Boring Machines For Sale

Category

Boring Machines

105 Results Found

$ 13,500

SCM TECH Z 30 CNC MACHINING CENTER (W/ATC/BORING): -- Specifications:Working Field "X" axis 120" (3,050 mm); "Y" axis 52.7" (1,340 mm) for routing & 44" (1,118 mm) for boring; "Z" axis stroke 7.8" (200 mm); max. material thickness 3.9" (100 mm). -- Positioning Speed:"X" & "Y" Axes are 197 FPM (60 MPM); "Z" axis is 72 FPM (22 MPM).Axes positioning by: AC Brushless motors and YASKAWA drives; high precision ball screw drive system in "X", "Y". "Z" Axes;All axes ride on prismatic guideways & sliding blocks. -- Worktable:(6) "TV" Tubeless mobile support rails, (2) vacuum pods per rail; (4) pneumatic lifter rails for heavy panels.(6) Pneumatic pop-up backstops, (6) pneumatic pop-up front stops; (2) pneumatic pop-up side stops.LED Display positioning assistance for the support rails & vacuum pods; (2) independent working fields. -- Boring Head:3 HP (2.2 kW) motor - 4,000 RPM; (15) independent vertical spindles: (8) Spindles in "X" & (7) spindles in "Y".(6) Horizontal spindles (2 + 2) in "X" & (1 + 1) in "Y-axis".(1) X-axis grooving saw with 100 mm dia. blade - 6,000 RPM. -- Machining:(1) 10 HP (7.5 kW) Electro-spindle router with: HSK F63 Adaptor; variable speed from 1,000 - 24,000 RPM, max. torque achieved at 12,000 RPM.Static inverter for stepless speed & rapid shutdown rotation.(1) 6-Position ATC tool plate mounted on the on the machine for "on the fly" ATC; max. tool weight is 8 kG (17.6 Lbs). -- Operator & Machine Control:PC Front-End with: SCM "UNIVERSAL K2" + "Xilog Plus" + Windows "XP" Pro Operating System; 15" CRT color display, CELERON 2 GHz processor, enclosed in air-conditioned cabinet. -- Complete with:(1) 100 m³/Hr Vacuum Pump; automatic lubrication system; "BUMP STOP" safety system. -- Actual Model is SCM TECH Z30 R6

$ 9,900

SCM TECH 95 CNC MACHINING CENTERWorking cap.: X-Axis = 110" (2,800 mm) and Y-axis = 35.4" (900 mm), Z-axis = 3-7/8" (100 mm); positioning by ball screw, speed on X-axis = 1,988 IPM, Y-axis 1,771 IPM and Z-axis = 885 IPM, all by Brushless AC Servo Drives. -- Equipped with: (10) Independent vertical boring spindles forming a T-configuration with (2) spindles on the X-axis. A total of (2) horizontal spindles for boring on the front/back edges of the panel, (1 + 1) in the X-axis; -- Work table; Equipped with (6) adjustable panel supports each with (3) vacuum cups and (2) panel back stops. Includes (4) panel side stops & central stop for positioning the perimeter of parts. -- Options included: (1) 9 HP Electrospindle with ISO 30 tool holder inverter driven 1,500 - 24,000 RPM, RH & LH rotation selected through program, 4-position automatic tool changer,; worktable set up for (2) independent working areas with (8) rear stops, (4) lateral stops and (1) central stop for mirror-image operation. -- Separate control cabinet with: "NUM" Controller, 8-1/2" monitor, alphanumeric keyboard, Pentium Micropressor, 3-1/2" disk drive and RS-232 serial port.

SILVER SJK-21 Horizontal & Vertical Boring on 32 mm centers.(21) Spindles in line on one boring head (aluminum alloy single block), drills vertically from top & horizontally from rear. -- Features pneumatic adjustment for horizontal boring.Specifications: -- Max drill dia. is 1.38" (35 mm); Max panel thickness is 2.36" (60 mm); Table size 36" x 19.75" (914 x 502 mm). -- Length of cross fence is 102" (2,600 mm); length of aluminum table fences are 39" (1,000 mm) to the left and 28" (710 mm) to the right with flip stops.Equipped with: -- Depth stop adjustment, (2) holddown air cylinders, and foot pedal operation for clamping/drilling cycle. -- 2 HP - 3,600 RPM TEFC motor with thermal overload protection and low voltage controls.. -- Includes (12) Quick change chucks..

SILVER SJK-19T Line Boring MachineSingle line vertical boring machine with (19) spindles at 32 mm centers driven through a powerful 1.5 HP motor.Equipped with: -- Foot pedal controlled pneumatic boring cycle -- Adjustable boring feed speed -- Adjustable boring depth for fast changeover -- 2 Pneumatic cylinder clamp for solid hold-down to the material. -- 3 Meter long back fence for long line boring with flip stops -- (2) Positioning pins at both end of boring head to set up for longer line boring quickly -- Quick change chuck for fast changeover (19 pcs included)Specifications: -- No. of Spindles....................................................................................... 19 -- Distance between each spindle.............................................................. 32 mm -- Max Boring Depth .................................................................................. 60 mm (2.36") -- Working Table Size................................................................................ 800 x 500 mm (31.5" X 19.68") -- Table Height from Floor......................................................................... 780 mm (30.35") -- Max Boring Depth from Edge................................................................. 155 mm (6") -- Electric .................................................................................................. 220 V / 60 Cy / 3-Ph -- Machine Size (LxWxH) ........................................................................... 920 X 670 X 1490 mm (36.25" x 26.37" X 58.66") -- Net Weight ............................................................................................ 220 kgs. (484 Lbs)

SILVER - SJK-65: Construction & Line Boring Machine(4) Vertical Boring Heads; 21-spindle from bottom on 32 mm centers; (1) Horizontal Boring Head; (21) spindles on 32 mm center. -- 3" (75 mm) Max. drilling depth; (3) 4.0 HP - 3,450 RPM motors; pneumatic-hydraulic drill head advance with: Speed control with working speed or (0 - 15) cycles per min.; head height adjustment with: Mechanical digital readout; 51" x 37" working capacity. -- Equipped with: (2) Pneumatic holddown clamps; pneumatic foot pedal control.

Call for Price

VITAP - POINT K2 2.0 : CNC Machining Center (w/ATC/Boring) + Includes: "VITAP Bar Nesting System." -- SpecificationsVITAP - K2 2.0 CNC Center is the best and most technically advanced machine for wood processing. The K2 has a patented "Double Dynamic Transport (DDT)" System with: Double clamp technology that creates smooth panel movement.With an automatic tool changer and modern software, the programming for this machine is easy and efficient to use. This machine is perfect for companies of all sizes and is the optimal choice for your CNC woodworking needs. -- Working FieldMax. panel size "X" Axis infinite; "Y" axis 49.2" (1,250 mm); "Z" axis 1.97" (50 mm).Min. panel size "X" axis 10" (270 mm); "Y" axis 5.9" (150 mm); "Z" axis 0.1" (3 mm). -- Positioning Speed"U" Axis Panel feeding speed 82 FPM (25 MPM); "X" & "Y" axes 197 FPM (60 MPM); "Z" axis 49 FPM (16 MPM).Axes positioning by AC drives & brushless motors; the "Panel" moves in "X" axis & the "Machining Units" move in "Y & Z" axis.Max. Panel weight is 176 Lbs (80 kG). -- Work Area: Vitap "DDT" + "Vitap Bar Nesting System":DDT is short for "Double Dynamic Transport", a clamping system for work pieces on CNC Machining Centers, for moving the workpiece in "X" axis.The function of the DDT system consists of: (2) Gripper/clamps that move the workpiece in the same or alternate direction. This allows for a significantly longer travel distance of the workpiece compared to the travel distance of the gripper/clamps. DDT System is a requirement for Bar Nesting."VITAP Bar Nesting" is a special form of combining a Beam Saw & Nesting at the same CNC Machining Center. VITAP Bar Nesting is also designed to combine the advantages of nesting technology with the possibility of horizontal drilling.VITAP Bar Nesting is a technology that has been specially developed for VITAP Machining Centers. The prerequisite is a machine in which the X-axis is generated through the movement of the workpieces. A further prerequisite is the presence of (2) grippers for workpiece movement, known at VITAP as "DDT-System".Bar Nesting is not a complete nesting of the workpieces, as the large-sized (Ripped) panels must still be crosscut into stripes on a Saw.NC Controlled "Optical Material Sensor" creates a: “0“ Panel reference point by reading the panel's ends; this ensures that RH & LH (mirror image) panels will always be symmetrical.Fixed RH ("U" axis) panel clamping device with: Automatic panel adjustment according to the programmed information; LH side pressure clamp with automatic adjustment & pneumatic locking according to the panel width; scratch resistant idle rollers for panel positioning from the bottom & sides. -- Boring Unit (1) 2.2 HP (1.7 kW) - 3,600 RPM motor; (12) independent vertical spindles on 32 mm centers with: 6-Spindles in "X" axis & 6-spindles in "Y" axis.(8) Horizontal Spindles with: (2 + 2) spindles in "X" axis & (2 + 2) spindles in "Y" axis.(1) "X" Axis grooving saw: 7,000 RPM with 100 mm m

Call for Price

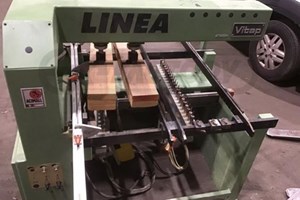

Vitap Forma Boring Machine 21 Vertical Spindles 21 Horizontal Spindles Approx $1000 worth of carbide bits DUAL LINE machine and there are (2) vertical lines of 21 spindles each for a total of 42 ...... PLUS an additional single line of 21 horizontal spindles!

VITAP LINEA 42 Line Boring SystemSpecifications: -- (2) Drill heads of (21) spindles ea., drills from bottom up, ea. support with 2 HP motor and (21) spindle boring block w/panel support mounted on top; -- Drills panels from 100 - 3,000 mm in length, and 100 - 950 mm in width. Complete with: -- Digital readouts for boring blocks, 2,000 mm bar scale fence with (5) adjustable flip stops. -- (2) Moveable overhead pneumatic holddown cylinders, foot pedal for clamping & boring cycle.

VITAP ALFA - 27: Construction/Line Borer27-Spindle boring head on 32 mm centers; drills vertically from bottom-up and head rotates to horizontal position for edge boring; head rotation is pneumatic with switch control. -- 2-3/4" Max. drilling depth; 2-1/2 HP - 2,800 RPM motor; pneumatic drill head advance with speed control; head height adjustment with mechanical digital readout; 34" x 20" table size; max. workpiece width 31-1/2". -- Equipped with: Left- & right-side fences for construction boring; (2) pneumatic holddown clamps; 118" line boring fence w/flip stops; pneumatic foot pedal control; magnetic starter; overload protection.

$ 4,100

VITAP - 27-Spindle: Boring MachineSpecifications: 27-Spindle boring head: On 32 mm centers; drills vertically from bottom up, and head rotates to horizontal position for edge boring; head rotation is pneumatic with switch control. -- 2.5 HP - 2,800 RPM Motor; pneumatic drill head advance with speed control; head height adjustment with mechanical digital readout; 14" x 42" table size.Equipped with: (4) Pneumatic holddown clamps; 118" line boring fence with: (4) Flip stops; pneumatic foot pedal control.

Call for Price

WEEKE BHC 350 4/10 CNC MACHINING CENTER: Specifications: -- Working cap.:"X" axis: 3,750 mm (147.6"), "Y" axis: 1,250 mm (49.2"), 80 mm (3.1") max. material thickness. -- Positioning Speed: "X" axis is 196 FPM (60 MPM), "Y" axis 164 FPM (50 MPM) & "Z" axis 66 FPM (20 MPM). The heads travels on THK linear motion guides on all axes. -- Worktable: (6) Moveable support rails, raise-and-lower panel feeding rails, (3) matrix style vacuum pods per rail.(6) Pneumatic backstops, (6) Pneumatic front stops, (2) movable pneumatic side stops, and the dual central zero-stop creates (2) working zones. -- Boring Unit:(1) 3.5 HP, 1,500 - 7,000 RPM Motor; equipped with (24) independent vertical spindles with (16) spindles in "X" axis & (8) spindles in "Y" axis.(4) Horizontal spindles with (1+1) in the "X" axis & (1+1) in "Y" axis;(1) "X" axis grooving saw for max. 100 mm dia. blade, 2,000 - 7,000 RPM. -- Machining:(1) 8 HP HSK F63 Liquid cooled electro-spindle powered by KEB frequency inverter, programmable from 1,200 - 18,000 RPM (constant torque from 9,000 - 18,000 RPM), RH or LH rotation. -- Operator & Machine Control:IPC control with "WEEKE MCC" + Windows "XP" + WoodWOP 5.0 operating system; 15" high resolution color graphic monitor, standard keyboard & mouse for data entry, 1.44MB floppy disk drive, CD ROM drive.EtherNET interface for possible LAN connection to office PC, RS-232 serial interface for simple PC connection; all mounted in separate free-standing control cabinet.WoodWOP allows for the machine to be programmed off-line with the same intuitive icon driven software that the operator has on the machine controller."BECKHOFF" programmable logic control (PLC) operating system for (3) axes; linear, circular & helical interpolation. -- Complete with:(1) 100 m³/Hr Vacuum pump, man-height safety enclosure around rear & sides of machine, 2-zone safety mats (will stop machine if operator enters work area). Actual Model is WEEKE BHC 350 4/10 .

Call for Price

WEEKE VENTURE 08M CNC MACHINING CENTER (W/ATC, "C" AXIS); -- Specifications:Working Capacity "X" Axis is 127.9" (3,250 mm), "Y" axis is 49.2" (1,250 mm) for boring & 52.2" (1,325 mm) for routing, "Z" axis stroke is 7.2" (185 mm), max. material thickness 4.9" (125 mm). -- Positioning Speed: "X" & "Y" Axis 263 FPM (80 MPM, "Z" axis 66 FPM (20 MPM); The machine head travels on THK linear motion guides on all axes. -- Worktable:(6) Movable K-Table support rails w/side mounted raise-and-lower panel feeding rails, (2) vacuum pods per rail; (6) pneumatic backstops, (2) pneumatic side stops create (2) working zones.Setup assistance through the PC control display for precise rail & vacuum pod positioning. -- Boring Unit:3 HP (2.2 kW) Motor, variable speed from 1,500 - 7,500 RPM; (12) vertical "QUICK CHANGE" drill spindles, (8) spindles in "X" axis & (4) in "Y" axis.(6) Horizontal spindles with (2 + 2) in "X" axis & (1 + 1) in "Y" axis; -- Machining: (1) 12 HP (9 kW) Liquid cooled electro-spindle router with HSK F63 adaptor, w/programmable 1,250 - 24,000 RPM, constant torque from 9,000 - 24,000 RPM, RH or LH rotation; powered by a 11 KVA frequency inverter.(1) NC Controlled "C" axis for 360° horizontal processing; (18) Total ATC positions with (1) 8-position ATC tool changer plate mounted on the head for "on the fly" ATC & (1) 10-position ATC rack mounted at the RH side of the machine base. -- Operator & Machine control: WEEKE IPC "PC 85T Power Control" + Windows "XP" + WoodWOP 5.0 operating system; "Beckoff" PLC for (3) axes with linear, circular & helical interpolation.15" TFT Monitor with 2D / 3D "REAL TIME" graphics, industrial keyboard for data entry, CD R/W & 1.44 MB floppy drives, modem, USB slot, RS-232 serial interface for possible simple PC connection; all mounted in separate free-standing control panel. -- Complete with:(1) 100 m³/Hr Vacuum Pump, 2-zone safety mats (will stop machine if operator enters work area), safety fences, scrap conveyor, hand held pendant controller. -- Actual Model is WEEKE VENTURE 08 M BHC

Call for Price

Call for Price

Call for Price

Weeke ABD 060 Bore & Dowel Machine This machine will be available in December 2023. - CNC DOWEL INSERTER FOR HORIZONTAL DRILLING AND DOWEL INSERTING - ENGINEERED TO SPRAY GLUE OR WATER - FEATURES A SORBTECH MAIN BEAM TO MINIMIZE VIBRATION - PNEUMATIC CONTROL OF CEBTER STOP AND RIGHT AND LEFT FENCES - OPEN END TABLE FOR MACHINING PARTS LONGER THAN 48” - VIBRATING HOPPER FOR AUTOMATIC FEEDING OF DOWELS - LARGER 17” DISPLAY AND WOODWOP PROGRAMMING - SERVO CONTROL OF DRILL HEIGHT AND DRILL DEPTH VIA PROGRAM - 3 INDEPENDENT SPINDLES ON 32MM CENTERS - BAR CODE READER

Call for Price

WEEKE VENTURE 106M (BMG 111) CNC MACHINING CENTER (W/ATC/BORING): -- Specifications: Working Capacity: "X" Axis is 123.2" (3,130 mm); "Y" axis is 61.02" (1,554 mm); "Z" axis stroke is 7.2" (185 mm); max. material thickness 5.9" (150 mm). -- Positioning Speed: "X" & "Y" Axis travel speed of 262 FPM (80 MPM); "Z" axis travel speed of 66 FPM (20 MPM).The machine head travels on THK linear motion guides on all axes. -- Worktable:(6) Movable K-Table support rails with: Side mounted raise-and-lower panel feeding rails; (2) vacuum pods per rail.(6) Pneumatic backstops; (2) pneumatic side stops create (2) working zones.Laser Positing System setup assistance for precise rail & vacuum pod positioning. -- Boring Unit:3 HP (2.3 kW) Motor; variable speed from 1,500 - 7,500 RPM; (12) vertical "QUICK-CHANGE" drill spindles: (7) Spindles in "X" axis & (5) in "Y" axis.(6) Horizontal spindles with: (2 + 2) In "X" axis & (1 + 1) in "Y" axis. -- Machining: (1) 12 HP (9 kW) Air-Cooled electro-spindle router with: HSK F63 Adaptor with: Programmable 1,250 - 24,000 RPM; constant torque from 9,000 - 24,000 RPM; RH or LH rotation; powered by a frequency inverter.(1) 8-Position ATC magazine located at the RH side of the machine. -- Operator & Machine Control: WEEKE IPC "PC 85 Power Control" + Windows "XP" + WoodWOP 6.1 Operating System; INTEL Core2 Duo Processor; "BECKOFF" PLC for (3) axes with: Linear, circular, & helical interpolation.17" TFT Monitor with: 2D / 3D "REAL-TIME" graphics; industrial keyboard; mouse for data entry.(1) SATA Hard drive; 160 GB; central USB front side bus connection; Ethernet connection 10/100 Mbit; all mounted in separate free-standing Control Panel. -- Complete with:(1) 84 m³/Hr Vacuum Pump: 3-Zone safety mats (will stop machine if operator enters the active work area); safety fences; scrap conveyor; handheld pendant controller. -- Actual Model is: WEEKE VENTURE 106M / BMG 111.

Call for Price

WEEKE - VENTURE 230 L: CNC Machining Center (w/ATC/Boring/C-Axis) -- Specifications: Working Capacity: "X" Axis is 180" (4,500 mm); "Y" axis is 60" (1,500 mm) for boring; 64" (1,600 mm) for routing; "Z" axis stroke is 7.2" (185 mm); max. material thickness 4.9" (125 mm). -- Positioning Speed"X & "Y" Axes travel speed: 361 FPM (110 MPM); "Z" Axis travel speed: 66 FPM (20 MPM).Machine head travels on: THK linear motion guides on all axes. -- Worktable(8) Movable K-Table support rails with: (6) Side mounted raise-and-lower panel feeding rails; (2) vacuum pods per rail; (8) pneumatic backstops: (2) Pneumatic side stops create (2) working zones.Setup assistance through LED displays on the support rails for precise rail & vacuum pod positioning. -- Boring Unit3 HP (2.2 kW) Motor; variable speed from 1,500 - 7,500 RPM; (21) vertical drill spindles: (11) Spindles in "X" axis & (10) in "Y" axis. (10) Horizontal spindles with: (3 + 3) In "X" axis & (2 + 2) in "Y" axis.(1) NC Controlled 0° - 90° "X" / "Y" grooving saw; 125 mm dia. saw blade. -- Machining(1) 16 HP (12 kW) Air-Cooled electrospindle router with: HSK F63 Adaptor; programmable 1,250 - 24,000 RPM; constant torque from: 9,000 - 24,000 RPM; RH or LH rotation; powered by a frequency inverter.(1) NC Controlled "C" axis for: 360° Horizontal processing.(28) Total ATC positions with: (1) 14-Position Rotary ATC tool changer magazine at the back of the machine head; for "on the fly" ATC.(1) 14-Position Rotary ATC tool changer magazine mounted on the RH side of the machine. -- Operator InterfaceWEEKE IPC "PC 85 Power Control" + Windows "XP" + WoodWOP 6.0 Operating System; "BECKOFF" PLC for: (3/4) Axes linear; Circular & Helical interpolation.15" TFT Monitor; industrial keyboard for data entry; CD R/W; 1.44 MB floppy drives; modem; USB slot; RS-232 serial interface for possible simple PC connection; all mounted in separate free-standing control panel. -- Complete with:(2) 100 m³/Hr Vacuum Pumps; 2-zone safety mats (will stop machine if operator enters work area); safety fences; scrap conveyor; handheld pendant controller. -- Actual Model: WEEKE VENTURE 230 L

$ 31,950

WEEKE BHX 050 CNC MACHINING CENTER (VERTICAL): -- Specifications: Flexible "Vertical" Machining Center that uses less than 5 sq/m of valuable floor space, in addition to an innovative Panel Handling System. -- Working Cap.:Max. workable part size for "X" axis is 98.4" (2,500 mm); "Y" axis 33.4" (850 mm); max. part thickness 2.4" (60 mm).Min. worktable part size for "X" axis is 7.8" (200 mm); "Y" axis 2.7" (70 mm); min. part thickness of 0.47" (12 mm). - Automatic infeed & outfeed from the LH or RH side. -- Positioning Speed:The "BHX 050" can reach movement speeds of 164 FPM (50 MPM) in "X" & "Y" axes & 50 FPM (15 MPM) in "Z" axis with total safety, providing an unmatched working capacity. -- Boring Unit:(1) 3 HP (2.3 kW), Variable speed from 1,500 - 7,500 RPM motor, (8) independent vertical spindles with: (4) spindles in "X" axis & (4) spindles in "Y" axis.(3) Horizontal Spindles with (1+1) in "X axis & (1) spindle in "Y" axis.Boring block has QUICK-CHANGE spindle system. -- Operator & Machine Control:WEEKE "POWER CONTROL" + Windows + WoodWOP 6.0 + Operating System; "IntelCore 2 DUO" Processor.17" TFT Monitor; international keyboard, soft touch keypad & industrial mouse; RS-232 serial ports, USB ports; (1) 1.44 MB floppy disk drive, (1) CD RW drive, modem, Ethernet connection.Real-time multitask processing; programs can be transferred via diskette or downloading by wire is possible. -- Complete with:Pneumatic part clamping devices; sound enclosure and complete set of safety devices. -- Options Include: (1) "X" Axis grooving saw; 9,000 RPM, saw blade dia. 100 mm. (1) 7 HP (5 kW) Electro-spindle router with hydraulic "QUICK-CHANGE" tool system & "ETP 25" tool holders; variable speed from 6,000 - 18,000 RPM. -- Actual Model is WEEKE BHX 050.

$ 22,500

WEEKE - BHX 055: CNC Boring Machine (P to P Vertical) -- SpecificationsFlexible "Vertical" Machining Center that uses less than 5 sq/m of valuable floor space in addition to an innovative panel handling system. -- Working Cap.:Max. workable part size for "X" axis is 120" (3,050 mm); "Y" axis 33.4" (850 mm), max. part thickness 2.4" (60 mm).Min. worktable part size for "X" axis is 7.8" (200 mm); "Y" axis 2.7" (70 mm); min. part thickness of 0.47" (12 mm). - Automatic infeed & outfeed from the LH or RH side. -- Positioning SpeedThe "BHX 055" can reach movement speeds of 164 FPM (50 MPM) in "X" & "Y" axis & 50 FPM (15 MPM) in "Z" axis with total safety - providing an unmatched working capacity. -- Boring Unit:(1) 3 HP (2.3 kW) Variable speed from 1,500 - 7,500 RPM motor; (13) independent spindles with: (8) Spindles in "X" axis & (5) spindles in "Y" axis.(4) Horizontal spindles with: (1 + 1) in "X" Axis & (1 + 1) in "Y" axis.Boring block with "Quick Change" vertical spindle system. -- Operator & Machine Control:WEEKE "Power Control PC 85" + Windows + WoodWOP 6.0 Operating System; Intel Core "2 DUO" Processor.17" TFT Monitor: International keyboard, soft touch keypad & industrial mouse; RS-232 serial ports, USB ports; (1) 1.44 MB floppy disk drive, (1) CD RW drive: modem, Ethernet connection.Real time multitask processing: Programs can be transferred via diskette or downloading by wire is possible. -- Complete with:Pneumatic part clamping devices; sound enclosure; complete set of safety devices. -- Options Include:(1) "X" Axis grooving saw, 9,000 RPM, max. saw blade dia. 100 mm.

$ 37,080

WEEKE - BHX 050: CNC Machining Center (Vertical) -- Specifications Flexible "Vertical" Machining Center: Uses less than 5 sq/m of valuable floor space; includes an innovative Panel Handling System. -- Working CapacityMax. workable part size for: "X" Axis: 98.4" (2,500 mm); "Y" axis 33.4" (850 mm); max. part thickness 2.4" (60 mm).Min. worktable part size for: "X" Axis: 7.8" (200 mm); "Y" axis 2.7" (70 mm); min. part thickness of 0.47" (12 mm). - Automatic infeed & outfeed from the LH or RH side. -- Positioning Speed"BHX 050" Reaches movement speeds of: 164 FPM (50 MPM) in "X" & "Y" axes; 50 FPM (15 MPM) in "Z" axis with total safety; provides an unmatched working capacity. -- Boring Unit(1) 3 HP (2.3 kW) Variable speed from: 1,500 - 7,500 RPM Motor; (8) independent vertical spindles with: (4) Spindles in "X" axis; (4) spindles in "Y" axis.(3) Horizontal Spindles with: (1 + 1) in "X axis; (1) spindle in "Y" axis.Boring block has: QUICK-CHANGE Spindle system. -- Operator & Machine ControlWEEKE "POWER CONTROL" + Windows + WoodWOP 6.0 + Operating System; "IntelCore 2 DUO" Processor.17" TFT Monitor; international keyboard; soft touch keypad; industrial mouse; RS-232 serial ports; USB ports; (1) 1.44 MB floppy disk drive; (1) CD RW drive; modem; Ethernet connection.Real-time multitask processing; programs can be transferred via diskette or downloading by wire is possible. -- Complete with:Pneumatic part clamping devices; sound enclosure; complete set of safety devices.Options include: (1) "X" Axis grooving saw: 9,000 RPM; saw blade dia. 100 mm. (1) 5 HP (3.6 kW) Electrospindle router with: Hydraulic "QUICK-CHANGE" tool system; "ETP 25" tool holders; variable speed from 6,000 - 18,000 RPM. Voltage transformer: 600 Volts operation. -- Actual Model: WEEKE BHX 050.

.gif)