704-288-1904

Carolina Machinery Sales (CMS) works in the sawmill, pallet and woodworking industries. In addition to the buying and selling of used equipment, we work as brokers and take in machines on consignment. Give us a call today!

Industry

Sawmill

395 Results Found

704-288-1904

Call for Price

Call for Price

Call for Price

Call for Price

Call for Price

Call for Price

Call for Price

Morgan Unscrambler - Hydraulic Drive Cant Chop Saw - 20" Blades, 6"x9" Capacity, 10 HP Motor, Pneumatic Cycle, Fixed Stop Smith Resaw - 15 HP Motor, 13'2" x 1.25" Bands, variable feed speed - MISSING drive motor and gearbox for the feed belt. Includes: Powered infeed conveyor leading to the resaw with VFD. Machine required 480v/3Ph for saws, 240v/1Ph for VFD units and controls. All control contacts are contained in a single box. All wires were labeled upon removal.

PalletPal Spring Lift Table Specifications Load capacity 400 to 4500 lbs., depending on springs Load size .......50" wide x 50" long x 72" high (max.) Length 45 1/4 inches Width (base frame) 36 3/4 inches Compressed height 9 1/2 inches Extended height 27 3/4 inches Rotating ring, outside diameter 43 5/8 inches Rotating ring, inside diameter 40 5/8 inches Adjustment for sloping floors Can adjust for floor slope up to 1:25 using optional adjustable feet 4 Available

4000# capacity 96” x 64” table size raised height 38-1/2" Lowered height 14-1/2" pneunatic operation Rotatable table 360 degrees safety skirts

Call for Price

Call for Price

Call for Price

Call for Price

Call for Price

Stromab Stromab TR350 Up Cut Saw 4 HP Motor (230v/3ph) Variable Feed Speed This was a demo machine. Ready to ship!

Call for Price

Call for Price

Call for Price

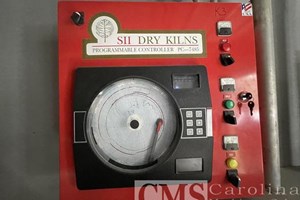

CMS represents Big on Dry (BOD) Thermo Wood Kilns in the USA. This system is another on elf our customers in the USA who is producing mostly poplar and oak decking. Big on Dry has improved the Thermo-Modification process with their THERMOWOOD (THW) line and provides complete "turn key" systems. The PLC control systems allow programming for a wide variety off wood applications. This allows the same systems to work with very delicate wood that is hard to treat to thicker wood that will be used for outdoor products. The THW system can also be used as a conventional kiln with steam. Basic systems include: - Kiln completely built with stainless steel and aluminum - Initial humidy of 10-15% is reduced to 5-6% - Loading options: Side or Trolley - Heating options: Gas or Wood Burner - Humidification: Combined Spraying System

Timber Treatment Solutions (TTS) manufacturers specialized timber treatment and preservation equipment. These systems are engineered to our specific customers specifications and applications. The TTS systems are turn key with installation and service available. - High Pressure Impregnation Plants - Low Pressure Impregnation Plants - Automated Material Handling Systems - Dip Tanks - Automation available - Hot Oil Treatment - Treatment Tunnels for individual lieces - Timber Incising Machines - Automation and control systems

Call for Price

Timber Treatment Solutions designs and manufactures turnkey high pressure wood treatment plants for impregnating timber to Use Class 3, Use Class 4 and a variety of other requirements. These plants generally include: – - an autoclave with quick closing door(s) - one or several tanks to store the treatment chemical - a process skid, with all necessary pumps, valves, and pipes - a timber pack handling system, from completely manual to fully automated - a mixing / dosing system - a PC or HMI based control system with our latest plant operating system There are lots of possible configurations, and our teams will be able to advise the most suitable high pressure wood treatment plant for you, according to your needs and budget. Plants can be designed for any of the processes required by the timber impregnation industry: – - Bethel (full cell) – this is the most common for treatment of timber to Use Class 3 and 4 - Rueping (empty cell) – this process cycle is used for more specialist lumber treatments, such as creosote and copper oil, where the impregnation rate needs to be reduced on highly absorbent wood species - Lowry - Special cycles using any combination of vacuum, air pressure & fluid pressure phases, which can be designed on request WHEN TO USE HIGH PRESSURE IMPREGNATION High pressure treatment is widely used whenever deep impregnation of wood by a preservative required: – - Sawn or round posts using water-based copper chemicals (UC3 / UC4) - Poles, sleepers, posts using Creosote, Creosote/Oil mix, CuNap & Copper Oil - Construction timber with fire retardant chemical - For specific applications, such as resin or furfural impregnation before curing