Jointers and Finger Jointers For Sale

Category

Jointers and Finger Jointers

35 Results Found

Call for Price

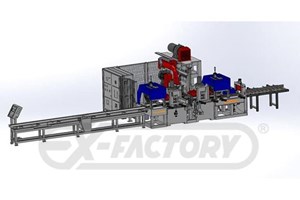

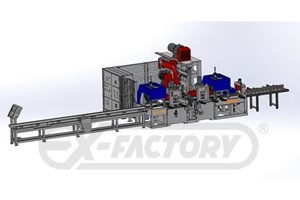

CAM-WOOD IAT 620-150H INVERTER DRIVEN FINGER JOINT SYSTEM 3" X 6":Lay-Up and Block-Staging Infeed Conveyor: -- 24" Wide x 31.5" long belt conveyor powered with 1/2 HP motors. Conveyor is controlled by the operating and system. Feeds at a constant rate of 180 FPM. Block delivery is controlled by the operator and machine system criteria to feed the Shaper. The conveyor facilitates keeping the system full and productive. FSR-62I Right Hand Inverter Type Finger Joint Shaper: -- Feed table is 24" wide and accepts blocks from 6" wide x up to 31.5" long x 5/8" to 6" wide. Shaper spindle is driven by a 20 HP motor and is equipped with provisions for vertical adjustment of 20 mm up and 20 mm down. Spindle diameter is 50 mm and runs at 6,600 RPM. 8-1/4"; maximum shaper cutterhead diameter - without knives. 10 HP - 4,800 RPM Cutoff and trim saw; accepts 10" dia. x 100 tooth x 5 mm blades. 2 HP - 2,850 RPM Scoring saw, accepts 7" dia. x 50 tooth x 5 mm blades. Table movement is Inverter driven; powered by a 3 HP + 3 HP inverter motor with cycle speeds from 1 to 4 cycles/Min. Motor senses load and varies travel speed as needed. Speed is also controlled by system criteria STC-62A Single Table Transfer Conveyor to the 2nd (Left Hand) Shaper: -- 24" Wide x 31.5" long belt conveyor. Powered with (1) 1/2 HP motor. Controlled by system criteria. Feeds at a constant rate of 180 FPM. FSL-62I Left Hand Inverter Type Finger Joint Shaper with Glue Extruder: -- Feed table is 24" wide and accepts blocks from 6" up to 31.5" long x 5/8" to 6" wide. Shaper spindle is driven by a 20 HP motor. Spindle diameter is 50 mm and runs at 6,600 RPM. 8-1/4" maximum shaper cutterhead diameter - without knives. 10 HP - 4,800 RPM Cutoff and trim saw; accepts 10" dia. x 100 tooth x 5 mm blades. 2 HP motor powers a top and a 2nd 2 HP motor powers a bottom scoring saw, both running at 2,850 RPM; accepts 7" dia. x 50 tooth x 5 mm blades. Conveyer powered by 1/2 HP motor. Table movement is Inverter driven; powered by a 3 HP + 3 HP inverter motor with cycle speeds from 1 to 4 cycles/Min. Motor senses load and varies travel speed as needed. Speed is also controlled by system criteria Injection Type Glue Applicator: -- Extrudes adhesive into the fingers without the messy runoff associated with glue rollers. 6" Comb height is standard. Finger pitch 4 mm, 10 - 12 mm finger length is standard equipment (special sizes available as optional equipment) STC-62A Single Table Conveyor Belt to the Assembly Section: -- 24" Wide x 31.5" long belt conveyor. Powered with (1) 1/2 HP motor. Controlled by system criteria. Feeding at a constant rate of 180 FPM. FJ-500A (198") Assembly Press with Cut-Off Saw: -- Capacity from 1" to 6"; wide x 1/2" to 3" high x and from 6' to 16-1/2' long. A 2 HP motor powers the upper and a 2nd 2 HP motor powers lower pre-assembly/crowder rolls. With 5 HP infeed inverter drive. In-feed speed from 30 to 230 FPM. Speed is controlled by system criteria. 5 HP - 2,85

CAM-WOOD FSM-460AX Finger Joint ShaperSingle Finger joint Shaper with 8" min. and unlimited max. block length; 4" max. block thickness, maximum timber height to feed into assembly press is 3"; 18" max. block width (horizontal joint only); 18" table working width.Equipped with: -- Shaper spindle powered by 10 HP belt drive motor with 50 mm dia. spindle turning at 5,500 RPM; 160 mm (6.3") max. dia. cutter. -- Trim-saw powered by 5 HP direct drive motor at 2,850 RPM and a 1" dia. saw spindle; swings 180 mm (7") max. blade dia. -- Table cycles 2 to 4 per Min via the hydraulic system with a 2 HP hydraulic power unit. Includes 5" dia. dust outlet.Features: -- Manual Fingerjointer performs end trimming and shaping functions on right and left end of blocks. -- Air-operated clamp holding blocks firmly in place. After the workpiece is clamped, the table feeds past the saw and shaper spindles to perform trimming and finger-joint operations; trim saw cuts blocks exactly 90° ends. -- Shaper spindle is precision-constructed for cutting fingers accurately; swings up to 6" dia. tooling. -- Spindle height adjustment is displayed on the dial readout for easy adjustment. -- Table travels on a precision linear guide for stability; table traverse driven by hydraulic power system smooth and accurate block feeding. -- Variable feed speed permits proper feed for hard or soft wood. -- Cast iron frame and table for durability.

CAM-WOOD MODEL FSG-150X Manual FINGER JOINT GLUE APPLICATOR -- Manual operation of sliding table ; Specification: -- Glue roller type -- Working width 24" maximum -- Working thickness 6" -- Glue roller drive 1/2 HP with reducer -- Standard clus height 4"

CAM-WOOD SFJ-460L FINGER JOINT ASSEMBLY PRESS SYSTEM With Optional GluingDescription: -- The SFJ-460L is an automatic Assembly System, Cutoff Saw, and Press. The system performs three functions; pre-assembles finger jointed blocks with glue previously applied in the FSG 150 manual Glue Applicator (not included), cuts the assembled boards to length, and performs the final assembly when pressed by a powerful hydraulic system. When pressing is complete, boards are fed out of the Press. -- Power feed for feeding boards, stops automatically at the desired board length using the included cut-off saw as standard equipment for cutting boards to length. -- The maximum assembled board length is 15'. Specifications: -- Max. length capacity, 188"; max. width, 6"; max. thickness, 3". -- Feed speeds from 0 - 26 FPM; -- Cutoff Saw runs at 3,500 RPM and is powered by a 5 HP motor; Blade diameter is 355 mm (14") with a 1" arbor; -- With 1/2 HP feed motor and 5 HP hydraulic pump motor. Option: -- Manual Gluing unit FSG 150 Additional $ 8,990Note: Same press with 6,000 mm (19.7') capacity additional price is $6,900

CAM-WOOD TYPE F1, MODEL FAH 8" X 30’ HORIZONTAL FULLY AUTOMATIC FINGER JOINT SYSTEM - SINGLE CHAIN TYPEMECHANICAL SPECIFICATIONS FOR THE FEED SYSTEM: -- Operating speed: 120 to 150 lugs/Min -- Intermittent feed motor: 2 HP + 1:25 -- Feed chain motor: 30 HP (20 kW) Servo Drive (C2) MECHANICAL SPECIFICATIONS: RIGHT-SIDE SHAPER: -- Cutterhead Motor: 25 HP -- Spindle size: 2-3/4"; (70 mm) -- Maximum cutter head body diameter: 10"; -- Cutterhead speed: 5,500 RPM at 60 Hz -- Trim Saw Motor: 15 HP -- Trim Saw blade size: 12"; (305mm) x 80 Tooth x 5mm kerf -- Cut-off saw Speed: 4,300 RPM -- Scoring saw motor: 3 HP -- Scoring saw blade: 7"; (180mm) x 50 Tooth x 5mm -- Scoring saw spindle speed: 4,200 RPM -- Holddown rise and lower motor: 1/2 HP (C3) MECHANICAL SPECIFICATIONS: LEFT-SIDE SHAPER: -- Cutterhead Motor: 25 HP -- Spindle size: 2-3/4"; (70 mm) -- Maximum cutter head body diameter: 10"; -- Cutterhead speed: 5,500 RPM at 60Hz -- Trim Saw Motor: 15 HP -- Trim Saw blade size: 12"; (305 mm) x 80 Tooth x 5 mm kerf -- Cut-off saw Speed: 4,300 RPM -- Scoring saw motor: 3HP -- Scoring saw blade: 7"; (180 mm) x 50 Tooth x 5 mm -- Scoring saw spindle speed: 4,200 RPM -- Holddown rise and lower motor: 1/2 HP -- Glue Application by GLUE COMB -- Standard glue height: 6"; High, 3.8 mm pitch 3.8 mm. Finger lengths from 10 to 12 mm (Other lengths available) (K) MECHANICAL SPECIFICATIONS: SHAPER OUT-FEED: -- Speed: 230 FPM -- Feed Motor: (1) 3 HP -- Vacuum device blower with 3"; Vacuum port: 5 HP (G) MECHANICAL SPECIFICATIONS: PRE-JOINT ASSEMBLY: --Feed chain drive: (2) 3 HP motors --In-feed Inverter: (1) 7-1/2 HP --Chain type: Flat top double chain --Feeding speeds from 30 to 300 FPM (H) MECHANICAL SPECIFICATIONS: 30’ (9.3M) ASSEMBLY PRESS: --Working dimension: 1"; to 8"; wide x 0.60"; to 2 3/8"; high x up to 30’ long --Upper & lower roll power: (2) 2 HP motors --In-feed Inverter: 7-1/2 HP --In-feed speed: 30 to 300 FPM --PROGRAMMABLE Cut-off saw power: 5 HP --Cut-off Blade dimensions: 14"; Dia. x 120 Tooth x 1"; bore --Cut-off saw speed: 2,850 RPM --Hydraulic power: 5 HP (With high speed oil tank) --Cycle Speed: 1 to 8 Cy/MinPRODUCTION CAPACITY - PARAMETERS: -- Based on a 480-minute shift -- Finger length to customer’s specifications -- Average infeed length at the shaper section is 20"; --A verage block cross section is 2"; x 4"; -- Chain speed at the Shaper sections is 150 lugs/Min -- Press capacity is (8) 30’ loads per minute (maximum) CAPACITY OF THE SHAPERS WHEN FINGER JOINTING 2"; X 4"; x 20" BLOCKS -- (120) Blocks per minute -- x 20"; Average infeed length -- x 480 Minutes per shift -- x 0.8 Rate of utilization = 76,800 lineal feet per shift CAPACITY OF THE PRESS ASSEMBLING 30’ LENGTHS: -- (8) Assembled lengths per minute -- x 20’ Per minute -- x 480 Minutes per shift -- x 0.8 Rate of utilization = 66,440 lineal feet per shift -- NOTE: If using the cutoff saw for multi-section pressin

CAM-WOOD TYPE F1, MODEL FAH 8" X 40’ AUTOMATIC HORIZONTAL FINGER JOINT SYSTEM - SINGLE CHAIN TYPE (including Feeding System from Optimizing Saw)Technical Specifications: -- Working thickness: 17 mm to 60 mm (.66" to 2 3/8") -- Working width: 25 mm to 205 mm ( 1" to 8") -- Maximum finish length: 12 Meters ( 40') -- Glue type: PVAC -- Timber moisture: 8% to 12% -- Infeed quality must be S4S with tolerance +/- 02 mm, wood need 90° right angle and straight MECHANICAL SPECIFICATIONS FOR THE FEED SYSTEM: -- Operating speed: 120 to 180 lugs/Min -- Intermittent feed motor: 2 HP + 1:25 -- Feed chain motor: 30 HP (20 kW) Servo Drive (C2) MECHANICAL SPECIFICATIONS: RIGHT-SIDE SHAPER: -- Cutterhead Motor: 25 HP -- Spindle size: 2-3/4"; (70 mm) -- Maximum cutter head body diameter: 10"; -- Cutterhead speed: 5,500 RPM at 60 Hz -- Trim Saw Motor: 15 HP -- Trim Saw blade size: 12"; (305 mm) x 80 Tooth x 5 mm kerf -- Cut-off saw Speed: 4,300 RPM -- Scoring saw motor: 3 HP -- Scoring saw blade: 7"; (180 mm) x 50 Tooth x 5 mm -- Scoring saw spindle speed: 4,200 RPM -- Holddown rise and lower motor: 1/2 HP (C3) MECHANICAL SPECIFICATIONS: LEFT-SIDE SHAPER: -- Cutterhead Motor: 25 HP -- Spindle size: 2-3/4"; (70 mm) -- Maximum cutter head body diameter: 10"; -- Cutterhead speed: 5,500 RPM at 60 Hz -- Trim Saw Motor: 15 HP -- Trim Saw blade size: 12"; (305 mm) x 80 Tooth x 5 mm kerf -- Cut-off saw Speed: 4,300 RPM -- Scoring saw motor: 3 HP -- Scoring saw blade: 7"; (180 mm) x 50 Tooth x 5 mm -- Scoring saw spindle speed: 4,200 RPM -- Holddown rise and lower motor: 1/2 HP -- Glue Application by GLUE COMB -- Standard glue height: 6"; High, 3.8 mm pitch 3.8 mm. Finger lengths from 10 to 12 mm (Other lengths available) (K) MECHANICAL SPECIFICATIONS: SHAPER OUT-FEED: -- Working size: Length 150 mm to 900 mm ( 6" to 35-7/16"); Width 25 to 205 mm (1" to 8") -- Speed: 70 m/Min ( 230 FPM) -- Infeed inverter : (1) 3 HP -- Vacuum device blower with 3"; Vacuum port: 5 HP (G) MECHANICAL SPECIFICATIONS: PRE-JOINT ASSEMBLY: -- Working size: Thickness 17 mm to 60 mm (5/8" to 2,3/8"); Width 25 mm to 205 mm (1" to 8") --Feed chain drive: (2) 3 HP motors --In-feed Inverter: (1) 7-1/2 HP --Chain type: Flat top double chain --Feeding speeds from 10 to 90 m/Min (32 to 292 FPM) (H) MECHANICAL SPECIFICATIONS: 40’ (12 M) ASSEMBLY PRESS: --Working dimension: 3/4"; to 8"; wide x 0.60"; to 2-3/8"; high x up to 40’ long --Upper & lower roll power: (2) 2 HP motors --In-feed Inverter: 7-1/2 HP --In-feed speed: 10 m to 70 m/Min (32 to 227 FPM) --PROGRAMMABLE Cut-off saw power: 5 HP --Cut-off Blade dimensions: 14"; Dia. x 120 Tooth x 1"; bore --Cut-off saw speed: 2,850 RPM --Hydraulic power: 5 HP (With high-speed oil tank) --Cycle Speed: 1 to 6 Cy/MinPRODUCTION CAPACITY - PARAMETERS: -- Based on a 480-minute shift -- Finger length to customer’s specifications -- Average infeed length at the shaper section is 500 mm (20";) --Average block cross-

CAM-WOOD TYPE F1, MODEL FAH 8" X 20’ AUTOMATIC HORIZONTAL FINGER JOINT SYSTEM - SINGLE CHAIN TYPE (including Feeding System from Optimizing saw)Technical Specifications: -- Working thickness: 17 mm to 60 mm (0.66" to 2-3/8") -- Working width: 25 mm to 205 mm ( 1" to 8") -- Maximum finish length: 6.2 Meters ( 20') -- Glue type: PVAC -- Timber moisture: 8% to 12% -- Infeed quality must be S4S with tolerance +/- 02 mm, wood need 90° right angle and straight MECHANICAL SPECIFICATIONS FOR THE FEED SYSTEM: -- Operating speed: 120 to 180 lugs/Min -- Intermittent feed motor: 2 HP + 1:25 -- Feed chain motor: 30 HP (20 kW) Servo Drive (C2) MECHANICAL SPECIFICATIONS: RIGHT-SIDE SHAPER: -- Cutterhead Motor: 25 HP -- Spindle size: 2-3/4"; (70 mm) -- Maximum cutter head body diameter: 10"; -- Cutterhead speed: 5,500 RPM at 60 Hz -- Trim Saw Motor: 15 HP -- Trim Saw blade size: 12"; (305 mm) x 80 Tooth x 5 mm kerf -- Cut-off saw Speed: 4,300 RPM -- Scoring saw motor: 3 HP -- Scoring saw blade: 7"; (180 mm) x 50 Tooth x 5 mm -- Scoring saw spindle speed: 4,200 RPM -- Holddown rise and lower motor: 1/2 HP (C3) MECHANICAL SPECIFICATIONS: LEFT-SIDE SHAPER: -- Cutterhead Motor: 25 HP -- Spindle size: 2-3/4"; (70 mm) -- Maximum cutter head body diameter: 10"; -- Cutterhead speed: 5,500 RPM at 60 Hz -- Trim Saw Motor: 15 HP -- Trim Saw blade size: 12"; (305 mm) x 80 Tooth x 5 mm kerf -- Cut-off saw Speed: 4,300 RPM -- Scoring saw motor: 3 HP -- Scoring saw blade: 7"; (180 mm) x 50 Tooth x 5 mm -- Scoring saw spindle speed: 4,200 RPM -- Holddown rise and lower motor: 1/2 HP -- Glue Application by GLUE COMB -- Standard glue height: 6"; High, 3.8 mm pitch 3.8 mm. Finger lengths from 10 to 12 mm (Other lengths available) (K) MECHANICAL SPECIFICATIONS: SHAPER OUT-FEED: -- Working size: Length 150 mm to 900 mm ( 6" to 35-7/16"); Width 25 to 205 mm (1" to 8") -- Speed: 70 m/Min ( 230 FPM) -- Infeed inverter : (1) 3 HP -- Vacuum device blower with 3"; Vacuum port: 5 HP (G) MECHANICAL SPECIFICATIONS: PRE-JOINT ASSEMBLY: -- Working size: Thickness 17 mm to 60 mm (5/8" to 2,3/8"); Width 25 mm to 205 mm (1" to 8") --Feed chain drive: (2) 3 HP motors --In-feed Inverter: (1) 7-1/2 HP --Chain type: Flat top double chain --Feeding speeds from 10 to 90 m/Min (32 to 292 FPM) (H) MECHANICAL SPECIFICATIONS: 20’ (6.2 M) ASSEMBLY PRESS: --Working dimension: 3/4"; to 8"; wide x 0.60"; to 2-3/8"; high x up to 20’ long --Upper & lower roll power: (2) 2 HP motors --In-feed Inverter: 7-1/2 HP --In-feed speed: 10 m to 70 m/Min (32 to 227 FPM) --PROGRAMMABLE Cut-off saw power: 5 HP --Cut-off Blade dimensions: 14"; Dia. x 120 Tooth x 1"; bore --Cut-off saw speed: 2,850 RPM --Hydraulic power: 5 HP (With high-speed oil tank) --Cycle Speed: 1 to 6 Cy/MinPRODUCTION CAPACITY - PARAMETERS: -- Based on a 480-minute shift -- Finger length to customer’s specifications -- Average infeed length at the shaper section is 500 mm (20";) --Average block cros

CAM-WOOD Continuous in-line Long Board Vertical Finger Joint System, Model "UCT-305"Up to 12"; Wide x 4-1/4" Thick x Unlimited Assembled Length System Specifications: -- Incoming board lengths from 39"; to 236" (1,000 mm - 6,0000 mm). -- Board widths from 2"; to 12"; (50 mm - 305 mm). -- Board thickness from 1" to 4.3"; (25 mm - 110 MM). -- Board out-feed length 40’. (could be increase with outfeed conveyor) -- Glue type to be used: PVAC. (Glue pump and applicator not included) -- Board species: SOFTWOOD and HARDWOOD. -- Board moisture content: 8% to 12%. -- Infeed board qualities: Lumber runs best on Finger Jointers when surfaced on (4) sides (S4S) (Tolerance +/- .2 mm (.008"). System prefers straight boards with 90-degree corners. UCT-305 Mechanical Specifications: -- Top infeed feed rolls powered with (2) 2HP motors. -- Bottom infeed feed rolls powered with (2) 2 HP motors. -- In-feed Inverter with (2) 7.5 HP motors. -- Auxiliary conveyor wheel with 2.6 HP servo motor. -- Top Shaper Spindle powered with a 30 HP motor. -- Bottom Shaper Spindle powered with a 30 HP motor. -- Maximum Cutterhead length, 12“(305 mm). -- Maximum Cutterhead diameter, 6.3“(160 mm). -- Typical cutter pitch, 4.0 mm. Length, 10 mm - 12 mm (Other sizes available). -- Shaper spindle moving power by 2.6 HP Servo Motor. -- In-feed speed from 32 to 295 FPM (10 ~90 m/Min). -- Outfeed cut-off saw motor, 10 HP. -- Cut-off sawblade, 24“ dia x 120 teeth (included). -- Cut-off sawblade speed, 2,850 RPM. -- Hydraulic pump power, 30 HP. -- Outfeed conveyor, (2) 2 HP drives. -- Top outfeed feed rolls powered with (2) 2 HP motors. -- Lower outfeed feed rolls powered with (2) 2HP motors. -- Out-feed Inverter with (2) 7.5 HP motors. -- Glue injection Glue Applicator for Standard PVAC glue. (glue pump not included) -- Hydraulic oil tank with 150-gal capacity (oil not included)Outfeed options: -- Outfeed roller conveyor 20'' X 8' long Additional: $ 4,890 per sectionNot included with the machine: -- Cutter heads for finger jointer (we can provide quote) -- Gluing system with pump and nozzle Optional Cross Infeed Conveyor System:Optional Automatic 20 ft Cross InfeedPower Conveyor System Working size L = 1000 MM ~ 6000 MM, W= 50 ~ 305 MM, T=25 ~ 110 MM ( Lenght 39" - 236" X Width 2" -12", Thickness: 1" to 43.3")Infeed roller Conveyor 3 HP1Cross feeding system 3 HP1Feeding speed of 15 M/min (48'/min.)Storage area width 2500 mmAdditional cost: $61,990Glue pump Option: -- Graco 1K PUR Glue SystemAdditional cost: $ 48,990NOTE: Training, installation & tooling not included TO BE PROVIDED LOCALLY -- Electric power supply to Motor Control Center -- Constant voltage (voltage deviations max.: 5%) -- Temperature range for computer control should not exceed 95°F. -- 65% Maximum relative air humidity for computer control system --Dust exhaust system: (V=30M/S at a low pressure of 12M BAR) --Compressed air connection to machinery: 7~8 KG/cm² – 8 BAR --Electrical cabli

Call for Price

CAM-WOOD IAT 620-100HX INVERTER DRIVEN FINGER JOINT SYSTEM 3" X 6" X 16.5 feet long medium capacity Finger Jointing SystemIncoming Block Specifications: -- Incoming block lengths from 6"; to 31.5"; -- Blocks must be at least 50% longer than their width. -- Block thickness from 1/2"; to 3" -- Block width from 1"; to 6" -- Assembled lengths from 10’ to 16’ (Options 20’ or 24’) -- For use with PVAC adhesives (glue pump and nozzle not included) -- Works equally well with soft and hardwoods. -- Moisture content from 8 to 12% -- Blocks to be surfaced on (4) sides through a Moulder or 4-sided Planer to ± 0.2 mm with 90° right angle corners.Lay-Up and Block-Staging Infeed Conveyor: -- 24" Wide x 31.5" long belt conveyor powered with 1/2 HP motors. The conveyor is controlled by the operating system. Feeds at a constant rate of 180 FPM. Block delivery is controlled by the operator and machine system criteria to feed the Shaper. The conveyor facilitates keeping the system full and productive. FSR-62I Right Hand Inverter Type Finger Joint Shaper: -- Feed table is 24" wide and accepts blocks from 6" to 31.5" long -- 5/8" to 6" width -- 1/2" to 3" thickness -- Shaper spindle is driven by a 20 HP motor and is equipped with provisions for vertical adjustment of 20 mm up and 20 mm down. Spindle diameter is 50 mm and runs at 6,600 RPM. 6.3"; (160 mm) maximum shaper cutterhead diameter (cutter head not included) -- 5 HP - 4,800 RPM Cutoff and trim saw; accepts 10" dia. x 100 tooth x 5 mm blades. -- 2 HP - 2,850 RPM Scoring saw, accepts 7" dia. x 50 tooth x 5 mm blades. -- Conveyor powered by 1/2 HP motor. -- Table movement is inverter driven; powered by a 3 HP inverter motor with cycle speeds from 1 to 4 cycles per minute. Motor senses load and varies travel as needed. TC-62 Single Table Transfer Conveyor to the 2nd (Left Hand) Shaper: -- 24" Wide x 31.5" long belt conveyor. Powered with (1) 1/2 HP motor. Controlled by system criteria. Feeds at a constant rate of 180 FPM. FSL-62I Left Hand Inverter Type Finger Joint Shaper with Glue Extruder: -- Feed table is 24" wide and accepts blocks from 6" to 31.5" long -- 5/8" to 6" width. -- 1/2" to 4" thickness -- A 20 HP motor drives shaper spindle. Spindle diameter is 50 mm and runs at 6,600 RPM. 6.3" (160 mm) Maximum shaper cutterhead diameter (cutter head not included). -- 10 HP - 4,800 RPM Cutoff and trim saw; accepts 10" dia. x 100 tooth x 5 mm blades. -- 2 HP motor scoring saw, running at 2,850 RPM; accepts 7" dia. x 50 tooth x 5 mm blades. -- Conveyer powered by 1/2 HP motor. -- Table movement is Inverter driven; powered by a 3 HP inverter motor with cycle speeds from 1 to 4 cycles/Min. Motor senses the load and varies travel as needed. Speed is controlled by system criteria. Included Injection Type Glue Applicator: -- Extrudes adhesive into the fingers without a messy runoff. 4" Comb height is standard. -- Finger pitch 4 mm, 10 - 12 mm finger length is standard equipm

CAM-WOOD FJ-17 (FM) 6" X 16' Long Semi-Automatic Finger Jointer System(4) Version possible on this model. Choose the one that suits your needsTechnical Specifications:Incoming Block Requirements: -- Incoming block lengths No Limit (Manual Loaded). Blocks must be at least 50% longer than their width. -- Block thickness from 1/2"; to 3" -- Block width from 1"; to 6" -- Assembled lengths from 8’ to maximum 16’ or (20’ Options Add Extra ...$5,675.00) or 24’ (Options Add Extra ...$11,450.00) -- For use with PVAC adhesives Glue pump is not included -- Works equally well with soft and hardwood Blocks. Moisture content from 8 to 12% -- Blocks to be surfaced (4) sides through a Moulder or 4-sided Planer to ±0.2mm with 90° right angle cornersThis semi-automatic system is offered in (4) different versionsVersion 1: -- Finger Shaper (FSM-460A) + Conveyor (RO-62) x 2 + Assembly Press (FJ-500A) The price: $82,900.001. Semi-Auto Finger Shaper Process the finger at one side 2. Manually flip/turn to the other side and make fingers again at the same shaper,3. Manual blush applied the glue,4. Semi-Automatic finger jointer press The price: $92,150.00Version2: -- Finger Shaper (FSM-460A) + Conveyor (RO-62) x 2 + Manual Gluer (FSH-150) + Assembly Press (FJ-500A) 1. Semi-Auto Finger Shaper Process the finger at one side.2. Manually flip/turn to the other side and make fingers again at the same shaper,3. Manual Glue Spreader applied the glue,4. Semi-Automatic finger jointer pressThe price: $103,250Version 3: -- Finger Shaper with Gluer (FSM-621) + Conveyor (RO-62) x 2 + Assembly Press (FJ-500A) 1. Semi-Auto Finger Shaper Process the finger at one side.2. Manually flip/turn to the other side and make fingers again at the same shaper,3. Automatic Glue Spreader applied the glue at the second finger process,4. Semi-Automatic finger jointer press The price: ...$116,600.00Version 4:Finger Shaper (FSM-460A) + RO-62 x 3 + Finger Shaper with Gluer (FSM-621) + Assembly Press (FJ-500A)1. Semi-Auto Finger Shaper Process the finger at one side.2. Push to the next (2nd) Semi-automatic finger shaper with Auto Glue Spreader and applied the glue at the other side,3. Semi-Automatic finger jointer pressThe price: ...$ 159,900Description of Each Unit:FSM-460A Semi-auto finger shaper (Air-hydraulic type) -- Working timber width (Horizontal Direction); 1"; to 6"; -- Maximum timber total width fit on working table 18"; -- Maximum working height (Vertical direction); 4"; -- Maximum timber thickness (Height feed into assembly press); 3"; -- Working timber length; No Limit (Timber length must be at least 50% longer than the timber width to be processed.) -- Trim saw/Hogging blade 180 mm x 50T x 5 mm x 1 pcs. Trim/Hogging saw speed; 2,850 RPM -- Trim/Hogging saw motor 5 HP x 1 -- Finger shaper motor; 10 HP x 1 . Finger spindle Speed; 5,500 RPM. Spindle size; 50 mm, OD of finger cutter; OD160 mm -- Table movement by pneumatic–hydraulic cylinder -- Cycle time

Call for Price

CAM-WOOD HSTC-62 HIGH SPEED LONG BOARD VERTICAL FINGER JOINTER with the following Specifications: Technical Specifications: -- Infeed lenght 1000 mm to 5,000 mm (39" to 16') -- Working width 50mm - 300 mm (1.9" to 11.9") -- Working thickness 25 mm tp 100 mm (1" to 3.9")HSTC-62A Infeed Belt Conveyor: -- Working dimension: 24"; wide x 16’ long -- Speed at 110 FPM -- One 3 HP Inverter Drive Motor SHAPER #1: DFSR-62I - Left Side Heavy Duty Finger Joint Shaper -- Working dimension: 24"; wide x 2"; to 12"; high x 39"; to 16' long -- Scoring Saw: 2 HP motor -- Scoring Saw Blade: 7"; diameter x 50 tooth -- Scoring Saw speed: 2,850 RPM -- Trim Saw Spindle: 15 HP motor -- Trim Saw Blade: 12"; diameter x 80 tooth -- Trim Saw Speed: 2,800 RPM -- (2) Finger Joint Spindles, (1) for rough cut and (1) for finish cut, each with a 30 HP motor -- Spindle diameter: 50 mm -- Diameter of cutterhead possible without knives: 8-1/4"; -- Shaper Spindle speed: 3,800 RPM -- Conveyor belt with 3 HP Inverter Drive -- Table cycle by 3 HP Drive Motor -- Table cycle speed from (1) to (4) cycles per minute (depends on work)HSTC-62A HEAVY SINGLE TABLE OUTFEED TRANSFER CONVEYOR -- Working dimension: 24"; wide X 16’ long -- Speed at 110 FPM -- One 3 HP Inverter DriveHSTC-62A SINGLE TABLE INFEED TRANSFER CONVEYOR -- Working dimension: 24"; wide X 16' long -- Speed at 110 FPM -- One 3 HP Inverter DriveSHAPER #2: DFSR-62I - RIGHT SIDE HEAVY DUTY FINGER JOINT SHAPER WITH GLUE APPLICATOR -- Working dimension: 24"; wide x 1"; to 10"; high x 8"; to 16' long -- Scoring Saw: 2 HP motor -- Scoring Saw Blade: 7"; diameter x 50 tooth -- Scoring Saw speed: 2,850 RPM -- Trim Saw Spindle: 15 HP motor -- Trim Saw Blade: 12"; diameter x 80 tooth -- Trim Saw Speed: 2,800 RPM -- (2) Finger Joint Spindles, (1) for rough cut and (1) for finish cut, each with a 30 HP motor -- Spindle diameter: 50 mm -- Diameter of cutterhead possible without knives: 8-1/4"; -- Shaper Spindle speed: 3,800 RPM -- Conveyor belt with 3 HP Inverter Drive -- Table cycle by 3 HP Drive Motor -- Injection type adhesive spreader with standard glue height of 10"; -- Glue system included is for PVAC. (glue pump not included) -- Optional APQUIP Glue System available at extra cost -- Optional Glue Equipment available for Loctite HB X Glue at extra priceHSTC-62B OUTFEED CONVEYOR WITH BELT CLEANER -- Working dimension 24"; long X 16’ wide -- Speed at 115 FPM -- (1) 3 HP Inverter Drive -- (1) 1/2 HP motor for conveyor cleaning device HSCB-62 TIPPING CONVEYOR W/NARROW CONVEYOR -- Flips boards from vertical to horizontal for automatic feed to the Press -- Working dimensions: -- (1) Conveyor at 24"; wide x 16’ long -- (1) Conveyor at 12"; wide x 16’ long -- Speed 110 FPM -- 3 HP Inverter Drive UFJ-600 FINGER JOINT CONTINOUS ASSEMBLY MACHINE FOR INFINITE LENGTHS -- Working dimension 1-3/8"; to 12" wide X 1"; to 4"; thick by unlimited lengths -- In-feed speed from 100 to 165 FPM -- Cut-Off Saw: 7-1/2

CAM-WOOD SFJ-3800-205-FM-FAH HIGH SPEED, LONG BOARD, HORIZONTAL JOINT, FINGER JOINTER: Specifications: -- Double Chain & Slat Type Shaper Section designed for long incoming boards -- Manual infeed; Slat Bed Feed Chain runs at up to 75 FPM; lugs on 30" centers. Slat Bed powered with a 15 HP gear motor with 1:40 gear ratio. -- Table Transfer Conveyor (Powered), even ends boards to the Right and Left Shaper Fences: powered by (2) 7-1/2 HP motors -- Power raising and lowering of the holddown assemblies on both Shaper Sections; Powered with (2) 2 HP motors -- (1) Pair Scoring Saws with 2 HP motors, 50mm arbor, 2,850 RPM, scoring blade size of 7"; x 50 tooth, (4) Blades included -- (1) Pair Trim Saws with 10 HP motors, 50mm arbor, 4,275 RPM, trim saw blade size of 10"; x 100 tooth. (2) Blades included -- (1) Pair Vertical Hogging Shaper Spindles with 10 HP motors, 50mm arbor, 4,375 RPM, hogging blade size of 9.4"; x 50-tooth. (2) Blades included -- (1) Pair Vertical Finish Shaper Spindles with 20 HP motors, 50mm diameter spindles, 5,300 RPM. For -- 50mm bore x 160mm dia. cutterheads; finger length of 1.122";; cutterheads and knife profile to buyer’s specification -- Extrusion Type Glue Application System for PVAC Glues; mounted on Right Side Shaper Section. Includes glue pump, valves, and glue injection thru the applicator comb machined to buyer's specifications. -- Optional APQUIP Glue System available at extra cost -- Optional Glue Equipment available for Loctite HB X Glue at extra price -- Deduct $5,200 if provided without a Glue SystemSCC-20 TRANSFER CONVEYOR -- Conveyor between Shaper Section to the Press Section -- Working dimension: from 1"; to 8"; wide x 12"; to 12’-6"; long -- Speed 230 FPM -- Powered by (1) 3 HP HSC-65 HIGH-SPEED PRE-PRESS ASSEMBLY SECTION -- Working dimensions: 1"; to 8"; wide x 3/4"; to 2-1/4"; high x up to 21’ long -- (2) 5 HP motors drive the double flat-top chains -- Feed speeds from 32 to 295 FPM -- Includes (1) 15 HP Frequency Converter to power the feed chain motors at speeds determined by incoming boards lengths NFJ-1500 50’ HEAVY-DUTY AUTOMATIC ASSEMBLY PRESS -- Working dimension: 1"; to 8"; wide x 3/4"; to 2-1/4"; high x up to 50’ long -- Power of upper rollers: (2) 3 HP motors with a 1:10 gear ratio -- Power of lower roller: (1) 5 HP motor with a 1:10 gear ratio -- In-feed Inverter: (1) 15 HP motor -- In-feed speed: From 32 to 295 FPM -- Cut-off saw: With 7.5 HP motor driving the arbor at 2,850 RPM -- Sawblade: 14"; Diameter x 120 tooth -- Hydraulic power to the Pressing Cylinders: (2) 20HP with high-speed oil tank -- Hydraulic pressure output: 1,700 PSI at the joint -- Capacity (1) to (4) 50’ assembled boards per minute -- Machine comes arranged with equipment to assemble (3) sizes of material cross sections according to buyer’s specifications for width within +/-3/16"; width toleranceSYSTEM REQUIREMENTS FOR INCOMING BOARDS -- Incoming lumber length: 1’ to 12

CAM-WOOD TYPE F1, MODEL FAH, 6"; X 20’ Horizontal Fully Automatic Finger Joint System Single Chain TypeMECHANICAL SPECIFICATIONS FOR THE FEED SYSTEM: -- Operating speed: 120 to 150 lugs/Min -- Intermittent feed motor: 2 HP + 1:25 -- Feed chain motor: 30 HP (20 kW) Servo Drive (C2) MECHANICAL SPECIFICATIONS: RIGHT-SIDE SHAPER: -- Cutterhead Motor: 25 HP -- Spindle size: 2-3/4"; (70 mm) -- Maximum cutter head body diameter: 10"; -- Cutterhead speed: 5,500 RPM at 60 Hz -- Trim Saw Motor: 15 HP -- Trim Saw blade size: 12"; (305mm) x 80 Tooth x 5mm kerf -- Cut-off saw Speed: 4,300 RPM -- Scoring saw motor: 3 HP -- Scoring saw blade: 7"; (180 mm) x 50 Tooth x 5 mm -- Scoring saw spindle speed: 4,200 RPM -- Holddown rise and lower motor: 1/2 HP (C3) MECHANICAL SPECIFICATIONS: LEFT-SIDE SHAPER: -- Cutterhead Motor: 25 HP -- Spindle size: 2-3/4"; (70 mm) -- Maximum cutter head body diameter: 10"; -- Cutterhead speed: 5,500 RPM at 60Hz -- Trim Saw Motor: 15 HP -- Trim Saw blade size: 12"; (305 mm) x 80 Tooth x 5 mm kerf -- Cut-off saw Speed: 4,300 RPM -- Scoring saw motor: 3HP -- Scoring saw blade: 7"; (180 mm) x 50 Tooth x 5 mm -- Scoring saw spindle speed: 4,200 RPM -- Holddown rise and lower motor: 1/2 HP -- Glue Application by GLUE COMB -- Standard glue height: 6"; High, 3.8 mm pitch 3.8 mm. Finger lengths from 10 to 12 mm (Other lengths available) (K) MECHANICAL SPECIFICATIONS: SHAPER OUT-FEED: -- Speed: 230 FPM -- Feed Motor: (1) 3 HP -- Vacuum device blower with 3"; Vacuum port: 5 HP (G) MECHANICAL SPECIFICATIONS: PRE-JOINT ASSEMBLY: --Feed chain drive: (2) 3 HP motors --In-feed Inverter: (1) 7-1/2 HP --Chain type: Flat top double chain --Feeding speeds from 30 to 300 FPM (H) MECHANICAL SPECIFICATIONS: 20’ (6.2M) ASSEMBLY PRESS: --Working dimension: 3/4"; to 6"; wide x 0.60"; to 3"; high x up to 20’ long --Upper & lower roll power: (2) 2 HP motors --In-feed Inverter: 7-1/2 HP --In-feed speed: 30 to 300 FPM --PROGRAMMABLE Cut-off saw power: 5 HP --Cut-off Blade dimensions: 14"; Dia. x 120 Tooth x 1"; bore --Cut-off saw speed: 2,850 RPM --Hydraulic power: 5 HP (With high speed oil tank) --Cycle Speed: 1 to 8 Cy/MinPRODUCTION CAPACITY - PARAMETERS: -- Based on a 480-minute shift -- Finger length to customer’s specifications -- Average infeed length at the shaper section is 20"; --A verage block cross section is 2"; x 4"; -- Chain speed at the Shaper sections is 150 lugs/Min -- Press capacity is (8) 20’ loads per minute (maximum) CAPACITY OF THE SHAPERS WHEN FINGER JOINTING 2"; X 4"; x 20" BLOCKS -- (120) Blocks per minute -- x 20"; Average infeed length -- x 480 Minutes per shift -- x 0.8 Rate of utilization = 76,800 lineal feet per shift CAPACITY OF THE PRESS ASSEMBLING 20’ LENGTHS: -- (8) Assembled lengths per minute -- x 20’ Per minute -- x 480 Minutes per shift -- x 0.8 Rate of utilization = 66,440 lineal feet per shift -- NOTE: If using the cutoff saw for multi-section pressin

Call for Price

CAM-WOOD IAT 620-150HX INVERTER DRIVEN FINGER JOINT SYSTEM Lay-Up and Block-Staging Infeed Conveyor: -- 24" Wide x 31.5" long belt conveyor powered with 1/2 HP motors. The conveyor is controlled by the operating and system. Feeds at a constant rate of 180 FPM. Block delivery is controlled by the operator and machine system criteria to feed the Shaper. The conveyor facilitates keeping the system full and productive. FSR-62I Right Hand Inverter Type Finger Joint Shaper: -- Feed table is 24" wide and accepts blocks from 6" to 31.5" long x 5/8" to 6" wide. Shaper spindle is driven by a 20 HP motor and is equipped with provisions for vertical adjustment of 20 mm up and 20 mm down. Spindle diameter is 50 mm and runs at 6,600 RPM. 8-1/4"; maximum shaper cutterhead diameter - without knives. -- 5 HP - 4,800 RPM Cutoff and trim saw; accepts 10" dia. x 100 tooth x 5 mm blades. 2 HP - 2,850 RPM Scoring saw, accepts 7" dia. x 50 tooth x 5 mm blades. -- Conveyor powered by 1/2 HP motor. -- Table movement is inverter driven; powered by a 3 HP inverter motor with cycle speeds from 1 to 4 cycles per minute. Motor senses load and varies travel as needed. TC-62 Single Table Transfer Conveyor to the 2nd (Left Hand) Shaper: -- 24" Wide x 31.5" long belt conveyor. Powered with (1) 1/2 HP motor. Controlled by system criteria. Feeds at a constant rate of 180 FPM. FSL-62I Left Hand Inverter Type Finger Joint Shaper with Glue Extruder: -- Feed table is 24" wide and accepts blocks from 6" to 31.5" long x 5/8" to 6" wide. Shaper spindle is driven by a 20 HP motor. Spindle diameter is 50 mm and runs at 6,600 RPM. 8-1/4" Maximum shaper cutterhead diameter - without knives. -- 10 HP - 4,800 RPM Cutoff and trim saw; accepts 10" dia. x 100 tooth x 5 mm blades. 2 HP motor powers a top and a 2nd 2 HP motor powers a bottom scoring saw, both running at 2,850 RPM; accepts 7" dia. x 50 tooth x 5 mm blades. -- Conveyer powered by 1/2 HP motor. Table movement is Inverter driven; powered by a 3 HP + 3 HP inverter motor with cycle speeds from 1 to 4 cycles/Min. Motor senses load and vary travel as needed. Speed is controlled by system criteria. Injection Type Glue Applicator: -- Extrudes adhesive into the fingers without a messy runoff. 6" Comb height is standard. Finger pitch 4 mm, 10 - 12 mm finger length is standard equipment (special sizes available as optional equipment) STC-62A Single Table Conveyor Belt to the Assembly Section: -- 24" Wide x 31.5" long belt conveyor. Powered with (1) 1/2 HP motor. Controlled by system criteria. Feeding at a constant rate of 180 FPM. FJ-500A (240") Assembly Press with Cut-Off Saw: -- Capacity from 1" to 6"; wide x 1/2" to 3" high x and from 6' to 16-1/2' long. motor powers the upper and lower pre-assembly driven by (2) 2 HP motor . -- 5 HP infeed inverter drive. In-feed speed from 30 to 230 FPM. Speed is controlled by system criteria. -- 5 HP - 2,850 RPM Cutoff saw accepts 14" dia. x 120 tooth x 4 mm kerf blade. Cutoff Saw c

CAM-WOOD HIAT-620-205 WITH 3"; HIGH X 8"; WIDE X 20’ LONG WORKING CAPACITIESTECHNICAL SPECIFICATIONS:Incoming Block Requirements: --Incoming block lengths from 6'' to 39"; (optionnal 122") --Blocks must be at least 50% longer than their width. --Block thickness from 1/2"; to 3 1/2" --Block width from 1"; to 8" - --Assembled lengths from 10’ to 20’ - 24’ Optional --For use with PVAC adhesives --Works equally well with soft & hardwoods. --Moisture content preferred from 8% to 12% --Blocks should be surfaced (4) sides to ± 0.2 mm with 90° right-angle corners. To be supplied by the customer: --Electric power supply to electrical cabinet --Constant voltage with deviations of 5% or less --Temperature range for computer control should not exceed 95°F. --Maximum humidity for computer control system under 65% --Hydraulic oil --Skilled operating and maintenance personnel --Motor Control Center with under-voltage and overload protection; includes UL and CSA approved electrical components. Electric parts only, not the complete machine. --Total electricity demand: 63.75 KW, 85 HP --30 HP Compressor with a 50-to-60-gallon Air Receiver PRODUCTION CAPACITIES:Shaper Capacity: --Shift = 480 minutes --Finger length to buyer’s requirement --As an example: 1-1/2"; X 5/1/2"; X 24"; average finished block size at the Shapers --Shaper max. speed of (3) table strokes per minute --Table cycles will change as block widths become “wider"; or “taller"; at the Shapers --Table accepts up to (16) blocks when vertical finger jointing 1-1/2"; X 5/1/2"; example blocks. --Table accepts up to (4) blocks when horizontal finger jointing 5-1/2"; x 1-1/2"; example blocks.Press Capacity: --Assembly Press w/2 operators: -- (4) Table loads per min. x 20’ lengths x 480 min. per shift x 0.8 rate of utilization = 30,720 lineal feet per shift OR 36,864 lineal feet per shift with 24’ Press)Production Calculations: --VERTICAL Finger Jointing w/2 operators: -- Capacity of the shaper when finger jointing 1-1/2"; x 5-1/2"; x 2’ long blocks: (3) tables stroke per minute X 16-blocks per table load X 2’ average infeed block length x 480 minutes per shift X 0.8 rate of utilization = 36,864 lineal feet per shift (63.34 M³) --HORIZONTAL Finger Jointing w/2 operators: -- Capacity of the shaper when finger jointing 5-1/2"; x 1-1/2"; x 2’ long blocks: (3) table strokes per minute X 4 blocks per table load x 2’ average infeed block length x 480 minutes per shift X 0.8 rate of utilization = 9,216 lineal feet per shift (19.46 M³) NOTE: Capacity is maximum as shown at Assembly Section and is dependent on blocks thru the Shapers System consists of

CAM-WOOD Continuous in-line Long Board Vertical Finger Joint System, Model "UCT-210"Up to 210 mm (8") Wide x 75 mm (2.95") Thick x Unlimited Assembled Length System Specifications: -- Incoming board lengths from 39"; to 118" (1,000 mm - 3,0000 mm). -- Board widths from 1.96"; to 8.26"; (50 mm - 210 mm). -- Board thickness from 1" to 2.95"; (25 mm - 75 MM). -- Board out-feed length unlimited (Conveyor to be quoted separately) -- Glue type to be used: PVAC. with Standard pneumatic pump and spreader included ( For different glue then PVAC Glue pump and applicator not included) -- Board species: SOFTWOOD and HARDWOOD. -- Board moisture content: 8% to 12%. -- Infeed board qualities: Lumber runs best on Finger Jointers when surfaced on (4) sides (S4S) (Tolerance +/- .2 mm (.008"). System prefers straight boards with 90-degree corners. UCT-210 Mechanical Specifications: -- Top infeed feed rolls powered with (1) 2 HP motors. -- Bottom infeed feed rolls powered with (1) 2 HP motors. -- In-feed Inverter with (1) 5 HP motors. -- Top Shaper Spindle powered with a 30 HP motor. -- Maximum Cutterhead length, 8.2“(210 mm). -- Maximum Cutterhead diameter, 7"“(180 mm). -- Typical cutter pitch, 4.0 mm. Length, 10 mm - 12 mm (Other sizes available). -- Shaper spindle moving power by 2.6 HP Servo Motor. -- In-feed speed from 32 to 195 FPM (10 ~60 m/Min). -- Outfeed cut-off saw motor, 5 HP. -- Cut-off sawblade, 14“ dia x 120 teeth (included). -- Cut-off sawblade speed, 2,850 RPM. -- Hydraulic pump power, 30 HP. -- Top outfeed feed rolls powered with (1) 2 HP motors. -- Lower outfeed feed rolls powered with (1) 2HP motors. -- Out-feed Inverter with (1) 5 HP motors. -- Glue injection Glue Applicator for Standard PVAC glue. Infeed/Outfeed options: -- Infeed power roller conveyor 6000mm (236") long Additional: $ 8390 -- Outfeed powered roller conveyor 15,000 mm (48') long Additional $ 43,890Optional Automatic 20 ft Cross InfeedPower Conveyor System Working size L = 1000 MM ~ 6000 MM, W= 50 ~ 305 MM, T=25 ~ 110 MM ( Lenght 39" - 236" X Width 2" -12", Thickness: 1" to 43.3")Infeed roller Conveyor 3 HP1Cross feeding system 3 HP1Feeding speed of 15 M/min (48'/min.)Storage area width 2500 mmAdditional cost: $61,990 -- Outfeed roller conveyor 20'' X 8' long Additional: $ 4,890 per sectionNot included with the machine: -- Cutter heads for finger jointer (we can provide quote) -- Gluing system with pump and nozzle if different then PVAC glueGlue pump Option: -- Graco 1K PUR Glue System Additional cost: $ 48,990NOTE: Training, installation & tooling not included TO BE PROVIDED LOCALLY -- Electric power supply to Motor Control Center -- Constant voltage (voltage deviations max.: 5%) -- Temperature range for computer control should not exceed 95°F. -- 65% Maximum relative air humidity for computer control system --Dust exhaust system: (V=30M/S at a low pressure of 12M BAR) --Compressed air connection to machinery: 7~8 KG/cm² – 8 BAR --Electrical c

CAM-WOOD IAH-SC Inverter Drive, End-Less Auto Finger Jointer SystemFinger jointer shaper with gluer and troughfeed press for unlimited lengthTechincal Specifications: -- Infeed timber working length(min-max) L = 300MM ~ 2500MM (11.9" - 98.4") --Timber length to be processed must be at least 50% longer than the timber width to beprocessed. -- Timber working thickness T = 15MM ~ 75MM (1/2" - 3") -- Timber working width W = 35MM ~ 255MM (1 3/8" - 10") -- Timber out-feed length L = ENDLESS -- Glue type to be used PVAC (glue pump not included) -- Timber moisture 8 ~ 12 % -- lnfeed qualities: Timber must be processed via four sides moulder machine (tolerance: ±0.2mm) and wood needs 90 degrees right angle, four planning clear, straight. FSL 6121 Inverter Type FingerShaper With Glue ApplicatorSpecifications: -- Working dimension W=620mm (24.5"). L=150mm~2500mm. (6" - 98") Thickness=15mm~75mm (1/2" - 3") -- Motor of finger spindle 20HP 1pcs -- Spindle size 50mm -- OD of finger cutter OD160 mm(without finger cutter) -- Finger spindle RPM 5500RPM -- Power of Cut-off saw 7.5HP 1pcs -- Size, cut-off saw 255mm x 100T x 5mm (with saw blade) 1pcs -- RPM, cut-off saw 4800rpm/min -- Power of scoring saw 2HP 2pcs -- Size, scoring saw 180mm x 50T x 5mm (with saw blade) 2pcs -- RPM, scoring saw 2850rpm/min -- Conveyor drive power 1/2HP 1pcs -- Table movement INVERTER system power, 3HP + 3HP inverter 1pcs -- Glue Applier injection glue spreader -- Standard glue height H=100mm (3.9") Pitch 4.0mm .157") L=10-12mm (3/8" -7/16") (special size made by optional) -- Cycle speed packing/min 1-4 times/min (TOP SPEED) -- Double cylinder clamping -- ROLLER DEVICE AT FEEDING & OUTPUT LOCATION OF SHAPERUFJ-600 Unlimited lenght Finger Joint PressSpecifications: -- Working dimension Width: 35mm-255mm (1 3/8" - 10"). Thickness: 25mm-100mm. 1" -3.9") Length : Unlimited -- Infeed speed 10M-90M / min (32.5' - 292'/min.) -- Power of upper roller 2H P 1: 10 2pcs -- Power of lower roller 2HP 1: 10 2pcs -- In-feed Inverter 5HP 2pcs -- Cut-off saw, power 7.5HP 1pcs -- Cut-off dimensions 455 x 120T x 25.4M M (with saw blade) 1pcs -- Cut-off saw, RPM 2850rpm/min -- Hydraulic power 15HP 1pcs -- Out-feed table size 2M x 3 -- Oil tank 200L -- Max. capacity without HSC 18M / min(full status)Production Capacity: -- Working time 480 MIN/SHIFT -- Finger length MADE BY ORDER -- Average infeed length at the finger jointing line 2500 MM (98") -- Average timber cross section 255X50 MM (10.2" X 2") -- Shaper max speed 4/2 TABLE/MIN; the speed will change by the working height of wood -- Number of timber pieces per shaper table(horizontal finger jointing 50X255 mm (2" X 10")) 2 PIECES -- Capacity of the press 18M/MIN (58.5'/min) -- The data is the max capacity for one-section cutting, the capacity will be amended while multi­ section cutting. -- Rate of utilization 80%CAPACITIES OF THE COMPONENTCAPACITY OF THE SHAPER -- (HORIZONTAL FINGER JOINTING for 50X255 mm

CONCEPTION CRP-180 Short Block Feeder Infeed ConveyorSpecifications: -- About 4 m long X 1.2 m wide, 2-ply rubber belt, friction back with Photocell for automatic operation -- Short Block Feeder; Blocks to be 25mm longer than width -- 14' rotating carousel with adjustable speed via VFD with Motorized wheel to avoid blockage -- Exit opening adjustable to the block width -- 200 mm x 7m long belt conveyor to carry the blocks to index rolls; Servo indexer controlling the flow powered by an electric motor; Speed-up belt powered by an electric motor -- Wane System: Scanner to detect wane integrated in conveyor -- Display screen to show wane detected; Kicker to kick blocks that are not in good orientation -- Conveyor to return it into the spreader belt conveyor -- Automatic Operations

Call for Price

DOUCET FX 150 Automatic Feed to Finger JointerModel "MT-10-GD" automatic feed to Finger Jointer, chain feeding system driven on the bottom and right-and-left sides, feeds boards up to 6" max. width. -- Model "FX-150" right-hand Shaper section: Cap. 3/4" - 2" max. thickness, 1-1/2" - 8" max. width (with lugs on 12" centers, 6" max. width on 9" centers), 5" min. - 96" max. length. -- Equipped with: 5 HP Trim saw, 15 HP Shaper motor, PLC controls on shaper section, dual feed chain with lugs on 12" centers, 45 FPM fixed feed speed, 5 HP feed drive, PLC controlled extrusion type glue applicator with 12-gal. tank, sound enclosure and cabinet type base. Transfer to the assembly press. -- Includes: Stainless friction plates on assembly table, board holddown on all (4) sides, sound enclosure, cabinet type base and all protective hoods, (1) 8-bolt cutterhead with knives and setup stand. -- Approx. 8,000 linear ft./shift or more based on 12" average infeed length.This unit has no control panel

GRECON PJ 150/500 and PF 10-610 Finger Jointer and PressFinger jointer and Press systemSpecifications: -- Grecon Finger Joint System Including: Model PJ 150/500 Shaper -- Trim Saw 5 HP -- Shaper Head 30 HP -- Glue Application Head -- Timber Width 30 mm - 159 mm (1.2" - 6.25") -- Timber Thickness 12 mm - 80 mm (.5" - 3.15") -- Timber Length 250 mm - 1780 mm (9.84" - 70") -- Infeed Belt Conveyor 20" Wide X 34" LongAfter the Finger joint shaper: -- Manual Roll Conveyor with Rotation for Turning Workpieces 22" X 68" -- Outfeed Belt Conveyor 20" X 39" -- Driven Roll Conveyor 20" X 120" -- Powered Belt Conveyor Prior to Press 7" X 86"Model Press PJ 10/6100 Finger Joint Assembly Press: -- Maximum Pressing Length 240" -- Cut-Off Saw Motor 3HPNote: The machine will be reconditioned upon placement of order.

.gif)