Equipment For Sale

10590 Results Found

Call for Price

TWIN FLOW Air Make-Up Unit 14,000 CFM. Vertical mount with Remote Control Panel: -- CFM: 14,000 CFM @ 1.75" ESP, 10 HPTEFC motor -- BTU: 1.38 MBTUH -- Burner: MAXON burner -- Temperature Control: 80º F temperature rise in spray cycle -- -- Mounting: Vertical, outdoor/indoor mounted -- Fuel required: Natural gas, 0.3 PSI pressure -- Intake/Discharge: Vertical, screened, air intake with vertical discharge -- Filter Sections: V-Bank style with 1’’ cleanable air intake disposable type filters -- Gas Control: Control cabinet and pre-piped gas combustion system mounted on burner section to FM, Electronic Modulation -- Specifications includes: Digital Temperature Controller, ON/OFF & Summer/Winter Switch, pressure regulator, metering valve, pilot pressure regulator & pilot gas valve, flame rod, high limit switch, air flow switch, power transformer, ignition transformer and spark plug -- Electrical Control cabinet includes: main breaker disconnects, magnetic motor starters with adjustable overload protection for air makeup, motor fuse protection -- Enclosure Design: Framed, with 18 ga. metal walls and 1" insulation -- Note: Available in Horizontal and Vertical mount. Please inquire. -- Also available: Controls option: - Two stages for 14,000 or 7,000 CFM at extra cost of about $3,000.

Call for Price

TWIN FLOW Air Make-Up Unit 7,000 CFM. Vertical mount with Remote Control Panel: -- CFM: 7,000 CFM @ 1.75" ESP, 5HP/575v/3ph/60Hz TEFC motor -- BTU: 0.68 MBTUH -- Burner: MAXON burner -- Temperature Control: 80º F temperature rise in spray cycle -- Mounting: Vertical, outdoor/indoor mounted -- Fuel required: Natural gas, 0.3 PSI pressure -- Intake/Discharge: Vertical, screened, air intake with vertical discharge -- Filter Sections: V-Bank style with 1’’ cleanable air intake disposable type filters -- Gas Control: Control cabinet and pre-piped gas combustion system mounted on burner section to FM, Electronic Modulation -- Specifications includes: Digital Temperature Controller, ON/OFF & Summer/Winter Switch, pressure regulator, metering valve, pilot pressure regulator & pilot gas valve, flame rod, high limit switch, air flow switch, power transformer, ignition transformer and spark plug -- Electrical Control cabinet includes: main breaker disconnects, magnetic motor starters with adjustable overload protection for air makeup, motor fuse protection -- Motor Control: Control cabinet includes: main breaker disconnects, magnetic motor starters with adjustable overload protection for air makeup, motor fuse protection -- Enclosure Design: Framed, with 18 ga. metal walls and 1" insulation -- Note: Available in Horizontal and Vertical mount. Please inquire.

Call for Price

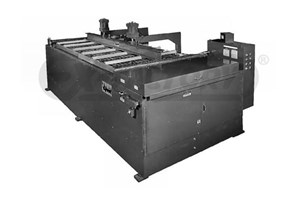

TYLER 2400 SLOT-WALL MACHINE: -- Specifications:Produces T-slot "slat-wall" for architectural/store fixtures. 4' x 8' (48" x 97") max. panel cap., 2' x 2' (24" x 24") min. panel cap., min. panel thickness = 0.5" max. panel thickness = 1.5"; The Tyler 2400 can machine up to (40) panels/Hr, depending on material density, thickness and the slot profile. -- Equipped with: (18) Router spindles all on 3" fixed centers, spindles are driven in groups of (3) with (6) 7.5 HP - 3,450 RPM motors, all router spindles rotate @ 15,400 RPM. -- Operation: Panels remain stationary on top, pneumatically clamped in place while the bottom mounted router bank traverses the full length of the panel with a high-speed return, variable feed speed control, router assembly traverses on ground & polished rails with chain drive. -- Panels are positioned along the 8' rear edge fence line, distance from the panel edge to the centerline of the 1st cut can be adjusted from 0.0" - 3" (1 router spindle pitch). -- Overhead hold-down assembly with (2) large air cylinders and (5) arms with spring loaded clamping pads hold the panel in place. Panels are loaded from the 8' front and exit to the side. -- Includes: Operator controls for the machine cycle and a "setup" mode of operation; machine cutting cycle is initiated by a 2-hand operator safety buttons located on the right front of machine. - Produces approx. (30 - 40) panels per hour. -- Available Options at Additional Cost:Router spindles on 4'- & 100-mm centers; 48" x 121" workpiece capacity increases left-to-right workpiece (length) capacity.60" x 97" workpiece capacity increases front-to-back workpiece (width) capacity & includes (1) additional multi-spindle router head.60" x 121" workpiece capacity increases front-to-back & left-to-right workpiece capacity & includes (1) additional multi-spindle router head.

Call for Price

Tyler Kerfsaver XL Resaw 1-1/4" Blades 36" Diameter Bandwheels Includes: Feed system that can tilt to mill tapered siding

Call for Price

Call for Price

Tyrone Berry SMA 260 1,500 PSI Hydraulic Carriage Drive w/US 200 HP / 1,800rpm Drive, Air cooled, Dual Heat Exchangers, Soft Hydraulic Lines s/n: A0579

.gif)