pallet Equipment For Sale

465 Results Found

$ 19,700

RAIMANN - KM-310, ...Gang (Multi-Blade) Rip Saw12-1/4" Max. width cap., 13-1/2" chain width, 50 HP - 4,200 RPM V-belt driven arbor.Features: -- "Quickfix Hydro-Quick" Arbor: Multiple Saw blades are mounted on the arbor, they slide up-and-down the arbor into position and lock into place by tightening the end of the arbor; no tools & no spacers required. -- Frequency controlled feed speed of 13 - 110 FPM, 2.2 HP feed drive, chain spikes every 3rd chain link, automatic chain lubrication.Specifications: -- 300 mm (11.8") Max. saw blade dia. with 80 mm (3.15") bore, 65 mm (2.55") dia. arbor. -- Provides 3" max. depth of cut with pressure shoe, 3-1/2" depth of cut without. -- Manual thickness adjustment of upper holddown rolls with indicator scale. -- 6" Throat depth to the right of blade; 7/8" min. strip width, 17-3/4" min. stock length.Equipped with: -- (4) Sets of top & bottom antikickback fingers. -- Extended infeed with additional bed roll, and adjustable infeed fence. -- Motor load meters and automatic STAR DELTA starting. -- Automatic over thickness shutoff on infeed and 7-1/4" dia. dust hood. -- (4) Laser lights.Also included: -- (6) Used blades.

$ 103,950

RAIMANN KR 310 2M Multiple Rip Saw System ( 2 Moving Blades )12-1/4" Max. width cap., 13-1/2" chain width, 50 HP - 4,200 RPM V-belt driven arbor.Equipped with:& Features -- Quick Fix arbor with: (2) Movable blade and (3) fixed blades; (5) Laser Lights. -- Enlarged movable saw housing with 25" pass through. Ball threaded adjustment of spindle. Saw blades mounted to individual collars. -- Chain with spikes every 3rd link, with automatic oiler with indicator light. -- Driven fluted lower roller with smooth upper roller for smooth feeding. Auto oiler fo guide lubrication. -- (4) Sets of anti-kickback fingers and 12" dia. dust hoods. Raimtech E5 with TimberMax Software optimizing software; makes it possible to get the most out of incoming lumber. -- The software optimizes rips for width or grade. -- TimberMax calculates the most profitable ripping solution for each board at which time shifting saw blades are positioned automatically. -- Infeed includes a infeed belt conveyor with pressure roller. -- Infeed is mounted on slide that automatically adjusts the board in the best position before entering the saw. -- Conveyor is 24" wide X 120" long. ( This option has to be verified )Cutting Specifications -- Cutting depth with 12" Dia. saw blades, 2-1/2" with pressure shoe; 4" without pressure shoe. -- Variable feed speed, 16 - 158 FPM, feed drive 2 HP motor.Additional Features -- Sound enclosure with vertical pneumatic lifting -- Adjustable infeed fence. -- Automatic over thickness shutoff on infeed. -- Automatic starting and swing arbor mount for control panel.

$ 79,300

RAIMANN KR 310 2M Multiple Blade Rip Saw System with Valu-Rip Infeed12-1/4" Max. width cap., 13-1/2" chain width, 50 HP - 4,200 RPM V-belt driven arbor.Equipped with: -- Quick Fix arbor with: (2) Movable blades and (3) fixed blades; (5) Laser Lights. -- Enlarged movable saw housing with 25" pass-through. Ball threaded adjustment of spindle. Saw blades mounted to individual collars. -- Chain with spikes every 3rd link, with automatic oiler with indicator light. -- Driven fluted lower roller with smooth upper roller for smooth feeding. Auto oiler for guide lubrication. -- (4) Sets of anti-kickback fingers and 12" dia. dust hoods. -- Raimtech E5 with TimberMax Software optimizing software; making it possible to get the most out of incoming lumber. The software optimizes rips for width or grade. TimberMax calculates the most profitable ripping solution for each board at which time shifting saw blades are positioned automatically. Infeed includes an infeed-belt conveyor with a pressure roller. Infeed is mounted on a slide that automatically adjusts the board in the best position before entering the saw. The conveyor is 24" wide X 120" long.Cutting Specifications: -- The cutting depth with 12" Dia. saw blades is 2-1/2" with a pressure shoe and 4" without a pressure shoe. -- The variable feed speed is 16 - 158 FPM, and the feed drive is a 2 HP motor.Features: -- Sound enclosure with vertical pneumatic lifting -- Adjustable infeed fence. -- Automatic over-thickness shutoff on infeed. -- Automatic starting and swing arbor mount for control panel.Also included: -- Valu-Rip infeed system 16' long -- (4) Movable Laser light Note: The machine, chain feed, and arbor, have recently been refurbished.

$ 59,500

RAIMANN KR 310 2M Multiple Rip Saw System ( 2 Moving Blades )12-1/4" Max. width cap., 13-1/2" chain width, 50 HP - 4,200 RPM V-belt driven arbor.Equipped with & Features: -- Quick Fix arbor with: (2) Movable blade and (3) fixed blades; (4) Laser Lights. -- Enlarged movable saw housing with 25" pass through. Ball threaded adjustment of spindle. Saw blades mounted to individual collars. -- Chain with spikes every 3rd link, with automatic oiler with indicator light. -- Driven fluted lower roller with smooth upper roller for smooth feeding. Auto oiler for guide lubrication. -- (4) Sets of anti-kickback fingers and 12" dia. dust hoods. Cutting Specifications -- Cutting depth with 12" Dia. saw blades, 2-1/2" with pressure shoe; 4" without pressure shoe. -- Variable feed speed, 16 - 158 FPM, feed drive 2 HP motor.Additional Features -- Sound enclosure with vertical pneumatic lifting -- Adjustable infeed fence. -- Automatic over thickness shutoff on infeed. -- Automatic starting and swing arbor mount for control panel.Note: Transformer for 600 volts included if necessary

Raimann ValueRip RipMax.NOTE : Never been set-up or installed. Specifications -- 17 Points of width measurement for basic shape detection -- Industrial PC with ergonomic, touch screen. -- TimberMAX optimizing/tally software, based on shape optimizing. -- System will automatically position fence and moving blades appropriate to the solution. Equipped with & Features -- Moving lasers display rip solution prior to ripping. -- 10-14 Average number of boards processed per minute by the operator. Note: This is based on 10 ft. boards with no overrides. -- New, unused machine. Sold in 2021, Never Installed

$ 67,375

RAIMANN - KR 310 2M: Multiple Blade Rip Saw System with "Valu-Rip" Infeed12-1/4" Max. width cap.; 13-1/2" chain width; 50 HP - 4,200 RPM V-belt driven arbor.Specifications -- Quick Fix arbor with: (2) Movable blades; (3) fixed blades; (5) Laser Lights. -- Enlarged movable saw housing with: 25" Pass-through. Ball threaded adjustment of spindle. Saw blades mounted to individual collars. -- Chain with spikes every 3rd link with: Automatic oiler with indicator light. -- Driven fluted lower roller with: Smooth upper roller for smooth feeding.Auto. oiler for guide lubrication. -- (4) Sets of: Anti-kickback fingers & 12" dia. dust hoods.Cutting Specifications -- Cutting depth with: 12" Dia. saw blades; 2-1/2" with a pressure shoe; 4" without a pressure shoe. -- Variable feed speed: 16 - 158 FPM; feed drive: 2 HP motor.Equipped with & Features -- Sound enclosure with vertical pneumatic lifting. -- Adjustable infeed fence. -- Automatic overthickness shutoff on infeed. -- Automatic starting and swing arbor mount for Control Panel.Also Included: -- "Valu-Rip" Infeed System: 16' Long. -- (4) Movable Laser lights.

$ 49,445

RAIMANN - KR 310 2M: Multiple Rip Saw System (2 Moving Blades)12-1/4" Max. width cap.; 13-1/2" chain width; 50 HP - 4,200 RPM V-belt driven arbor.Equipped with & Features -- Quick Fix arbor with: (2) Movable blades; (3) fixed blades. -- Movable Operator pedestal with: LED Screen; pushbutton controls. -- Chain with spikes every 3rd link; automatic oiler with indicator light. -- Driven fluted lower roller with: Smooth upper roller for smooth feeding.Auto. Oiler for guide lubrication. -- (4) Sets of anti-kickback fingers; 12" dia. dust hoods.Cutting Specifications -- Blade Diameter: 9.8" - 15". -- Cutting depth with: 12" Dia. saw blades; 2-1/2" with pressure shoe; 4" without pressure shoe. -- Variable feed speed: 16 - 158 FPM; feed drive: 2 HP Motor.Additional Features -- Sound enclosure with vertical pneumatic lifting. -- Adjustable infeed fence. -- Automatic over thickness shutoff on infeed. -- Automatic starting and swing arbor mount for control panel.

$ 143,000

RAIMANN (WEINIG) - VarioRip 310 M: Infeed & (2) Moving Blades SystemClean, very hard-to-find 2014 (Infeed 2022) WEINIG RAIMANN Variorip 310 M: Optimizing Rip Saw with: (2) Moving Blades & Infeed SystemSpecifications -- Working dims: Length: 24″ to 184″; width to 12.2″ (310 mm); thickness 0.59″ - 3.94″ (184″ is fence length). -- Cutting dims: Width min.: 5/8″ (1st movable blade); min. 1-5/8″ - 10-1/4″ (2nd movable blade); fixed pocket: 1″. -- Production in auto. mode: 7 x 10′ Boards/Min. -- Saw. 50 HP Motor with: Arbor dimension of 2.6″; RPM: 4,200. -- Quick fix arbor (handturn nut) for position blades. -- Saw blade dia.: 12″ - 14″ (300 - 350 mm). -- Blade positions: Ball screw adjustment. -- Chain: 12-3/4″ Width steel chain with every 3rd link with spikes. --. Automatic oiler: For chain lubrication. -- The chain has auto. shutoff when the oil level is low.ROTO Chain brush for: Continuous chain cleaning of debris; (4) sets of anti-kickback fingers. -- Feed: Variable 26 - 157 FPM (8 - 48 MPM); 3 HP motor.Equipped with & Features -- Controller. RAIMANN "TimberMAX" with: 15″ Color screen storage for (100) cut lists. -- Production recording and yield. -- Also includes: (4) Lasers with mounts; spare parts; manuals.Footprint & Weight: Infeed: 3,306 Lbs & Roughly 8' x 16'.Saw: 4,603 Lbs & Roughly 6' x 6'.The Saw slightly offsets the infeed; the footprint together is a little larger (...probably closer to 9' x 23').NOTE: Saw is: 2014, INFEED is 202.SOME Spec's need to be verified.

$ 19,500

RAIMANN KM-US BV Gang Rip Saw with one (1) Moving BladeSpecifications: -- (1) Shifting blade with foot pedal control; -- Fixed blades mounted to individual collars that slide up-and-down the arbor into position, then lock into place by tightening the "Quick fix" nut on the arbor, no tools & no spacers required. -- 12" Dia. saw blades, 65 mm (2-1/2" dia.). -- Arbor, 3-1/2" max. depth of cut. -- 20" centers between upper holddown rollers (wood holddown shoe plate not included). -- 6" Throat depth to the right of the blade. -- 3/4" Min. strip width, 21" min. stock length.Equipped with & Features: -- Variable feed speed 16 - 110 FPM, -- Feed drive 1.2 HP motor; -- Chain spikes every 3rd chain link, -- Automatic chain lubrication, -- (2) Sets of top & bottom anti-kickback fingers, -- Extended infeed with additional bed roll, adjustable infeed fence. -- Complete with: Automatic over-thickness shutoff on infeed, -- Automatic starting, -- 8" Dia. dust hood. -- Includes (4) Lasers and Tooling as pictured.

Call for Price

Call for Price

Call for Price

Rayco Edge 480 Volt with Reducer to 240 Volt 3 Stringer S/N 98040 Out and Ready to Ship.

Call for Price

Call for Price

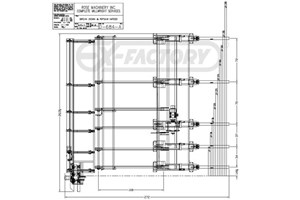

ROSE MACHINERY BDH/LC/LCFT Automated Infeed SystemAutomated, high speed Infeed System for Gang Rip Saws of all makes and models and other similar machines. -- 5-Arm Breakdown Hoist - Electric hoist accepts loads 4' wide x 4' high x 4' - 24' long; 10 HP gear motor (with brake) powers the hoist and holds the load. -- Hoist actuated through foot switches for up & down; limit switches provide max. up & down positions; (5) lifting arms tilt load at 50° allowing layers to spill onto the takeaway conveyor; 16,000 Lbs. max. lift cap. -- Landing Chain - Features: (6) Strands of roller chain; powered by a 5 HP gear motor at 60 FPM nominal rate. -- Tail end constructed with integral slide, stock transits from Breakdown Hoist; head shaft & gear motor supported by tubular steel frame with bolts to allow for leveling at installation. -- Material stops at the head end so the operator can flip & grade each piece. -- Chain races fabricated from steel, UHMW PE wear strips on the top race and on the return race; conveyor is 42' long. -- Magnetic motor starter with foot switch for operator to start & stop of the chain. -- Lateral Chain Feed Table "LCF2013-20": Feeds material 3" - 10" wide x 4' to 24' long x 1" to 3" thick; variable 50 - 200 FPM Feed rate; adjustable fence throughout 3/4" range for alignment with the Rip Saw (or other machines). -- (6) 30" long, low friction steel flattop infeed chains for long life non-marking transport; 1 HP gear motor. -- (3) Powered smooth steel & non-marking feed rolls, 2 HP gear motor; rolls & chains controlled by variable speed drives. -- (3) Overhead pinch rollers, 5" dia., urethane covered; 1st (2) pinch rollers powered by individual 2-1/2" bore air cylinders to singulate pieces onto a 2' bridge; 3rd roller keeps the board moving on the bridge; pinch rolls triggered by photoelectric cells. -- Note: Fabricated frames and appropriate parts of the items in this quotation will be painted with (1) coat of industrial grade Shady Lane Green enamel; guards and appropriate moving parts painted with Safety Orange. -- All gear motors, mechanical equipment, limit switches, sensors or photoelectric devices, as required for each item of this quotation, are supplied and mounted; all pneumatic cylinders or other pneumatic power devices and their valves supplied and mounted; connecting hoses & fittings installed. -- Filter/Regulator units supplied, mounted, and connected by hose to the valves; Note: Compressed air service to equipment is by others.

Call for Price

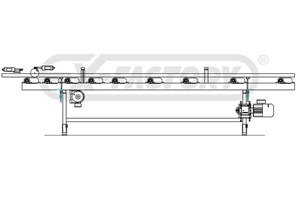

Ripsaw Feeder with 32" wide feed rolls on 18" thru 28" roll centers; will feed 3' thru 16' lumber. With 24" of in-out fence travel; feed speeds from 50 to 150 FPM; 3/4 HP feed roll drive and 3/4 HP fence drive via gear motor with brake. -- Fabricated frame of structural steel with boots that allow +/- 1" elevation adjustment. 3-1/2" dia. steel feed rolls driven by a variable frequency drive for speed adjustment; rolls are canted to aid in holding stock against the fence. -- Powered fence with 24" fence travel is easily shifted via joystick control for stock alignment with the sawblades. -- With pneumatic powered gate to keep material from feeding until the operator initiates the feed sequence. -- Urethane covered idler pinch roll is attached to the fence and is powered down at the start of the feed sequence. When a photocell detects the board is clear of the gate, the pinch roll and gate will return to their normal position. Electrical control panel ready for connection to the power supply.

Call for Price

ROSE MACHINERY HBR Horizontal Band RE-RIP SawThe Horizontal Band Re-Rip Saw is an effective and efficient means of ripping short blocks into as many as six (6) set rip widths. Rip widths are easily adjustable, as well as the setting for stock thickness.Advantages of the system: -- Compact, efficient use of floor space. -- Accurate cutting of rips with minimum tear-out. -- Short blocks, 4" minimum length, without taper problems. -- Straight through feed design, good for sorting. -- Minimum dust collection required. -- Single point scrap collection. -- One saw drive motor, requires less power. -- Safety, no kickback problems.Specifications: -- Five (5) rip widths - (6) optional -- 20 HP bandsaw drive -- 30" diameter band wheels, 2" wide face -- (2) 3/4 HP feed works drives -- 1-1/2 HP feed belt drive -- 1" to 6" rip width (independently adjustable in each lane) -- 10" maximum board width at maximum rip -- 4" maximum waste piece width -- 3/4" to 2" stock thickness (all lanes adjust together) -- 4" minimum stock length -- 36" maximum stock length -- 80 FPM feed speed -- 52" to 58" pass line height -- Motor starters and push buttons included, wired for 440 volt, 3 phase, 60 Hz (uses standard mag starters) -- An automatic band lubrication system is includedOptional Equipment: -- For SIX (6) LANES, add ...$5,600 (SORTER increases $3,700) -- Automatic machine grease lubrication system, add ...$ 9,200 -- Ergonomic overhead stock slide, add ...$ 5,600 -- Output conveyor and sorter for 5-LANEsingle side discharge, add ...$47,300 -- Output conveyor and sorter for 6-LANE single side discharge, add ...$51,100 -- Operator's platform, add ...$ 7,900 -- Optional voltage configuration: 220/380/440V, 50HZ, add ...$2,900 -- Start-up and training, add $1,000 per day plus expenses at costHorsepower Requirements: -- (1) @ 20 HP -- (1) @ 1-1/2 HP -- (2) @ 3/4 HPDust Collection: -- (2) outlets, 6" diameter, 5,200 FPM velocity @ 2,300 CFMCompressed Air Required: -- 90 PSI @ 1.4 CFM

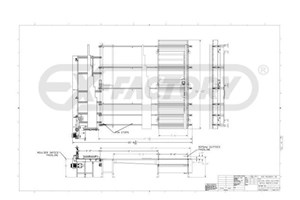

ROSE MACHINERY LCFCMS14 PANEL RIPPER TO MOULDER TRANSFER SYSTEM OUTFEED ROLLCASE: -- Outfeed Rollcase receives material from the LHI Panel Ripper at 47 1/4"; elevation and drops down to place the lumber onto the Transfer Chains at 42"; elevation. 66"; wide rolls are 2-12"; diameter steel rolls, snap in style on 12"; centers. Rolls are powered by a line shaft using round Eagle Belts and a 1-1/2 HP gear-motor. The conveyor will be fabricated from tubular and sheet steel and designed to interface with the Transfer Chains. The conveyor speed is 80-120 FPM to create a gap between courses exiting the Panel Ripper. The drop will be triggered when a photocell detects the leading end of the boards, creating a far side lumber line. A pneumatic cylinder provides lifting power. When the transferred boards clear the rolls, another photocell triggers the rolls to return to the up position. Stock length handled by the Outfeed Rollcase is from 6’ to 16’. Elevation adjustment is +/- 1";.TRANSFER CHAINS: -- Transfer Chains receive material from the Outfeed Rollcase. The Transfer Chains are fabricated from tubular and structural steel. There are (6) strands of 2060H conveyor chain approximately 17’-6"; CC long, leaving 11’ clear space to accumulate (2) layers of ripped strips. (2) sets of pin stops are incorporated to keep the layers separate. The conveyor is powered by a 1-1/2 HP gear motor. Conveyor speed is 90 FPM maximum. Elevation is 42"; +/- 1";. LATERAL CHAIN FEED TABLE (ROSE MODEL LCFCMS14): -- Standard duty low friction flat top steel infeed chains drive the stock to the fence. The fence is adjustable for alignment with downstream equipment such as a Moulder. (3) lower powered feed rolls are smooth steel and non-marking. The feed rolls and chains are controlled by adjustable frequency drives. (3) upper pinch rolls are 5"; diameter urethane. The first (2) rolls singulate pieces while (1) pinch roll keeps the board moving on the bridge. The pinch rolls are triggered by photocells. A PLC in the control cabinet cycles the outputs based on operator input. Operator controls allow for start and stop of the chains and rolls, the feed to be paused, the rolls to be reversed and speed controls. -- Fabricated structural steel frame -- Passline height 42"; +/- 1"; -- Stock width 2"; to 9"; -- Stock Thickness 1/4"; to 4"; -- Stock Length 6’ - 16’ -- Rolls include a variable feed rate from 60 to 300 FPM -- Feed roll drive is by a 3 HP gearmotor -- (6) infeed chains, each 50"; long, are driven by a 1-1/2 HP gearmotor -- Infeed chain's variable feed rate is 20 to 75 FPM -- 2-1/2"; bore air cylinders actuate the pinch rolls -- With 3/4"; fence adjustment. ELECTRICAL CONTROLS: -- Controls are incorporated in the LCF Cabinet for the above Transfer System. It consists of operator controls, (2) VFDs, and additional PLC I/O and programming. STARTUP: -- 2-days startup assistance is included. Travel expenses are billed se

ROSE MACHINERY TRANSFER SYSTEM: PANEL RIPPER TO MOULDER INFEED OUTFEED TRANSFERA Rollcase will carry stock away from a LHI 72" Panel Ripper. When the stock reaches the far end-stop, a 6-Strand Transfer Belt will pop up and take the stock to a Lateral Chain Feeder (supplied by others). The lifting mechanism is triggered by photocells and powered by an air bag using plant air. When the stock clears the Rollcase, the transfer will return to the down position to receive the next batch of strips. Rollcase Specs:17' 0" long; 76" between frame; 1.9" dia. X 12 gauge rollers. Galvanized rollers are set high on 3" centers. 5-1/2" x 1-1/2" x 12 gauge formed steel channel frames; welded construction. 120 FPM maximum. Dual shaft w/jump chain; underhung drive; timing belt driven; 1 HP, 575 volt/3ph/60hz motor; less controls. With (3) H-style leg supports; 34" top of roller; adjustable 32" to 38", with knee braces. Fixed angle end-stop. Frame is powder coated blue; guards powder coated yellow. Transfer Specs:B/17 purple power twist belt; 36" strand centers; 10'-0" long. UHMW chain track; airbag lifting style; thru frame; 36" top of chain. With 1/2 HP Boston 575 volt/3ph/60hz motor with Boston reducer for 120 FPM; less controller; proximity switches to detect carriage position are mounted only; solenoid valve, mounted and plumbed; filter/regulator - mounted and plumbed. With central bearing lube. Frame is powder coated blue; guards powder coated yellow Electrical Controls:ROSE provides an Electrical Control & Cabinet that will control the above Outfeed Transfer System. Electrical Control will incorporate a fused disconnect for incoming power, transformer and power supply for control voltage, (4) variable frequency drives for the motors, a PLC to read input devices and control output devices, and pushbuttons/switches for operator control. The panel will be mounted and wired to the enclosed devices. Incoming power and other field wiring is by others. Two days startup assistance is included. Travel expenses will be billed at cost separately.Conditions:All gear-motors, mechanical equipment, limit switches, sensors or photoelectric devices as required for each item of this quotation, will be supplied and mounted. All pneumatic cylinders or other pneumatic power devices and their valves will be supplied and mounted. They will have connecting hoses and fittings installed. Filter/Regulator units will be supplied, mounted and connected by hose to the valves. Compressed air service to equipment is by others.Exclusions:This proposal describes the machinery to be provided by Rose Machinery Inc.. The equipment supplied by Rose Machinery Inc. is specifically limited to the items actually described in the itemized details of this quotation. Unless specifically mentioned herein, all other items and services are the responsibility of the Buyer. State or local sales taxes, or any permit or other fees that may be required are not included. All field wiring, plumbing, and installat

Call for Price

2009 Rotochopper E256 Grinder/Shredder | 200 HP electric rotor drive motor | 50 electric hydraulics motor |

RT 3rd Man Nailer with Stacker- 50x48. Fairly new, Lightly used machine, stored indoors. No guns. All air operated. Located in Minnesota. #C967

.gif)

.jpg?width=300&height=200&mode=pad)

.jpg?width=300&height=200&mode=pad)