704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

2011 Results Found

704-841-2001

$4,850

OLIVER 4430 20" PLANER WITH HELICAL HEAD20" Maximum stock width cap., 1/4" to 8" max. stock thickness, 10" minimum stock length. Equipped with: -- 5 HP Main drive motor and mechanical raising and lowering of the cutter head. -- Fixed bed height of 29-7/8". Table dimensions 20"L X 21"W. Overall all table dimensions with infeed and outfeed bed extensions 51"L X 21"W. -- 3-1/4" Dia. Helical Cutter Head with 4-sided carbide inserts. -- Auto-Depth lock via nitrogen-charged cylinders eliminates snipping. -- 8" Max. thickness adjustment via handwheel includes LED Digital readout for head positioning. -- 4-Post support for proper head alignment.Complete with: -- 5" Dust outlet and built-in mobile base for ease of movement

Call for Price

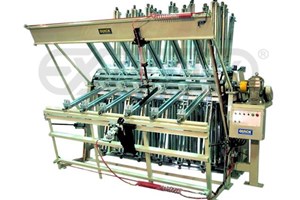

QUICK 20 Section Automatic Clamp Carrier: -- Clamp Carrier: (20) Sections with 8-1/2' width cap., (6) heavy duty zinc plated clamps per section (120 clamps total), 32" opening on clamps (other lengths available). -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- For face gluing, Rocking Plates available as optional equipment. -- Equipped with: -- Fully Automatic Hydraulic Clamp Tightener with adjustable torque limiter, integral Pneumatic Panel Flatteners and Electric Motor Drive with fully Automatic Carrier Rotation Cycle. Two control panels maximize ease-of use. Rack and pinion carriage traverse system is solid and quietFeatures: -- The QUICK Automatic Clamp Carrier is the ideal labor-saving device for the high-production furniture or cabinet manufacturer. The Automatic Clamp Carrier cuts labor costs in half by allowing the Clamp Carrier operator to perform other tasks (such as applying glue to stock, etc.) while the machine automatically flattens panels, tightens clamps, rotates, and loosens clamps. -- After loading wood into a section of clamps, the operator presses the "Auto Tighten" button. The hydraulic Automatic Carriage then traverses from left to right, flattening panels and tightening clamps that it finds along the way. When the Carriage reaches the right end of its traverse, the machine performs an automatic rotation cycle, which brings the next section of clamps down to the operator’s position. The Carriage then traverses from right to left, loosening clamps that it finds along the way. -- The Fully Automatic Clamp Carrier can also be used in manual or semi-automatic modes, by pressing buttons on the Control Panels. -- Complete with & Includes: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: 20 Section machine can produce up to (500) panels per shift!

QUICK 14-Section Pneumatic Clamp Carrier with 16-1/2' width capacity and Glue applicatorWith (15) Standard zinc plated clamps per section (210 clamps total), 48" opening on clamps Standard Features include: Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment (2) Panel Flattener with easy to use controls.(2) Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time! Complete with:Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.14-Section Clamp will produce 300 panels

Call for Price

QUICK 40 Section Automatic Clamp Carrier: -- Clamp Carrier: (40) Sections with 8-1/2' width cap., (6) heavy duty zinc plated clamps per section (240 clamps total), 40" opening on clamps with quick adjustment (other lengths available). -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- For face gluing, Rocking Plates available as optional equipment. -- Equipped with: -- Fully Automatic Hydraulic Clamp Tightener with adjustable torque limiter, integral Hydraulic Panel Flatteners and Electric Motor Drive with fully Automatic Carrier Rotation Cycle. Two control panels maximize ease-of use. Rack and pinion carriage traverse system is solid and quietFeatures: -- The QUICK Automatic Clamp Carrier is the ideal labor-saving device for the high-production furniture or cabinet manufacturer. The Automatic Clamp Carrier cuts labor costs in half by allowing the Clamp Carrier operator to perform other tasks (such as applying glue to stock, etc.) while the machine automatically flattens panels, tightens clamps, rotates, and loosens clamps. -- After loading wood into a section of clamps, the operator presses the "Auto Tighten" button. The hydraulic Automatic Carriage then traverses from left to right, flattening panels and tightening clamps that it finds along the way. When the Carriage reaches the right end of its traverse, the machine performs an automatic rotation cycle, which brings the next section of clamps down to the operator’s position. The Carriage then traverses from right to left, loosening clamps that it finds along the way. -- The Fully Automatic Clamp Carrier can also be used in manual or semi-automatic modes, by pressing buttons on the Control Panels. -- Complete with & Includes: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.

QUICK 40 Section 10.5' Heavy Duty Hydraulic Clamp Carrier: -- Clamp Carrier: (40) Sections with 10-1/2' width cap., -- (10) heavy duty zinc plated clamps per section (400 clamps total), 40" opening on clamps with quick adjustment (other lengths available). -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- For face gluing, Rocking Plates available as optional equipment.Equipped with: -- (1) Hydraulic clamp tightener for 10.5' -- (1) Hydraulic clamp tightener 10.5' for second operator -- (1) Pneumatic Panel Flatteners for 10.5' wide -- (1) pneumatic panel fattener 10.5' wide for second operatior -- Electric Motor Drive with fully Automatic Carrier Rotation Cycle.Two control panels maximize ease-of use. Rack and pinion carriage traverse system is solid and quiet -- Complete with & Includes: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.Note: this machine has 2 hydraulic tightener and 2 Pneumatic panel flattener for (2) operator)If one operator is fine the machine price could be reduce by $3,600

QUICK 20" Wide Conveyorized Glue Applicator -- 20" Wide grooved rubber glue applicator roll with stainless steel doctor blade and glue reservoir. -- Features easy adjustment or removal of doctor blade, -- 18' Overall length, 8' infeed before the glue roller and 10' outfeed conveyor. Equipped with: -- Heavy Duty 0.25 HP motor drive for slat-type conveyor and glue roll, limit switch with wand for automatically stopping the slat bed conveyor when stock reaches the Clamp Carrier, adjustable safety slip clutch. Complete with: -- Foot levelers, -- Heavy Duty crossbars, chain guard, high-quality anti-stick urethane finish, and owner & operator's manuals.

QUICK 30-Section Heavy Duty Clamp Carrier with 12-1/2' width capacity -- With (9) Standard zinc plated clamps per section (270 clamps total), 32" opening on clamps.Standard Features include: -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Panel Flattener with easy-to-use controls -- Second Panel Flattener for the second operator -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger-activated tightener is more confidence-inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate the need for manual adjustment of rear clamp jaws. -- Second pneumatic Clamp tightener for the second operator -- Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes the entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly Every time!Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high-quality urethane finish coating, and toolbox with spare parts & tools.

QUICK 6-Section Pneumatic Clamp Carrier with 20-1/2' width cap. & Dual Operator's Stations, -- (16) Heavy Duty zinc plated clamps per section (96) clamps total), 50" opening on clamps. Jaw sizes of clamps is 3-1/2" high x 4-3/4" wide, with 1° inward draft. Equipped with DUAL OPERATOR'S STATIONS including: -- (2) Pneumatic overhead panel flatteners, -- (2) Pneumatic clamp tighteners -- Semi-automatic rotation via electric motor drive; with separate buttons for Front Rest Out, Rotate Reverse, Rotate Forward, and Front Rest In.Standard Supply includes: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high-quality urethane finish coating, and toolbox with spare parts & tools.

QUICK 20 Section 16.5' Heavy Duty Clamp Carrier Specifications: -- 20-Section Thick Stock Pneumatic Clamp Carrier; 16-1/2' width cap.; -- (12) Clamps, each with 3 1/2" high jaws and 44" clamp opening for a total of (240) clamps. -- All clamps are heavy duty type; zinc plated and with 1° inward draftEquipped with: -- Dual operator package with (2) pneumatic overhead panel flatteners, -- (2) Pneumatic clamp tighteners. -- Semi-automatic rotation via electric motor drive and separate buttons for Front Rest Out, Rotate Reverse, Rotate Forward and Front Rest In.Standard features: -- Heavy-duty thick stock frame with 3" dia. shafts and 6" I-beam legs; -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high-quality urethane finish coating, and toolbox with maintenance tools.

QUICK F-CGAP-20-11-17 20" Wide Conveyorized Glue Applicator -- 20" Conveyorized Glue Applicator, 20" wide grooved rubber glue applicator roll and holddown roller with stainless steel doctor blade and glue reservoir.Features: -- Easy adjustment or removal of doctor blade, 30' overall length. -- 11' Infeed before the glue roller . -- 17' Outfeed conveyor. Equipped with: -- Heavy Duty 0.25 HP motor drive for slat-type conveyor and glue roll, limit switch with wand for automatically stopping the slat bed conveyor when stock reaches the Clamp Carrier, adjustable safety slip clutch. Complete with: -- Foot levelers. -- Heavy Duty crossbars. -- Chain guard, high quality anti-stick Urethane finish. -- Owner & operator's manuals.OPTION:Hold Down roll for face gluing 20" wide: $ 700 additional

QUICK 20 Section Heavy Duty Pneumatic Clamp Carrier: -- Clamp Carrier: (20) Sections with 8-1/2' width cap., (6) heavy duty zinc plated clamps per section (120 clamps total), 44" opening on clamps (other lengths available). -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- For face gluing, Rocking Plates available as optional equipment. -- Equipped with: Panel Flattener with easy to use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation: Push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time! -- Complete with & Includes: Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: 20 Section machine can produce up to (500) panels per shift!

Call for Price

QUICK '6-SECTION HEAVY DUTY-P CLAMP CARRIER (Pneumatic). -- Overall Data: Heavy Duty 16.5' wide (16.5' maximum stock length capacity), 6-section Thick Stock Pneumatic Clamp Carrier with (72) 3.5" high, 40" opening clamps; (12) clamps per section. -- Includes: Pneumatic Clamp Tightener, Pneumatic Panel Flattener, Electric Motor Drive with Automatic Rotation Cycle. -- Major Parts & Components list as follows:Qty Part# Description Each Total (1) A-CCFP-16.5-06 CC Frame Pneumatic, 16.5' wide, 6 Sect. $9,900.00 $9,900.00(72) B-CLMP-3.5-40 Clamp, 3.5" high jaw, 40" opening 82.00 5,904.00(1) C-PCT1-16.5-06 Pneumatic Clamp Tightener, 16.5' wide, for 6-sect. CC 4,450.00 4,450.00(1) D-PPF1-16.5 Pneumatic Panel Flattener, 16.5' wide 2,200.00 2,200.00 (1) E-EMDR-06-16.5 Electric Motor Drive for 6 Sect. CC, 16.5' wide, #135 2,450.00 2,450.00 TOTAL ..................................................................................................................................... $ 24,904.00.OPTIONAL(24) B-CLMP-3.5-40 Clamp, 3.5" high jaw, 40" opening 82.00 $1,968.00 -- Note: Lead time is about (8 - 10) weeks.

QUICK CRFT-08 Clamp Rack The QUICK Clamp Rack’s moderate cost, ultra high-quality clamps, super-strong frame and efficient use of floor space makes it the ideal gluing station for the small to mid-sized cabinet shop, furniture manufacturer or millwork producer.Includes: -- 8' width capacity, 6-row (3 rows on each side) Clamp Rack with (16) heavy-duty, zinc-plated, hand-tightened clamps. Clamps are 40" opening (32" opening is available), with 3.5" high x 4.75" wide jaws, with 1° inward draft.Standard Features: -- Standard features include super heavy-duty frame with 4" x 4" structural tubing cross beams, 4" x 6" structural tubing legs, and 4" x 4" structural tubing feet. -- Two-position feet can be configured for one-sided or two-sided Rack operation. -- All tubing ends are angled and/or closed for maximum strength and proper aesthetics. -- High-quality urethane finish. -- Clamps are exceptionally heavy-duty, with full box frame construction, and feature quick-release rear jaws and long, smooth handles for maximum ease-of-use.

QUICK CRFR-12 Panel and Door ClampThe QUICK Clamp Rack’s moderate cost, ultra high-quality clamps, super-strong frame and efficient use of floor space makes it the ideal gluing station for the small to mid-sized cabinet shop, furniture manufacturer or millwork producer.Includes: -- 12' width capacity, 6-row (3 rows on each side) Clamp Rack with (24) heavy-duty, zinc-plated, hand-tightened clamps. -- Clamps are 40" opening (32" opening is available), with 3.5" high x 4.75" wide jaws, with 1° inward draft.Standard Features: -- Standard features include a super heavy-duty frame with 4" x 4" structural tubing cross beams, 4" x 6" structural tubing legs, and 4" x 4" structural tubing feet. -- Two-position feet can be configured for one-sided or two-sided Rack operation. -- All tubing ends are angled and/or closed for maximum strength and proper aesthetics. -- High-quality urethane finish. -- Clamps are exceptionally heavy-duty, with full box frame construction, and feature quick-release rear jaws and long, smooth handles for maximum ease of use.

QUICK F-TTGQA-12 Glue Spreader Table top unit for glue applications on a smaller scale.Equipped with: -- 1/4 HP Motorized 60 RPM steel roller and an approximately (2) quart capacity stainless steel reservoir; both easily removable for clean up. -- Spread roller, rubber grooved - roller dimension 12" X 6"; speed of roller 92 FPM. -- Table top dimension: approximately 2' X 3'. Options: To keep the glue fresh and from cleaning the reservoir daily (1) F-TTGA-COVER-12 Stainless Steel Cover for TTGA, 12" wide, please add ...$195.00.

QUICK R-RCGS-1-24-6 TOP GLUE SPREADER with 6" MAXIMUM OPENING. Features: -- Grooved rubber covered glue rollers are acid and heat resistant. -- Easy to clean, 5-7/8" chrome plated doctor roller. -- Comes standard with a fixed 64 FPM feed rate. -- Variable speed drive of 40 to 118 FPM is optional - ADD ...$1,090 -- Durable chain drive provides years of trouble-free operation. -- Simple to access handwheels allow the operator to make quick adjustments when panel thicknesses change. -- Complete with: Safety stop bars and roll guard hood, all-aluminum drip pan catches clean-up water.Specifications: -- 1-Sided Roller Coater (applies glue to top side of board or panel. -- Working thickness: Adjustable from 0 to 152 mm (0 to 6"); adjustable via handwheel. -- Maximum material width: 630 mm (24"). -- Application rolls quantity: 1. -- Application rolls material: SBR rubber, 60 durometer (Shore A). -- Application rolls diameter: 205 mm (8"). -- Application rolls grooving: (20) Grooves per inch. -- Doctor rolls quantity: 1. -- Doctor rolls material: Chrome-plated steel. -- Doctor rolls diameter: 148 mm (5.8"). -- Doctor rolls grooving: None (smooth rolls). -- Drive motor power: 1.5 kW (2 HP). -- Feed rate: Fixed at 64 FPM (optional: adjustable speed from 40 to 118 FPM; ADD ...$1,090) -- Includes emergency stop bars at front and back of the machine. -- Includes stainless steel waste glue drip pan. -- Includes Roll Guard's / Hoods

Call for Price

QUICK MODEL R-RCGS-1-36-6 TOP GLUE SPREADER with 6" MAXIMUM OPENING -- Features: -- Grooved rubber covered glue rollers are acid and heat resistant. . -- Easy to clean, 5-7/8" chrome plated doctor roller. -- Comes standard with a fixed 64 FPM feed rate. -- Variable speed drive of 40 to 118 FPM is optional - ADD $900 -- Durable chain drive gives years of trouble-free operation. -- Simple to access handwheels allow the operator to make quick adjustments when panel thicknesses change. -- Complete with: Safety stop bars and roll guard hood, all aluminum drip pan catches clean-up water. -- Specifications: -- 1-Sided Roller Coater (applies glue to top side of board or panel. -- Working thickness: Adjustable from 0 to 152 mm (0 to 6"); adjustable via hand wheel. -- Maximum material width: 630 mm (24"). -- Application rolls quantity: 1. -- Application rolls material: SBR rubber, 60 durometer (Shore A). -- Application rolls diameter: 205 mm (8"). -- Application rolls grooving: (20) Grooves per inch. -- Doctor rolls quantity: 1. -- Doctor rolls material: Chrome-plated steel. -- Doctor rolls diameter: 148 mm (5.8"). -- Doctor rolls grooving: None (smooth rolls). -- Drive motor power: 1.5 kW (2 HP). -- Feed rate: Fixed at 64 FPM (optional: adjustable speed from 40 to 118 FPM; ADD $900.00) -- Includes emergency stop bars at front and back of machine. -- Includes stainless steel waste glue drip pan.

QUICK R-RCGS-1-24 Top Roll Glue SpreaderGrooved rubber covered applicator roller is acid and heat resistant. -- Easy to clean, 5-7/8" chrome plated doctor roller. -- Comes standard with a fixed 80 FPM feed rate. -- Durable chain drive gives years of trouble-free operation. -- Simple to access handwheels allow the operator to make quick adjustments when panel thicknesses change. -- Complete with: Safety stop bars and roll guard hood, stainless steel drip pan catches clean-up water. -- Variable speed drive of 40 to 118 FPM is optional

Grooved rubber covered glue rollers are SBR / acid and heat resistant. -- Easy to clean, 6-7/8" hardened rubber doctor roller. -- Comes standard with a fixed 80 FPM feed rate. -- Durable chain drive gives years of trouble-free operation. -- Simple to access handwheels allow the operator to make quick adjustments when panel thicknesses changes up to a 1-3/4" opening. -- Complete with: Safety stop bars and roll guard hood, all aluminum drip pan catches clean-up water. -- Also Avalable with: -- 17" Wide -- 24" Wide -- 36" Wide. -- 48" Wide. -- Variable speed drive of 40 to 118 FPM. -- 6" or more Opening.

QUICK R-RCGS-1-63 Top Only Glue SpreaderTop only rubber covered glue rollers are SBR 60 durometer / acid and heat resistant.Features: -- Working thickness adjustable from 0 - 45 mm (0" to 1.77") via hand wheel -- Maximum working width: 1,600 mm (63") -- Application rolls diameter 210 mm (8.27") with 20 grooves per inch -- Doctor roll NBR rubber 175 mm diam. (6.9") with 98 durometer -- Easy to clean, 6-7/8" hardened rubber doctor roller. -- Variable speed feed 40 to 118'/min. (Optional) -- Durable chain drive gives years of trouble-free operation. -- Simple to access handwheels allow the operator to may quick adjustments when panel thicknesses change. Complete with: -- Safety stop bars in front and rear of the machine -- Roll guard hood, -- Stainless drip pan catches clean-up water.