Equipment For Sale

10564 Results Found

Haas VF-2SS-125 Super Speed Vertical Milling Machine CNC Center with Robot Package 30" x 16" x 20" 4th Axis Drive Chip Auger High Speed Machining Option Wireless Probe System Aux Coolant Filter Programmable Coolant Dynamic Work Offset Chip Strainer WIFI Camera Programmable Air Aluminum jaws 100 mm Robot Package with dual gripper 10-Piece CAT 40 ER Collet/Chuck Toolholder Power Chuck

Call for Price

HAAS - 2000XL 2.0, ...Mobile ShredderLow Hours; 2018 YMFG.Specifications & Features: -- Can be used at any location (comfortable transport measurements). -- Easy & quick positioning thanks to crawler track and radio remote control. -- Shreds different materials with just (1) tool configuration. -- High throughput capacity of up to 100 tons/Hr. -- Resistant against foreign bodies. -- Low wear cost and long lifetime. -- Service and maintenance friendly. -- No wrappings; self-cleaning. -- Quiet main drive.

Call for Price

Standard Features to be confirmed STANDARD PROGRAM MEMORY, 1 GB 30-GALLON COOLANT TANK 4000-RPM SPINDLE .4.0.0.0.-r.p.m..S.p.in.d.l.e.,.2.0.h.p.. 12-STATION BOLT-ON TOOL TURRET BOLT-ON TOOLHOLDER KIT, 3/4" Bolt-On Toolholder Kit; includes 1 each 0.75" Face Groove Holder, 1 each 1" ID, 1 each 1.25" ID, 4 each coolant .bl.o.c.k.,.4.e.a.c.h. 8.3" HYDRAULIC CHUCK, A2-6 EARLY POWER-FAILURE DETECTION MODULE Early Power-Failure Detection Module; senses a power failure or severe drop in incoming line voltage ETHERNET INTERFACE Ethernet Interface; allows you to easily transfer files to and from the machine over a local wired network. .......................................................... HAASCONNECT: REMOTE MONITORING HaasConnect: Remote monitoring of your Haas machine. Requires the machine to ethernet Approx 200 hours on lathe. Also available at a additional price a 2022 HRT 160 SS 4th axis

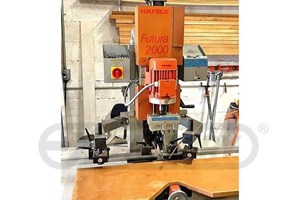

RAFIX - Futura 250: Hinge Boring & Inserting Machine with 1-1/2 HP MotorSpecifications -- High-quality air cylinder (80 mm bore with 650 ft. Lbs of pressure @ 90 PSI) rated for 3-1/2 million 3" strokes.A skilled Operator can bore & insert in (3 - 4) seconds. -- Features: (2) Types of boring depth adjustment: Drawbar style for quick and easy adjustment and a solid stop adjustment for the changing of door thickness applications. This allows changing of the door thickness and still bore the same depth without adjustment. -- Fixed table with: Adjustable back rail to control the tab location. -- Enclosed cutting area for better chip removal with blow off nozzle to assist in chip evacuation and adjustable 2" & 4" vacuum hookup. -- Pneumatic drilling unit with push button control. -- Includes: Adjustable cutting speed control; indicator light; reset thermal circuit breaker; emergency stop button; drill & insert buttons (2-hand activation for Operator safety); rotary switch for pair of pneumatic holddown clamps; 600 mm ruler & (4) flip stops.

Call for Price

Call for Price

Vent Block Drill VBD New never used Motor: Heavy Duty 5 HP - 3 phase - 220v or 440 v (Please specify when ordering) Block Sizes: 2 x 4 through 2 x 12 on center 2 x 14 and larger off center Air Supply: 100 psi Drills: 3-wing Carbide Tipped Spindles: Alloy Steel - Double ended Frame: 2" Steel With Powder Coat Finish Covers: 10 Gauge (1/8" Thick) Aluminum Dimensions: Height - 60 inches, Width - 60 inches, Depth - 33 inches Shipping weight: 750 lbs. - (Including crate) New Never Used!!

Firewood Automation is your go to distributor for HakkiPilke’s complete line up of quality firewood production machinery. Like the world’s best-selling professional class firewood processor with cycle time of 3.5 seconds, 19 inch diameter, 24 inch length, up to 16-way wedge to provide unbeatable productivity. Features: HakkiCutTM, HakkiSplitTM, AC10, oil cooler, infeed assistant, log landing plates, no v-belts extremely low maintenance. Over 150 units sold during the first 12 months after the launch in 2016, many customers processing over 1,500 cords of firewood annually. Highly reliable electric control system that minimizes the number of components requiring maintenance. Process logs with the press of only two buttons when infeed assistant is in use. Log landing plates ensure smooth processing every single cut. Very low overhead costs.

Firewood Automation is your go-to distributor for HakkiPilke’s complete line up of quality firewood production machinery. Like the Falcon 37 featuring simple mechanics and hydraulic joystick controls, the Falcon 35 is a perfect machine for small- and mid-sized firewood operations, specialty wood producers as well as home and ranch users. Falcon 35 boasts a 3-second splitting cycle and ergonomic one hand control, 14 inch diameter, 20" length and up to 6-way wedge. Plus, our exclusive 2-speed splitting, fast hydraulic functions, no electrics, no v-belts and very low maintenance. Falcon 35 is the modern version of the 1X37 which dominated the global firewood market from mid 1990s until late 2000s. Over 800 international Falcon 35 owners and non-existent spare parts demand proves it the perfect firewood processor for years of seasonal use and no problems.

Call for Price

Introducing the revolutionary Hakki Pilke 55 Pro – Semi-automatic firewood factory with innovative functions! The Hakki Pilke 55 Pro was designed for effective professional firewood processing in close cooperation with firewood professionals around the world. The innovative functions of 55 Pro ensures superior performance in all conditions and situations. It demolishes 55 cm (22") logs of hardwood to high quality firewood with 40 tons (44 US tons) splitting power and high-performance hydraulic functions. The Hakki Pilke 55 Pro brings the firewood processing to the modern age with innovative and automatic functions. With the new HakkiMultiBlade™ you can split up to 24 pieces and then easily change to 8 pieces in only seconds. The automatic hydraulic height adjustment of the splitting blade ensures consistent high-quality firewood even when the diameter of the logs varies. The system has an innovative sensor that measures the diameter of each log and adjusts the splitting blade height accordingly to get optimal results. The 55 Pro has a modern data monitoring system with easy-to-use monitor screen. The monitoring system is collecting important data from machine’s productivity and processes. You get a real-time information about processed volumetric measurements, hours of operation, splitting method and safety covers. You can also control a lot of different functions of the machine, such as the stroke of splitting cylinder and the wood measuring device, by this monitor. User can easily change the wanted length for the firewood from the monitor. The measuring device moves automatically to the correct position based on the selected length. The productivity level of 55 Pro is unbeatable with the delay-free HakkiSplit™ splitting system with half-stroke function for making short firewood faster. You can choose the splitting to return after full, half or one-third of the stroke.

The sturdiest log decks designed for full control of logs of varying quality even when piled up in layers for greater efficiency. Log tables are easily extendable offering 2-3 times larger loading space than competitors. Fast chain movements and log separating features allow improved productivity of infeed operations. HakkiFeed 470-series are designed for full control of awkward knotty and crooked logs. Choose 3-chained HakkiFeed 472 for longer logs and 2-chained HakkiFeed 471 with adjustable width for shorter logs. The low priced HakkiFeed 422 is perfect for smaller operations with varying log lengths and quality. Available now from Firewood Automation!

Firewood Automation is your go to distributor for HakkiPilke’s complete line up of quality firewood production machinery. Like the world’s best-selling professional class firewood processor with cycle time of 3.5 seconds, 17 inch diameter, 24 inch length, up to 12-way wedge to provide unbeatable productivity. Features: HakkiCutTM, HakkiSplitTM, AC10, oil cooler, infeed assistant, log landing plates, no v-belts extremely low maintenance. Over 150 units sold during the first 12 months after the launch in 2016, many customers processing over 1,500 cords of firewood annually. Highly reliable electric control system that minimizes the number of components requiring maintenance. Process logs with the press of only two buttons when infeed assistant is in use. Log landing plates ensure smooth processing every single cut. Very low overhead costs. Perfect weight ratio makes it very easy to move on site.

The Hakki Pilke Raven 33 is a reliable and easy-to-use firewood processor – get ready to make firewood with unparallelled ease. The machine’s direct drive hydraulics enable simultaneous functions with effortless motions of the operating lever. Minimal need for maintenance makes the use of machine cost-efficient. Options Include: 6 way splitting wedges, Multiple Log Deck options, gas engine Power Unit

DEMO Unit Hakki Pilke Roller is a stand-alone disc cleaner to achieve the very best quality and debris free firewood. It is great for large quantities of firewood under the demand of daily use and can be used together with a front loader. Capacity is high enough to be used with multiple firewood processors at once. 10 feet outfeed conveyor is included discharge directly to bags or truckload. Units have hydraulic drive motors which are speed adjustable and reversible. Disk screen area is 20" wide x 8' long, conveyor is 18.5" wide x 10' long.

$ 16,000

DEMO unit Radial Firewood Stacking Conveyor 26' long Adjustable height 11'6" to 16' Hydraulic powered wheel for radial movement (hydraulic motor can be bypassed for yard movement) Includes Grizzly Bars w/ debris chute

Two strand hydraulic live deck with powered rollers. Adjustable width up to 4'9" wide and 11'10" long. Extension kits are available to extend the length up to 24'11" long.

NEW Unit Hakki Pilke Roller is a stand-alone disc cleaner to achieve the very best quality and debris free firewood. It is great for large quantities of firewood under the demand of daily use and can be used together with a front loader. Capacity is high enough to be used with multiple firewood processors at once. 10 feet outfeed conveyor is included discharge directly to bags or truckload. Units have hydraulic drive motors which are speed adjustable and reversible. Disk screen area is 20" wide x 8' long, conveyor is 18.5" wide x 10' long.

Firewood Automation is your go-to distributor for HakkiPilke’s complete line up of quality firewood production machinery. Like the simple to operate high speed professional class firewood processor with cycle time of 3 seconds, 15 inch diameter, 24" length, up to 8-way wedge to provide unbeatable productivity. Features: HakkiCutTM, HakkiSplitTM, AC10, no v-belts and very low maintenance. This machine boasts the easy push button controls and advanced cutting system to make it a top choice amongst producers. Extra features are scaled down to make it the number one choice among top producers looking for highest productivity with smaller investment. Weighing under 2,000 pounds the 38 Pro is moved easily with even small or compact tractors.

Maximize your processor or splitters production with the addition of a hydraulic feeder, the HakkiFeed 422 log rack makes feeding logs to the feed rollers an effortless process. The feed rollers spin simultaneously with the firewood processor’s input conveyor ensuring that the logs keep moving. The HakkiFeed 422 log rack can be connected to Hakki Pilke 38, 43 and 50 models, as well as the Raven and Falcon models with an additional valve and connector set. Thanks to the hydraulic feeder, the HakkiFeed 422 log rack makes feeding logs to the feed rollers an effortless process. The feed rollers spin simultaneously with the firewood processor’s input conveyor ensuring that the logs keep moving. The HakkiFeed 422 log rack can be connected to Hakki Pilke 38, 43 and 50 models, as well as the Raven, Falcon models and many competitor processors as well. Available now from Firewood Automation!

.gif)

.jpg?width=300&height=200&mode=pad)

.jpg?width=300&height=200&mode=pad)