Woodworking Equipment For Sale

1690 Results Found

$ 138,900

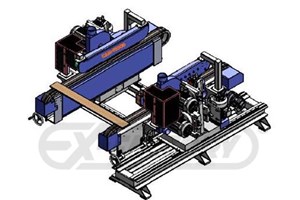

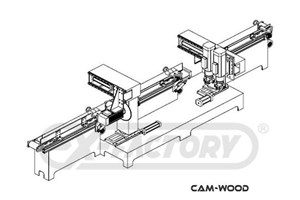

CAM-WOOD SET-88DET-SHJCJC 8-Head, 96" Double End Tenoner -- Suitable for mass production of woodworking task for double-end cutting, tenoning, grooving, profiling and sanding -- Scoring, Hogger/Saw, Jump Shaper, Jump Shaper: Total (4) stations on both sides. -- A solid, powerful machine great for Heavy-Duty production.Capacity: -- The specially designed numeric controller allows quick setting of sizes, for the tolerance within 0.004";. -- Variable speed, through feed, wide rubber pad chain, spring-loaded dogs at 8" center conveyor for the best finish selections. -- Heavy-duty pressure rolls at top of wide width conveyor to hold the material tight to prevent sliding during the cutting process. -- Shaper heads can be moved up & down, forward & backward. -- Max. 96" working capacity, min. 12"; max. 3-1/8" opening, 24" load area in front of hold-downs. -- The automatic high-speed through feed device allows for perfect finishing at speeds ranging from 20 - 66 FPM. -- Motorized opening with LED indicator.Each side equipped -- Top Scoring saw unit , 2 HP - 3,600 RPM motor, 1" dia. arbor & up to 8" blade -- Hogging/ Trim saw tiltable unit, 5 HP - 3,600 RPM motor, 1" arbor and up to 10" blade. -- Jump Shape/coping head unit, 7.5. HP - 4,500-7,000 RPM motor, 40mm dia. arbor for 6" to 8" cutter head. -- Jump Shape/coping head unit, 7.5 HP - 4,500-7,000 RPM motor, 40 mm dia. arbor for 6" to 8" cutter head -- Variable feed speed from 20 - 66 FPM, 2 HP motor, steel feed chains with plastic anti-slip pads and dogs at 16" center. -- Spring-loaded overhead hold-down beams w/endless belts. -- Separate electrical control cabinet with operator controls.Options Not Included -- Hopper feed magazine $3,960) -- Extended infeed 42" in front of hold-down belt $4,900) -- Sound enclosure $ 8,900Floor space : 8.5' X 9' X 6', weight 10,500 Lbs

$ 165,500

CAM-WOOD SET-812 SCCWW, Double End Tenoner with Sanding12-Head Double End Tenoner, suitable for mass production in a woodworking factory, processing double end cutting, tenoning, grooving, moulding, and sanding.Features: -- Automatic high-speed through feed device allows for perfect finishing at speeds ranging from 20 - 75 FPM. -- In addition to the double-end cutting, all the settings and other processing can also be executed with high accuracy. -- Since the machine is so versatile, we believe it will be one of the most satisfactory machines for bulk production lumber-processing factories. -- The specially designed numeric controller allows quick setting of length sizes for tolerance within 0.004". -- The numeric control system provides highly accurate settings, and a special memory retains all settings, even if there is a power failure. -- Variable speed, through feed, wide rubber pads with spring-loaded dogs located at 16" center distance with conveyor speed for the best finish selections. -- Heavy-duty powered pressure rolls at top of the wide width conveyor holds the material tight to prevent sliding during the cutting and sanding process. -- Shaper head can be moved up & down, forward & backward. -- Workstations are powered by industrial motors for full power cutting and utilizing the entire sanding capacity range. -- Two sanding heads can use brush, flap wheel or profile disc for fine finish with one pass. -- Trim saws and sanding heads can be tilted for different angular setup. -- Heavy cast iron base for durability and heavy duty usage.Specifications: -- Thickness: ½" to 4" -- Length: 10" to 96" -- Miter Saw Blade: 10" x 30 mm Dia. -- Grooving Saw Blade: 8" x 1" Dia. -- Shaper Cutter: 6" - 10" x 30 mm Dia. -- Feed Speed: Variable, 20 ~ 75 FPM -- Trim Saw 3 HP x 2, 3,450 RPM -- Hogging Saw 10 HP x 2, 3,450 RPM -- Jump Shaper 10 HP x 2, 4,500 to 7,000 RPM -- Shaper 10 HP x 2 4,500 to 7,000 RPM -- Belt Sanding 3 HP x 2, 0-1500 RPM -- Brush Sanding 3 HP x 2 with 30 mm arbor 0-1500 RPM -- Feeding 3 HP x 1 -- Width (Opening) Setting 1 HP x 1 Option: -- Sound enclosure ...$ 7800

CAM-WOOD SET-88TS-SHJC 96" 10 Heads Double End Tenoner: -- 96" Double end tenoner with Scoring, Hogging, Jump coping, coping and belt sandingCapacity: -- Max. 96" working capacity, min. 12"; max. 4" opening, 24" load area in front of hold-downs. -- Motorized opening with LED indicator; -- Single-post machine, single "dual-track" base, right side fixed, left side movable.Each side equipped -- Head 1: Bottom scoring unit, 3 HP - 3,600 RPM motor, 1" dia. arbor & up to 10" blade; -- Head 2:Top Hoging/triming head, 3 HP - 3,600 RPM motor, 1" dia. arbor for up to 10" blade; -- Head 3 Vertical Jump shaping head, 5 HP - 7,200 RPM motor, 6" to 8" tool capacity & 1 1/4" dia. arbor, -- Head 4: Universal shaping head, 5 HP - 7,200 RPM motor, 6" to 8" tool capacity & 1 1/4" dia. arbor, -- Head 5: Belt sanding unit with 2 HP motor, belt sanding speed 300-1,200 RPM -- Variable feed speed from 12 - 52 FPM, 1 HP motor, steel feed chains with plastic anti-slip pads and dogs at 6" center, --Spring loaded overhead hold-down beams w/endless belts. -- Separate electrical control cabinet with operator controls.Options Available: -- Hopper feed magazine (additional $4,990) -- Extended infeed 42" ( additional$4,600) -- Sound enclosure ( additional $ 8,900) -- Auto transfer line (4' X 8') with transfer table ( additional$ 38,900)

$ 159,900

CAM-WOOD SET-410-SHJJA 50" Double End Tenoner with Sanding(10) Heads Double End TenonerFeatures: -- The automatic high-speed through feed device allows for perfect finishing at speeds ranging from 20 - 66 FPM. -- Suitable for mass production in woodworking factory for processing of double end cutting, tenoning, grooving, moulding, and sanding. -- In addition to the double end cutting, all the settings and other processing can also be executed with high accuracy. -- Since the machine is so versatile, we believe it will be one of the most universally satisfying machines for bulk production in lumber-processing factories. -- The specially designed numeric controller allows quick setting of length sizes for tolerance within 0.004". -- Variable speed, through feed, wide rubber pad, spring-loaded dogs at 16" center conveyor for the best finish selections. -- Heavy-duty powered pressure rolls at top of wide width conveyor to hold the material tight to prevent sliding during the cutting and sanding process. -- Shaper head can be moved up & down, forward & backward. -- Equipped with industrial motor for full power cutting and sanding capacity. -- Two sanding heads can use brush, flap wheel or profile disc for fine finish with one pass. -- Trim saws and sanding heads can be tilted for different angular setup. -- Heavy cast iron base for durability usage.SPECIFICATIONS: -- Material Thickness: ½" to 4". -- Material Length: 10" to 50". -- Scoring Saw Blade: 12" x 1" Dia. -- Hogging Saw Blade: 8" x 40 mm dia. arbor. -- Shaper Cutter: 6" - 10" x 40 mm dia. arbor. -- Feed Speed: 20' - 66' Variable, Motor 3 PH, 220/440 V. -- Trim Saw 5 HP x 2. -- Hogging saw blade 10 HP x 2. -- Jump Shaper 15 HP x 2. -- Jump Shaper 15 HP x 2. -- Brush/Disc Sanding 2 HP x 2 with inverter for variable RPM. -- Feed Drive 3 HP x 1. -- Width Setting 1HP x 1. Option: -- Sound enclosure $ 8,900 -- Hopper feed magazine $ 3,900 -- 42" extend infeed conveyor before top hold down $ 4,900

CAM-WOOD SET-84 -TS - SH Double End Tenoner, (4) Heads4-Head machine (two on each side) with Scoring/Cutting and HoggingCapacity & Style: -- Max. 98" working capacity, min. 12"; max. 4" opening, 24" load area in front of hold-downs. -- Single-post machine, single "dual-track" base, right side fixed, left side movable. -- Motorized opening with LED indicator.Each side equipped with: -- Scoring head, 3 HP - 3,600 RPM motor, and 1" dia. arbor for up to 10" blade. -- Hogging/cutting unit 5 HP - 3,600 RPM motor, 1" dia. arbor, 10" max. dia. cutter-head. -- Variable feed speed from 12 - 52 FPM, 1 HP motor, steel feed chains with plastic anti-slip pads, and dogs at 6" center. -- Spring loaded overhead hold-down beams with endless belts. -- Separate electrical control cabinet with operator controls.Options Available: -- Cross transfer system with transfer line 4' X 8' transfer table with rollers (additional $38,900). -- Hopper feed magazine (additional $3,990). -- 42" Infeed extension (additional $4,500) -- Sound enclosure ...$6,900 -- Electric motor brake -- Central supportNote: Pictures are showing the machine with several options included

CAM-WOOD SET-105TS- SCT Double End Tenoner, (6) Heads W Split SawCapacity & Style: -- Max. 120" working capacity, min. 35"; max. 3" opening, 24" load area in front of hold-downs. -- Single-post machine, single "dual-track" base, right side fixed, left side movable. -- Motorized opening with LED indicator.Each side equipped with: -- Top trim head, 5 HP - 3,600 RPM motor, 1" dia. arbor for up to 10" blade. -- Cope shaping head, 7.5 HP - 7,200 RPM motor, (150 mm) 5-7/8" long x 1" diameter arbor, 6" to 8" max. dia. cutter head -- Variable feed speed from 12 - 52 FPM, 2 HP motor, steel feed chains with plastic anti-slip pads, and dogs at 6" center. -- Spring-loaded overhead hold-down beams with endless belts. -- Separate electrical control cabinet with operator controls.Also Included: -- Central support -- Central trim saw with 5 HP, 3,600 RPM motor, saw will cut from bottom , hold down roller each side of the bladeOptions Available: (Pricing to be confirmed at time of order) -- Cross transfer system with transfer line 4' X 8' transfer table with rollers (additional ...$38900). -- Hopper feed magazine (additional ...$3,990). -- 42" Infeed extension (additional ...$4,500) -- Pneumatic jump control on scoring or shaping unit. -- Sound enclosure (...$6,900) -- Electric motor brake -- Tilting headNote: Pictures are showing the machine with several options included

$ 41,500

CAM-WOOD SET-14TS Double End Tenoner, (4) Heads, with Single feed chain for Narrow PartsFeatures: --The automatic high-speed through feed tenoner allows for perfect finishing at speeds ranging from 1 ~ 43 FPM. -- Suitable for mass production for processing of double-end cutting, tenoning, grooving, and moulding. -- SET-14TS Shaper, Sander: Total (2) stations on both sides. -- Variable speed, through feed, wide rubber pad, and spring-loaded dogs feed chain for the best finish selections. -- Heavy-duty pressure rolls at top of the wide-width conveyor to hold the material tight to prevent sliding during the cutting process.Specifications: --Max. Working Thickness 2" --Working Width 2-3/4"; ~ 10"; -- Working length 4" to 14" -- First head Tilting cutting saw -- Second head Tilting cutting Saw --Optional: Shaper Cutter Heads, Sander Heads 6" ~ 8" x 1" Dia. --Feed Speed 1' ~ 43' FPM, Variable --Feed Drive 3 HP, 220 or 440 V -- Saw Heads 5 HP x 2 -- Saw heads 5 HP x 2 -- Feed drive motor 1 HP

$ 19,990

CAM-WOOD SET 83-3M Single End TenonerIt performs tenon, moulding functions. -- Three tenon cutters, cope spindles accepts general shaper cutter. -- Suited for cutting tenons, finger joints for windows or door frames and general joint-tenon. -- Hand, manually operated clamping and feeding of stock. -- Then two horizontal moulding, tenon spindles and one vertical coping spindle enables machine to perform edge tenon, moulding. -- Since each head is adjusted independently, a wide variety of tenons can be cut. -- At the end, the cope spindle provides 6000 RPM cutting, allowing to feature a spindle sharperSpecifications: -- Table Size 31"; W x 12"; L -- Max. Length of Cut ~ -- Min. Length of Cut 5"; -- Max. Width of Cut Pass Once 5", Pass Twice 8"; -- Max. Tennor Height 5"; -- Max. Tenoner Depth 6"; -- HORIZONTAL COPING HEADS X 2 UNITS (M1 & M2) -- Cutter Head Dia. 6-3/4";, Cutter Arbor Dia. 30 mm, Cutter Head Length 2-3/8";, Cutter Speed 4,000 RPM -- VERTICAL COPING HEAD (M3), Cutter Head Dia. 5";, Cutter Arbor Dia. 30 mm, Cutter Head Length 2-3/8";, Cutter Speed 4,000 RPMTRAVERSE -- Saw Longitudinal Travel 3" -- Saw Vertical Travel 3" -- Carriage Cross Travel 20" -- MOTOR Saw & Tenoner Head 3 HP x 2 -- Cope Head 5 HP x 1 -- DUST HOOD Out Diameter 6"; x 2

$ 99,990

CAM-WOOD - SET-48TS-CHX, ... Double End Tenoner for Chevron & Herringbone FlooringSpecial design Servo Control for Chevron & Herringbone Double End TenonerFeatures: -- Servo Control for +45° or –45° and 90° cutting. -- The automatic high-speed through feed device allows for perfect finishing at speeds ranging from 12 - 52 FPM. -- Feed chain with dogs at 10" center distance. -- Suitable for mass production of woodworking factory for processing of double end cutting, tenoning, grooving, moulding, and sanding. -- Possibility for: Scoring Saw, Trim Saw, Jump Coping, Shaper, Coping. -- Total (4) stations at each side. -- Reversed direction cutting jump shaper head with sensor for automatic move in and out for perfect cutting to prevent tearing at end edge. -- HMI Plus PLC controller for user-friendly easy setting and operation. -- Powerful machine is great for heavy-duty production. In addition to the double end cutting, all the settings and other processing can also be executed with high accuracy. -- Since the machine is so versatile, we believe it will be one of the most satisfactory machines for bulk production lumber-processing factories. -- The specially designed numeric controller allows quick setting of sizes for tolerance within 0.004";. -- Variable speed, through feed, wide rubber pad, and spring-loaded dogs conveyor for the best finish selections. -- Heavy-duty pressure rolls at top of wide width Conveyor to hold the material tight to prevent sliding during the cutting process. -- The Shaper head can be moved up & down, forward & backward. -- Equipped with: Industrial motors for full power cutting capacity. Specifications: -- Max. working thickness: 2";. -- Max. working length: 45° is 49";. -- Max. working length: 90° is 48". -- Min. working length: 45° is 18". -- Min. working length: 90° is 13-3/4". -- Scoring/Main saw blade (dia.): 10" x 1". -- Shaper cutter (dia.): 6" - 8" x 1" -- Feed speed 12' - 52', variable power 3 PH - 220/440 Volt. -- V-Scoring saw: 3 HP x 2. -- Trim saw: 3 HP x 2. -- Jump Shaper: 5 HP x 2 Stationary. -- Shaper: 5 HP x 2. -- Feed motor by Servo: 1 kW x 1; Width setting by Servo 0.75 kW x 1.Available Options: -- Total sound enclosure cover: Add ...$7,900. -- Infeed Hopper Magazine: Add ...$4,990.

$ 92,900

CAM-WOOD CS-650SCC Double End Matcher For Herringbone and Chevron FlooringNC Controlled Trough Feed Type End Matcher for Chevron and Herringbone flooringSpecifications: -- Working Width 1-1/2"; to 6"; -- Working Thickness 1/2"; to 1"; -- Working Length 8"; to 50"; -- Feed Speed 70 FPM with inverter -- Cycle time can be 4 to 8 second per piece1st Saw Station: -- Saw Blade Diameter 10"; -- Saw Motor 7-1/2 HP -- Feed Motor 1 HP with Gear Reducer & Inverter. -- Auto Stop & Align2nd Feeding Station: -- Feed Motor 1 HP with Gear Reducer & Inverter. -- Auto Stop & Align3rd Tennon Station: -- High Frequency HSD Routers with HSK63 Spindle, 11 kW (15 HP) x 2 units -- Forward and Reversed Direction at each spindle. -- Feed Motor 1 HP with Gear Reducer & Inverter. -- Auto Stop & AlignFeatures: -- Special Design CHEVRON & HERRINGBONE Double End Tenoner -- Servo control for 45° and 90° cutting. -- The automatic high-speed through feed device allows for perfect finishing at speeds ranging from 45 ~ 70 FPM by inverter -- Suitable for mass production of woodworking factory for processing of double-end cutting, tenoning, grooving, moulding, and sanding. -- Scoring Saw, Trim Saw, Jump Coping shaper, and Coping Shaper: Total 4 stations at each side. -- HMI plus PLC controller for easy setting and operation. -- It is a powerful machine great for heavy-duty production. -- In addition to the double-end cutting, all the settings and other processing can also be executed with high accuracy. -- The specially designed numeric controller allows quick setting of sizes for tolerance within 0.004";. -- Variable speed, through feed, wide rubber pad, spring-loaded dogs conveyor for the best finish selections. -- Heavy-duty pressure rolls at top of a wide conveyor to hold the material tight to prevent sliding during the cutting process. -- Shaper heads can be adjusted to move up & down, forward & backward. -- Features industrial motors for full power cutting capacity.Optional equipment: -- Total sound enclosure add: ...$ 7,900 -- Infeed magazine add ...$ 4,900

$ 20,990

CAM-WOOD WP-760 15 HP Single Sided 30" Planer Features: -- Spiral cutterhead provides precise, efficient planing with low noise levels. -- Automatic digital thickness controller for quick & accurate setting. -- Motorized worktable raises & lowers by separate motor for more efficient operation. -- Specially designed infinitely variable feed system is powered by a separate motor and allows adjustment to the exact feed rate and allows precision smooth finish planing on both hard or softwoods. -- The sectional infeed roller & anti-kickback device & chip breaker provides greater safety for the operator -- Exhaust dust hood with 4"; dia. outlet for proper chip extraction. -- The motorized worktable includes twin quick adjustable bed rollers that can be adjusted for rough & finish planing on damp or dry lumber ensuring a consistently smooth planed finish. -- Precision sealed long-life ball bearing. -- Industrial motor for powerful cutting capacity. Heavy gauge sheet metal frame and base for maintenance-free serviceSpecifications: -- Table Area 38" x 31" -- Max. Planing Width 30" -- Max. Planing Thickness 8" -- Mini. Planing Thickness 3/16" -- Cutterhead Speed 5,500 RPM -- Cutterhead Diameter 4-3/4" Spiral -- Knife Dimensions 14 mm x 14 mm -- Feeding Speed (Var.) 15 ~ 75 FPM -- Max. Cutting Depth 5/16" -- Feed Motor 2 HP -- Cutterhead Motor 15 HP, 3 Ph, 230 V -- Table Elevation Motor 1 HP -- Digital Thickness Control Yes -- Dust Hood Outlet 5"G.W. 2450 Lbs

$ 8,389

CAM-WOOD WP-2000S Single Sided Planer20" Planer with solid cast iron construction and Spiral Cutter Head.Features & Specifications: -- Precision ground cast iron table w/manual adjustment by hand wheel via (2) large lead screws. -- Scale & pointer readout for accurate thickness adjustments. -- Fixed feed (30 FPM) speed setting for consistent stock removal. -- Sectional steel infeed roller & segmented chip breaker. -- Independently adjustable feed rollers. -- (2) Externally adjustable bed rollers. -- Hinged top for easy access to cutterhead & gear assembly. -- 3 HP Self-braking motor. -- Magnetic starter & thermal overload switch and Emergency stop. -- Operations manual, parts list & tool kit. Optional: CT-SCH-14T - 14 mm x 14 mm SPIRAL CUTTERHEAD BLADES ...$3.30 each

$ 45,139

CAM-WOOD WP-1400H 52"; Heavy Duty Planer with S.C.H.55" Cap. solid cast iron construction planer with powerful 25 HP motor.Features & Specifications: -- Precision ground cast iron table with motorized worktable raising & lowering, manual adjustment by hand wheel via (2) large lead screws. -- Digital thickness display with touchpad positioning control for accurate thickness adjustments. -- 5" Spiral cutterhead with 4-sided carbide inserts provide precise, efficient planning with low noise levels. -- With (4) each 4" diameter dust outlets. -- Sectional steel infeed roller & segmented chipbreaker. -- Independently adjustable feed rollers. -- (2) Externally adjustable bed rollers. -- Hinged top for easy access to cutterhead & gear assembly. -- Self-braking motor. -- Magnetic starter & thermal overload switch. -- Emergency stop. -- Operations manual, parts list & tool kit. Machining Specifications: -- Max. Cut Width 52". -- Max. Cut Thickness 8". -- Max. Cut Depth ¼". -- Min. Cut Length 9". -- Cutting Speed 3,600 RPM. -- Table Size (W x L) 55" x 55". -- Main Motor 25 HP, 3 Ph. -- Feed Motor 5 HP. -- Table Raising Motor 1 HP. -- Feed Rate (Variable) 0 ~ 50 FPM. -- Shipping weight 7,400 Lbs.

$ 65,000

CAM-WOOD TX-P10AAT FRONT LOAD AUTOMATIC PANEL SAW: Shop Saw -- Specifications: 128" (3,250 mm) Max. rip cut cap. & 128" (3,250 mm) max. pull-back front/back; 10 HP (7.45 kW) saw blades motor, 1" dia. arbors,4" (101 mm) max. depth of cut with 355 mm (13.9") dia. blade at 4,500 RPM,160 mm (6.3") scoring blade at 6,000 RPM blade speed. -- Positioning Speed:2 HP Saw carriage drive motor, variable cutting speed from 16 - 98 FPM (5 - 30 MPM), return speed of 98 FPM (30 MPM). -- Pusher Fence: Programmable rear material push fence with servo drive, made of square tubular steel bar;0.5 HP pusher motor, rack & pinion drive, 16 - 49 FPM (5 - 15 MPM) speed. -- Operator & Machine Control:PC Controller with touch-screen to program cutting patterns or individual line cutting operation, graphic displays, self-diagnostics, machine parameter list; touch-screen keypad for data entry. -- Complete with: (3) Bakelite covered front support tables and fully covered rear table; (optional air flotation tables available at additional cost)(4) Dust collector outlets, (1) on each end of the saw base, (1) on the right side at cut-line height, and (1) on the right-hand side on top of the pressure beam. -- Available Options: ● (1) TX-ATSA AUTO SIDE ALIGNMENT DEVICE = $2,300.00 additional cost; ● (3) TX-PFT AIR FLOATING TABLES = $3,690.00 additional cost. -- Actual Model is CAM-WOOD TX-P10AAT

$ 69,500

CAM-WOOD TX-P12AAT FRONT LOAD AUTOMATIC PANEL SAW: -- Specifications: 149.6" (3,800 mm) Max. rip cut cap. & 149.6" (3,800 mm) max. pull-back front/back; 10 HP (7.45 kW) saw blades motor, 1" dia. arbors,4" (101 mm) max. depth of cut with 355 mm (13.9") dia. blade at 4,500 RPM,160 mm (6.3") scoring blade at 6,000 RPM blade speed. -- Positioning Speed:2 HP Saw carriage drive motor, variable cutting speed from 16 - 98 FPM (5 - 30 MPM), return speed of 98 FPM (30 MPM). -- Pusher Fence: Programmable rear material push fence with servo drive, made of square tubular steel bar.0.5 HP pusher motor, rack & pinion drive, 16 - 49 FPM (5 - 15 MPM) speed. -- Operator & Machine Control:PC Controller with touch-pad to program cutting patterns or individual line cutting operation, graphic displays, self-diagnostics, machine parameter list; touch-screen keypad for data entry. -- Complete with: (3) Bakelite covered front support tables and fully covered rear table; (optional air flotation tables available at additional cost)(4) Dust collector outlets, (1) on each end of the saw base, (1) on the right side at cut-line height, and (1) on the right-hand side on top of the pressure beam. -- Available Options: ● (1) TX-ATSA AUTO SIDE ALIGNMENT DEVICE = $2,300.00 additional cost. ● (3) TX-PFT AIR FLOATING TABLES = $3,690.00 additional cost. -- Actual Model is CAM-WOOD TX-P12AAT

Call for Price

CAM-WOOD TX-P330X FRONT LOAD AUTOMATIC PANEL SAW: "High Production Saw" -- Specifications: 126" (3,200 mm) Max. rip cut cap. & 126" (3,200 mm) max. pull-back front/back; 15 HP (11.2 kW) saw blades motor, 1" dia. arbors,3-1/8" (82.5 mm) max. depth of cut with 355 mm (13.9") dia. blade at 4,500 RPM,180 mm (7") scoring blade at 6,000 RPM blade speed. -- Positioning Speed:2 HP Saw carriage drive motor, variable cutting speed from 16 - 150 FPM (5 - 46 MPM), return speed of 100 FPM (30 MPM). -- Pusher/Gripper Fence: Programmable rear material push/gripper fence with AC servo drive, 1 HP pusher motor, rack & pinion drive, 16 - 80 FPM (5 - 24 MPM) speed. -- Operator & Machine Control:PC Controller with touch-screen to program cutting patterns or individual line cutting operation, graphic displays, self-diagnostics, machine parameter list; touch-screen keypad for data entry. -- Complete with: TX-ATASA automatic side alignment device, (3) Bakelite covered front support tables and fully covered rear table; (optional air flotation tables available at additional cost)(4) Dust collector outlets, (1) on each end of the saw base, (1) on the right side at cut-line height, and (1) on the right-hand side on top of the pressure beam. -- Available Options: ● (3) TX-PFT AIR FLOATING TABLES = $3,690.00 additional cost. ● (1) TX-P3SB THIRD JUMP SCORING UNIT = $4,290.00 additional cost. ● (1) PC BASE CONTROL (Optional with OPTIMIZE SOFTWARE) = $4,890.00

$ 38,450

CAM-WOOD TX-P10A Front-Load Manual Panel SawSpecifications: -- 128" Max. rip cut cap. & 128" max. front/back, 10 HP saw blades motor, 1" dia. arbors; -- 4" Max. depth of cut with 355 mm (13.97") dia. blade at 4,500 RPM, 160 mm (6.30") scoring blade at 6,500 RPM blade speed. Features: -- 1 HP Saw carriage drive motor, variable cutting speed from 16 - 98 FPM, return speed of 98 FPM. Equipped with: -- (2) Flip stops and (2) air cylinder stops on fence; (3) front support tables (optional air tables available - add $ 3,690), Steel rear tables. -- (3) Dust collector outlet/connections, (1) on each end of the saw base, and (1) on the right-hand side at cut-line height.

$ 18,990

CAM-WOOD WP-660A Single-Sided 15 HP, 26" PlanerFeatures: -- Spiral cutter-head provides precise, efficient planning with low noise levels. -- Automatic digital thickness controller for quick & accurate settings. -- The motorized worktable raises & lowers by a separate motor for more efficient operation. -- The specially designed infinitely variable feed system is powered by a separate motor and allows adjustment to the exact feed rate for planning a precision smooth finish on both hard and softwoods. -- The sectional infeed roller & anti-kickback device & chip breaker provides greater safety for the operator -- Exhaust dust hood with 4"; dia. outlet for proper chip extraction. -- The motorized worktable includes twin quick adjustable bed rollers that can be adjusted for rough & finish planing on damp or dry lumber ensuring a consistently smooth planed finish. -- Precision-sealed long-life ball bearing. -- Industrial motor for powerful cutting capacity.Heavy gauge sheet metal frame and base for maintenance-free serviceSpecifications: -- Table Area 35" x 27" -- Max. Planing Width 26" -- Max. Planing Thickness 11-3/4" -- Mini. Planing Thickness 3/16" -- Cutterhead Speed 5500 RPM -- Cutterhead Diameter 4-3/4" Spiral -- Knife Dimensions 14 mm x 14 mm -- Feeding Speed (Var.) 15 ~ 60 FPM -- Max. Cutting Depth 3/8" -- Feed Motor 1 HP -- Cutterhead Motor 15 HP, 3 Ph, 230 V -- Table Elevation Motor 1 HP -- Digital Thickness Control Yes -- Dust Hood Outlet 5"

$ 34,990

CAM-WOOD PL-24 TOP & BOTTOM STRAIGHTENING PLANER8" x 24" Capacity Planer for accurate and powerful two-sided planing in one pass.Includes (1) set of Spiral Insert Cutterheads with (1) set of 15 x 15 x 2.5 mm Carbide Knives with (4) Cutting EdgesReplacement Knives: CT-SCH-15T 15 x 15 x 2.5 mm Spiral Knives - $3.60 EACHDeduction for HSS Knives in lieu of Carbide Insert Spiral Heads - Deduct $3,000 Specifications: -- 25"; Max. Planning Width, 3/8" to 8"; Max. Planning Thickness. -- 1/4";Max. Cutting Depth. -- 12"; Min. Planning Length. -- 15 to 70 FPM Feed Speeds (Variable). -- 4,200 RPM Cutter Head Speed. -- Spiral Carbide Insert Cutterheads with 15 x 15 x 2.5 mm carbide insert knives with (4) cutting edges -- 25 HP Top Head Motor. -- 20 HP Bottom Head Motor. -- 5 HP Feed Motor and 1/2 HP Elevation Motor. -- Net weight 7,200 Lbs. Equipped with: -- Standard equipment includes Automatic Thickness Controller for quick, accurate thickness adjustments. -- Top and bottom Spiral Carbide Insert Cutterheads with 15 x 15 x 2.5 mm Insert Knives for accurate and powerful two-sided planing in a single pass. -- The Planer’s table surface is precision ground then chrome-plated and polished to a mirror finish; wear resistance, easy to clean and maintain.Feed System: -- Heavy-duty upper feed carpet (conveyor) with spring-loaded steel “fingers"; holds stock firmly against the Planer’s table; prevents stock splitting while providing positive feed and smooth finish for rough and finish planing. -- The conveyor (carpet) is fitted with numerous pressure pins, or fingers, which firmly holds and stabilizes stock during the planing process. Fingers apply moderate pressure to the stock and provides accurate planing while preventing wide cupped boards from splitting and feeding problems while planing narrow material. -- (4) Powered feed rolls are driven via a gearbox linked to heavy-duty chains and sprockets; provides smooth even feeding during rough and finish planing. -- Stepless variable speed control (Inverter driven) for smooth adjustment of feed speed depending on the material hardness, depth of cut & width; allows for the best finish and feed speed. -- Anti-kickback device provides safety and is designed to work in unison with a conveyor stop. Safeguards mechanical parts in case of overload situations.Features: -- The heavy-duty CAST IRON frame supports the worktable, helps dampen vibration, and ensures years of dependable service. -- Powerful industrial motors for maximum cutting capacity. -- All precision sealed-for-life bearings for long and durable use. -- A built in cutterhead stand is designed for convenient knife changing at the bottom cutterhead. -- Changing knives on the upper cutter head only requires removal of the upper dust chute. -- Setup time is minimized to set cutter head height using the auto material thickness device. -- The top and bottom cutter heads are precision balanced to provide smooth, chatter-fre

$ 30,990

CAM-WOOD PL-18 18" Wide Top & Bottom Straightening Planer. -- 18" Planer with straight knife heads with HSS knives for accurate and powerful two-sided planning in one pass.ADD for Spiral Heads with Carbide Insert Knives... $4,000.00Replacement Knives:CT-SCH-14T 14 mm wide x 2.0 mm thick Spiral Knives - $2.90 EACHCT-SCH-15T 15 mm wide x 2.5 mm thick Spiral Knives - $3.60 EACHSpecifications: -- 17-3/4"; Max. Planning Width. -- 3/8 to 8" Max. Planning Thickness. -- 1/4"; Max. Cutting Depth. -- 10"; Min. Planning Length. -- 15 to 70 FPM Feeding Speed (Inverter Driven). -- 4,200 RPM Cutter Straight Knife Head Speed. (6,000 RPM for Spiral Cutter Head). -- (4) Knife Cutterheads. -- 15 HP Upper Motor. -- 10 HP Bottom Motor. -- 2 HP Feed Motor. -- 1/2 HP Elevation Motor. -- Table Size (L x W) 88" x 16". -- N.W. 6,500 Lbs.Features: -- Standard equipped with automatic thickness controller, easy, accurate and quick setting for the cutting thickness. -- Upper & lower straight knives or spiral cutterheads for accurate and powerful two-sided planing in one pass. -- The worktable surface is precision ground and then electric chrome-plated and polished to a smooth mirror finish. The durable wear resistance surface is easy to clean and maintain. -- A heavy-duty feed conveyor with metal spikes firmly holds stock securely to the worktable and feeds positively giving a smooth finish for rough or final planning. -- Stepless variable speed control for smooth adjustment of feed rate depending on the material hardness, depth of cut & width to provide the best finish surface and fast cutting performance. -- The infeed conveyor is fitted with numerous pressure pins so the feeding process can be firmly stabilized. It will moderately press the stock, and then accurate planing of the surface can be performed to prevent jumping during processing of narrow or bent material. -- The (4) power feed rollers are driven with a geared transmission box linked with heavy-duty drive chains and gears to provide a smooth even feeding during rough or finish planning. -- A twist torsion anti-kickback device provides additional safety. It’s designed to work in conjunction with the built-in conveyor stop. It safeguards mechanical parts in case of overload. -- The heavy-duty rigid cast iron frame supports the worktable, helps dampen vibration and ensures years of dependable service. -- Powerful industrial motor for maximum cutting capacity. -- All precision sealed long-life bearing for durability -- A swivel stand is designed for convenient knife changing on the bottom cutterhead. -- Changing the knife on the upper cutterhead only requires removal of the upper dust chute. -- The optional spiral insert head design allows for fast, accurate insert changes and minimum down time. -- Setup time is minimized to set cutterhead height using the auto material thickness device. -- The top and bottom cutterheads are precision balanced to provide consistently smooth cha

.gif)