Equipment For Sale

10436 Results Found

Call for Price

48" Precision Chipper with 100hp motor, vibratory conveyor feed included. $12,000 Call 706-271-8444 or 423-584-7380

Call for Price

Call for Price

Call for Price

Used Precision horizontal stationary chipper, 66”, 6 knife. Precision Husky stationary electric chipper Horizontal infeed Bottom discharge 6 knife Knife size: 21 ½” x 6” Choice of electric motors available Can provide a video of shaft/disk rotating with dial indicator on shaft. Chipper was cleaned & repainted, we do have photos before we painted it Additional photos, vidoes and information available. Contact us for a delivered price.

Call for Price

Call for Price

Call for Price

Call for Price

Call for Price

Call for Price

Call for Price

Call for Price

Call for Price

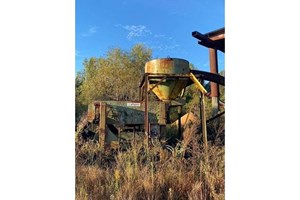

75" Precision Chipper - bottom discharge with rechipper spout for oversized chips. 6 knife blanked to 3.

$ 13,500

Precision vibrating conveyor, 18" wide pan x 30' long, 12" tall sides, BRAND NEW fiberglass paddles, excellent condition

75" Precision 4 knife chipper with side discharge. Progress 7 x 7 Chip Shaker. Will not separate. Call 800-459-2148 for more info.

$ 16,000

- Precision American Corp self-contained debarker. Can take aprox 20' log. It is 40' long and 8'6" wide Call 800-459-2148 for more info.

2001 PRECISION HUSKY PROGRIND 1000 TUB GRINDER REDUCED 275 HP New Fixed Teeth New Auger Motors Good Tires Runs Well

Complete chip plant includes: - The infeed is 12’ above ground level. They were feeding it one log at a time with a shovel. - There is a single chain 12” wide leading to the debarker. - The debarker is a Salem 20” ring debarker with mcdiarmond controls. - From the debarker it goes through I think is a metal detector. It’s is enclosed, 8’ long with a belt conveyor. - 75’ of 3-strand chain that reduces to 2-strand chain for 35’ then goes to another 2-strand chain for 12’ then goes into the chipper. - The chipper is a Precision with 2- 400 hp high efficiency 3 phase motors. - From the chipper the chips drop onto a 42”x50’ inclined belt that leads to the 2 deck screen. The screen is 92”x20’ - The waste goes on a 9”x20’ incline belt and dropped into a truck. - The chips go out on a 3-strand 100’ conveyor (strands are 14” wide) to a radial stacker for loading trucks. The stacker belt is 42”x65’ - Chips can be redirected to blower unit system that will transport them to a rail siding to so they can be loaded into a rail area. It starts out with 75’ of 12” pipe running on the ground. Then it sweeps straight up to a height of about 24’ and goes 150’ to a siding across the county road. The chip loading facility is intact. - The hog is located back by where the logs are loaded onto the chain going to debarker. Here’s a list of the conveyors going back to the Kockums hog. It has a 24”x36” opening at the top. - Conveyors: 12”x100’, 12”x 25’, 12”x60’. All of these conveyors are 1 strand steel.

.gif)