LUMBERMENOnline.com’s Latest Industry News & Articles

Submit your company’s latest news or articleLEESBURG, VA. – The American Wood Council (AWC) has been awarded a $250,000 grant from the U.S. Department of Agriculture (USDA) to conduct research on the fire performance of mass timber buildings. AWC will partner with the National Fire Protection Association’s (NFPA) Fire Protection Research Foundation and the Property Insurance Research Group.

The AWC proposal is intended to advance the construction of taller wood buildings in the United States by demonstrating the fire performance of newer mass timber products. Over the last several years, tall wood buildings have been completed around the world using this new technology – including a 9-story building in London, 10-story in Prince George, Canada, and 14-story building now under construction in Bergen, Norway. These buildings have consistently demonstrated the successful application of mass timber technologies.

“Findings from this project will inform the building community and the insurance industry, providing an increased level of confidence in both the adequacy of this new construction type and when setting fire insurance premiums. This is a new method of construction to insurers, and in order to provide reasonable insurance coverage, they need to understand the performance of the material,” said AWC Vice President of Codes & Regulations Kenneth Bland.

Increased use of wood in building construction also holds great promise for improved environmental impacts.

“Innovative mass timber wood products encourage sustainable forestry and capture large amounts of carbon, thereby reducing greenhouse emissions through both sequestration and the substitution of wood for more carbon-intensive products. The construction of tall wood buildings would put America at the forefront of an emerging global opportunity,” said AWC President & CEO Robert Glowinski.

When announcing the USDA 2015 Wood Innovations grant recipients, Agriculture Secretary Tom Vilsack said, “Working with our partners, the Forest Service is promoting deployment of new technologies, designed to support new market opportunities for wood energy and innovative wood building materials."

The Property Insurance Research Group, a consortium of property insurance companies, is providing $175,000 toward the project, which will be managed by the NFPA Fire Protection Research Foundation and is expected to last two years.

This short course will provide practical knowledge about how lumber is effectively kiln dried and describe the scientific background on related wood properties and processes. It will have value for the beginner as well as experienced kiln operators and with supervisors, sales, and marketing personnel. Instruction, by university faculty and industry experts, will be both in the classroom and through hands-on lab exercises using our 1000 BF steam heated dry kiln to dry a load of hardwood lumber. For additional information and questions regarding this workshop contact Phil Mitchell, (919) 515-5581, [email protected]

2015 Dry Kiln Operator's Short Course

NC State University

Raleigh, NC

May 19 - 22, 2015

Cost: $295 per person

Wallingford’s Inc. ®, the exclusive distributor for Clark Tracks Ltd. in the United States, is pleased to announce an $800 rebate promotion on purchases made in 2015 of the already proven Terra TL plate system for tandem axle forestry equipment. Wallingford’s Inc. is very excited to offer this incredible incentive to the retail customer. For the first time in the United States, Wallingford’s Inc. will send the end user a check for $800 to see the difference that Clark tracks will provide.

The Terra range from Clark Tracks is the Ultimate Multi-Terrain and all season track system for forwarders, harvesters and tandem wheel skidders. The unique plate design offers a proven and effective Double Grouzer bar that provides the essential needs of every machine operator. Superior maneuverability, excellent floatation, increased machine stability, reduced fuel consumption, unsurpassed traction control, and highly reduced ground disturbance are just a few of the many benefits that Clark Tracks provide.

Wallingford’s Inc. is offering this unprecedented rebate on the following three options, the TL-85, TL-95 and the FX-95. The TL-85 is designed for typical forestry equipment, up to 14t payload or medium sized harvesters and is manufactured to provide the best performance as a Multi-Terrain track with either 24mm or 28mm link system and unique plate design. The TL-95 is a heavy duty track most often used for large machinery, for example, large harvesters or forwarders with 14t (metric) payload or greater. The TL-95 offers the same unique design in a larger 28mm link system as standard and thicker plate. The FX-95 continues the exceptional performance of the Terra products by combining the 28mm linking system with two larger rocky anti-skid spikes per plate between the Double Grouzer bars. This track is particularly suited to the heaviest forwarders (19t payload and greater) which can also be specified for Tigercat skidders and forwarders using extra-long tandem axles. The FX-95 yields the ultimate in traction and long life for the largest of machinery.

Clark Tracks are proudly built in Dumfries, Scotland on a solid reputation with over 25 years of experience that each consumer can confidently place their trust. Clark Tracks Ltd. and Wallingford’s Inc. would like to invite you to experience the performance and quality of Clark Tracks. For more information, please visit www.clarktracksusa.com

A broad range of topics and industry leaders will be on hand to discuss everything from marketing, green vs dry kilned firewood, business management and equipment selections.

If you're a firewood professional, or are considering adding firewood production to your forest industry related operation, this workshop held in Voorheesville, NY on Thursday, May 7th at the William F Rice, Jr Extension Center is a must attend event.

To request further information contact Harry Watt at 704-880-5034.

Rogue River, OR (April 2015) – At Wagner Meters, we continue to go above and beyond for our customers. We are happy to announce another upgrade to the L600 Series digital recording hand-held moisture meters that increases the battery life by more than five times.

With the previous power circuit, the average battery life of the L600 Series digital meters was eight hours of ON time. With the upgrade, mills can now use any L600 Series digital meter for up to 50 hours of ON time.

If you have an older version of an L600 Series digital moisture meter, it can be upgraded to the new power module, providing you significantly improved battery performance.

To learn more about Wagner Meters’ L600 Series digital recording hand-held moisture meters, visit Wagner Meters’ Forest Products division page.

WASHINGTON – American Forest & Paper Association (AF&PA) President and CEO Donna Harman and American Wood Council (AWC) President and CEO Robert Glowinski issued the following statements on the U.S. Environment Protection Agency’s (EPA) Science Advisory Board (SAB) Biogenic Carbon Panel hearing, during which members heard testimony on the agency’s revised draft Framework for Assessing Biogenic Carbon Dioxide (CO2) Emissions from Stationary Sources.

A link to the associations’ full joint testimony is available here: http://bit.ly/1IuM4D6

Donna Harman, President and CEO, AF&PA:

“EPA has noted that energy from many biomass manufacturing residuals is carbon neutral. As most of the renewable energy paper manufacturers use comes from these residuals, it’s important to us that the agency fully recognize their benefits, which include fossil fuel displacement and avoidance of additional greenhouse gases that would occur from alternative disposal.”

Robert Glowinski, President and CEO, AWC:

“In order for the framework to work as intended, it must be based on robust data and sound science that can be consistently applied across greenhouse gas policies and regulations. It’s also crucial the framework be easy to implement, workable in practice, predictable and transparent.”

###

About AF&PA

The American Forest & Paper Association (AF&PA) serves to advance a sustainable U.S. pulp, paper, packaging, and wood products manufacturing industry through fact-based public policy and marketplace advocacy. AF&PA member companies make products essential for everyday life from renewable and recyclable resources and are committed to continuous improvement through the industry’s sustainability initiative - Better Practices, Better Planet 2020. The forest products industry accounts for approximately 4 percent of the total U.S. manufacturing GDP, manufactures over $200 billion in products annually, and employs approximately 900,000 men and women. The industry meets a payroll of approximately $50 billion annually and is among the top 10 manufacturing sector employers in 47 states. Visit AF&PA online at www.afandpa.org or follow us on Twitter @ForestandPaper.

About AWC

The American Wood Council (AWC) is the voice of North American wood products manufacturing, representing over 75 percent of an industry that provides approximately 400,000 men and women with family-wage jobs. AWC members make products that are essential to everyday life from a renewable resource that absorbs and sequesters carbon. Staff experts develop state-of-the-art engineering data, technology, and standards for wood products to assure their safe and efficient design, as well as provide information on wood design, green building, and environmental regulations. AWC also advocates for balanced government policies that affect wood products.

www.awc.org | @woodcouncil

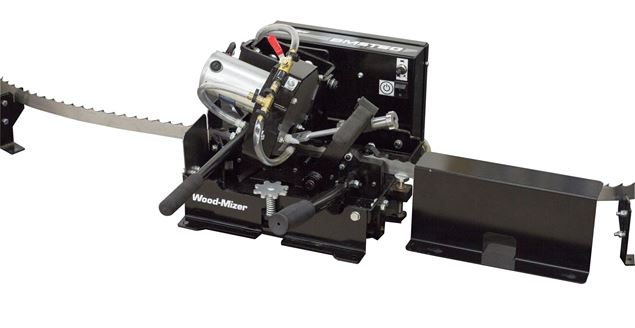

Wood-Mizer LLC, the world’s leading sawmill manufacturer, introduces the new BMST50 Blade Sharpener and Tooth Setter. The BMST50 will join Wood-Mizer’s extensive line of blade maintenance equipment ranging from personal to professional blade sharpeners and tooth setters.

The Wood-Mizer BMST50 enables blade sharpening and setting with a single machine. Manually operated, this efficient, space saving unit will lower operation time and costs by providing a complete blade ready for sawing. With a capacity of 1” to 1.5” blades, the BMST50 offers many adjustable features to maintain blade precision and accuracy.

Main Features

- 1” to 1.5” wide blade compatibility

- 4,7, Turbo 7, 9, 10, 13 degree with 7/8” tooth spacing supported blade profiles

- Tooth Setter Gauge included for consistent and accurate setting

- CBN full profile technology used for precise sharpening

“Wood-Mizer has always focused on providing a variety of blade maintenance solutions for the industry,” said Wood-Mizer Blades Manager John Storm. “The BMST50 gives individuals and small business owners an affordable opportunity to sharpen and set their own blades, eliminate downtime, and continue sawing with the precision and performance Wood-Mizer blades are known for.”

The BMST50 is currently available for purchase worldwide. For more information on Wood-Mizer’s complete line of blades and blade maintenance equipment, visit www.woodmizer.com/blades.

###

As the leading manufacturer of portable band sawmills for more than 30 years, Wood-Mizer offers an extensive line of portable and industrial sawmill equipment. The company supports its equipment with legendary customer service, blades, and blade maintenance equipment. For more information about Wood-Mizer, call 800.553.0182 or visit www.woodmizer.com.

WASHINGTON – The American Wood Council (AWC) has collaborated with companies and organizations in the lumber industry to release recommended guidelines for Weights and Measurement Labeling.

The guidelines can be found on the AWC website for reference: http://www.awc.org/NewsReleases/2015/weightsandmeasures.php

All states have laws and regulations describing how lumber must be labeled in order to protect consumers. Many states use the Uniform Regulation for the Method of Sale of Commodities, otherwise known as NIST Handbook 130, as the basis for these regulations.

“Concern has been raised recently on how lumber is being labeled for retail sale,” said AWC President and CEO Robert Glowinski. “To assist industry manufacturers in understanding the requirements of NIST Handbook 130, as applied to lumber, we have placed an easily digestible synopsis on our website and encourage the industry to use it as a resource.”

Given the potential variation among individual state requirements, however, manufacturers are strongly encouraged to consult with their own counsel and advisors regarding labeling of their products.

###

The American Wood Council (AWC) is the voice of North American wood products manufacturing, representing over 75 percent of an industry that provides approximately 400,000 men and women with family-wage jobs. AWC members make products that are essential to everyday life from a renewable resource that absorbs and sequesters carbon. Staff experts develop state-of-the-art engineering data, technology, and standards for wood products to assure their safe and efficient design, as well as provide information on wood design, green building, and environmental regulations. AWC also advocates for balanced government policies that affect wood products.

www.awc.org | @woodcouncil

Morbark, Inc., the manufacturer of the Boxer® line of compact utility loaders, has introduced the all-new Boxer 900HD. The 900HD made its trade show debut at the TCI Expo in Hartford, Ct., held Nov. 13-15, 2014, and will be shown in Morbark’s booth (#8013) at The ARA Rental Show this week in New Orleans. The model is scheduled to begin production in April 2015.

Designed from the ground up to be the most powerful and capable mini-skid steer available in the market, the Boxer 900HD is the culmination of two years of preparations.

“The Boxer 900HD is engineered to exceed other mini-skid steers,” said Jason Showers, Boxer Product Manager. “The 900HD includes many class-leading characteristics previously found only on full-size skid steer models, like a 48-HP Tier 4 Final diesel engine with Diesel Oxidation Catalyst (DOC) that does not require after treatment, dual pattern operator controls and a 94-inch hinge pin height that will allow users to easily dump material over the side of a 6-foot truck bed.”

The 900HD also features a class-leading 35% SAE (calculated) rated operating capacity of 939 lb. (425 kg). With an advanced torsional track suspension for a smooth ride and the ergonomic cockpit design — complete with dual pattern joystick controls, spring-cushioned operator platform, front and side padding, electronic engine display, cup holders and 12-volt auxiliary outlet — the Boxer 900HD provides enhanced operator comfort and utility.

The track tensioning system applies even track tension with simple adjustment to promote longer service life. The hydraulics package features a hydrostatic drive with 15-GPM (57 L/min) flow and dual auxiliary remotes with machine pressure relief block on the high-flow remotes. Like other Boxer compact utility loaders, the 900HD has a universal attachment plate to handle more than 50 attachments suited to any job.

AMERIMULCH® INTRODUCES THE MOBILETROM™

Unique to the Industry – Simple - Self-Contained - Portable

Twinsburg, OH – Amerimulch®, a member of the ChromaScape® family of brands, released in the spring of 2014 its new MobileTrom™ coloring system. This is a unique and innovative piece of equipment based on its mobility, inclusive power unit and production capacity.

The brilliant simplicity of the ColorTrom® is now available in a self-contained, portable unit. If you are looking to enter the color-enriched mulch industry, or simply expand your current operation, and if 100 yards per hour hits your production target, the MobileTrom is the equipment for you! It is an attractive option to handle the challenges of multiple sites with the versatility to meet all of your manufacturing needs – Coloring Simplicity from Amerimulch. That includes our commitment of customer satisfaction and Real Tangible Value©.

Amerimulch® provides landscape coatings and equipment for the production of profitable, in-demand color-enriched mulches. Our colorants are formulated for superior bonding, coating and coverage and our equipment is designed for producers who want simple, effective, high-volume production. Take the next step in landscape coatings and technology with Amerimulch.

For more information, please visit amerimulch.com or speak with your regional sales manager 1.888.556.3304.

Established in 1998, ChromaScape® is recognized as one of the world’s top producers of color dispersions and specialty additives, providing product to many markets under the brand names Amerimulch®, Solution Dispersions, ChromaPave® and Innotech® Decorative Concrete Products. The company has a wealth of experience in the colorant industry and is committed to building a sustainable, environmentally friendly organization that provides Real Tangible Value© to its customers.

LEESBURG, VA. – The American Wood Council's 2015 Permanent Wood Foundation Design Specification (PWF) standard has been approved by the American National Standards Institute as an American National Standard. The PWF is referenced in the International Code Council's 2015 International Residential Code and International Building Code.

The standard provides structural requirements for designing wood foundations, most commonly used in the upper Midwest. A Permanent Wood Foundation system is intended for light frame construction including residential buildings.

There are only minimal changes in the 2015 version of the PWF standard, mostly related to ensuring internal references to ASTM and AWC standards are current.

Designers may begin using provisions of new standards upon approval by the authority having jurisdiction. Many code officials will allow for the use of new standards, particularly when they are developed through a consensus process.

The 2015 PWF is available in electronic format on the AWC website http://www.awc.org/standards/pwf/2015.php.

“Back To Our Roots – 50 Years and Still Growing”

The Kentucky Forest Industries Association (KFIA) will hold its 50th Annual Meeting on March 25-27, 2015 at The Embassy Suites in Lexington, Kentucky. The association plans to host over 400 company representatives from throughout the region. There will be a variety of discussions and activities to enjoy during the event. A number of opportunities will be made available for attendees to gather and discuss current issues, and meet with customers both new and old. The meeting will get underway with a golf outing at the University Club of Kentucky Golf Course in Lexington, Kentucky and a Unique Horse Farm Tour.

The exhibit area will be open throughout the meeting and the Tree Farm Awards Luncheon will recognize outstanding individuals for their achievements in the forest industry community. We will have a special presentation from President Abraham Lincoln to honor all of KFIA’s past presidents.

Speakers will include Dean Nancy Cox; from the University of Kentucky College of Agriculture will provide information on the past 50 years of working with the University of Kentucky. James R. Comer, Commissioner of Agriculture for the state of Kentucky will give us an update on the Kentucky Proud Program, wood industry involvement and what the future may hold. Lee Andrews, Kentucky Field Office Supervisor will provide an update on the Northern Long-eared Bat and the potential affects on forest management if listed as an endangered species.

For more information on exhibiting or attending the 2015 Annual Meeting or KFIA programs and membership, please call 502/695-3979, email [email protected] or visit the website at www.kfia.org.

(2).jpg)

.gif)