704-288-1904

Carolina Machinery Sales (CMS) works in the sawmill, pallet and woodworking industries. In addition to the buying and selling of used equipment, we work as brokers and take in machines on consignment. Give us a call today!

Industry

Woodworking

660 Results Found

704-288-1904

Call for Price

Call for Price

Call for Price

Call for Price

Call for Price

Call for Price

Call for Price

Call for Price

Call for Price

Call for Price

Call for Price

Call for Price

Barr Mullin Wondersaw Optimizer with Computerized Laser Controls Tichniess: Up to 3" Width: 31" Min cut: 4" Feed height: 34-1/2" Floor Space: Apprx 21' x 15' 480 volt

Call for Price

84" maximum opening; 9" minimum opening on 90° trim; (2) 3 HP trim saw motors; 16" dia. saw blade capacity; 1" diameter saw arbor; (2) 3 HP boring units (boring heads not included); saws and boring units tilt 10° up, 23° down and swivel 90° for simple or complex miter work; .5 HP motorized open and close; (2) pneumatic holddown clamps; saw and boring units upgraded to hydraulic control; 5 HP hydraulic pump; retrofitted with electric brake system

Call for Price

Bertheson Press Platform size 51 Wide X 102 Long with 2 16 ft shuttle driven aluminum runner platforms. Pressure 2500 psi and we ran a temperature of 350 degrees for Tego and 165 degrees for plywood. The Press can laminate Tego Film glue or pva c glue. This press is a double shuttle and can laminate up to 14 ft by double pressing on shuttle. We can get the press operational if you are interested. We only have to hook up the power. Very good condition!

Biesse Rover B Edge semi automatic pod setting 4 coil magazine vertical and horizontal drill bank main spindle with U axis Milling X1: 5055 mm Y1: 1600 mm Edgebanding X2: 4100 mm Y2: 1600 mm Milling Module H74 - Z1: 245 mm Module H29 - Z2: 290 mm

Call for Price

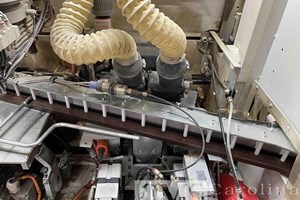

Machine Equipped as follows: NC 410 PC Based Controller Keyboard with Floppy Drive Automatic Strip Feed Magazine Belt Driven Top Pressure Beam Multi-Coiled Infeed Magazine RT63 Pre-Milling Unit SP20 Glue System w/ Pre-Melt Unit Hot Air Gluing system Automatic Infeed Pressure System T45 Front & Rear End Trimming Units w/Tilt RS10 Top & Bottom Rough Trimming Units RF30 Top & Bottom Fine Trimming Units AR10 4 Motor Corner Rounding Trimming Units RB30 Top & Bottom Profile Scraping Units RC10 Top & Bottom Glue Scraping Units SZ30 Top & Bottom Oscillating Buffing Units PH10 Top & Bottom Edge Heaters Specifications: Min. Panel Thickness:....................10mm? Max. Panel Thickness:....................60mm? Height of Edge-Band Material:…..15-65mm? Min. Banding Thickness:.................0.3mm ? Max. Banding Thickness:........ ...... 20mm? Min. Panel Length:...........................150mm? Min. Panel Width:............................ 100mm? Feed Speeds:.................................10-24m./min? Electrics: ......................................... 460-480V 3 Phase