704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

Industry

Woodworking

1847 Results Found

704-841-2001

$4,000

GRIZZLY G9968 1-1/4" 7-1/2 HP Spindle Shaper, with Power FeederSpecifications: -- Table size 33-1/4" x 91-3/4" x 33" H. -- Table insert dia. 4, 8, &13". -- Spindle length 6". -- Max. cap. under nut 5-1/2". -- Max. cutter dia. 8-1/2". -- Spindle stroke 5". -- Spindle speeds 5,500, 7,500, & 10,000 RPM.Equipped with: -- 7-1/2 HP - 3,450 RPM Motor, with Brake. -- Forward & Reverse spindle rotation. -- Spindle lock. -- 45-1/4" L x 5-1/8" H Cast-iron fence. -- Front table pullout extensions.Complete with: -- 2003 GRIZZLY "G7873" 1 HP 4-Speed 3-Roll Power Feeder, 220 V/60 Cy/3 Ph., with Speeds 13, 26, 33, & 66 FPM.Shaper Dimensions: 92" x 40" x 45" H.Shaper Height with Feeder: 60"Shaper Weight: 1,540 Lbs.Feeder Weight: 144 Lbs.

GRIZZLY G1021 15" STRAIGHT KNIFE PLANER15" Width cap. with 1/4" - 6" thickness opening, 1/16" max. depth of cut; 2 HP single-phase motor belt drives 2-knife reversable, 3-15/64"dia. cutterhead at 5,500 RPM; head with high speed steel knives, max. thickness 6-1/8", min. 3/16"; dual feed speed of either 11 or 22 FPM; 16" x 15" cast iron table, 11-1/3" table extentions on infeed/outfeed. -- Complete with: Magnetic controls, 2" dia. metal infeed & outfeed rollers, fabricated steel base, and large hand wheel for cutterhead assembly adjustment.

$11,610

GUBISCH MODEL CP-230 4 HEAD PUSH FEED MOULDER: -- 4-Head (T-R-L-B), working capacity 6" x 4". -- Head sequence: Top 15 HP, right/left 15 HP and bottom 15 HP motor. -- Spindle dia. 1-13/16" all heads with cutterhead speed of 6,000 RPM on vertical spindles and 7,000 RPM on horizontal spindles. Heavy duty, built-in profile jointers on spindles #2, #3 and #4. -- Mechanical adjustment for spindle settings. Spindle adjustments from the front side of machine. -- Variable speed feed drive via 7-1/2 HP, variable speed motor with speeds from 16 to 120 FPM; with (2) powered rollers from the top and (2) powered rolls in the table. -- Infeed table;chromed table plates. --Pneumatic jointers on all 4 heads Amazingly well built Moulder; off-the-shelf parts accessibility; low maintenance/operating costs.

Call for Price

HAAS - 2000XL 2.0, ...Mobile ShredderLow Hours; 2018 YMFG.Specifications & Features: -- Can be used at any location (comfortable transport measurements). -- Easy & quick positioning thanks to crawler track and radio remote control. -- Shreds different materials with just (1) tool configuration. -- High throughput capacity of up to 100 tons/Hr. -- Resistant against foreign bodies. -- Low wear cost and long lifetime. -- Service and maintenance friendly. -- No wrappings; self-cleaning. -- Quiet main drive.

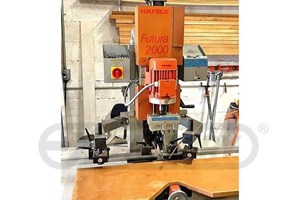

RAFIX - Futura 250: Hinge Boring & Inserting Machine with 1-1/2 HP MotorSpecifications -- High-quality air cylinder (80 mm bore with 650 ft. Lbs of pressure @ 90 PSI) rated for 3-1/2 million 3" strokes.A skilled Operator can bore & insert in (3 - 4) seconds. -- Features: (2) Types of boring depth adjustment: Drawbar style for quick and easy adjustment and a solid stop adjustment for the changing of door thickness applications. This allows changing of the door thickness and still bore the same depth without adjustment. -- Fixed table with: Adjustable back rail to control the tab location. -- Enclosed cutting area for better chip removal with blow off nozzle to assist in chip evacuation and adjustable 2" & 4" vacuum hookup. -- Pneumatic drilling unit with push button control. -- Includes: Adjustable cutting speed control; indicator light; reset thermal circuit breaker; emergency stop button; drill & insert buttons (2-hand activation for Operator safety); rotary switch for pair of pneumatic holddown clamps; 600 mm ruler & (4) flip stops.

HAMMEL 750D HAMMERMILL NEW IN 2019Approx 3,000 Hours --Hydraulic recycling machine with 2 slow running tool shafts --Suitable for Wood (Old wood, construction & demolition wood, rhizomes, green waste, pallets, cable drums) or Rubbish (Domestic waste, industrial and commercial waste) and Paper, paper rolls, aluminum profiles and balesAdvantages: --Increased performance for more throughput --low energy consumption --Very easy to maintain --User-friendly handling by IFM control --Better accessibility of the control panels --Low noise --Tilt funnel with increased inclination for optimum material flow --Mobile on a chain or semi-mobile on a hooklift

HAMMOND DK-1055-B Cyclone Dust Collector w/ After-FilterSelf-contained indoor cyclone type unit w/afterfilter bags, the blower wheel is located on the clean air side and is direct driven by 7.5 HP motor @ 3,600 RPM, performance ranges 3,470 CFM @ 5" H20, 2,727 CFM @ 8.6" H20, 2,200 CFM @ 11.4" H20. -- (1) 10" Dia. inlet and (1) 8.5" x 15" outlet; waste discharges via bottom of unit to (2) 55-gal. drums (drums not included). -- Includes: Multi-exhaust manifold with (4) after-filter bags, 167 sq. ft. cloth area, push button starter.

SPX FLOW HANKISON HPRN200 200 CFM Non-Cycling Refrigerated Compressed Air DryerSpecifications: -- Cap. 200 SCFM at 100 PSIG & 100° F. -- Max. working pressure 232 PSI. -- Max. inlet temperature 120° F -- Refrigerant type R-407C.Equipped with: -- 200 W (1/4 HP) Refrigeration compressor motor. -- Stainless steel cross flow heat exchanger. -- LED Dew point indicator. -- Dry alarm contact. -- Timed electronic drain valve.

$1,500

SPX FLOW HANKISON HPRN200 200 CFM Non-Cycling Refrigerated Compressed Air Dryer Specifications: Cap. 200 SCFM at 100 PSIG & 100° F. Max. working pressure 232 PSI. Max. inlet temperature 120° F Refrigerant type R-407C. Equipped with: 200 W (1/4 HP) Refrigeration compressor motor. Stainless steel cross flow heat exchanger. LED Dew point indicator. Dry alarm contact. Timed electronic drain valve. CURRENCY NOTE: Negotiable Price is listed in U.S. Dollars.

Call for Price

HARMONY - S60-XDRC: Vertical BalerSpecifications: -- Motor: 20 HP. -- Bale Size: 30";x 60"; ≤ 48";. -- Bale Weight (OCC): Up to 1,000 Lbs. -- Feed Opening: 25″ x 60″. -- Ram Force: 92,360 Lbs. -- Volume: X-Large 7" cylinder. -- Loaded onto your Truck!

WOLVERINE Two Ram Auto Tie Baler with Infeed Conveyor --Cylinder replaced in 2018 --BALE SIZE Width 46"Height: 31"Length: 61" --BALE VOLUME cu.ft. 50 --CAPACITY cu ft./hour 10,975 --CHARGE BOX OPENING inches 41" x 60" --HOPPER OPENING inches 40-3/8" x 60" --MAIN PUMP 60 GPM --SYSTEM PRESSURE PSI 3500 --MAIN RAM FACE PRESSURE PSI 145 --EJECTOR RAM FACE PRESSURE PSI 84 --SHIPPING WEIGHT 20 TonsBALING MATERIALBulk OCCSolid WasteNewsprintWhole Aluminum CansSteel CansPlasticNon-FerrousHDPE

HARRIS/SELCO - HLO-60AREB: Horizontal Auto-Tie Baler -- Motor: 2 – 100 HP. -- Cylinder: Rebuilt 12″. -- Hopper: 80″ Long. -- Hours of Operation: 14,000. -- Tons Per Hour/OCC: Up to 26 Tons. -- Includes 72″ MAYFRAN Steel Belt Feed Conveyor.

--AT AUCTION-- HEESEMANN KSA 8 CSD 80" Lacquer/Sealer Sander This is a Very Special "extra wide" HEESEMANN equipped with: HEESEMANN's patented "CSD" selective pressure adjustment system, sensors placed every 5/8" (16 mm) sense part configuration; pressure for each segment can be preprogrammed to provide less pressure on the outer edges, or more in the center if desired. The "CSD" computer control will hold a max. of (20) programs. Equipped with: Segmented Polishing Platen: Segments are computer controlled to conform to irregular shaped panels; sanding pressure on panel edges is adjustable. Platen will accept panel thickness variation up to 5/64" (2 mm). Dual speed motor: 26 & 31 kW (35 & 42 HP); abrasive belt speed: 10 + 20 MPS (33 + 66 FPM); abrasive belt size: 2,050 mm x 3,250 mm (80.7" x 128"); pneumatic air tension and tracking control. 250 mm Dia. Rotary Panel Cleaning Brush, 5 HP motor, 150 mm Outfeed Rotary Panel Cleaning Brush, and 2 HP motor. Additional Features: Vacuum bed assembly to ensure flatness of parts and feeding of small parts. Computer control and monitor, light indication of panel movement; electronic abrasive belt tracking. Feed System: Variable feed speed from 5 - 15 MPM (16 - 49 FPM); 4 kW (5 HP) feed motor; motorized thickness opening. NOTE: This Sander had a "Brand New" ...$ 17,000 display/control installed shortly before it was taken out of service in 2016. The machine has been in storage since that time.

$52,250

HEESEMANN LSM-8/3-OSR Wide Belt Finishing Sander, 52" and (3) Heads; Equipped with: (1) longitudinal segmented platen head. and (2) Orbital Platens -- 1st Head: Longitudinal segmented platen head. Segmented Polishing Platen, 20 & 27 HP dual speed motor. electronically controlled segments to conform to panel size,.2620 x 1350 mm (91.4 x 53.2") Sanding belt. - Equipped with HEESEMANN's patented "CSD" selective pressure adjustment system, sensors placed every 16 mm (5/8") sense part configuration; pressure for each segment, to eliminate sand through, can be pre-programmed to provide less pressure on the outer edges or more in the center if desired. The "CSD" computer control will hold a maximum of (20) programs. -- 2nd & 3rd Heads: OSR Dual orbital action head with (1) high-speed orbit on sanding pad, powered by 3 kW (4.5 HP) motor.Secondary oscillation movement of platens powered by 1.5 HP motor. Upstream and downstream vacuum chutes on each head for dust localized dust pickup.- Platens feature "quick change" abrasive material; Both orbital heads with variable speed inverter drives. -- Outfeed Rotary Brush with cleaning brush loading with single end adjustment , 6" max. dia., 3.4 HP motor. -- Variable feed speed from 13 to 82 FPM, 6.5 HP feed drive. -- Infeed and outfeed Ssissor Lift and Control box shown are not included. -- Motorized thickness opening 1/4" to 3-5/32" max. - -- Power Consumption: 63 KW, 75 Amps. -- Separate display console for CSD control.

$85,500

HEESEMANN - LSM 8-5 RRRL, ...53" Wide Belt Sander53" Width cap.: Drum, Drum, Drum, and CSD® Pad.Head Configuration:• Unit 1 - Longitudinal Sanding Unit: Steel contact roller, helically grooved. - Single-speed 48 HP motor, electronic braking.• Unit 2 - Longitudinal Sanding Unit: Rubber-covered contact roller, helically grooved. - Single-speed 35 HP motor, electronic braking.• Unit 3 - Longitudinal Sanding Unit:- Rubber-covered contact roller, helically grooved. - Single-speed 35 HP motor, electronic braking, bi-directional drive.• Unit 4 - Longitudinal Sanding Unit: CSD® Segmented pad system, 2-speed 20/26 HP motor, electronic braking.• Unit 5 - Panel Cleaning Brush: Fiber trimming, 2.3 HP Motor.Specifications: -- Working height: 880 mm (34.64"). -- Workpiece thickness: 3 mm to 150 mm (1/8" to 6"). -- Working width: 1,300 mm (51-1/8"). -- Longitudinal belt: 1,350 x 2,620 mm (53" x 103"). -- Machine voltage: U.S. Electrics 480 Volts, 3-Phase, 60 cycles.Constant Pass LineController: -- Industrial PC. -- TFT Color touchscreen. -- Windows® Operating System. -- (100) Memory addresses for: • CSD® sanding pressure. • Sanding start/stop. • Sanding belt speeds. • Grit sequence indication. • Sanding belt selection - "ON/OFF". • 1-Button sequenced starting for all motors.RS-232 Serial port.RJ-45 LAN Port.Modem with software licenses.For All additional, detailed specs, select the "View Literature" link .

$13,050

HEESEMANN MFA-8 D Wide Belt Sander (4) Heads; 53" Width cap. Veneer/ Sealer Sanding Wide Belt.Great Lacquer/Sealer sander with: (2) Segmented polishing platen, (2) Orbital heads, (1) De-nibbing/Polishing brush.Head Configuration: Head 1: Segmented polishing platen, 5/8 wide segments CSD Control, Variable speed abrasive belt with inverter RPM control, 15HP motorHead 2: Segmented polishing platen, 5/8 wide segments CSD Control, Variable speed abrasive belt with inverter RPM control, 15HP motorHead 3: Orbital head with composite/dense fiber loading; 5HP motorHead 4: Orbital head with composite/dense fiber loading: 5HP motor(1) Brush Type head for de- nibbing and polishingSpecifications: -- LCD monitor with graphic display and key pad entry, 20 program capacity, -- Pressure for each segment can be pre-programmed to provide less pressure on the outer edges or more in the center if required.Equipped with & Features -- Air blast abrasive belt cleaner on heads 1 & 2. -- Variable feed speed from 10 to 49 FPM via 2 HP feed drive. -- Motorized thickness opening 1/4" to 3-5/32" max. -- Rubber covered Infeed and out feed holddown rolls.

$33,750

Heesemann MFA6 (3) Head Wide Belt Sander, 53" width cap. Drum Drum, Segmented platenHead configuration1st Head: Steel contact roll, 30 HP motor2nd Head: Rubber covered contact roll, 20 HP motor3rd Head: Segmented polishing platen, electronically controlled segments to conform to panel size, 20 HP motor4th Station: Outfeed rotary panel cleaning brush, 2 HP motor.Specifications -- Platen head equipped with: HESSEMANN's Patented "CSD-32" selective pressure adjustment system; sensors placed every (32 mm) sense part configuration, pressure for each segment can be pre-programmed to provide less pressure on the outer edges or more in the center if desired. -- Both contact rolls with NC positioning and auto grit compensation, automatic line control for platen independent of feed speed determines automatically the correct part in time for the pressure segmentEquipped with & Features -- Outfeed rotary panel cleaning brush, 2 HP motor. -- 55" x 103" Abrasive belts on all heads with abrasive belt air cleaners, "ICP" control for all sander functions, (20) programs storrage. -- Variable feed speed from 10 - 49 FPM, 3 HP feed drive with inverter control. -- Vacuum conveyor bed assembly with suction fan and )motor mounted in machine base, motorized thickness opening 0" - 5-7/8" w/digital readout, constant passline of conveyor bed assembly 35" height.NOTE Some Spec's need to Varified

$9,900

IRONWOOD P500 508 mm (20") Surface Planer, with Spiral Insert Cutterhead Specifications: 20" (508 mm) max. Width cap., 11.8" (300 mm) max. thickness cap., 0.393 (10 mm) min. thickness cap., 0.325 (8 mm) max. cut depth, 8.6 (220 mm) min material length (un-butted). 7.5 HP Main motor, 3.8" (98 mm) dia. cutter-head with 4.0' (102 mm) cutting circle @ 4,800 RPM; Spiral cutter-head with 75, 2-sided Carbide cutter inserts. Equipped with: Digital Position Controller for Up/Down of the Table. Variable speed by Frequency Inverter from 19 to 39 FPM / 1 HP feed motor. 0.25 HP Motorized support table, 29.4 (748 mm) long x 22.1" (562 mm) wide bed; the table is supported by (4) oversized columns with height positioning via keypad entry within the digital controller. Automatic power off when the top safety hood is opened. Both the infeed chip-breaker and the outfeed pressure rollers incorporate spring-pressured adjustments to ensure positive contact on the workpiece as it is passed through the planer. Two 3” adjustable bed rollers for planing of rough or finished lumber, as well as glued panels. Complete with & more: Magnetic starter, Adjustable bed rollers, (1) 6" dia. Dust outlets. Requires 800 CFM; Instruction Manual & Parts List; Shipping weight 1,800 Lbs. Features: The IRONWOOD P500 Series of 20” thickness planers provide operators with solid thickness planning machinery that offers a powerful cutting performance. This machine features an enhanced heavy-duty cast iron table that is heat-treated and precision ground to assure the greatest rigidity and stability during intense cutting operations. The Ironwood Planers offers enhanced engineering designs and superior build construction for long-lasting and trouble-free performance. CURRENCY NOTE: Negotiable Price is listed in U.S. Dollars.

IRONWOOD SLR 305 Straight Line Rip Saw Specifications: -- Width capacity of 18" and glue line tolerance up to 8'. -- Variable auto-lubrication system providing consistent lubrication to the chain track and automatically adjusting to the chain feed speed -- Minimum Material Length÷ 203 mm (8";). -- Material Thickness, Minimum- Maximum: 6.35 mm (0.25";) to 85 mm (3.35") -- Distance between Blade and Column 457 mm (18"). -- (8) Hold-down Rollers. -- Work Table Height 800 mm (31.5";). -- Saw Arbor Motor 15 HP. -- Saw Arbor Speed 4,500 RPM. -- Saw Blade Diameter 200-300 mm (8“ - 12“). -- Saw Arbor Diameter 25.4 mm (1";). -- Feed Speed 56 - 131 FPM. -- Feed Motor 2 HP.Equipped with & Features: -- Laser device to ensure straight line ripping entire length of the material. -- Maximum safety protection available with multiple rows of extended anti-kickback fingers and a side protection guard. Equipped with & Features -- (8) Accurately aligned pressure rollers extend from the cast iron machining head to provide absolute butting tolerances, low maintenance, and superior safety -- Solid steel cylindrical positioning rod and quick cam, cast iron fence provide accurate set-up, fast movement, and dust-free operations. -- Table Area (W x L) 950 mm (37";) x 1,450 mm (57";). -- Net Weight 2090 Lbs. -- Dust channel outlet (saw guard) 102 mm.

$12,780

IST (Industrial Surface Technologies) - AW 80, ...Industrial Washer with vibration.ISTpure's Stir Wash Tanks are designed to clean complex parts with an adjustable stirring platform for up to 100 stirrings per minute.Parts washers by stirring are very effective in thoroughly cleaning the surface and interior cavities of parts or batches of parts of any size.Simply load the parts into the tank through the opening in the top, set the cycle time and agitation speed Specifications: -- Tank capacity: 80 gallons -- Stirring System: Self-cleaning stirring platform with top loading that facilitates loading/unloading operations -- Adjustable Stirring Speed: Ranges from 0 to 100 stirrings per minute -- Pneumatic System: Operates at 120 psi pressure -- Inner tub made entirely of stainless steel components -- Included Attachment: Hand Wash Brush with Continuous Flow -- Standard Pump: Electric Motor -- Fluid Capacity 80 gallons -- Fluid Level 12" 17 1/2" -- Load Capacity 250 lbs 750 lbs --Overall Dimensions (D x W x H) 33" x 51 1/2" x 66 1/2" -- Interior Dimensions (D x W x H) 27 1/4" x 44 1/2" x 28" -- Tub Dimensions (D x W) 17 1/2" x 41 1/2" 27 3/4" X 54" -- Shipping Weight 556 lbs -- Compressed air required 8 cfm@ 120 p