704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

2035 Results Found

704-841-2001

EMC EXPLORER 1100 2RK ... Wide Belt Sander with (2) Sanding Heads; Roller and Combination head roller/pad.Versatile, medium duty machine, ideal for cabinet shops etc.TECHNICAL DATA: -- Useful working width 1,100 mm (43"). -- Working thickness min./max. mm 3 - 170 (1/8" - 6-11/16"). -- Abrasive belt dimension (length) 1,900 mm (75") x (width) 1,120 mm (44"). -- Feed belt speeds adjustable by electronic inverter from 3 to 17 m/Min (10 - 55 FPM). Head configuration:1st Head: Steel Contact Roller -- Roller diameter 142 mm (6") -- Automatic abrasive belt grit compensation with "Grit-Set System". -- On/Off Selector control with pneumatic piston to select roller. -- Motor power 11 kW (15 HP). -- Automatic Star-delta starter. -- Speed rotation: 18 m/Sec (59 FPS).2nd Head: Combination Roller & Pad. -- Roller diameter 142 mm (6"). -- Rubber covered roller with hardness 45 Shore. -- Automatic abrasive belt grit compensation with "Grit-Set System". -- On/Off Selector control with pneumatic piston to select roller. Flexible sanding pad. Quick Change System for removable pad with felt, rubber and graphite. Rotating cutting speed 17 m/Sec (55.8 FPS). --Driven by same main motor.Abrasive belts oscillation by means of electronic photocell sensor.Feed System: -- Working thickness min./max. mm 3 - 190 (1/8" - 7-1/2"). -- Motorized table lifting including fine adjustment, on 4 precision screws. Natural rubber conveyor belt, machined. Automatic feed belt centering device. Electronic digital display for working thickness; resolution 0.1 mm (0.004"). -- Feed belt speeds adjustable by electronic inverter from 3 to 17 m/Min (10 - 55 FPM). Centralized Control Cabinet: -- Control panel with self-diagnostics alarm control unit. -- Analog load meters on main control cabinet. -- Table lifting-lowering thickness system, electrically controlled. -- AUTOMATIC Delta - Star starter on main motor and IP 54 protection against dust & moisture. Centralized Independent Pneumatic Control Cabinet: -- Pneumatic air filter with automatic water-drain system. -- Pneumatic adjustment for "Grit set system". --Pneumatic plant working without lubrication. Compressed air pressure 6 bar (85 PSI). IP 54 protection against dust & moisture. Safety Features: -- Anti-kickback infeed protection. -- Oversized parts infeed protection by swinging bar. -- Emergency push buttons front & rear. --Automatic brakes on main motor. -- Automatic emergency stop and alarm displayOption: TAMPICO Cleaning Brush, 150 mm (6") diameter. Please add ...$3,400USA UL or Canada CSA Safety Features

Call for Price

EMC MERCURY 1350 2RK ... Wide Belt Sander with (2) Sanding Heads; Roller and Combination head roller/pneumatic pad.Versatile, medium duty machine, ideal for cabinet shops etc.TECHNICAL DATA: -- Useful working width 1,350 mm (53"). -- Working thickness min./max. mm 3 - 170 (1/8" - 6-11/16"). -- Abrasive belt dimension (length) 2,200 mm (86-5/8") x (width) 1,320 mm (52"). -- Feed belt speeds adjustable by electronic inverter from 3 to 19 m/Min (10 - 62 FPM). Head configuration:1st Head: Steel Contact Roller -- Roller diameter 180 mm (7"), spirally grooved. -- Automatic abrasive belt grit compensation with "Grit-Set System". -- Motor power 11 kW (15 HP) driving both heads, with soft starter. -- On/Off Selector control with pneumatic piston to select roller. -- Automatic Star-delta starter. -- Speed rotation: 18 m/Sec (59 FPS).2nd Head: Combination Roller & Pad. -- Roller diameter 140 mm (5-1/2"). -- Rubber covered roller with hardness 45 Shore. -- Automatic abrasive belt grit compensation with "Grit-Set System". -- On/Off Selector control with pneumatic piston to select roller. -- New pneumatic aluminium sanding pad, lamina 40 mm. With On/Off selector. -- Quick Change System for removable pad with felt, rubber and graphite. -- Rotating cutting speed 18 m/Sec (59 FPS). -- Driven by same main motor, with soft starter.Abrasive belts oscillation by means of electronic photocell sensor.Feed System: -- Working thickness min./max. mm 3 - 170 (1/8" - 6-11/16"). -- Motorized table lifting including fine adjustment, on 4 precision screws. Natural rubber conveyor belt, machined. Automatic feed belt centering device. Electronic digital display for working thickness; resolution 0.1 mm (0.004"). -- Feed belt speeds adjustable by electronic inverter from 3 to 19 m/Min (10 - 62 FPM). -- Table rollers. Extension supports with idle rollers in infeed & outfeed.Centralized Control Cabinet: -- Control panel with self-diagnostics alarm control unit. -- Analog load meter on main control cabinet. -- Table lifting-lowering thickness system, electrically controlled. -- AUTOMATIC Delta - Star starter on main motor and IP 54 protection against dust & moisture. Centralized Independent Pneumatic Control Cabinet: -- Pneumatic air filter with automatic water-drain system. -- Pneumatic adjustment for "Grit set system". -- Pneumatic plant working without lubrication. Compressed air pressure 6 bar (85 PSI). IP 54 protection against dust & moisture. Safety Features: -- Anti-kickback infeed protection. -- Oversized parts infeed protection by swinging bar. -- Emergency push buttons front & rear. --Automatic brake on main motor. -- Automatic emergency stop and alarm displayUSA UL or Canada CSA Safety Features

Call for Price

EMG SEMI-AUTOMATIC Twin Stair Trencher; 2" x 12" Max. stringer size, semi-automatic operation. The feed/indexing of boards is automated and the routers are moved manually for the stair cuts.Specifications: -- (2) 3 HP Belted motors to "top & bottom" 18,000 RPM spindles, 1-1/2" depth of plunge cut, T & B heads are arranged to advance in-and-out to facilitate open plain stairs. -- Pneumatic advance and twin table clamps each rated at over 2,000 Lbs.Features: -- Any rise and run, whether straight or tapered, can be achieved in just a few minutes of setup. Includes: -- Overload protection with on-control resets, individually timed motor startup with adjustable 2nd delay.NOTE: Available with CNC fully automatic operation. the top automated section is a bolt-on to the base of the semi-auto frame. Please ask for a Quote.

Call for Price

3" Min. & 16" max. wedge length, taper from 1/2" to 2" thickness, mixed in hopper, angle & width of wedge is fully adjustable with one face at 90°. -- Equipped with: 10" Dia. saw blade with 2 HP direct drive motor, hopper feeds material up to 16" long with a width up to 8"; air operated with 6 CFM compressed air requirement, 1.8 Sec/stroke, 4-3/4" dust outlet. -- Features: Walk away, "hands free" operation. Auto-shutoff feature and capability to cut glue blocks. -- Complete with: Self-diagnostics, built-in starter, automatic shutoff feature, air filter & lubricator.

Call for Price

ENCORE - EP-100: Portable Tire BalerSpecifications -- Bale chamber: 60" x 30". -- Cylinder size: 6" (2-Cylinder). -- Cycle time: Under 30 Sec. -- Passenger tire processing time: 400 per Hour. -- Type of trailer: Gooseneck. -- Number of retainer dogs: 10.Equipped with: -- KABOTA Diesel Engine.

Call for Price

Plant Boiler System for up to 60,000 pounds of steam production per hour (1790 HP) with the following features and main components: -- (2) ENGLISH BOILER AND TUBE, INC. Boilers each rated for 20,700 pounds of steam per hour each. However, manufacturer specified they can be operated at 30,000 pounds per hour with dry wood or bark fuel (12 percent moisture). -- 250 PSI operating pressure ratings on each Boiler. -- VFD Drives on all main Motors. (The plant uses a maximum 75 HP for each boiler.) -- Electrical Controls. -- (1) Boiler has an Oil Burner for operating optionally on oil if sawdust or wood chips is not available. -- Chemical Water Conditioning System and Pumping System. -- De-aerator and Condensate Tank. -- Multi-clones for particle emissions reduction and abatement. -- (2) Fuel Storage Silos (25’x40’ & 20’x38’) with LAIDIG Model 243 Track-Driven Unloaders. -- Fuel Transfer Conveyors. -- The Silos also are included at the price shown and are available individually. See our listings DB-010162 and DB-010163 for details and individual pricing. -- Boilers can be purchased individually or as a pair. -- Professional removal and installation services are available.

Call for Price

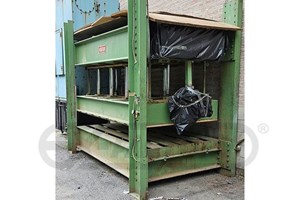

ENTERPRISE - 1616 2-RAM: Horizontal Baler -- 300 HP. -- Overall length: 34'-7" x Width 17'-3". -- Charging chamber: 28" D x 60" W x 110" L. -- Approx. bale size: 31" x 45" x 62".

$37,500

Heesemann MFA6 (3) Head Wide Belt Sander, 53" width cap. Drum Drum, Segmented platenHead configuration1st Head: Steel contact roll, 30 HP motor2nd Head: Rubber covered contact roll, 20 HP motor3rd Head: Segmented polishing platen, electronically controlled segments to conform to panel size, 20 HP motor4th Station: Outfeed rotary panel cleaning brush, 2 HP motor.Specifications -- Platen head equipped with: HESSEMANN's Patented "CSD-32" selective pressure adjustment system; sensors placed every (32 mm) sense part configuration, pressure for each segment can be pre-programmed to provide less pressure on the outer edges or more in the center if desired. -- Both contact rolls with NC positioning and auto grit compensation, automatic line control for platen independent of feed speed determines automatically the correct part in time for the pressure segmentEquipped with & Features -- Outfeed rotary panel cleaning brush, 2 HP motor. -- 55" x 103" Abrasive belts on all heads with abrasive belt air cleaners, "ICP" control for all sander functions, (20) programs storrage. -- Variable feed speed from 10 - 49 FPM, 3 HP feed drive with inverter control. -- Vacuum conveyor bed assembly with suction fan and )motor mounted in machine base, motorized thickness opening 0" - 5-7/8" w/digital readout, constant passline of conveyor bed assembly 35" height.NOTE Some Spec's need to Varified

$55,000

HEESEMANN LSM-8/3-OSR Wide Belt Finishing Sander, 52" and (3) Heads; Equipped with: (1) longitudinal segmented platen head. and (2) Orbital Platens -- 1st Head: Longitudinal segmented platen head. Segmented Polishing Platen, 20 & 27 HP dual speed motor. electronically controlled segments to conform to panel size,.2620 x 1350 mm (91.4 x 53.2") Sanding belt. - Equipped with HEESEMANN's patented "CSD" selective pressure adjustment system, sensors placed every 16 mm (5/8") sense part configuration; pressure for each segment, to eliminate sand through, can be pre-programmed to provide less pressure on the outer edges or more in the center if desired. The "CSD" computer control will hold a maximum of (20) programs. -- 2nd & 3rd Heads: OSR Dual orbital action head with (1) high-speed orbit on sanding pad, powered by 3 kW (4.5 HP) motor.Secondary oscillation movement of platens powered by 1.5 HP motor. Upstream and downstream vacuum chutes on each head for dust localized dust pickup.- Platens feature "quick change" abrasive material; Both orbital heads with variable speed inverter drives. -- Outfeed Rotary Brush with cleaning brush loading with single end adjustment , 6" max. dia., 3.4 HP motor. -- Variable feed speed from 13 to 82 FPM, 6.5 HP feed drive. -- Infeed and outfeed Ssissor Lift and Control box shown are not included. -- Motorized thickness opening 1/4" to 3-5/32" max. - -- Power Consumption: 63 KW, 75 Amps. -- Separate display console for CSD control.

$14,500

HEESEMANN MFA-8 D Wide Belt Sander (4) Heads; 53" Width cap. Veneer/ Sealer Sanding Wide Belt.Great Lacquer/Sealer sander with: (2) Segmented polishing platen, (2) Orbital heads, (1) De-nibbing/Polishing brush.Head Configuration: Head 1: Segmented polishing platen, 5/8 wide segments CSD Control, Variable speed abrasive belt with inverter RPM control, 15HP motorHead 2: Segmented polishing platen, 5/8 wide segments CSD Control, Variable speed abrasive belt with inverter RPM control, 15HP motorHead 3: Orbital head with composite/dense fiber loading; 5HP motorHead 4: Orbital head with composite/dense fiber loading: 5HP motor(1) Brush Type head for de- nibbing and polishingSpecifications: -- LCD monitor with graphic display and key pad entry, 20 program capacity, -- Pressure for each segment can be pre-programmed to provide less pressure on the outer edges or more in the center if required.Equipped with & Features -- Air blast abrasive belt cleaner on heads 1 & 2. -- Variable feed speed from 10 to 49 FPM via 2 HP feed drive. -- Motorized thickness opening 1/4" to 3-5/32" max. -- Rubber covered Infeed and out feed holddown rolls.

--AT AUCTION-- HEESEMANN KSA 8 CSD 80" Lacquer/Sealer Sander This is a Very Special "extra wide" HEESEMANN equipped with: HEESEMANN's patented "CSD" selective pressure adjustment system, sensors placed every 5/8" (16 mm) sense part configuration; pressure for each segment can be preprogrammed to provide less pressure on the outer edges, or more in the center if desired. The "CSD" computer control will hold a max. of (20) programs. Equipped with: Segmented Polishing Platen: Segments are computer controlled to conform to irregular shaped panels; sanding pressure on panel edges is adjustable. Platen will accept panel thickness variation up to 5/64" (2 mm). Dual speed motor: 26 & 31 kW (35 & 42 HP); abrasive belt speed: 10 + 20 MPS (33 + 66 FPM); abrasive belt size: 2,050 mm x 3,250 mm (80.7" x 128"); pneumatic air tension and tracking control. 250 mm Dia. Rotary Panel Cleaning Brush, 5 HP motor, 150 mm Outfeed Rotary Panel Cleaning Brush, and 2 HP motor. Additional Features: Vacuum bed assembly to ensure flatness of parts and feeding of small parts. Computer control and monitor, light indication of panel movement; electronic abrasive belt tracking. Feed System: Variable feed speed from 5 - 15 MPM (16 - 49 FPM); 4 kW (5 HP) feed motor; motorized thickness opening. NOTE: This Sander had a "Brand New" ...$ 17,000 display/control installed shortly before it was taken out of service in 2016. The machine has been in storage since that time.

$90,000

HEESEMANN - LSM 8-5 RRRL, ...53" Wide Belt Sander53" Width cap.: Drum, Drum, Drum, and CSD® Pad.Head Configuration:• Unit 1 - Longitudinal Sanding Unit: Steel contact roller, helically grooved. - Single-speed 48 HP motor, electronic braking.• Unit 2 - Longitudinal Sanding Unit: Rubber-covered contact roller, helically grooved. - Single-speed 35 HP motor, electronic braking.• Unit 3 - Longitudinal Sanding Unit:- Rubber-covered contact roller, helically grooved. - Single-speed 35 HP motor, electronic braking, bi-directional drive.• Unit 4 - Longitudinal Sanding Unit: CSD® Segmented pad system, 2-speed 20/26 HP motor, electronic braking.• Unit 5 - Panel Cleaning Brush: Fiber trimming, 2.3 HP Motor.Specifications: -- Working height: 880 mm (34.64"). -- Workpiece thickness: 3 mm to 150 mm (1/8" to 6"). -- Working width: 1,300 mm (51-1/8"). -- Longitudinal belt: 1,350 x 2,620 mm (53" x 103"). -- Machine voltage: U.S. Electrics 480 Volts, 3-Phase, 60 cycles.Constant Pass LineController: -- Industrial PC. -- TFT Color touchscreen. -- Windows® Operating System. -- (100) Memory addresses for: • CSD® sanding pressure. • Sanding start/stop. • Sanding belt speeds. • Grit sequence indication. • Sanding belt selection - "ON/OFF". • 1-Button sequenced starting for all motors.RS-232 Serial port.RJ-45 LAN Port.Modem with software licenses.For All additional, detailed specs, select the "View Literature" link .

Call for Price

54" 3-Head Orbital Sander, For abrasive belt cross-grain scratch removal with (3) Orbital Platen Heads & (1) Rotary Brush Head Configuration: 1st, 2nd, & 3rd Heads: Each with 5" W Platen, Dual orbital action, High-speed orbit on sanding pad with 3 kW (4 HP) Motor, Secondary oscillation with 1-1/2 HP Motor, "Quick-change" abrasive material, Inverter drive; Rotary Brush: 6" Maximum diameter, 3-1/2 HP Motor, Brush loading, Ionization bar for final fine dust collection Vacuum conveyor bed with 10 HP Blower motor, Inverter-controlled variable speed drive with 4 HP Motor & Variable feed speeds 15 - 66 FPM, Automatic conveyor belt tracking, Automatic parts thickness, with 1/8" - 4-5/8" Thickness range & Programmable height adjustment, (4) Screw jacks PC-based control, Windows XP, Touchscreen monitor, Infeed & outfeed spring-loaded hold-down rolls, Infeed hand safety stop, outfeed emergency stop, Digital motor load meters, High-efficiency dust extraction NOTE: Machine is currently in storage.

$39,700

HEIAN FP-151-MC-2113 5-Axis CNC MachineFor high speed & precision routing/trimming & sizing wood and composite parts.Equipped With: -- (2100 mm) x (1,300 mm), moving table, fixed bridge style machining center; mahogany vacuum table. -- 3.7 kW, NT 30 Type ATC spindle, variable speed from 2,000 - 18,000 RPM with 8-position tool carousel. -- FANUC "16i CNC Control, 10.4" LCD , RS-232C/PCMCIA (memory card). Features: -- 5-Axis simultaneous motion, M & G code programming, inch or metric operation. -- Working Axes Stroke & Speed: X-Axis (2,600 mm) 60 m/Min; Y-axis (1,600 mm) 40 m/Mn; Z-axis (800 mm) 20 m/Min -- C-axis +/- 270°; B-axis +/- 110°; C-axis travels at 4,000°/Min and B travels at 4,000°/Min. -- Complete with assorted tool holders.

HENDRICK - PRO-V MP3: Automatic Vertical Panel SawSpecifications & Features -- 126" Cutting length (cuts vertically top to bottom); adjustable depth of cut up to 2-3/8"; 14" blade dia. with: 1" Dia. bore; single blade scoring; 7.5 HP main motor. -- Equipped with: -- Heavy-Duty precision machined squaring fence; Formica laminated back table surface; full length pneumatic holddown bar with: Sensitive safety tape on both sides of holddown; 1 HP drive; 2-speed automatic saw carriage; travels 30 & 60 FPM (saw travel/return adj. to cut length). -- Complete with: -- (5) Adjustable flip stops on: (3) Positioning bars; ready for Dust Collector hookup. Actual model: Pro-V MP3 - Specifications subject to verifications.

$32,500

HMC 2-Saw Trimmer Model ET-10,;Complete with the following features: --16′ capacity. --Push Button Setworks. --Left hand (feeds from left to right). --Cuts up to 8″ thick. --Belt Conveyor for waste.NOTE: Removed from service and it was running just fine at the time of removal. Stored outside.

Call for Price

HOCKER POLYTECHNIK - MultiStar Series: Pulse Jet Baghouse 33,000 CFM (56,000 cbm/Hr) based on 5.2 to 1 Air-to-cloth ratio (FPM: Average air velocity thru filter media) with: 6,345 Square feet of filter area. -- Filtration: Filters are automatically cleaned by Pulse-Jet system based on supply of: 1" Dia. dried clean compressed air line from Plant. Cleaning automatically controlled via timed cycles or by the Delta P, which is the differential pressure across the filter bags. -- Supplied with: (4) HOCKER DER - 040/45022 Radial BI fan; each directly driven by: 30 HP - TEFC 3,600 RPM High efficiency motors; mounted on the clean air side. Rated for a total of: 33,000 CFM at 16" SP (4,000 Pa). Fan inlets are: 18" (450 mm) Dia. each. Non-return flap camper on the outlet side. -- Includes Electrical panel with: PLC Controls; explosion relief panels; sprinkler heads in the clean air plenum; ATEX approved construction with 11-gauge electroplated galvanized steel shell with: Clean air outlet not returned to plant. -- Equipped with: (1) HP Rotary Air Lock. -- Control - SIEMENS - SIMATIC TPI200. PLC Controller housed in a floor-mounted central control panel with: Modem module for allowing HOCKER online access to assist in program changes; 12" TFT color, touchscreen display.All starters & contacts for included motors.Pictorial guided navigation and fault messages are displayed in text.Graphic images, curves, bar diagrams, parameter adjustment settings, and fault report.FI MF 22.0 kW SPS Ctrl.: Allows startup of several fans, one after the other. -- VFD Drives on each motor with: Automatic motor tuning; automatic startup; min./max. speed limits; DC brakes; operating hours meter. -- Includes: Access ladder to upper catwalk and exterior pipe; Heavy-Duty galvanized for outdoor operation. -- Professional dismantling & transportation available upon request.

Call for Price

HOFER HOP 160 K Hydraulic Door/Veneer Heavy Duty Cold PressSpecifications:Platen size 63" deep x 98" long, Total Daylight/Opening 32".available. Currently set at about 13" opening. Top platen is hydraulically powered by a 2.2 KW power pack. and has (10 sets) of bolt holes for manual adjustment of daylight opening.Equipped with:(8) 3-1/4" Diameter Hydraulic cylinders, Rack & pinion platen leveling adjustment.Front and back loading (access on all sides).Heavy duty steel structural beams. Bolted top and bottom platens.Features:Pneumatically loaded 3 +1 rows of idle rollers on bottom platen for ease of feeding the load in and out front of press. Air valve for up/down selection of bottom platen rollers.Hydraulic closing speed adjustment.Electrical controls on right hand side.Dimensions/Weight: 124" x 72" x 122" H. Approx. 12,000 Lbs.

Call for Price

HOFFMANN PU 2 DOVETAIL ROUTER (SINGLE SPINDLE) Pneumatic Dovetail Routing Machine - Dovetail routing machine for use with HOFFMAN dovetail butterfly connectors. - Maximum routing height 4", Max. workpiece height 5-3/4" - Table size 15-1/2” x 27-1/2” x 36-1/2” H - Production speed: Approx. 16 SPM (2 Complete rectangular frames) - (1) HOFFMANN "UAD 33 F" 33,000 RPM 1,000 W Router motor - 45° Fence, Accurately positions material with guide in table keyway, Quick adjustments made by adjusting fence plate - Pneumatic hold-down, Pneumatic foot pedal Includes: - Extra HOFFMANN "UAD 33 F" 33,000 RPM 1000 W Router Motor - 2007 HOFFMANN "FM1000" 35,000 RPM 1,000 W Router Motor - (2) 16” x 48” x 35” H Left-Hand & Right-Hand Aluminum Frame Tables, with 3/4” Thick Top, & 2” x 2” Aluminum frame - Palletized Dimensions: 42” x 42” x 60” H

HOLYTEK - YRT 100: Round End Tenoner -- Twin positioning tables with: Traversing single cutterhead design; fully automatic work cycle; tables alternate into the cutting cycle for continuous operation; rotational movement of cutterhead is externally adjusted. Capacity: -- Width of tenon: 0" - 3.9" Plus both radii; thickness of tenon: 1/8" - 1-3/16"; depth of tenon: 3/8" - 1-3/4"; 1/4" - 3-1/2" with special tooling. Specifications: -- Belt driven cutterhead, 3 HP - 6,000 RPM spindle; 1 HP motor with variable rotational movement of cutterhead; straight, simple or compound angles are easily adjusted with tables. -- (2) 14" x 9" Tilting tables: 0° - 15° Up, 0° - 30° down, and 0° - 20° to the side; each table with: Pivoting fences & miter gauges, vertical height adjustment. -- Overhead pneumatic holddowns. -- Production rate approx.: (13) Pieces per Min.