704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

2009 Results Found

704-841-2001

Call for Price

EXCALIBUR- 1042-60, ...Dual Shaft ShredderSpecifications: -- Motor: 60 HP. -- Opening: 42x 25". -- Cutters: 1 1/8" Wide. --Includes Control Panel -- Includes Stand but no Hopper÷ Loaded onto your Truck.

Call for Price

EXCEL - 2R10 2: Ram Baler with Steel Belt Infeed Specifications -- New in 2001. -- Motor: 2 - 50 HP. -- Main Cylinder: 10"; - Recently rebuilt. -- Bale Weight (OCC): Up to 1,500 Lbs. -- Cycle Time: 16 Seconds. -- Bale Size: 60"; x 45"; x 30";. -- Feed Opening: 40"; x 90";. -- Comes with spare eject & main cylinder (needs rebuilding). -- Includes: 72"; Wide MAYFRAN steel belt Infeed Conveyor with 15’ lower horizontal.

Call for Price

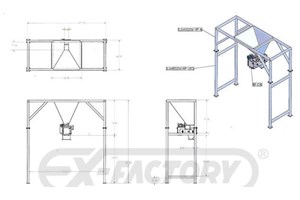

SPECIAL FEEDER FOR HAMER 2080FFS BAGGER -- Hopper 37 Cubic Feet and Support -- With Scale Support System -- Belt Feeder with Discharge to Existing Hamer Form-Fill and Seal -- Brand New -- Loaded on your Truck

Call for Price

LOOSE BAGGING SYSTEM "MCSRE"System includes and is supplied with: -- Hopper BF 87 Cu/Ft. and Support, Charging Hopper to Integrate with product Delivery Conveyor -- CON PD 24X24: 24 Feet Product Delivery Conveyor -- Hopper Stand BF: Hopper and Support 37 Cu/Ft. Surge Hopper for 5 GV Duplex Net Weight Bagging System -- GV-52 - DUPLEX GRAVITY/VIBRATORY TRAY: Duplex unit for (20) Bags/Minute -- Spout to Meet Customer's Bag -- CON 512: Bag Closing Conveyor. 12 Feet Long -- PACKRITE XROL: Heat Sealer with Extra Set of CO.Loaded on your Truck

Call for Price

MCRS is a Bagging System for mulch, compost, rock, or sand. This system is complete with a 2-yard product surge hopper, a 20' X 24" wide troughed incline product delivery conveyor with a cleated belt, an 8' bag closing conveyor, and a custom 7.5 HP Elec/hydraulic power unit. The system can fill bags by time and depth of stream or digitally with load cells.Standard construction carbon steel Powder Coated Industrial Gray(RAL 7046).The MCRS operation has been designed for one man to bag fill, bag close, and stack three bags per minute continually. -- The operator hangs bag #1 on the scale, hits the palm switch to close the CG spout, and automatically fills it. -- Bag #1 will drop once the timer times out onto the moving conveyor and hangs bag #2 into position, hits the palm switch, and starts the filling. -- The operator steps to his left. Bag #1 contact a wand switch and is in position underneath the impulse sealer. --The operator starts the bag into the impulse sealer. Once completed, bag #1 is then manually stacked. -- Bag #2 filled and waiting for the operator's return. -- Bag #2 is then released, and bag #3 hung. -- The process is then repeated.The Front End loader feeds the system. Consists of the following --infeed hopper --incline conveyor --dosing system --bag closing system:Bag Closing System Consists of a (CON 508) 8' long x 1' wide smooth top belt to take bags into aposition where a wand switch manually stops them. The bags are then prepared and enteredinto theImpulse Sealer (31103737610) Programmable Impulse Sealer for the repeated sealing of thermoplastic films such as polyethylene and polypropylene. This automatic single-impulse heat sealer is controlled by a plug-in transistorized circuit board and electronic timers. The timed closure ensures an even and consistent seal. --THE PRICE REFLECTS AN UPGRADE FROM THE IMPULSE SEALER TO A SEWING SYSTEM.The operator has hands free to handle the product quickly. This type of machine generally increases workers' productivity.The electric foot pedal is included for manual operation. -- Seal Length: 24" -- Seal Thickness: 8 mil -- Seal Width: 10 MM

Call for Price

EXPRESS SCALE MCRS-180ELECHYD LOOSE BAGGING LINEComplete Loose Bagging Line including the Following; -- Hopper Stand and Support 37 cu' BF/GV/AUG -- GB Bag Fill Machine -- BF-14 Belt Feeder -- Bag Closing Conveyor 510-LP -- Fishbein Sewing Machine -- Hopper 87 cu' with Support -- Belt transfer Conveyor 27' -- Loaded on your Truck

Call for Price

COMPLETE LOOSE BAGGING SYSTEM System includes: -- Feed Hopper 3 Yards Capacity. ( 87 Cu.Feet) -- 24 feet Incline Conveyor. -- GB Mechanical Bagging Scale -- Feeding Hopper 37 Cu.Feet with Stand. -- Packrite Xtrol Impulse Sealer. -- Motorized Bag Conveyor. -- Loaded on your Truck.

EXTEND LIGHT GY610S Double Sided Strato Planer 24" x 8" Cap., min. material length 12-1/2" and min. thickness 3/8";Equipped with: -- 25 HP top & 20 HP bottom belt drive motors -- Helical Spiral Cutterheads which rotate @ 4,600RPM; (6) rows or spirals of 4-sided carbide inserts. -- Variable feed speed from 20 - 95 FPM, powered by a 3 HP drive to lower feed rolls & upper feed mat; -- Infeed table hard chrome plated for maximum wear resistance, relieving upper feed mat with spring loaded spikes; allows cupped bowed or warped boards to feed into the heads for maximun straightening capability. -- Powered lowering & raising of bed table on (4) columns via a 1 HP motor, hand wheel for fine adjustment of thickness control. Complete with: -- Spiral cutterheads, digital control for accurate thickness setting, -- Side mounted electrical control & operator panel, -- Automatic feed chain tensioning, -- Staggered upper infeed fingers to eliminate small part jambs.

EXTREMA XF-DC4 Power Feeder w/Mounting ColumnExtrema has a wide range of power feeders that range from compact junior feeders to large 5-roller feeders. The XF-DC4 Series features a 4-roller system with variable speeds. Includes the 2/3 HP DC brushless servo motor for higher torque and better variable speed control than a 1HP AC motor.Specification: -- "EXTREMELY" Heavy duty 4-Roll Power Feeder with 4-3/4" & 2-1/4" rubber rollers. -- 2/3 HP Motor with forward/reversing switch. -- Variable speed from 7-72 FPM -- Heavy duty cast aluminum construction of the feeder housing. -- Cast iron stand components with fully adjustable mounting column. -- 3/4" Flotation of rollers for material thickness variations. -- Standard reach from base is 720 mm / 28-3/8" (optional 850 mm / 33-7/16" arm available)

Call for Price

"EXTREMA XF-34.3 Power Feeder w/Mounting Column;EXTREMELY" Heavy duty 3-Roll Power Feeder with 4-3/4" & 2-1/4" rubber rollers. -- 1 HP Motor with forward/reversing switch. -- (4) Speeds of 13 - 26 - 36 & 72 FPM. -- Heavy duty cast aluminum construction of the feeder housing. -- Cast iron stand components with fully adjustable mounting column. -- 3/4" Floation of the rollers. -- Standard reach from base is 720 mm / 28-3/8" (optional 850 mm / 33-7/16" arm available)

Call for Price

EXTREMA XF-38.1 Power Feeder w/Mounting Column;"EXTREMELY" Heavy duty 3-roll Power Feeder with 4-3/4" & 2-1/4" rubber rollers. -- 1 HP Motor with forward/reversing switch. -- (8) Speeds of 7 - 13 - 18 - 22 - 26 - 36 - 43 - 55 & 108 FPM. -- Heavy duty cast aluminum construction of the feeder housing. -- Cast iron stand components with fully adjustable mounting column. -- 3/4" Floation of the rollers. -- Standard reach from base is 720 mm / 28-3/8" (optional 850 mm / 33-7/16" arm available)

Call for Price

EXTREMA XF-38.3 Power Feeder w/Mounting Column;"EXTREMELY" Heavy duty 3-Roll Power Feeder with 4-3/4" & 2-1/4" rubber rollers. -- 1 HP Motor with forward/reversing switch. -- (8) Speeds of 7 - 13 - 18 - 22 - 26 - 36 - 43 - 55 & 108 FPM. -- Heavy duty cast aluminum construction of the feeder housing. -- Cast iron stand components with fully adjustable mounting column. -- 3/4" Floation of rollers for material thickness variations. -- Standard reach from base is 720 mm / 28-3/8" (optional 850 mm / 33-7/16" arm available)

Call for Price

EXTREMA XF-3J Power Feeder w/Mounting Column;3-Roll Power Feeder with (3) rubber feed rollers. -- 0.25 HP Single phase motor. -- (4) Speeds of 20 - 26 - 33 & 43. -- Cast aluminum construction of the feeder housing. -- Heavy cast iron Universal Stand components. -- 1/2" Flotation of the rollers. -- Fully adjustable Mounting Column w/locking joints.

Call for Price

EXTREMA XF-44.1 Power Feeder w/Mounting Column;"EXTREMELY" Heavy duty 4-roll Power Feeder with 4-3/4" & 2-1/4" rubber rollers. -- 1 HP Motor with forward/reversing switch. -- (4) Speeds of 13 - 26 - 36 & 72 FPM. -- Heavy duty cast aluminum construction of the feeder housing. -- Cast iron stand components with fully adjustable mounting column. -- 3/4" Flotation of the rollers. -- Standard reach from base is 720 mm / 28-3/8" (optional 850 mm / 33-7/16" arm available)

Call for Price

EXTREMA XF-44.3 Power Feeder w/Mounting Column;"EXTREMELY" Heavy duty 4-Roll Power Feeder with 4-3/4" diameter x 2-1/4" wide rubber rollers. -- 1 HP Motor with forward/reversing switch. -- (4) Speeds of 13 - 26 - 36 & 72 FPM. -- Heavy duty cast aluminum construction of the feeder housing. -- Cast iron stand components with fully adjustable mounting column. -- 3/4" Flotation of the rollers. -- Standard reach from base is 720 mm / 28-3/8" (optional 850 mm / 33-7/16" arm available).

EXTREMA XF-54T.3 Power Feeder w/Mounting Column;"EXTREMELY" Heavy duty 5-roller CONTINUOUS BELT Power Feeder with (3) 44.5" x 1/2" tracks. -- 1 HP Motor with forward/reversing switch. -- (4) Speeds of 15 - 28 - 39 & 78 FPM. -- Heavy duty cast aluminum construction of the feeder housing. -- Cast iron stand components with fully adjustable mounting column. -- 3/4" Floatation travel of the rollers. -- Standard reach from base is 720 mm / 28-3/8" (optional 850 mm / 33-7/16" arm available)

Call for Price

"EXTREMA XF-54T.1 Power Feeder w/Mounting Column;EXTREMELY" Heavy duty 5-roller continuous belt Power Feeder with (3) 44.5" x 1/2" tracks. -- 1 HP Motor with forward/reversing switch. -- (4) Speeds of 15 - 28 - 39 & 78 FPM. -- Heavy duty cast aluminum construction of the feeder housing. -- Cast iron stand components with fully adjustable mounting column. -- 3/4" Floatation of the rollers. -- Standard reach from base is 720 mm / 28-3/8" (optional 850 mm / 33-7/16" arm available)

Call for Price

EXTREMA XF-34.1 Power Feeder w/Mounting Column;EXTREMELY" Heavy duty built 3-Roll Power Feeder with 4-3/4" dia. and 2-1/4" wide rubber rollers. -- 1 HP Motor with forward/reversing switch. -- (4) Speeds of 13 - 26 - 36 & 72 FPM. -- Solid cast aluminum construction of the feeder housing. -- Cast iron stand components with fully adjustable mounting column. -- 3/4" Floatation of the rollers. -- Standard reach from base is 720 mm / 28-3/8" (optional 850 mm / 33-7/16" arm available).

EXTREMA DB-75 TYPHOON BLOWER. Capacity 7.5 HP motor and rated at 4,700 CFM. -- Solid heavy gauge steel construction. -- Heavy duty 13.5" dia. dynamically balanced steel impeller. -- 12" Inlet, 13.5" impeller, 14" outlet. -- Rotatable collection port for use in a variety of applications. -- Safety guards on all inlets. -- Complete with magnetic starter. -- Note: 460 Volt available

EXTREMA DCF-327E Baghouse Dust Collector.Features a 16" inlet; unit has (3) sections with (9) socks per section. -- Filter Socks: 6" Dia. x 70-7/8" for greater air-to-filter ratio; (1) Micron filter. -- Available for outdoor & indoor use; unit is enclosed. -- Excellent addition to the "DCY Typhoon" Dust Collector; ...ask us why!