LUMBERMENOnline.com’s Latest Industry News & Articles

Submit your company’s latest news or articleCooper Machine is excited to announce that we are now offering MIT's line of Pallet Equipment including a Carousel Block Cutter, Chamfering Machine and Pallet Trimmer. More information on this equipment can be found on our website at http://www.coopermachine.com/Sawmill-Equipment/59/PalletMachinery.

Cooper Machine also has great options for sawmills looking to produce pallet stock including an Overhead Scragg with Vertical Edgers, Yield Champ (Sharp Chain Scragg with Cant Edger), Cutup Systems, Unscramblers, Edgers, Automated Cant Trimmers, Slab Recovery Systems/Resaws, Handling Equipment, Sorting Systems and Kilns.

We are also honored to now be a member of the National Wooden Pallet and Container Association. We're looking forward to seeing everyone in Tucson next Spring.

Baker Products have innovated a new log to lumber system from their pre-existing equipment, in a new layout to lower labor, increase production, and provide maximum yield. The system uses 2 employees, and begins with one operating the Baker BP Dominator Sawmill. This Sawmill is equipped with hydraulic kickers in the outfeed roll case to either, kick timbers into the automated Baker Timber Stacker, or to kick waney edge boards to the Band Edger’s feeding deck. From the Band Edger’s feeding deck, an employee grabs a waney edge board and feeds it into the Baker Band Edger, to eliminate its waney/barky edges. On the outfeed side of the Edger, a hydraulic table top lifts the edged board and two edging strips, sliding them onto a belted conveyor. This conveyor delivers the material back to the employee who feeds the edger. He then stacks and bundles the boards and edging strips. The core of the logs, AKA timbers, that are transferred into the automated Baker Timber Stacker are stacked into a bundle, banded, and forklifted to their designated area. In the end, you have bundled timbers, bundled boards, bundled edging strips, and bundled slabs, giving you your most maximum yield out of your log and lowest labor cost.

Baker Products is proud to introduce their newest partner machine, the Wood Wizz. This machine is designed to surface and finish slabs, burls, tabletops, and even recycled timber. The machine is ideal for woodworkers who want to add value to their material and produce a perfect finish without any tear, ridging, or burn marks.

The Wood Wizz is powered by a variable speed 3-HP, motor and runs on a Z axis. It includes a large 5” (125 mm) cutter, 10 square cutter inserts, speed controller, two inverters, sanding disk with pads & sand paper, dust tower, dust hosing and fittings. The machine is equipped with a variable speed and power feed control box, with controls on the gantry, and also includes edging/joining cutter to combine two or more pieces of material, flawlessly.

Rustic wood table tops and wide slabs can produce high margins and the Wood Wizz, from Baker Products allows you to economically put a planer smooth finish on all types of slab, timber or beams.

Introducing the new Wood-Mizer FS500 Log Splitter! Featuring 29 tons of brute wood splitting force, the FS500 splits wood in both directions and produces up to two cords of firewood an hour with a 4.5 second cycle time. Fully-loaded with a heavy-duty trailer package, 2-stage hydraulic pump, oil cooler, log lift, and optional remote start, this mid-size splitter is equipped with a 3-way wedge and perfect for bundle wood and firewood businesses looking to maximize efficiency and productivity. Wood-Mizer Log Splitters are engineered for performance and built in the USA by the world leader in portable sawmills for nearly 35 years. Call 800.553.0182 or visit www.woodmizer.com/logsplitters for more information.

PRS held an Open House event April 29th- 30th at their Jacksonville, IL facility. This event hosted companies from different states and countries to see demonstrations of PRS machinery and the CAPE Mach 2 Nailing Line. PRS displayed some of their equipment including the Optimax 2016, Prosaw Band Dismantler, Stringer-Mate Stringer Splicer, and more. The CAPE Mach 2 was also operating along with a CAPE technician on-hand to discuss the complete product line. This event drew interest for customers with a variety of machinery needs. Be on the look-out for another potential open house this fall!

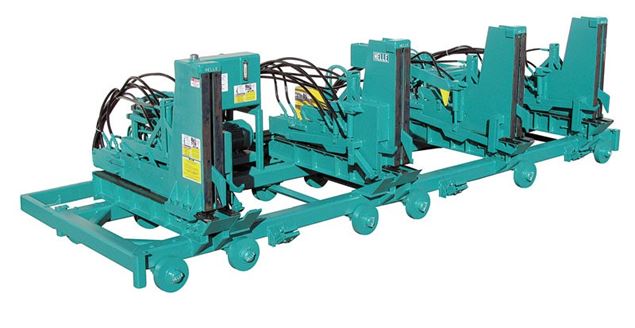

Sawmill operators are the number one engine for design improvements. Anticipating and addressing those needs has been the driving force of the Helle family and the entire staff at Sawmill Hydraulics since the creation of the hydraulic chain log turner. The new Compact Linear Positioning line of carriages from Sawmill Hydraulics is a prime example of addressing a critical need. LP technology has been unavailable to many mills due to the carriage width requirements and pricing that has put this important technology out of the grasp of many mills. To make LP technology available to every mill, Sawmill Hydraulics redesigned the way hydraulic cylinders are incorporated so the new Compact LP carriage is easily retrofit to nearly all currently running mills. This space savings also leads to tremendous savings on new mill projects as well.

In addition to the revolutionary space saving design, every Compact LP carriage is tailored to your space, your needs and your product and comes standard with proven Helle Linear Tech Touch Screen Setworks as well as optional scanning, thus eliminating the need for third party setworks. See the Compact LP carriage at outside exhibit space C7 at the 2016 Richmond EXPO and schedule your no obligation on-site assessment.

WASHINGTON – American Wood Council (AWC) Vice President, Government Affairs Sarah Dodge has issued the following statement regarding today’s passage of the “Clean Distributed Energy Grid Integration Act” (S. 2012) in the U.S. Senate. The bill included an amendment led by Sen. Susan Collins (ME) which would require the Secretaries of Energy and Agriculture and the Administrator of the Environmental Protection Agency to jointly ensure that federal policy relating to forest bioenergy: (1) is consistent across all departments and agencies; and (2) recognizes the full benefits of the use of forest biomass for energy, conservation and responsible forest management.

“AWC greatly appreciates the inclusion of Senator Collins’ biomass amendment in the Senate bill. Our member facilities use every part of the raw materials in the manufacture of wood products and to generate the energy needed to do so. In fact, almost 80 percent of the energy from AWC member facilities is generated from carbon-neutral biomass. This bill is a step in the right direction in getting our country’s public policies aligned to recognize our industry’s unique biomass use as carbon neutral and as part of the sustainable carbon cycle.

“However, we were disappointed language was left out which would facilitate product neutrality in the building energy code development process. AWC ardently believes that the Department of Energy should return to its congressionally-authorized role as a ‘technical advisor’ and not be using its position to advocate for particular products or technologies in building energy codes. These codes should be changed to remove prescriptive requirements mandating the use of particular products. They should instead be performance oriented and establish the requirements that any product, including wood, can demonstrate it meets. Wood is inherently capable of providing good thermal performance, helping to meet even the strictest energy requirements, while at the same time sequestering carbon from the air.

“We look forward to working with the conference committee and urge Congress to quickly move to reconcile House- and Senate-passed bills. AWC strongly supports the building energy code provisions in the House-passed bill and requests that any final energy legislation approved by Congress retain them to ensure all building materials have equal opportunity to contribute toward achieving building energy efficiency standards. Final legislation must also retain the Senate provisions recognizing the carbon benefits of biomass energy and requiring consistent policies across all departments and agencies, as well as the recognition of multiple green building certification systems.”

Terramac, a leading manufacturer of innovative rubber track crawler carriers, is pleased to announce the launch of its newest model, the RT14R. Equipped with unique rotational functionality, the RT14R allows operators to offload materials in a more efficient, precise and safe manner than ever before.

Manufactured in the USA, the RT14R is made entirely of premium components. Built with a rugged upper frame that rotates a full 360 degrees, the Terramac RT14R can carry and dump up to 28,000-lb. of material at any position, even while driving. This feature allows the RT14R to offload materials faster than a standard straight frame unit since the tracks don’t need to be counter rotated to drive another direction. Environmental damage and land restoration costs are also minimized as the RT14R dumps material without tearing up the surrounding ground.

The 40,000-lb. machine is powered by a QSL9.0 320-hp Tier 4 Final Cummins diesel engine (non DPF), boosting jobsite productivity while remaining highly fuel efficient, regardless of the application. In addition, the new unit showcases Terramac’s rubber track technology; a minimal 7.9-psi ground pressure while fully-loaded allows it to conquer soft or wet ground conditions and mountainous terrain where wheeled machines are likely to create ruts and get stuck. Low ground pressure and rotating functionality make the RT14R ideal for work in confined spaces and environmentally sensitive areas, such as: railroad track right of way access, rivers and levees, as well as general earthmoving, site prep and utility jobsites.

“The RT14R is a natural evolution of Terramac’s product line and we are excited to bring it to the market,” says Andrew Konopka, President of Terramac. “This new model provides contractors with a solution to tackle a range of applications while improving efficiency and cost savings.”

When it comes to safety and comfort, the Terramac RT14R is second to none. The innovative RT14R enhances jobsite safety by eliminating the amount of time an operator spends reversing a unit. This model offers rollover protective structure (ROPS) and falling object protective structure (FOPS). Terramac’s new RT14R is also ergonomically designed with upgraded features, including: a wide access door for easy entry and exit, windows on all sides and a large mirror for increased visibility. A multi-function joystick with dump controls provides user-friendly operation and a touch screen Parker IQAN-MD4 control system allows for full graphical, diagnostic and controller area network (CAN J-1939) gateway capability.

Furthermore, maintenance on the new RT14R is easy and cost effective. Track wear is significantly less as the upper structure can spin, resulting in reduced downtime and expenses for repairs. Additionally, a tilt hood on top of the engine enclosure provides access to the engine bay and a rear cab enclosure for fluid/filter checks makes routine maintenance quick and simple.

Terramac is committed to providing the best full service and parts availability in the industry. Terramac customers enjoy access to greater parts availability as well as timely and accurate delivery through Terramac’s full-line dealer network, dedicated support team, and convenient online ordering system.

Terramac® LLC, based in Elburn, IL, was established to produce the world’s leading crawler carrier models. Units are sold through a dealer network which offers customers easy-to-locate parts and service throughout the world. To learn more, please visit www.terramac.com or call 630-365-4800.

Mobile Manufacturing announces the release of two new sawmills, the Model 1206 and Model 1210. Both sawmills are larger and more powerful than previous models, increasing lumber size capacity and overall production. Both machines are powered by two 25 HP electric motors, and can cycle through a 16 foot long cut in as little as 8 seconds. The Model 1206 can cut lumber up to 6 ¼” x 12 ¼” and cuts two finished pieces per pass. The Model 1210 can cut 10 ¼” x 12 ¼”. Mobile sawmills are not limited by log diameter, and can be ordered to cut lengths up to 26 feet long.

“These machines were designed to address the needs of operations that need higher production, but don’t need portability”, said Ron Harriman, President of Mobile Manufacturing. “They are versatile, and can be used for dimensional lumber, for grade sawing, or for breaking down low-grade logs into 4” x 6” pallet cants.”

Both the vertical and horizontal blade arbors are powered by separate 25 HP 3 phase electric motors, and the horizontal arbor also powers a hydrostatic drive that moves the carriage through the log. Finished lumber is automatically removed from the cut, and the mills can be integrated into material handling systems.

Mobile sawmills utilize cost-efficient Stellite® tipped inserted teeth that provide long life as well as quick and easy maintenance on the saw or in a grinder room.

Located in Troutdale, Oregon Mobile Manufacturing has been producing sawmill equipment in their 45,000 square foot manufacturing facility since 1962. For more information, email [email protected], or call 877-272-9645.

Morbark, LLC, announced today its Board of Directors has appointed Dan Ruskin as Chief Executive Officer effective immediately. The announcement coincides with the recent sale of Morbark to Stellex Capital Management, a private equity manager that invests in both U.S. and international corporations.

“Dan is an excellent fit for Morbark,” said Ray Whiteman, Chairman of the Board and Managing Partner of Stellex Capital Management. “We have known Dan for close to 20 years, and his experience across multiple industries, in particular industrial markets such as heavy equipment, automotive, truck, and transport vehicles, have prepared him well for this position. One of Dan’s core strengths is his ability to build strong teams that can help organizations quickly meet their goals and enhance their profitability.”

Mr. Ruskin has an extensive management background in lean manufacturing, corporate turnarounds and restructurings. He has broad experience in helping companies by growing revenue, improving systems and operations, and institutionalizing practices to increase productivity.

“I’m excited, honored and humbled to have the opportunity to lead Morbark as we enter a new era of innovation and productivity,” said Dan Ruskin. “We will continue to fulfill our promise to our customers by capitalizing upon our strengths - innovative, robust and reliable products, a world-class dealer network, and the relentless practice of continuous improvement.”

Ruskin began his career as an industrial engineer in the aerospace and defense industry working on state-of-the-art defense projects, and his contributions helped make those projects more efficient and less costly. A former entity principal and practice leader for Plante & Moran AFME (PMAFME) Management Consulting and Restructuring practice, Ruskin worked to expand its industrial and manufacturing operations capabilities. He founded and managed Anchor Resource Management and Anchor Holdings – professional service firms that provide world-class company revitalization solutions and interim management services.

Ruskin will be relocating from Nashville, Tenn., to Winn, Mich., with his wife. He has three children and three grandchildren.

Shiocton, WI – Every pallet pre-cut operation requires accurate end trimming of a wide range of lengths and thicknesses. So Go Fast, the pallet industry’s most innovative machinery manufacturer, created a fast acting, adjustable head system that can process standard thicknesses up to 3 ½” and lengths up to 72” with longer lengths available upon request.

This exciting new machine was designed to provide durability and long-life at a price point that allows small operations and large custom crate manufacturers to replace their slow manual chop saws with a highly productive double end trimmer. Accuracy is enhanced by utilizing laser guide lights that move with the saws, lowering setup times. The DET-72’s standard 20” carbide saw blades and 5 HP electric motors (7.5 to 10 HP are available options) provide the power and flexibility needed to cut it all, from pallet deck boards and stringers to cants right off the scragg. The DET-72’s simple hand crank length adjustment system makes changing lengths fast, easy and accurate.

Like every machine from Go Fast, the DET-72 went through months of exhaustive testing under real-world pallet production, insuring that every Go Fast product improvement fits the company’s mission statement of improving production and profit, while continuing to keep designs simple and equipment costs low.

Wood-Mizer LLC, the world’s leading sawmill manufacturer, announces the addition of wood splitters to their diverse line of wood processing equipment. Acquiring the product line formally manufactured and marketed by Tempest Wood Splitters, Inc., Wood-Mizer now offers a variety of wood splitters ranging from compact units for personal use to commercial equipment for bundle and firewood businesses.

Tempest appealed to Wood-Mizer because of the advanced design and high performance of their wood splitting equipment line. The Minnesota-based Tempest Wood Splitters, Inc. was established in 2001 by Josh Larabee and his father as a solution to the backbreaking work they experienced splitting wood by hand. “Helping people eliminate the physical work that manual log splitting demands has been a dream come true for my dad and I throughout the years,” said Josh. “I look forward to seeing our wood splitting products continue to grow and assist individuals and businesses through the high quality distribution network and reputation for outstanding customer service that Wood-Mizer has delivered to its customers for more than 30 years.”

Wood-Mizer plans to offer a wide variety of wood splitting equipment beginning with top quality fully portable units and then expanding to also offer the skid-steer and auxiliary hydraulic unit attachments. The equipment will be priced from $7,000 to $25,000. “Wood-Mizer is continuously dedicated to providing our customers with a variety of high-quality wood processing equipment,” said Wood-Mizer COO Darryl Floyd. “Our new line of wood splitting equipment offers our customers yet another resourceful tool to efficiently and profitably process wood into another useful and marketable end product.”

The Wood-Mizer wood splitting equipment is now available to order. Visit www.woodmizer.com/woodsplitters for more information.

About Wood-Mizer

Trusted by tens of thousands of band sawmill owners in more than 120 countries, today Wood-Mizer is more than just the world’s leading portable sawmill manufacturer. With nearly 35 years of industry experience and knowledge, Wood-Mizer not only offers the extensive line of portable sawmills, but also industrial sawmills, resaws, edgers, kilns, wood splitters, bandsaw blades and blade maintenance equipment for woodworking hobbyists and forestry professionals. For more information about Wood-Mizer, call 800.553.0182 or visit www.woodmizer.com.

.gif)