woodworking Equipment For Sale

1959 Results Found

$ 47,000

CASADEI (PUTSCH-Branded) EBP-950 PMCR Automatic Edgebander, New, Never Used, with Pre-Mill & Corner RoundingSpecifications: -- Edgebanding thickness: 0.4 - 3 mm (0.02" - 0.12") Coil, 0.4 - 5 mm (0.02" - 0.20") Strip with Manual feed. -- Panel thickness 8 - 45 mm (0.31" - 1.77"), Min. panel width 95 mm (3.74"), & Min. panel length 110 mm (4.33"). -- Feed speed 9 MPM (29 FPM).Equipped with: -- Pre-Mill Unit, with (2) 0.75 kW (1 HP) - 12,000 RPM - 200 Hz Motors, Counter-rotation, (2) 60 mm Dia. x 52 mm H (2.36"; Dia. x 2.05"; H) Diamond cutterheads, Max. milling adjustment 2 mm (0.08"), & Dedicated extraction system with Blower. -- Anti-Adherence Spray Unit. -- Infrared lamp. -- PURE (PUR & EVA) Hot melt gluing system, with Teflon-coated glue pot with (6) 1,315 W Heating elements with (4) in Glue pot, (1) in Turret & (1) in Glue spreading roller, Thermostatic glue control, Automatic standby & Temperature display, and Automatic glue drainage. -- Pneumatically-operated guillotine. -- Pressure section, with (1) Large driven & (2) Small idler rollers. -- Feed chain, with Scratch resistant, non-slip rubber pads. -- Top pressure beam, with (2) Rows of rubber rollers. -- Safety enclosure. -- PLC Control, with ETOUCH 7" Backlit LCD touchscreen display, 99-Program Storage, & Diagnostics.Workstations: -- Front & Rear End Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, & (2) 80 mm (3.15";) Knives. -- Top & Bottom Flush/Bevel/Radius Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motors, 75 mm (2.95") Dia. Cutters with Disposable knives, 2 - 3 mm (0.08" - 0.012") Radii, & 15° Bevel. -- Corner Rounding Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, 50 mm (1.97";) Diamond cutterheads, 50 mm (1.97";) Vertical/Horizontal copiers for profiling straight, curved, & beveled edges, & PLC-selectable front, rear, or complete panel processing. -- Edge Scraping Unit, with 2 mm (0.08";) Cutters, -- Top & Bottom Glue Scraping Unit, with 120 mm (4.72";) Vertical disc copier. -- Top & Bottom Buffing Unit, with (2) 0.13 kW (0.17 HP) - 1,400 RPM Motors. -- Polishing Spray Unit, PLC-Controlled, with (2) Sprayers.NOTE: Sold "As Is" Without Warranty!

$ 41,500

CASADEI (PUTSCH-Branded) EBP-950 PMCR Automatic Edgebander, New, Never Used, with Pre-Mill & Corner RoundingSpecifications: -- Edgebanding thickness: 0.4 - 3 mm (0.02" - 0.12") Coil, 0.4 - 5 mm (0.02" - 0.20") Strip with Manual feed. -- Panel thickness 8 - 45 mm (0.31" - 1.77"), Min. panel width 95 mm (3.74"), & Min. panel length 110 mm (4.33"). -- Feed speed 9 MPM (29 FPM).Equipped with: -- Pre-Mill Unit, with (2) 0.75 kW (1 HP) - 12,000 RPM - 200 Hz Motors, Counter-rotation, (2) 60 mm Dia. x 52 mm H (2.36"; Dia. x 2.05"; H) Diamond cutterheads, Max. milling adjustment 2 mm (0.08"), & Dedicated extraction system with Blower. -- Anti-Adherence Spray Unit. -- Infrared lamp. -- FLEX Interchangeable gluing system, with Teflon-coated glue pot with (6) 1,315 W Heating elements with (4) in Glue pot, (1) in Turret & (1) in Glue spreading roller, Thermostatic glue control, Automatic standby & Temperature display, and Automatic glue drainage. -- Pneumatically-operated guillotine. -- Pressure section, with (1) Large driven & (2) Small idler rollers. -- Feed chain, with Scratch resistant, non-slip rubber pads. -- Top pressure beam, with (2) Rows of rubber rollers. -- Safety enclosure. -- PLC Control, with ETOUCH 7" Backlit LCD touchscreen display, 99-Program Storage, & Diagnostics.Workstations: -- Front & Rear End Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, & (2) 80 mm (3.15";) Knives. -- Top & Bottom Flush/Bevel/Radius Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motors, 75 mm (2.95") Dia. Cutters with Disposable knives, 2 - 3 mm (0.08" - 0.012") Radii, & 15° Bevel. -- Corner Rounding Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, 50 mm (1.97";) Diamond cutterheads, 50 mm (1.97";) Vertical/Horizontal copiers for profiling straight, curved, & beveled edges, & PLC-selectable front, rear, or complete panel processing. -- Edge Scraping Unit, with 2 mm (0.08";) Cutters, -- Top & Bottom Glue Scraping Unit, with 120 mm (4.72";) Vertical disc copier. -- Top & Bottom Buffing Unit, with (2) 0.13 kW (0.17 HP) - 1,400 RPM Motors. -- Polishing Spray Unit, PLC-Controlled, with (2) Sprayers.NOTE: Sold "As Is" Without Warranty!

$ 30,000

CASADEI (PUTSCH-Branded) EBP-950 PMCR Automatic Edgebander, New, Never Used, with Pre-Mill & Corner RoundingSpecifications: -- Edgebanding thickness: 0.4 - 3 mm (0.02" - 0.12") Coil, 0.4 - 5 mm (0.02" - 0.20") Strip with Manual feed. -- Panel thickness 8 - 45 mm (0.31" - 1.77"), Min. panel width 95 mm (3.74"), & Min. panel length 110 mm (4.33"). -- Feed speed 9 MPM (29 FPM).Equipped with: -- Pre-Mill Unit, with (2) 0.75 kW (1 HP) - 12,000 RPM - 200 Hz Motors, Counter-rotation, (2) 60 mm Dia. x 52 mm H (2.36"; Dia. x 2.05"; H) Diamond cutterheads, Max. milling adjustment 2 mm (0.08"), & Dedicated extraction system with Blower. -- Anti-Adherence Spray Unit. -- Infrared lamp. -- PURE (PUR & EVA) Hot melt gluing system, with Teflon-coated glue pot with (6) 1,315 W Heating elements with (4) in Glue pot, (1) in Turret & (1) in Glue spreading roller, Thermostatic glue control, Automatic standby & Temperature display, and Automatic glue drainage. -- Pneumatically-operated guillotine. -- Pressure section, with (1) Large driven & (2) Small idler rollers. -- Feed chain, with Scratch resistant, non-slip rubber pads. -- Top pressure beam, with (2) Rows of rubber rollers. -- Safety enclosure. -- PLC Control, with ETOUCH 7" Backlit LCD touchscreen display, 99-Program Storage, & Diagnostics.Workstations: -- Front & Rear End Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, & (2) 80 mm (3.15";) Knives. -- Top & Bottom Flush/Bevel/Radius Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motors, 75 mm (2.95") Dia. Cutters with Disposable R1/R2 3"; Knives, 2 - 3 mm (0.08" - 0.012") Radii, & 15° Bevel. -- Corner Rounding Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, 50 mm (1.97";) Diamond cutterheads, 50 mm (1.97";) Vertical/Horizontal copiers for profiling straight, curved, & beveled edges, & PLC-selectable front, rear, or complete panel processing. -- Edge Scraping Unit, with 2 mm (0.08";) Cutters, -- Top & Bottom Glue Scraping Unit, with 120 mm (4.72";) Vertical disc copier. -- Top & Bottom Buffing Unit, with (2) 0.13 kW (0.17 HP) - 1,400 RPM Motors. -- Polishing Spray Unit, PLC-Controlled, with (2) Sprayers. -- Antistatic & Cooling Spray UnitNOTE: Sold "As Is" Without Warranty!

$ 19,500

CASADEI (PUTSCH-Branded) EBP-950 PMCR Automatic Edgebander, New, Never Used, with Pre-Mill & Corner RoundingSpecifications: -- Edgebanding thickness: 0.4 - 3 mm (0.02" - 0.12") Coil, 0.4 - 5 mm (0.02" - 0.20") Strip with Manual feed. -- Panel thickness 8 - 45 mm (0.31" - 1.77"), Min. panel width 95 mm (3.74"), & Min. panel length 110 mm (4.33"). -- Feed speed 9 MPM (29 FPM).Equipped with: -- Pre-Mill Unit, with (2) 0.75 kW (1 HP) - 12,000 RPM - 200 Hz Motors, Counter-rotation, (2) 60 mm Dia. x 52 mm H (2.36"; Dia. x 2.05"; H) Diamond cutterheads, Max. milling adjustment 2 mm (0.08"), & Dedicated extraction system with Blower. -- Teflon-coated glue pot with (6) 1,315 W Heating elements with (4) in Glue pot, (1) in Turret & (1) in Glue spreading roller, Thermostatic glue control, and Automatic standby & Temperature display. -- Pneumatically-operated guillotine. -- Pressure section, with (1) Large driven & (2) Small idler rollers. -- Feed chain, with Scratch resistant, non-slip rubber pads. -- Top pressure beam, with (2) Rows of rubber rollers. -- Safety enclosure. -- PLC Control, with ETOUCH 7" Backlit LCD touchscreen display, 99-Program Storage, & Diagnostics.Workstations: -- Front & Rear End Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, & (2) 80 mm (3.15";) Knives. -- Top & Bottom Flush/Bevel/Radius Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motors, 75 mm (2.95") Dia. Cutters with Disposable R1/R2 Knives, Vertical nesting copiers, 2 - 3 mm (0.08" - 0.012") Radii, & 15° Bevel. -- Corner Rounding Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, 50 mm (1.97";) Diamond cutterheads, 50 mm (1.97";) Vertical/Horizontal copiers for profiling straight, curved, & beveled edges, & PLC-selectable front, rear, or complete panel processing. -- Edge Scraping Unit, with 2 mm (0.08";) Cutters.NOTE: Sold "As Is" Without Warranty!

$ 16,000

CASADEI (PUTSCH-Branded) EBP-950 PMVR Edgebander, New, Never Used, with Pre-Mill & Vertical RoundingSpecifications: -- Edgebanding thickness: 0.4 - 3 mm (0.02" - 0.12") Coil, 0.4 - 5 mm (0.02" - 0.20") Strip with Manual feed. -- Panel thickness 8 - 45 mm (0.31" - 1.77"), Min. panel width 95 mm (3.74"), & Min. panel length 110 mm (4.33"). -- Feed speed 9 MPM (29 FPM).Equipped with: -- Pre-Mill Unit, with (2) 0.75 kW (1 HP) - 12,000 RPM - 200 Hz Motors, Counter-rotation, (2) 60 mm Dia. x 52 mm H (2.36"; Dia. x 2.05"; H) Diamond cutterheads, Max. milling adjustment 2 mm (0.08"), & Dedicated extraction system with Blower. -- Anti-Adherence Spray Unit. -- Teflon-coated glue pot with (6) 1,315 W Heating elements with (4) in Glue pot, (1) in Turret & (1) in Glue spreading roller, Thermostatic glue control, and Automatic standby & Temperature display. -- Pneumatically-operated guillotine. -- Pressure section, with (1) Large driven & (2) Small idler rollers. -- Feed chain, with Scratch resistant, non-slip rubber pads. -- Top pressure beam, with (2) Rows of rubber rollers. -- Safety enclosure. -- PLC Control, with ETOUCH 7" Backlit LCD touchscreen display, 99-Program Storage, & Diagnostics.Workstations: -- Vertical Rounding End Trim Unit, with Diamond Cutterhead & PLC-selectable front, rear, or complete panel processing. -- Top & Bottom Flush/Bevel/Radius Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motors, 75 mm (2.95") Dia. Cutters with Disposable R1/R2 3"; Knives, 2 - 3 mm (0.08" - 0.012") Radii, & 15° Bevel. -- Edge Scraping Unit, with 2 mm (0.08";) Cutters, -- Top & Bottom Glue Scraping Unit, with 120 mm (4.72";) Vertical disc copier.NOTE: Sold "As Is" Without Warranty!

$ 95,000

PUTSCH-MENICONI KOPERNIC 4,200 x 2,200 mm CNC Vertical Machining Center, New with Parts Warranty, ATC, & C-AxisSpecifications: -- Working area X-Axis 4,200mm (165.35";), Y-Axis 2,220 mm (86.61";), & Z-Axis 100 mm (3.94";). -- Min. panel size 300 x 300 mm (11.81"; x 11.81";). -- Positioning speed: X-Axis 45 MPM (147 FPM), Y-Axis 30 MPM (98 FPM), & Z-Axis 15 MPM (49 FPM).Equipped with: -- Inclined Bakelite working table, with 20° Angle with respect to vertical, (12) Independently controlled vacuum zones with Solenoid valves with EtherCAT module & Digital vacuum pressure switch, and (10) Horizontal, (1) Left vertical & (1) Right vertical retractable pneumatic stops. -- Rack & pinion drive system on X & Y-Axes, with Automatic guide lubrication. -- Brushless motors, with EtherCAT Bus drives on All axes. -- Air pressure regulator, with digital pressure gauge. Machining: -- HSD 8 kW (10-3/4 HP) - 24,000 RPM ISO30 Air-cooled electro-spindle, with ER32 20 mm (0.79";) Chuck, High frequency inverter, & Variable spindle speeds to 24,000 RPM. -- CNC-Controlled C-Axis with 360° Rotation. -- Pneumatically actuated suction hood. -- 12-Position Automatic tool changer, with Automatic preset zero tool length probe.Control: -- OSAI “OPEN SMART CNC Control, with 21-1/2"; Display, EtherCAT Bus, USB & Ethernet ports, & MICROSOFT “WINDOWS 10"; Operating system. -- Remote pendant control.Complete with: -- Electrical Cabinet Cooling System. -- BECKER 6.6 kW (8.85 HP) 250 m³/h Vacuum Pump, with inverter for vacuum pressure adjustment from control. -- (6) ISO 30 Tool holders & (6) ER32 Clamps. -- 90° Grooving Cutter & HSD Shank for C-Axis Aggregate. -- 80 mm (3.15";) Cutter for shaving spoil board.Options available at additional cost: -- 150 mm (5.91";) Dia. Circular Tools for C-Axis Aggregate. -- 135° V-Grooving Cutter. -- Z48 Saw Blade.

$ 41,500

CASADEI (PUTSCH-Branded) EBP-950 PMCR Automatic Edgebander, New, Never Used, with Pre-Mill & Corner RoundingSpecifications: -- Edgebanding thickness: 0.4 - 3 mm (0.02" - 0.12") Coil, 0.4 - 5 mm (0.02" - 0.20") Strip with Manual feed. -- Panel thickness 8 - 45 mm (0.31" - 1.77"), Min. panel width 95 mm (3.74"), & Min. panel length 110 mm (4.33"). -- Feed speed 9 MPM (29 FPM).Equipped with: -- Pre-Mill Unit, with (2) 0.75 kW (1 HP) - 12,000 RPM - 200 Hz Motors, Counter-rotation, (2) 60 mm Dia. x 52 mm H (2.36"; Dia. x 2.05"; H) Diamond cutter-heads, Max. milling adjustment 2 mm (0.08"), & Dedicated extraction system with Blower. -- Anti-Adherence Spray Unit. -- Infrared lamp. -- FLEX Interchangeable gluing system, with Teflon-coated glue pot with (6) 1,315 W Heating elements with (4) in Glue pot, (1) in Turret & (1) in Glue spreading roller, Thermostatic glue control, Automatic standby & Temperature display, and Automatic glue drainage. -- Pneumatically-operated guillotine. -- Pressure section, with (1) Large driven & (2) Small idler rollers. -- Feed chain, with Scratch resistant, non-slip rubber pads. -- Top pressure beam, with (2) Rows of rubber rollers. -- Safety enclosure. -- PLC Control, with ETOUCH 7" Backlit LCD touchscreen display, 99-Program Storage, & Diagnostics.Workstations: -- Front & Rear End Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, & (2) 80 mm (3.15";) Knives. -- Top & Bottom Flush/Bevel/Radius Trim Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motors, 75 mm (2.95") Dia. Cutters with Disposable knives, 2 - 3 mm (0.08" - 0.012") Radii, & 15° Bevel. -- Corner Rounding Unit, with 0.22 kW (1/3 HP) - 12,000 RPM - 200 Hz Motor, 50 mm (1.97";) Diamond cutter-heads, 50 mm (1.97";) Vertical/Horizontal copiers for profiling straight, curved, & beveled edges, & PLC-selectable front, rear, or complete panel processing. -- Edge Scraping Unit, with 2 mm (0.08";) Cutters, -- Top & Bottom Glue Scraping Unit, with 120 mm (4.72";) Vertical disc copier. -- Top & Bottom Buffing Unit, with (2) 0.13 kW (0.17 HP) - 1,400 RPM Motors. -- Polishing Spray Unit, PLC-Controlled, with (2) Sprayers.NOTE: Sold "As Is" Without Warranty!

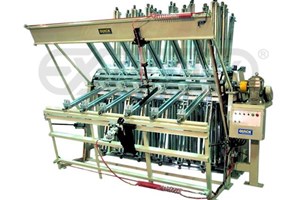

QUICK 20 Section 16.5' Heavy Duty Clamp Carrier Specifications: -- 20-Section Thick Stock Pneumatic Clamp Carrier; 16-1/2' width cap.; -- (12) Clamps, each with 3 1/2" high jaws and 44" clamp opening for a total of (240) clamps. -- All clamps are heavy duty type; zinc plated and with 1° inward draftEquipped with: -- Dual operator package with (2) pneumatic overhead panel flatteners, -- (2) Pneumatic clamp tighteners. -- Semi-automatic rotation via electric motor drive and separate buttons for Front Rest Out, Rotate Reverse, Rotate Forward and Front Rest In.Standard features: -- Heavy-duty thick stock frame with 3" dia. shafts and 6" I-beam legs; -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high-quality urethane finish coating, and toolbox with maintenance tools.

QUCK R-RCGS-2-17 Top & Bottom Glue SpreaderQUICK 17" wide Top and Bottom Glue Spreader with 0.04" - 1.75" thickness capacity.Features: -- (2) Grooved SBR Rubber (60 Durometer) covered 8" glue rollers, (2) 5.8" chrome covered doctor rolls. -- Converts quickly to Top only glue application when needed. -- Comes standard with a fixed 64 FPM feed rate (Optional 40-118 FPM Variable Speed Drive). -- Durable chain drive gives years of trouble-free operation. -- Simple-to-access hand wheels allow the operator to make quick adjustments when panel thicknesses change.Complete with: -- Roll guard hoods -- Emergency stop bars at front and back of machine for Operator Safety. -- Stainless Steel drip pan catches clean-up water.

QUICK R-RCGS-2-54 TOP & BOTTOM GLUE SPREADER54" Wide Top and Bottom Glues spreader with 0.04" - 1.75" thickness Capacity. -- Features: (2) Grooved rubber covered 8.3" glue rollers are acid and heat resistant, (2) 6.9" hardened rubber doctor rolls. -- Converts quickly to Top only glue application when needed. -- Comes standard with a fixed 80 FPM feed rate (Optional: Variable Speed Drive). -- Durable chain drive gives years of trouble-free operation. -- Simple to access hand wheels allow the operator to make quick adjustments when panel thicknesses change. -- Complete with: Safety stop bars roll guard hood, all aluminum drip pan catches clean-up water. -- Available Widths: -- 17" Wide -- 24" Wide -- 36" Wide. -- 48" Wide. -- 63" Wide.

QUICK 20" Wide Conveyorized Glue Applicator -- 20" wide grooved rubber glue applicator roll with stainless steel doctor blade and glue reservoir. -- Features easy adjustment or removal of doctor blade, 16' overall length, 8' infeed before the glue roller and 8' outfeed conveyor. -- Equipped with: Heavy Duty 0.25 HP motor drive for slat-type conveyor and glue roll, limit switch with wand for automatically stopping the slat bed conveyor when stock reaches the Clamp Carrier, adjustable safety slip clutch. -- Complete with: Foot levelers, Heavy Duty crossbars, chain guard, high quality anti-stick urethane finish, and owner & operator's manuals.

Grooved rubber covered glue rollers are SBR / acid and heat resistant. -- Easy to clean, 6-7/8" hardened rubber doctor roller. -- Comes standard with a fixed 80 FPM feed rate. -- Durable chain drive gives years of trouble-free operation. -- Simple to access handwheels allow the operator to make quick adjustments when panel thicknesses changes up to a 1-3/4" opening. -- Complete with: Safety stop bars and roll guard hood, all aluminum drip pan catches clean-up water. -- Also Avalable with: -- 17" Wide -- 24" Wide -- 36" Wide. -- 48" Wide. -- Variable speed drive of 40 to 118 FPM. -- 6" or more Opening.

Call for Price

36" wide Top and Bottom Glues spreader with .04" - 1.75" thickness Capacity. -- Features: (2) Grooved rubber covered 8.3" glue rollers are acid and heat resistant, (2) 6.9" hardened rubber doctor rolls. -- Converts quickly to Top only glue application when needed. -- Comes standard with a fixed 80 FPM feed rate (Optional 40-118 FPM Variable Speed Drive). -- Durable chain drive gives years of trouble-free operation. -- Simple to access hand wheels allow the operator to make quick adjustments when panel thicknesses change. -- Complete with: Safety stop bars roll guard hood, all aluminum drip pan catches clean-up water. -- Available Widths: -- 17" Wide -- 24" Wide -- 48" Wide. -- 54" Wide. -- 63" Wide.

Call for Price

QUICK MODEL R-RCGS-1-36-6 TOP GLUE SPREADER with 6" MAXIMUM OPENING -- Features: -- Grooved rubber covered glue rollers are acid and heat resistant. . -- Easy to clean, 5-7/8" chrome plated doctor roller. -- Comes standard with a fixed 64 FPM feed rate. -- Variable speed drive of 40 to 118 FPM is optional - ADD $900 -- Durable chain drive gives years of trouble-free operation. -- Simple to access handwheels allow the operator to make quick adjustments when panel thicknesses change. -- Complete with: Safety stop bars and roll guard hood, all aluminum drip pan catches clean-up water. -- Specifications: -- 1-Sided Roller Coater (applies glue to top side of board or panel. -- Working thickness: Adjustable from 0 to 152 mm (0 to 6"); adjustable via hand wheel. -- Maximum material width: 630 mm (24"). -- Application rolls quantity: 1. -- Application rolls material: SBR rubber, 60 durometer (Shore A). -- Application rolls diameter: 205 mm (8"). -- Application rolls grooving: (20) Grooves per inch. -- Doctor rolls quantity: 1. -- Doctor rolls material: Chrome-plated steel. -- Doctor rolls diameter: 148 mm (5.8"). -- Doctor rolls grooving: None (smooth rolls). -- Drive motor power: 1.5 kW (2 HP). -- Feed rate: Fixed at 64 FPM (optional: adjustable speed from 40 to 118 FPM; ADD $900.00) -- Includes emergency stop bars at front and back of machine. -- Includes stainless steel waste glue drip pan.

20" wide Conveyorized Glue Applicator, model F-CGAP-20-10-12, 20" wide grooved rubber covered roller with stainless steel doctor blade. Large knobs for easy adjustment or removal of doctor blade. Limit switch with wand for automatically stopping the slat blade conveyor when stock reaches the RF Press or Clamp Carrier. -- Heavy Duty, 3-phase 0.5 HP motor drives the conveyor and glue roll; motor is equipped with an adjustable slip clutch to prevent damage in case of a material jam. -- All components are Heavy Duty for years of trouble free operation. The stainless steel glue pan and doctor blade are easily removed without tools for quick clean-up. -- Optional 20" wide hold-down roll for face gluing part # F-HDRL-20. Price $800 - please specify this option at time of order.

²QUICK 14-Section Pneumatic Clamp Carrier with 12-1/2' width capacity With (8) Standard zinc plated clamps per section (112) clamps total), 38" opening on clamps Standard Features include: Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment Panel Flattener with easy to use controls.Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time! Complete with:Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools. 14-Section Clamp will produce 300 panels

Call for Price

Call for Price

Quick Clamp Carrier Model: SA-CCFP-10.5-14 10.5' Wide 14 Section Clamp: 2.5" high jaw, 38" opening Pneumatic clamp tightener Pneumatic Panel Flattener Electric Drive

1' x 10' pressing capacity via (10) 1' x 1' platens. Pod Press produces 78,000 lbs. total platen force (7,800 lbs. per platen) at 120 PSI supply air pressure; suitable for lighter-duty (high-pressure laminates to composite substrates) and heavier-duty (wood veneering) applications. 40" fixed daylight; vertical structural frame members and hinged containment fences arrangement for end-loading and side loading the press. -- Horizontally-adjustable vertical containment fences keep laminated material from sliding while under pressure. (10) 10"" maximum diameter air pods with 5" stroke; each air pod with separate hand-operated air valve; each air pod / platen activates individually. Main air valve controls all "activated" air pods at once; various pods are controlled together, or each pod can be controlled separately. -- NOTE: Special Press configuration for use in stile and rail entry and passage door operations.

Call for Price

QUICK '6-SECTION HEAVY DUTY-P CLAMP CARRIER (Pneumatic). -- Overall Data: Heavy Duty 16.5' wide (16.5' maximum stock length capacity), 6-section Thick Stock Pneumatic Clamp Carrier with (72) 3.5" high, 40" opening clamps; (12) clamps per section. -- Includes: Pneumatic Clamp Tightener, Pneumatic Panel Flattener, Electric Motor Drive with Automatic Rotation Cycle. -- Major Parts & Components list as follows:Qty Part# Description Each Total (1) A-CCFP-16.5-06 CC Frame Pneumatic, 16.5' wide, 6 Sect. $9,900.00 $9,900.00(72) B-CLMP-3.5-40 Clamp, 3.5" high jaw, 40" opening 82.00 5,904.00(1) C-PCT1-16.5-06 Pneumatic Clamp Tightener, 16.5' wide, for 6-sect. CC 4,450.00 4,450.00(1) D-PPF1-16.5 Pneumatic Panel Flattener, 16.5' wide 2,200.00 2,200.00 (1) E-EMDR-06-16.5 Electric Motor Drive for 6 Sect. CC, 16.5' wide, #135 2,450.00 2,450.00 TOTAL ..................................................................................................................................... $ 24,904.00.OPTIONAL(24) B-CLMP-3.5-40 Clamp, 3.5" high jaw, 40" opening 82.00 $1,968.00 -- Note: Lead time is about (8 - 10) weeks.

.gif)