Equipment For Sale

10434 Results Found

Call for Price

Call for Price

We have used Esco sorting and bunching grapples available. As well as skidder grapples for most major makes and models. We have the largest used logging parts inventory in the south. Call us for all of your used parts needs.

$ 42,500

Call for Price

Industrial Grade EUROVAC I Cyclone Separator & Cartridge Dust Collector Combination. -- Primary Separator: Cyclone on support stand and barrel waste collection: (A Rotary Air Lock with a larger waste bin can be added). Cyclonic action can remove up to 99% of dust and particles. -- SYS-030 Secondary Dust collection: Remaining 1% of dust collected using Cartridge Filter which are automatically cleaned by Pulse Jet cleaning using compressed air housed in a separate compressed air storage tank. -- Vacuum Producer: Heavy Duty cast iron turbine type pump with 10 HP energy efficient squirrel cage motors designed to run continuously all day. built-in thermal heat protection device, and overload protection in Control Panel. High 85" WC vacuum level. -- Control panel house pump starter controls with hand/auto selector for on demand starting. -- Features: Quiet operation with built sound deadening. Diaphragm valves for pulse jet cleaning. -- Approximate dimensions: 180" long x 70" wide x 72" high.

Call for Price

Evans Scragg Sharp Chain Feed Dbl Arbor , (2) 40" Bottom Saws, (2) 30" Top Saws, 50HP on Bottom & 30HP on Top, Cab and Controls

Call for Price

$ 8,900

Evans Log Trailer 37' 2 bunk Air lift 3rd axle Good tires Good brakes Current valid inspection

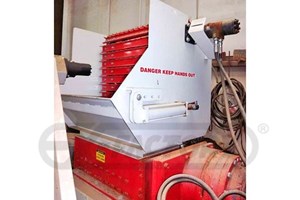

EVASHRED EV60E Dual Shaft Shredder with Infeed ConveyorEvashred is a well-known brand of commercial mobile and stationery shredders for solid waste designed and manufactured by F.V. Evans and Sons also known as Evans Engineering.Every type of shredder is designed specifically to shred a particular type of solid waste including Documents, Car & Truck Tyres, E-scrap (Hard Drives, Computers, Printers known as E-waste and e-scrap), Plastic, Foam rubber, Green Waste, Building Waste even Hospital WasteSpecifications: --30 kW / 40 HP Maximum Power --28-30 RPM Cutter Speed Rotation --Width 640 mm x 37 5mm Cutting Chamber Opening

$ 1,250

Used for the accurate radius measuring of cutterheads; allows for speedy tool changes on moulder. 12" Long x 6-1/2" base, 1-1/2" dia. arbor will handle up to 9-1/4" long tool body. -- Digital caliper rides up and down on precision machined octagonal bar. -- Options: T-bushings for 1-13/16" dia. & 40mm dia., please specify.

Call for Price

EXCALIBUR- 1042-60, ...Dual Shaft ShredderSpecifications: -- Motor: 60 HP. -- Opening: 42x 25". -- Cutters: 1 1/8" Wide. --Includes Control Panel -- Includes Stand but no Hopper÷ Loaded onto your Truck.

Call for Price

Excalibur Smart Incising for Round Timbers from Timber Treatment Solutions (TTS). - 63 mm - 200 mm Diameter (1.29"-7.8") - Minimum length of 200 mm to no max (7,8" - (9) Incising Heads - Self cleaning system for blades - Allows superior preservative penetration with pressure treatment - Optional: Customized builds for larger pole requirements

Call for Price

Timber Treatment Solutions now offers an advanced incising solution for square sawn timbers with EXCALIBUR PRO, allowing a superior penetration of the wood in the subsequent preservative pressure treatment. It offers the ability to incise specific sections of post, saving on preservatives while still focusing the treatment where it is needed most and helping to retain visual product aesthetics above the ground contact line. - 1” x 1” to 20” x 20” Section Capacity - No maximum length - Incision depth up to 3/4" - 2 sets of 2 incising heads, fully sequenced with each other - Self cleaning system for blades - Incises all four faces in a single pass with incising pattern sides finishing at the same point - Full- or part-post straight-through continuous incising with a simple choice of the length and place of incision anywhere on the post - Mechanical blade separation system allows rapid setting of the machine for different timber sizes - Auto self-calibration to ensure accurate incising every time and reduce operator error

Call for Price

EXCEL - EX60: (Non-Ferrous) Horizontal Closed Door Baler with Infeed ConveyorSpecifications: -- Motor: 20 HP. -- Cylinder: 9". -- Ram Force: 190,851 Lbs. -- Feed Opening: 40" x 55". -- Full Bale Chamber Penetration. -- Wear Liners: Hardrock 400. -- Automatic Shear Jam Correction.Price includes "Loading onto your Truck!"

Call for Price

EXCEL - 2R63, ...2-Ram Horizontal BalerSpecifications: -- Main. Cylinders: Twin 6". -- Eject Cylinder: 6" -- Main motor: 20 HP. -- Cycle Time: 29 Sec. -- Overall Force: 159,467 Lbs. -- Feed Opening: 60" x 54". -- Bale Size: 60" x 48" x 30".Equipped with: -- U.S. 343 13 Gauge Wire Tier

Call for Price

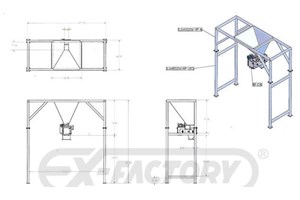

COMPLETE LOOSE BAGGING SYSTEM System includes: -- Feed Hopper 3 Yards Capacity. ( 87 Cu.Feet) -- 24 feet Incline Conveyor. -- GB Mechanical Bagging Scale -- Feeding Hopper 37 Cu.Feet with Stand. -- Packrite Xtrol Impulse Sealer. -- Motorized Bag Conveyor. -- Loaded on your Truck.

Call for Price

EXPRESS SCALE MCRS-180ELECHYD LOOSE BAGGING LINEComplete Loose Bagging Line including the Following; -- Hopper Stand and Support 37 cu' BF/GV/AUG -- GB Bag Fill Machine -- BF-14 Belt Feeder -- Bag Closing Conveyor 510-LP -- Fishbein Sewing Machine -- Hopper 87 cu' with Support -- Belt transfer Conveyor 27' -- Loaded on your Truck

Call for Price

MCRS is a Bagging System for mulch, compost, rock, or sand. This system is complete with a 2-yard product surge hopper, a 20' X 24" wide troughed incline product delivery conveyor with a cleated belt, an 8' bag closing conveyor, and a custom 7.5 HP Elec/hydraulic power unit. The system can fill bags by time and depth of stream or digitally with load cells.Standard construction carbon steel Powder Coated Industrial Gray(RAL 7046).The MCRS operation has been designed for one man to bag fill, bag close, and stack three bags per minute continually. -- The operator hangs bag #1 on the scale, hits the palm switch to close the CG spout, and automatically fills it. -- Bag #1 will drop once the timer times out onto the moving conveyor and hangs bag #2 into position, hits the palm switch, and starts the filling. -- The operator steps to his left. Bag #1 contact a wand switch and is in position underneath the impulse sealer. --The operator starts the bag into the impulse sealer. Once completed, bag #1 is then manually stacked. -- Bag #2 filled and waiting for the operator's return. -- Bag #2 is then released, and bag #3 hung. -- The process is then repeated.The Front End loader feeds the system. Consists of the following --infeed hopper --incline conveyor --dosing system --bag closing system:Bag Closing System Consists of a (CON 508) 8' long x 1' wide smooth top belt to take bags into aposition where a wand switch manually stops them. The bags are then prepared and enteredinto theImpulse Sealer (31103737610) Programmable Impulse Sealer for the repeated sealing of thermoplastic films such as polyethylene and polypropylene. This automatic single-impulse heat sealer is controlled by a plug-in transistorized circuit board and electronic timers. The timed closure ensures an even and consistent seal. --THE PRICE REFLECTS AN UPGRADE FROM THE IMPULSE SEALER TO A SEWING SYSTEM.The operator has hands free to handle the product quickly. This type of machine generally increases workers' productivity.The electric foot pedal is included for manual operation. -- Seal Length: 24" -- Seal Thickness: 8 mil -- Seal Width: 10 MM

EXPRESS SCALE CM-780D-II Bagging System with ConveyorsSpecifications: -- Air-operated double door weigh hopper: 3.5 CuFt -- Load cells: 100 KG (220 Lbs) -- Weigh Range: 10-110 Lbs or 5-100 kG -- Cycle Speed (simplex): 13 bpm (50 lbs or 25 kG) -- Cycle Speed (duplex): 22 bpm (50 lbs or 25 kG) -- Typical Accuracy: ±2-3 oz. or ±56-85 gramFeatures: -- 1280 Express Digital Programmable Controller with digital readout -- RS232 output -- Operator station. -- Protect individual or all parameters via pass-code protection -- Ethernet connectionSystem Equipped with: -- Gravity Feeder: High-Output Gravity Gate (13" x 8") 2-position for bulk and dribble feed. Handlingfree-flowing products such as grain, seed, and prilled fertilizers. Rated at 14-16 bags per minuteSimplex or 22-24 BPM - duplex. Typical accuracies will be +/- 2-3 ounces (56-85 grams). -- Spout Assembly: Dust Tight 21", 25", or 31" Circumference -- Hopper Surge: For simplex scale only, mild steel construction gray powder coated 40 CU' capacity(operator platform and handrail not included) 4"x 4" x 1/4" wall tube, 3/16" Metal Plate for wallsof Hopper. -- Conveyor: 22' x 18" product delivery: 2 HP Motor, 3" Scoop Cleat Belting w/ Hopper for Unloading Bulk Bags -- Bag Closing Conveyor with Air-Flo Hot Air Heat Sealer: 10' overall length, 1/2 HP motor, 12"-wide 3-ply neoprene smooth top belt, 110V variable speed motor mounted internally, adjustable conveyor height 13.5" to 18.5" and adjustable back plate, electrical controls include on/off switch.Backed by a 1 year warranty and lifetime customer support.

Call for Price

SPECIAL FEEDER FOR HAMER 2080FFS BAGGER -- Hopper 37 Cubic Feet and Support -- With Scale Support System -- Belt Feeder with Discharge to Existing Hamer Form-Fill and Seal -- Brand New -- Loaded on your Truck

.gif)

.jpg?width=300&height=200&mode=pad)