Glue Equipment For Sale

Category

Glue Equipment

125 Results Found

Call for Price

156" long x 60" wide x 80" high (3) vertical pneumatic Clamping bars (7) clamps that can be placed horizontal or vertical on perforated surface

$ 19,080

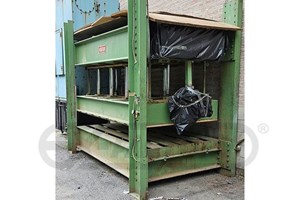

DEPENDABLE - 203, ...Cold Press40" x 102" Cap., side loading on 102" sideSpecifications: (3) Split upper platens: 34" wide x 40" deep; split platens can be interlocked for single platen operation. 45" Max. daylight opening with 12" down stroke hydraulic cylinders. (6) Rows of pop-up rollers in machine bed for loading & unloading. (3) 7-3/4" Dia. hydraulic press cylinders from the top; (1) per platen. Hydraulic power pack with 10 HP motor mounted on floor at end of Press.

Call for Price

Doucet Clamp Carrier Model SRH-40-8.5-240-36 40 Section Clamp 8.5' Wide (240) 2-1/2" x 36" Clamps - Rapid Change Voltage: 480/3/60

"NEW" Doucet RC - STOCK Gluer - Table top unit for glue applications on a smaller scale. Motorized stainless steel roller equipped with a 2 Litre capacity reservoir easily removable for clean up. -- Spread roller: Stainless steel with roller dimension 8" X 3 1/2"; speed of roller 50 FPM. -- Table top dimension: 20-1/2" x 13".

Call for Price

DOUCET CLAMP CARRIER 30 SECT X 8 FT 6 IN WIDE (200+) 36" CLAMPS MODEL SRH-1 SX30- 8.5-240-36 SN 87-10-28 Includes: HYD PWR PACK, PANEL FLATTENER Dismantled and ready to load!

Call for Price

Call for Price

DSI LD-1 CNC LOCKDOWEL PRESS:Specifications -- The DSI machine is designed to squeeze Lockdowel hardware into the edge of a pre-drilled panel. Our machines have over 5 years of actual factory usage, inserting tens of thousands of Lockdowels successfully, accurately, and quickly!! Features: Heavy duty construction. No compressed air requirements-only single phase 120 VAC. A large powerful drive motor. Rack and pinion movable fence and extruded aluminum beams and cross members. A solid aluminum fences with full adjustment capability.Benefits: A low cost alternative to those which have horizontal drilling capabilities and do not want to invest in the substantially more expensive machines that both drill and insert.Immensely faster, and much more accurate than hammering the Lockdowels in by hand. One or two person operation.Up to 8 Lockdowels inserted per machine cycle. Safety: Compact, Safe, Accurate. Machine functions are supervised by a safety rated control system including: two handed cycle start operation required. Safety light curtains & conveniently located emergency stop buttonsOperator Interface: The DSI machine includes a large touch screen for quick data entry and quick accuracy adjustments.Portable: The machine is on heavy duty casters. The infeed table folds down out of the way.

Call for Price

DSI - LD-1: CNC Lockdowel PressSpecifications -- The DSI machine is designed to squeeze Lockdowel hardware into the edge of a predrilled panel. Lockdowel machines: (5+) Have years of actual factory usage and inserts (10s) of thousands of Lockdowels successfully, accurately, and quickly! Features. Heavy-Duty construction. No "compressed air requirements only." Single-phase 120 VAC. - A large powerful drive motor. Rack & Pinion: Movable fence, extruded aluminum beams, and cross members. Solid aluminum fences with full adjustment capability.Benefits. Low cost alternative to those which have horizontal drilling capabilities, and do not want to invest in substantially more expensive machines that both drill & insert.Immensely faster and much more accurate than hammering; Lockdowels in by hand - A (1) or (2) person operation.Up to (8) Lockdowels inserted per machine cycle. Safety: Compact, safe, and accurate. Machine functions are supervised by: Safety rated control system including: 2-handed cycle start operation required. Safety light curtains & conveniently located emergency stop buttons.Operator Interface. The DSI machine includes a large touchscreen for quick data entry and quick accuracy adjustments.Portable: The machine is on Heavy-Duty casters. The infeed table folds down and out of the way.

Call for Price

Maximum Assembled Product Size: 37.5” x 98” Minimum Assembled Product Size: 11.375” (vertical) x 9.75” (horizontal) with spacer blocks 7.5” (vertical) x 5.5” (horizontal) Maximum Framing Width: 4” Minimum Framing Width: 1.5” Tubular Steel Frame THK Linear Bearings and Rails (1) Allen Bradley Compact Logix PAC (4) Allen Bradley Kinetix Servos and Drives a. (1) Vertical Beam b. (1) Horizontal Beam (2) On the Upper Right Hand Clamp to ensure that uniform pressure can be applied regardless of the cut accuracy of the frame parts (1) Hoffman Upright Enclosure Allen Bradley Control Components (Push Buttons, Relays, Power Supplies, Buzzer, etc.) (1) Hoffman Air Conditioner for Electrical Enclosure EMS Press Control/Server Communication Software Package (4) Tregarne Woodwelder with Production Gun

Call for Price

GANNOMAT - INDEX 130 LOGIC: CNC Bore, Glue & Dowel Inserter -- SpecificationsGANNOMAT "INDEX LOGIC": CNC Controlled Point-to-Point Drilling/Gluing/Dowel Insertion Machine for variable programming of boring patterns. -- "X", "Y" & "Z" Axis set by manual digital indicators. -- Working Width1,300 mm (51") x 3/4" - 7-3/4" Width x 1/2" - 3-1/8" material thickness with: (4) Independent working zones & LH/RH (mirror image).Table size: 4-1/2" x 52-3/4" x 35" H with 9" x 52" extension. -- (8) Vertical hold-down cylinders & zero center stop for horizontal part processing. -- Dowel Driving & Horizontal Boring: Integrated into (1) station; the dowel driving unit is located alongside the boring station; both units are mounted on (1) support. -- Horizontal Drilling & Boring Station: Head can be setup for 6 - 8 or 10 mm, dowel length from 25 - 50 mm (currently set up for 8 mm dia. x 50 mm long dowels). -- Doweling Station: Vibrating hopper; insertion head & dowel driving with air impulse; glue valves are controlled individually at the control cabinet; central adjustment for the amount of glue by means of a digital timer. -- Operator Interface: MS-XP & GANNOMAT Production software; 15" color touchscreen monitor interface; USB drive; bar code capable. -- Controller & Drive: BECKHOFF "C3620 TWINCAT V2.10". -- Complete with: (1) Glue tank; (1) water tank; auto lubrication system, and all original manufacturer's machine documentation. -- Actual Model is: GANNOMAT INDEX 130 LOGIC.

GANNOMAT INDEX 230 TREND CNC BORE, GLUE & DOWEL INSERTER: -- SpecificationsCNC Controlled horizontal Point-to-Point Drilling, Gluing & Dowel Inserting Work Center for absolute, incremental, variable (parametric) programming of boring patterns. -- Working FieldStop system (side fences) consisting of: Right hand, left hand, and center stop (all removable).(4) Independent zones for individual processing of (1 to 4) pieces. -- "X" Axis:Positioning speed: 246 FPM (75 MPM); CNC controlled and driven by rack & pinion for fast acceleration/deceleration of working unit. -- "Y" Axis:Set by mechanical digital counters. -- "Z" Axis:CNC Centering height adjustment of boring/inserting from the control. -- Working Length:2,300 mm (90-1/2") x 1/2" - 3-1/8" Material thickness; use as 2-field, LH & RH @ 1,150 mm (45-1/4") wide or 4-field with center fence, LH/RH - LH/RH @ field 570 mm (22.4") wide to increase throughput on smaller parts like drawers, stretchers, etc. -- Hold-down Cylinders:Total of (8) pneumatic, "quick change". -- Dowel Driving & Horizontal Boring:Integrated into (1) station; the dowel driving unit is located alongside the boring station; both units are mounted on (1) support. -- Horizontal Drilling Spindle:Can be setup for 6 - 8 or 10 mm, dowel length from 25 - 50 mm. -- Doweling Station includes Vibrating Hopper with: (1) Single-drop device and (1) outlet tube; insertion head & dowel driving with air impulse; mechanical dowel diameter & dowel length control prevents the insertion of any oversized dowels; setup for 8 mm dia. x 35 mm long dowels. -- Glue Valve/Amount:Controlled via software and can be adjusted by milliseconds; (2) standard separate stainless steel 1-1/2-gallons pressurized tanks (one for glue, one for water for occasional rinsing cycle). -- Operator & Machine Control: Windows "XP Pro" Operating System interphase and BECKHOFF "C3640 Twincat" PLC; easy to program GANNOMAT production software.Equipped with 15" Color monitor, CD-ROM drive, network card (for online operation); serial, parallel & USB interphase & soft-foil covered keyboard. -- Complete With: The unit is in good working condition. Includes docs, manuals and software CD's -- Options include:A new backup PLC that is unused. -- Actual model is: GANNOMAT INDEX 230 TREND.

GANNOMAT - INDEX 470 TB: CNC Bore, Glue & Dowel InserterSpecifications -- GANNOMAT "Index 470 TB": CNC Controlled Point-to-Point Drilling/Gluing/Dowel Insertion Machine for variable programming of boring patterns. -- X-Axis CNC Controlled via: Precision ball screw Servo drive; Y- & Z-Axis adjusted via mechanical spindles; set by manual digital indicators.Working Width -- 1,300 mm (51") x 3/4" to 7-3/4" Width x 1/2" - 3-1/8" material thickness with: (2) Fields; LH/RH (mirror image). -- (8) Vertical holddown cylinders: Horizontal part processing. -- Dowel driving & horizontal boring integrated into: 1-Station; dowel driving unit is located alongside the Boring Station; both units are mounted on (1) support. -- Horizontal Drilling & Boring Station head setup for: 6 - 8 or 10 mm; dowel length: From 25 - 50 mm.Dowel Station -- Vibrating hopper; insertion head & dowel driving with: Air impulse; setup for: 8 mm dia. x 50 mm long dowels. -- Glue valves controlled individually at Control Cabinet; central adjustment for the amount of glue by means of digital timer.Operating System -- MS-XP & GANNOMAT Production software; 15" color touchscreen monitor interface; USB drive; bar code capable; Controller & Drive:BECKHOFF - "C3620: TwinCAT V2.10".Complete with: -- (1) Glue tank; (1) water tank; auto lubrication system.

GANNOMAT INDEX 280 TREND CNC BORE, GLUE & DOWEL INSERTER: -- Specifications:CNC Controlled horizontal Point-to-Point Drilling, Gluing & Dowel Inserting Work Center for absolute, incremental, variable (parametric) programming of boring patterns. -- Working Field(4) Independent zones for individual processing of (1 - 4) pieces. Pneumatically activated Stop system (side fences) consisting of: Right-hand, left-hand, and center stop. Max. single part Length 2,800 mm (110"). As a 2-zone: LH & RH is 1,400 mm (55") each part. As a 4-zone with center fence: LH/RH is 700 mm (27.5") each part.Min/Max. Material Thickness 0.50" - 3.125" "X" Axis Positioning Speed 246 FPM (75 MPM) and driven by rack & pinion for fast acceleration/deceleration of working unit. "Y" Axis is set by mechanical digital counters. "Z" Axis is NC controlled height adjustment for boring/inserting units. -- Hold-down Clamps:Total of (10) pneumatic, "quick change" Hold-down Clamps. -- Dowel driving & horizontal boring:Integrated into (1) station; the Dowel Driving Unit is located alongside the Boring Station; both units are mounted on (1) support. -- Horizontal Drilling Spindle:Can be setup for 6 - 8 or 10 mm; dowel length from 25 - 50 mm. -- Doweling Station includes:Vibrating hopper with: (1) Single drop device and (1) outlet tube; insertion head & dowel driving with air impulse.Mechanical dowel diameter & dowel length control prevents the insertion of any oversized dowels. -- Glue Valve/Amount:Controlled via software and can be adjusted by milliseconds; (2) standard separate stainless steel 1.5 gal. pressurized tanks (one for glue, one for water to clean/purge the glue tubes. -- Operator Interface:GANNOMAT + BECKHOFF "C3640 Twincat" PLC Operating System.15" Touch-Screen color monitor; network card (for online operation); serial, parallel, USB ports. -- Actual model is: GANNOMAT INDEX 280 TREND. NOTE: Machine is currently setup for 8 mm dia. x 35 mm long dowels.

GANNOMAT - INDEX 130 LOGIC: CNC Bore, Glue & Dowel Inserter + Laser Measuring Device -- SpecificationsGANNOMAT "INDEX LOGIC": CNC Controlled Point-to-Point Drilling/Gluing/Dowel Insertion Machine for variable programming of boring patterns. -- "X" & "Y" Axis set by manual digital indicators; "Z" Axis adjusted via CNC controlled Servo drive. -- Working Width1,300 mm (51") x 3/4" - 7-3/4" Width x 1/2" - 3-1/8" material thickness with: (4) Independent working zones & LH/RH (mirror image).Table size: 4-1/2" x 52-3/4" x 35" H with: 9" x 52" Extension. -- (8) Vertical holddown cylinders & zero center stop for horizontal part processing. -- Dowel Driving & Horizontal Boring: Integrated into (1) station; the dowel driving unit is located alongside the boring station; both units are mounted on (1) support. -- Horizontal Drilling & Boring Station: Head can be setup for 6 - 8 or 10 mm; dowel length from: 25 - 50 mm (currently set up for 8 mm dia. x 50 mm long dowels). -- Doweling Station: Vibrating hopper; insertion head & dowel driving with: Air impulse; glue valves are controlled individually at the control cabinet; central adjustment for the amount of glue by means of a digital timer. -- Operator Interface: GANNOMAT Production software; 15" color touchscreen monitor interface; USB drive; bar code capable. -- Controller & Drive: BECKHOFF "C3620 TWINCAT V2.10". -- Complete with: (1) Glue tank; (1) water tank; auto lubrication system; all original manufacturer's machine documentation. -- Actual Model is: GANNOMAT - INDEX 130 LOGIC.

Call for Price

HOFER HOP 160 K Hydraulic Door/Veneer Heavy Duty Cold PressSpecifications:Platen size 63" deep x 98" long, Total Daylight/Opening 32".available. Currently set at about 13" opening. Top platen is hydraulically powered by a 2.2 KW power pack. and has (10 sets) of bolt holes for manual adjustment of daylight opening.Equipped with:(8) 3-1/4" Diameter Hydraulic cylinders, Rack & pinion platen leveling adjustment.Front and back loading (access on all sides).Heavy duty steel structural beams. Bolted top and bottom platens.Features:Pneumatically loaded 3 +1 rows of idle rollers on bottom platen for ease of feeding the load in and out front of press. Air valve for up/down selection of bottom platen rollers.Hydraulic closing speed adjustment.Electrical controls on right hand side.Dimensions/Weight: 124" x 72" x 122" H. Approx. 12,000 Lbs.

Call for Price

HYDREX HPX510-1 Hot Press, Single daylight opening. Suitable for laminating veneer panels/doors, decorative paper, fireproof board, etc.Features (Overall): -- Board size up to 5' x10', -- Front Controls for easy setup & operating configuration, incl. temperatures and cycle time , emergency pedal, quad temperature protection device. -- (8) Cylinders (upstroke) -- 120 Tons of overall pressure, -- Recirculating Thermal Oil heated with package heaters housed in a boiler tank.Detailed Specs: -- 122" x 61" Thermal Oil heated Hot Press with drilled steel platens, 1.5" thick, 4" Max Working height.. -- (8) Hydraulic "upstroke cylinders", 85 mm dia.; rack & Pinion guide system for parallel closing of the platens. -- 120 Ton total pressure, 40 PSI specific pressure over the entire platen area; 4.5 KW (6 HP) hydraulic pump motor. Platen moving speed 5 FPM -- 1.5 kW (2 HP) Hot Oil circulation pump; approx. 120° C (248° F) max. operating temperature. -- Loading from (3) sides; 39-1/2" from floor with lower platen in the down position: heavy I-beam welded steel frame construction. -- "Safety" emergency Stop Cable around the operating sides of the machine, and E-STOP mounted on the control panel. -- Features: "Last" (2) cylinders can be turned off to press shorter panels. - Overall press weight is approx. 19,500 Lbs).

Call for Price

HYDREX HPX510-5 Hot Press 120 Tons with (5) Daylight openings. Suitable for laminating veneer panels/doors, decorative paper, fireproof board, etc.Features (Overall): -- Board size up to 5' x 10', -- Front Controls for easy setup & operating configuration, incl. temperatures and cycle time, emergency pedal, and quad temperature protection device. -- (8) Cylinders (upstroke) -- 120 Tons of overall pressure, -- Recirculating Thermal Oil heated with package heaters housed in a boiler tank.Detailed Specs: -- 122" x 61" Thermal Oil heated Hot Press with drilled steel platens, 1.5" thick; -- (8) Hydraulic "upstroke cylinders", approx. 85 mm dia.; Rack & Pinion guide system for parallel closing of the platens. -- 120 Ton total pressure; 54 kW of heating power. 40 PSI specific pressure over the entire platen area; 4.5 kW (6 HP) hydraulic pump motor. -- 1.5 kW (2 HP) Hot Oil circulation pump; approx. 120° C (248° F) max. operating temperature. -- Max Working height is 4"; Loading from (3) sides; 39-1/2" from the floor with lower platen in the down position: heavy I-beam welded steel frame construction. -- "Safety" emergency Stop Cable around the operating sides of the machine, and E-STOP mounted on the control panel. -- Features: "Last" (2) cylinders can be turned off to press shorter panels. - Overall press weight is approx. 24,000 Lbs. -- Overall dimensions: 3,800 length (+610mm -boiler + 610mm -pump/tank) x 1,790 wide x 2,450 mm high.

Call for Price

HYDREX HPX48-1 Hot Press, Single daylight opening. Suitable for laminating veneer panels/doors, decorative paper, fireproof board, etc.Features (Overall): -- Board size up to 4' x 8', -- Front Controls for easy setup & operating configuration, incl. temperatures and cycle time, emergency pedal, and quad temperature protection device. -- (6) Cylinders (upstroke) -- 80 Tons of overall pressure, -- Recirculating Thermal Oil heated with package heaters housed in a boiler tank.Detailed Specs: -- 98" x 51" Thermal Oil heated Hot Press with drilled steel platens, 1.5" thick, 4" Max Working height.. -- (6) Hydraulic "upstroke cylinders", 85 mm dia.; rack & Pinion guide system for parallel closing of the platens. -- 80 Ton total pressure, 40 PSI specific pressure over the entire platen area; 4 KW (5.5 HP) hydraulic pump motor. Platen moving speed 5 FPM -- 1.5 kW (2 HP) Hot Oil circulation pump; approx. 120° C (248° F) max. operating temperature. -- Loading from (3) sides; 39-1/2" from the floor with lower platen in the down position: heavy I-beam welded steel frame construction. -- "Safety" emergency Stop Cable around the operating sides of the machine, and E-STOP mounted on the control panel. -- Overall press weight is approx. 12,500 Lbs). Overall dimensions 129" x 65" x 102" high.Also available with (3) openings - 100 Tons and (5) openings - 100 Tons.

Call for Price

HYDREX HPX410-5 Hot Press 160 Tons using (8) hydraulic cylinders, Five daylight openings. Suitable for laminating veneer panels/doors, decorative paper, fireproof board, etc.Features (Overall): -- Board size up to nominal 4' x 10' (about 51" x 126"). -- Front Controls for easy setup & operating configuration, incl. temperatures and cycle time , emergency pedal, quad temperature protection device. -- (8) Cylinders (upstroke) -- 160 Tons of overall pressure -- Recirculating Thermal Oil heated with package heaters housed in a boiler tank.Detailed Specs: -- Platen size 1300 mm x 3200 mm (51" x 126") approx. Thermal Oil heated Hot Press with drilled steel platens, 1.5" thick; -- (8) Hydraulic "upstroke cylinders", approx. 85 mm dia.; rack & Pinion guide system for parallel closing of the platens. -- 40 PSI specific pressure over the entire platen area; 54 kW heating power. Approx. 7.5 kW (10 HP) hydraulic pump motor. -- 1.5 kW (2 HP) Hot Oil circulation pump; approx. 120° C (248° F) max. operating temperature. -- Max Working height is 4"; Loading from (3) sides; 39-1/2" from floor with lower platen in the down position; Heavy I-beam welded steel frame construction. -- "Safety" emergency Stop Cable around the operating sides of the machine, and E-STOP mounted on the control panel. -- Overall press weight is approx. 27.500 Lbs. -- Optional: Extra Large Oil Heating Tank for Special Higher Temperatures if needed.

.gif)