector manages all cuts in 1-push onto the steel table for collection. WORKING CAPACITYMaximum board length before cutting: 5,100 mm (16').Minimum board length before cutting: 500 mm (19.6").TECHNICAL SPECIFICATIONSMain saw power: 15 HP.Saw blade specifications: SA600; Max. 00 mm; dia. bore 35 mm.Maximum pusher reading speed: 60 MPM (200 FPM)Maximum pusher pushing speed 60 MPM (200 FPM)CUTTING CROSS SECTION ● 0°: 100 mm x 360 mm / 160 mm x 310 mm. ● +/- 45°: 100 mm x 260 mm / 160 mm / 220 mm. ● +/- 70°: 100 mm x 120 mm / 160 mm x 100 mm.Minimum: 15 mm x 30 mm.Number of cuts within last 40 mm of board One: (1)Maximum workpiece weight: 110 kG (242 Lbs).Power Requirements ● 11 kW. ● Primary supply voltages: 220/380/420/440/460/480/560/580/600 V.Pneumatic Requirements ● Compressed air supply: 600 - 800 kPa (6 - 8 bar). ● Maximum air consumption: 300 Nl/min.Dust Extraction ● Intake diameter: 160 mm Upper; 120 mm lower/ ● Extraction System Collection speed: 28 M/s. ● Dust Extraction Capacity: 1

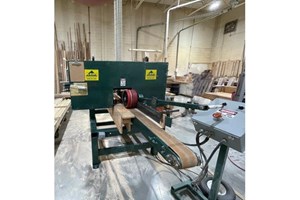

KENT - Single Head, ResawSpecifications: -- 15 HP Motor. -- Blade size: 168"; x 1"; x 0.035"; 2TPI. -- 6" Wide feed belt. -- Operational working heights: 1/4" minimum cut to 8"; maximum. -- Feed speed: 20 - 150 Feet per minute.

SAND-RITE DB-612 DLX Sander with Heavy Duty Cast Iron StandCustom ordered to fit your requirements with quick 3 week lead-time!Specifications: -- (1) 6" Diameter x 7" Wide pneumatic drum head , which allows the operator to regulate how firm the sanding head needs to be to conform the head to what they are sanding. -- Motor: 3/4 HP -- (1) B-12 Brush Head, which allows the sanding irregular surfaces with out loss of shape. -- And matching Heavy Duty Cast Iron Stand.

SAND-RITE DUO-DLX Spindle Sander; Horizontal spindle sander with 3/4 HP BALDOR motor. -- Optional brush heads sand irregular surfaces with out loss of shape, and the optional pneumatic drum heads (available in 2" to 8" diameters) allow the operator to regulate how firm the sanding head needs to be to conform the head to what they are sanding. -- Price does not include the stand - Add $308.00 Cast iron stand."Drums, brush heads, and sleeves are additional".Brush Head: ADD $ 175.00 2" X 8" pneumatic drum: ADD $ 140.008" X 9" pneumatic drum: ADD $ 302.00 Special note: 220 grit is the finest grit supplied for Brush Head

$6,500

SANDINGMASTER - KSB-900, ...Single Head Wide Belt Sander36" Width cap.; combination sanding head.Head: Rubber covered spiral grooved contact roll & finishing platen.Specifications:15 HP Main motor.37" x 75" Abrasive belt size.Electronic tracking and air tensioning of abrasive belt.Rubber covered infeed & outfeed holddown rollers & holddown shoes.Variable feed speed 15 - 45 FPM via 1.5 HP motor.0" - 5" Manual part thickness opening.Includes: Optional floating bed for sanding fine veneers.Equipped with & Features:Extended infeed.Load meter.Disc brake on main motor.Safety stop bar.

$18,500

SANDINGMASTER SA3300-900 TRIPLE HEAD WIDE BELT SANDER3-Head, 36" max. width cap. - 1st Head: 11" Dia. rubber covered contact roll, 24 HP motor; 2nd Head: 11" Dia. rubber covered contact roll, 18 HP motor; 3rd Head: Combination head with rubber covered contact roll and finishing platen, 18 HP motor. 37" x 75" Abrasive belts with electronic tracking. -- 2-Speed conveyor feed, 23 & 46 FPM, 1.0/1.7 HP motor, 0" - 6" motorized part thickness with LED readout, a joystick lever controls raise and lower of feed bed and start and stop of conveyor belt, also includes "SP-Matic" automatic part thickness setup. -- Thin veneer sanding package with rigid table setting for solid wood dimensioning and floating table setting for veneer sanding, infeed and outfeed spring loaded holddown shoes. -- Includes: Motor load meters, electronic brakes on sanding heads, infeed safety shutoff bar and 18" infeed conveyor area. Actual model "SA-3300-900".

SANDMAN DL7236 Downdraft Sanding Table;The SANDMAN Sanding Table is a dedicated sanding station that doubles as a workbench. -- 72" X 36" Rubberized work surface. -- 1.5 HP T.E.F.C. 220V 1-Phase motor with 10-5/8" LAU blower with sealed ball bearings. -- Industrial casters with 4" wheels, (2) ridged, (2) swivel-lock 2-ways. -- Hinged tilt-up top with gas strut lid support for easy filter servicing. -- Adjustable in height from 34" - 38". -- Grid system top adds versatility. -- 10.4 Cu. Ft. of built in storage area with 1 pull out shelf. -- 18 Months Limited WarrantyNOT IN STOCK - CALL OR EMAIL FOR CURRENT LEAD TIME TO SHIP. PRICING SUBJECT TO CONFIRMATION.

SANDMAN - DL7236: Downdraft Sanding TableSANDMAN Sanding Table is a dedicated sanding station that doubles as a workbench.Specifications: -- 72" x 36" Rubberized work surface. -- 1.5 HP T.E.F.C. - 220 V - 1-Phase motor with: 10-5/8" LAU Blower with sealed ball bearings. -- Industrial casters with: 4" Wheels: (2) Ridged; (2) swivel-lock 2-ways. -- Magnetic tool holder. -- Hinged tilt up top with: Gas strut lid support for easy filter servicing. -- Adjustable in height from: 34" - 38". -- Grid system top adds versatility. -- 10.4 Cu./ft. of built-in storage area with: 1 Pull out shelf. -- Easy filter service.

SANDMAN M7236 Downdraft Sanding Table110V 1 HP (M7236) T.E.F.C Motor with 15’ power cord. -- 72" x 36" Rubberized work surface. -- 10-5/8" LAU blower with sealed ball bearings. -- Industrial casters with 5" wheels, (2) ridged and (2) swivel-lock 2-ways. -- Hinged tilt-up top with gas strut lid support for easy filter servicing. -- Grid system top adds versatility. -- (18) Month warranty on parts.NOT IN STOCK - CALL OR EMAIL FOR CURRENT LEAD TIME TO SHIP. PRICING SUBJECT TO CONFIRMATION.