704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

2035 Results Found

704-841-2001

NORTHTECH NT-KL-43-RC Wide Belt Sander (2) Heads;43" width cap. Drum, Combination Head.Head Configuration:1st Head: Rubber-covered contact drum with 25 HP motor2nd Head: Combination head with a rubber-covered contact drum and 2-1/4" wide finishing platen, 20 HP motor.Specifications: -- Thickness opening with PLC control, (DP-525 controller) keypad entry automatically adjusts to any thickness with LED readout. -- 37" x 75" Abrasive belts, TRU-TRAK solid state abrasive belt tracking. -- Variable feed drive 13 - 49 FPM, 2 HP motor. -- Endless belt conveyor, infeed and outfeed rubber covered pinch rolls. -- Complete with: 0" - 6" Automatic part thickness set up.Equipped with & Features: -- Infeed and outfeed rubber covered spring loaded holddown rolls. -- Feed emergency stops at infeed. -- Disc brakes on sanding heads, electrical interlocks on main access doors, and motor load meters. -- Note: Year of manufacturing has to be verified.

NORTHTECH NT-EV-920RC Dual Head Wide Belt Sander2-Head Wide Belt Sanding Machine with 37" capacity. Specifications: -- First head 8-1/4" Dia. grooved rubber contact roll, with 20 HP motor. -- Second head: Combination finishing platen with grooved rubber roller and polishing pad, with 15 HP motor. -- Two (2) infeed and outfeed spring loaded holddown rollers; 2 HP variable speed feed drive. -- Sanding belt size: 37" X 85" and with electronic belt tracking. -- Motorized opening between conveyor bed and sanding heads. -- Ammeters for measuring motor loads. -- Includes spare abrasive belts.

NORTHTECH - SRS-12: Straight Line Rip-SawSpecifications --15 HP Motor; 1" dia. saw arbor; speed of 4,500 RPM, 8". -- Max. blade cap.: 12". -- Max. depth of cut: 3-5/16". -- Part length: 8" Min. -- Distance between saw & column: 18"; 60" W x 33" table. -- Feed & Chain: 2 HP Feed drive motor; variable feed speeds of: 59 - 72 - 91 - 111 & 137 FPM. -- 7" Wide double chain; with automatic chain lubrication.Equipped with & Feature: -- Top pressure system with: (6) Spring loaded holddown rollers. -- Double row antikickback fingers. -- Adjustable infeed fence. -- Safety side guard. -- 4" Dia. dust hood outlet. -- Push-button controls. -- Magnetic starters. - Overhead post for laser mounting.

NORTHTECH - NT-920C-200: 2-Head Planer Sander Specifications -- 2-Head. 37" width cap.; 1-knife planer head followed by a wide belt sander head. -- 0" - 6" Motorized opening with: PLC control; keypad entry; LED readout for part thickness. -- 1st Head. 6" Dia. helical planer head with: (6) Rows of staggered carbide inserts; each insert has (4) usable sides; 30 HP motor. -- 2nd Head. Combination sanding head with: 4-5/8" Dia. rubber covered contact roll; 2-1/2" wide finishing platen; 20 HP motor. -- 37" x 75" Abrasive sanding belt; solid-state belt tracking. -- 3 HP Variable feed drive from 15 - 50 FPM; endless belt conveyor with automatic tracking.Complete with: -- Infeed over thickness bar. -- Emergency stops at infeed & outfeed. -- Air-operated disc brakes on sanding heads. -- Electrical interlocks on main access doors. -- Electrical controls with overload protection. -- Motor load meters. -- Panel cleaning brush.

Call for Price

Rigid one piece welded steel frame, with 10 HP direct drive spindle motor at 7,800 RPM, 1-1/4" x 4-1/2" stackable multi-cutter spindle to mill stile, rail & raised panel profiles. -- Stackable cutter spindle with push button indexing to significantly reduce set-up time as each station is preset; the change from one cutter to another is achieved via a select switch for each operation. -- Complete with: X - Y Sliding table w/pneumatic holddown. -- 2-way linear movement for straight or arch top doors up to 50" long. -- 5" Dust collection hood, and cutter shield. -- Includes: (1) Cathedral arch templates, (1) complete set of tools.

NORTHTECH NT 1000-50HCVS Single-Sided 40" PlanerSpecifications: -- 40" Planer, 40 HP main motor, Helical Head, Adjustable bed rollers 15 mm x 15 mm x 2.5 mm Carbide Insert cutters. -- The spiral cutterhead provides a high chip removal rate, superior surface finish and low noise. -- Powerful 40 HP cutterhead motor makes this planer ideal for heavy-duty planing and meets high production requirements. -- Variable feed speed is mechanical variable from 0 - 90 FPM. -- Power elevation of the feed bed with "727 M Digital Table Adjustment" for fast accurate, and convenient thickness setting. -- Extra heavy rib reinforced cast iron table, surface precision ground. Equipped with: -- (4) Powered steel bed rollers. -- (4) Upper rollers. -- (2) Powered corrugated infeed rollers. -- (2) Powered urethane outfeed rollers. -- Upper and lower limit switches for opening control. -- (4) Dual 50 mm jack screws for raise/lower bed movement; 12" max opening. -- 2 HP Elevation motor with manual adjust. -- Rear E-Stop for added safety. -- Dual 6" dust ports requiring 1,000 CFM @ points of extraction.

$34,500

NORTHTECH NT-610EL Top & Bottom Planer:24" Wide x 7.5" thick capacity; 1/4" minimum thickness; 12" minimum stock length.Specifications: -- Cutterheads: 25 HP top head; 20 HP bottom head; 5,800 RPM on cutterheads; (6) row spiral insert cutterheads, Carbide knives 15 mm x 15 mm x 2.5 mm 4-sided -- Feed works: 3 HP variable speed feed with speeds from 20 to 75 FPM; 1 HP motorized raise and lower of bed; DP-525 digital thickness controller; Overhead carpet style feed system Equipped with & Features -- Sectional chip breaker; Hard chrome plated bed; Automatic lubrication for feed system; Amp load meter -- Dust Requirements: 3,800 CFM; (1)10" and (1) 7" dust outlet Seller states this machine has less than 600 Hours of use.

Call for Price

NORTHWOOD NW-105 NT 5' x 10' CNC Router, with ATC, Boring – 4,535 Hrs. only!IMPORTANT BIDDING NOTE: This lot is also part of Lot #003, which is a bulk lot consisting of Lots #003A & #003B. If the individual bid amounts for Lots #003A & #003B total more than the bulk bid amount for Lot #003, then Lots #003A & #003B will be awarded to the high bidder of each lot.Specifications: -- Table size 60" x 120" x 34" H, with Table thickness 1-1/2". -- Positioning speed 2,500 IPM.Equipped with: -- Moving cast-aluminum single-zone vacuum table, with Front-to-back configuration & (3) Pop-up location pins. -- HSD "ES 619" 8 kW (10-3/4 HP) - 24,000 RPM SK-30 Air-cooled electrospindle; Variable spindle speeds to 24,000 RPM. -- 8-Position Pneumatically-actuated tool changer, & Tool pre-setter.Features: -- Boring unit, with (13) Pneumatically-actuated Vertical spindles, (8) in X-Axis & (5) in Y-Axis, with 1.7 kW (2.25 HP) - 3,490 RPM Motor. -- All Axes with THK Precision contour linear guideways. -- X & Y-Axes with Closed loop AC Servo drives & Precision ground ball screws. -- Extra heavy-duty bridge.Operator Control: -- SIEMENS "SINUMERIK" CNC Touchpad Control, with 12" Display, RS-232 Port, & Remote pendant control with Touchpad.Complete with: -- Safety device. -- Documentation. -- 45 kVA 480/208Y/120 Transformer. -- (8) Toolholders.

NOVA TTF-6200 Dry Kiln System; Unassembled Front Load Kiln Designed to hold 5,100 bd. ft 4/4 Lumber, or 6,120 bd. ft 8/4 Lumber, Using 3/8" (9 mm) stickers. -- Specifications: Interior Dimensions: H 10' 3,5" (3.14 m), D 7'2"(2.19 m), W 25' 3" (7.7 m). -- Loading Door Opening: H 9' 10" (2.85 m), W 25' 3" (7.7 m). 1/8 " Aluminum sidewall bumpers, side hinged doors, exterior installation. -- Average 4/4 capacity: 5,100 bd. ft (12 m3) with 3/8" (9 mm) stickers. -- Average 8/4 capacity: 6,120 bd. ft (14 m³) with 3/8" (9 mm) stickers. -- Price shown is for kiln only. -- High horsepower heat requirement: 128 k BTU/hour. -- Heated Floor System, manuals and blueprints. -- Electrical Requirements: 230 VAC, 1 Phase, 60 Cycle, 25 kw/Hr max.

(2) Unassembled front load Kilns only System with high HP heat and exhaust designed to hold 8,461 bd/ft (20 cub.m) of 3/4" (25 mm) lumber and 10,475 bd/ft (25 cub.m) of 8/4" (50 mm) lumber (35 cbm). -- Kilns internal dimension: Height 12'3-1/2" (3.75 m), Depth 16' (4.88 m), Width 21' (6.4 m). -- Loading door opening of 10' (3.05 m) x 21' (6.4 m); 1/8" aluminum side wall bumpers, side hinged doors, exterior installation. -- High HP will service the heat requirements up to 245k BTU/Hr. -- Electrical requirement of 230 VAC, 3-Phase, 60 Cy; 7.21 kW/Hr. -- System includes: Timber Dry management automated Dry Kiln Controls for each kiln, touch-screen operator interface, data recording, optional remote access, and networking capability, Replacement part kit for a kiln. Manuals & Blueprints

$197,600

Unassembled Front Load Kiln with Standard Heat and Exhaust -- Interior dimensions: H 17' 6" (5.33 m), D 25' 8" (7.8 m), W 26' (7.9 m). -- Loading Door Opening: height 14'6" (4.4 m), width 25'3" (7.7 m). 1/8" Aluminum Bumper Walls, Top Hinge Door, Exterior Installation. -- Average 4/4 capacity: 25,459 Bd Ft. with 3/4" stickers. Average 8/4 capacity: 33,293 Bd Ft with 3/4" stickers. -- Price shown is for kiln only. -- Standard HP Heat requirement: 382k BTU suitable for drying dark hard woods; Optional high HP Heat requirement: 674k BTU suitable for drying softwood and white hardwoods. -- Electrical requirements: 480 VAC, 3 Ph., 60 Cy; 16.5 kW/Hr. Timber Management Control System with touch screen operator interface, data recording, remote access & networking capability. -- Features: Control room with heated air intake; 12'H x 4'D x 26'W. Top Hinge door opening System includes "230" electric chain hoist. Boiler Room: 12' W x 25' D x 17'6" H. 10' roll up & (1) access door. - Timber Dry Management Network Capability.

NOVA PELLET - N-Eco - 45 kW, ...Pellet Mill Low specific energy consumption per ton of pellet.Specifications: -- Capacity: 770 - 1,200 Lbs/Hr (350 - 550 kG/Hr) depending on the raw material. -- Main drive: 60 HP (45 kW). -- Pellet dimensions: 0.24" - 0.31" (6 - 8 mm) diameter. -- Raw Material: Wood chips, sawdust, wood shavings: 0.02" - 0.06" (0.5 - 1.5 mm) Length; 8 - 14% MC. -- Die: 15" (380 mm) Internal diameter; 0.6" - 2" (14 - 50 mm) long die holes. -- Roller: 7.2" (182 mm) Outer diameter.General specification: -- Pellet Mill with mechanical and electrical functioning system. -- Pellet Mill with (1) die and (2) Rollers. -- Electrical cabinet with: SIEMENS PCL System, touch screen, and remote modem connection. -- High efficiency motors with IE2 standards (Energy Saving). -- Raw material dosing system (frequency controlled). -- Mechanical level sensor for the saw dust hopper. -- Vegetable oil for start and end of production cycle. -- Automatic grease lubrication for rollers and main shaft. -- Electrical safety locks. -- CE conformity certificate.

NOVA PELLET - N-Midi - 90 kW, ...Pellet Mill with low specific energy consumption per ton of pellet. -- Capacity: 1,765 - 2,315 Lbs/Hr (800 - 1,050 kG/Hr) depending on the raw material. -- Main drive: 120 HP (90 kW). -- Pellet dimensions: 0.24" - 0.31" (6 - 8 mm) diameter. -- Raw Material: Wood chips, sawdust, wood shavings; 0.02" - 0.06" (0.5 - 1.5 mm) length; 8 - 14% MC. -- Die: 15.7" (400 mm) Internal diameter; 0.6" - 2" (14 - 50 mm) long die holes. -- Roller: 7.2" (180 mm) Outer diameter.General Specifications: -- Pellet Mill with mechanical and electrical functioning system. -- Pellet Mill with (1) die and (2) Rollers. -- Electrical cabinet with SIEMENS PCL system, touch screen, and remote modem connection. -- High efficiency motors with IE2 standards (Energy Saving). -- Raw material dosing system (frequency controlled). -- Mechanical level sensor for the saw dust hopper. -- Vegetable oil for start and finish of production cycle. -- Automatic grease lubrication for rollers and main shaft. -- Electrical safety locks. -- CE Conformity certificate.

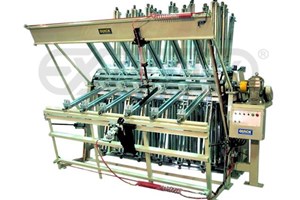

QUICK 6-Section Clamp Carrier with 16-1/2' width capacity6-Section Pneumatic Clamp Carrier with 16-1/2' width cap. -- (12) Heavy Duty zinc plated clamps per section (72 clamps total); 52" opening on clamps. -- Jaw size of clamps are 3-1/2" high x 4-3/4" wide, with 1° inward draft.Equipped with: -- Pneumatic overhead panel flattener 16-1/2' wide. -- Pneumatic clamp tightener -- Semi-automatic rotation via electric motor drive; -- Separate buttons for Front Rest Out, Rotate Reverse, Rotate Forward, and Front Rest In. -- Flexible conduit for electric wires.Features & Includes: -- Automatic air line oiler; -- High quality urethane finish coating. -- Toolbox with spare parts & tools.Floor space requirement: 236" W X 131"D X 148" H

QUICK 6-SECTION, 10'-1/2' Wide Pneumatic "Standard" Clamp Carrier: 6-Section Clamp typically produces (144) high quality edge glued panels per day (3 panels per section x 6 sections x 8 hours). Equipped with: -- (6) Sections with (8) clamps per section and 10-1/2' width capacity. -- (48) Clamps with 38" opening and 2-1/2" high x 4-3/4" wide jaws with 1° inward draft. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. Features: -- Semi-automatic electric motor drive. -- Pneumatic Panel Flattener for 10-1/2' wide Carrier with easy to use controls. -- Pneumatic Clamp Tightener with 3,000 RPM air wrench is (5 -10) times faster than competitive tighteners; 2-handed, trigger activated tightener is more confidence inspiring than the older, ergonomically awkward "swing-style" clamp tighteners. -- Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality Urethane finish coating, and tool box with spare parts & tools. -- NOTE: Clamp Carrier can be expanded to (14) or (20) sections at a later time. 14-Section Clamp will produce (300) panels per shift; 20-Section machine, (500) panels per shift.

Call for Price

QUICK 20 Section Automatic Clamp Carrier: -- Clamp Carrier: (20) Sections with 8-1/2' width cap., (6) heavy duty zinc plated clamps per section (120 clamps total), 32" opening on clamps (other lengths available). -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- For face gluing, Rocking Plates available as optional equipment. -- Equipped with: -- Fully Automatic Hydraulic Clamp Tightener with adjustable torque limiter, integral Pneumatic Panel Flatteners and Electric Motor Drive with fully Automatic Carrier Rotation Cycle. Two control panels maximize ease-of use. Rack and pinion carriage traverse system is solid and quietFeatures: -- The QUICK Automatic Clamp Carrier is the ideal labor-saving device for the high-production furniture or cabinet manufacturer. The Automatic Clamp Carrier cuts labor costs in half by allowing the Clamp Carrier operator to perform other tasks (such as applying glue to stock, etc.) while the machine automatically flattens panels, tightens clamps, rotates, and loosens clamps. -- After loading wood into a section of clamps, the operator presses the "Auto Tighten" button. The hydraulic Automatic Carriage then traverses from left to right, flattening panels and tightening clamps that it finds along the way. When the Carriage reaches the right end of its traverse, the machine performs an automatic rotation cycle, which brings the next section of clamps down to the operator’s position. The Carriage then traverses from right to left, loosening clamps that it finds along the way. -- The Fully Automatic Clamp Carrier can also be used in manual or semi-automatic modes, by pressing buttons on the Control Panels. -- Complete with & Includes: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.NOTE: 20 Section machine can produce up to (500) panels per shift!

QUICK 14-Section Pneumatic Clamp Carrier with 16-1/2' width capacity and Glue applicatorWith (15) Standard zinc plated clamps per section (210 clamps total), 48" opening on clamps Standard Features include: Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment (2) Panel Flattener with easy to use controls.(2) Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; two-handed, trigger activated tightener is more confidence inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. Electric Motor Rotation; push button, automatic cycle with indexing. Automatic Rotation Cycle includes entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time! Complete with:Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.14-Section Clamp will produce 300 panels

Call for Price

QUICK 40 Section Automatic Clamp Carrier: -- Clamp Carrier: (40) Sections with 8-1/2' width cap., (6) heavy duty zinc plated clamps per section (240 clamps total), 40" opening on clamps with quick adjustment (other lengths available). -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- For face gluing, Rocking Plates available as optional equipment. -- Equipped with: -- Fully Automatic Hydraulic Clamp Tightener with adjustable torque limiter, integral Hydraulic Panel Flatteners and Electric Motor Drive with fully Automatic Carrier Rotation Cycle. Two control panels maximize ease-of use. Rack and pinion carriage traverse system is solid and quietFeatures: -- The QUICK Automatic Clamp Carrier is the ideal labor-saving device for the high-production furniture or cabinet manufacturer. The Automatic Clamp Carrier cuts labor costs in half by allowing the Clamp Carrier operator to perform other tasks (such as applying glue to stock, etc.) while the machine automatically flattens panels, tightens clamps, rotates, and loosens clamps. -- After loading wood into a section of clamps, the operator presses the "Auto Tighten" button. The hydraulic Automatic Carriage then traverses from left to right, flattening panels and tightening clamps that it finds along the way. When the Carriage reaches the right end of its traverse, the machine performs an automatic rotation cycle, which brings the next section of clamps down to the operator’s position. The Carriage then traverses from right to left, loosening clamps that it finds along the way. -- The Fully Automatic Clamp Carrier can also be used in manual or semi-automatic modes, by pressing buttons on the Control Panels. -- Complete with & Includes: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.

QUICK 40 Section 10.5' Heavy Duty Hydraulic Clamp Carrier: -- Clamp Carrier: (40) Sections with 10-1/2' width cap., -- (10) heavy duty zinc plated clamps per section (400 clamps total), 40" opening on clamps with quick adjustment (other lengths available). -- Clamps jaws are 3-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. -- For face gluing, Rocking Plates available as optional equipment.Equipped with: -- (1) Hydraulic clamp tightener for 10.5' -- (1) Hydraulic clamp tightener 10.5' for second operator -- (1) Pneumatic Panel Flatteners for 10.5' wide -- (1) pneumatic panel fattener 10.5' wide for second operatior -- Electric Motor Drive with fully Automatic Carrier Rotation Cycle.Two control panels maximize ease-of use. Rack and pinion carriage traverse system is solid and quiet -- Complete with & Includes: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality urethane finish coating, and tool box with spare parts & tools.Note: this machine has 2 hydraulic tightener and 2 Pneumatic panel flattener for (2) operator)If one operator is fine the machine price could be reduce by $3,600

QUICK 20" Wide Conveyorized Glue Applicator -- 20" Wide grooved rubber glue applicator roll with stainless steel doctor blade and glue reservoir. -- Features easy adjustment or removal of doctor blade, -- 18' Overall length, 8' infeed before the glue roller and 10' outfeed conveyor. Equipped with: -- Heavy Duty 0.25 HP motor drive for slat-type conveyor and glue roll, limit switch with wand for automatically stopping the slat bed conveyor when stock reaches the Clamp Carrier, adjustable safety slip clutch. Complete with: -- Foot levelers, -- Heavy Duty crossbars, chain guard, high-quality anti-stick urethane finish, and owner & operator's manuals.