Equipment For Sale

9917 Results Found

$ 49,500

CNC FACTORY PYTHON XPR FLAT TABLE MACHINE (W/LOADING, UNLOADING): -- Specifications:5' x 10' Single Table machine: stationary phenolic table is machined with a square "MATRIX" grid pattern for fixturing parts, -- Working field:"X" axis 122" (3,099 mm), “Y"; axis 62"; (1,575 mm) , "Z" axis stroke is 12" (305 mm). -- Positioning speed:"X" & "Y" axis 233 FPM (71 MPM), "Z" axis 82 FPM (25 MPM);Closed loop AC Servo drive system driving precision helical rack & pinion in "X" & "Y" axis & ground ball screw in "Z" axis;All axes ride on extra large precision profile linear guide ways. -- Work Table:"MATRIX" grid pattern allows use of vacuum pods or closed cell rope gasketing material and use of spoil boards for "nested based machining".Pneumatic Pop-Up Pins for manual and automatic material placement. -- Machining:(1) 12 HP (9 kW) "HSD" Electro spindle with ISO 30 adaptor, spindle speeds from 1,000 - 24,000 RPM;(1) 12-position ATC tool plate mounted on the head for "on the fly" ATC. -- Operator & Machine Control:"SYNTEC 4E 21"; graphic industrial control center with hand held controller.Built-in continuous operation file saving and production override with speed control G-Code compatible with virtual every Cad and software including USB and Ethernet file control.Acceleration and deceleration working and repositioning; Tool wear history with built-in alarm stops, work coordinates and on screen programming19" High resolution monitor; Ergonomic industrial keyboard & mouse; USB drive; serial ports for RS-232; all housed in a separate dust free cabinet -- Complete with:(1) 250 m³/Hr vacuum pump; auto tool length measuring sensor; . -- Options Include:(1) NC controlled "Robotic" in-feed scissor-lift loading table; (1) Rake system; (1) NC controlled & powered belt out-feed table with vacuum sweeping system. -- Actual Model is CNC FACTORY PYTHON XPR 510.

Call for Price

Coe 47' x 26' Package type dry Kiln with Controls, 1989 Hurst gas boiler 150 PSI, 6900# Steam Per Hour S/N 51000-750-3, Condensate Tank & Pumps & Electrical. can Buy as a Package or Seperate the Hurst Boiler.

Call for Price

Call for Price

144L X 120"D X 144"H (25) Filter Screens (4) 12" X 48", (4) 4-tube light panels(1) Exhaust Fan 1HP 120V

Call for Price

Comac TAG 100 Package Kiln 30'x36' Gas fired with control room Looks like 70 MBF with 4/4 lumber

$ 32,000

ComacT Edger, 2-Saw Movable, All Motors - $32,000 - Call Jeff for more info at 574-370-5050

Call for Price

$ 62,000

Call for Price

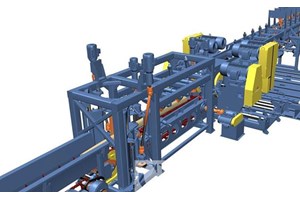

Photos coming Compact DDM6 Profile Canter Line Double Length Infeed Production: 27,000 Logs/ 24 hours, 360 FPM (2x6), 500 FPM 2x4 Infeed belt conveyor V flight scanning conveyor without the scanner and optimization system One pass small log processor Outfeed belt conveyor #1 Outfeed lifting belt conveyor #2 Outfeed belt conveyor #3 Lumber landing table Motor Control Centers (MCC) Programmable Logic Controller (PLC) - obsolete

Call for Price

Call for Price

Capacity:20,000 lbs @24" LC. Tier4 Engine. LPG. 183" Duplex mast- free lift. Less than 2,000 hours. Fork Positioner. Enclosed wide cab.

$ 3,000

COMEC - LON-LS, ...Horizontal Belt SanderSpecial design for sanding of straight or curved solid wood parts such as: Chair legs, chair backs and other similar & difficult-to-sand parts.10 HP Belt driven motor; 12" dia. contact drum for 10" wide x approx. 140" long abrasive belt; air tracking & belt tensioning. -- Stock is fed over the contact drum with an overhead variable speed, pneumatically tensioned feed wheel. -- Sander belt power: 6.6 kW (9 HP approx.) - 220/440 V, 60-Cy, 3-Ph motor.

$ 7,680

COMEC - FAS/2, ...Corner Milling MachineCOMEC FAS is a dedicated milling machine with: Inclinable heads for machining the corner of chair seats. Specifications: -- (2) Heads with: 5.5 HP motor and 40 mm spindle shaft. -- Max. cutter size: 150 mm (5.9"). -- Tilting of milling units: 20°/ +45° in horizontal plane. -- Fixed left hand column to support head unit. -- Max. working height: 200 mm (7.8").

$ 12,750

COMEVA - CUBE 3, ...Edgebander (Single Phase)The CUBE 3 from COMEVA is designed to be a very compact "every day" Edgebander. The CUBE 3 Edgebander is operated through a PLC control system with a touchscreen. The machine handles panel thicknesses of 0.315" up to 1.77" (8 mm to 45 mm), The coil feed accepts Edgebanding from 0.4 mm to 2 mm thick; strip material can be hand-fed.Equipped with: -- Heated infeed fence for optimum glue penetration. Large capacity Teflon coated glue pot (2.64 Lbs). -- Single motor End Trimming station -- Top & Bottom Trimming -- Top and bottom Buffing. -- Feed speed is variable between 9.8 & 23 FPM (3 - 7 MPM); feed chain pads with replaceable rubberized surface inserts. -- Rubberized holddown rollers with ball bearings for low friction and long life. Work stations: -- Pneumatically operated guillotine for up to 2 mm thick banding, followed by spring loaded double pressure rollers. -- Single front/rear trimming unit, 0.3 HP motor. -- Top & Bottom trimming units, (2) 0.5 HP motors. -- Top & Bottom buffing station, (2) 0.16 HP motors. -- Complete with: Safety enclosure protects the operator from noise and debris. Engineered & Manufactured by COMEVA S.L, in Spain.Includes: Owner’s Manual with mechanical & electrical schematics and parts breakdown; covered by a 1-Year Factory Warranty on parts.

$ 17,500

COMEVA C-400 B Programmable European Door Milling Machine: Specifications: -- Maximum door length, X-Axis 96" (2,440 mm). Maximum machining length from center to center of the farthest slots is 74.8" (1900 mm) based on a 120 mm hinge length. -- Working field Y-Axis 23.6" - 39.3" (600- 1,000 mm) min/max door width. -- Working field "Z" axis 1.18" - 2.36" (30 - 60 mm) min/max door thickness. Positioning: -- NC Controlled working table for X-, Y- & Z-axis part positioning & processing. X- Y- & Z- Axis movement via hardened round ways & ground ball screws.Work Table: -- (2) NC Controlled extruded aluminum support rails with (6) Non-Marking manually positioned pneumatic panel clamps. -- (1) NC Controlled extruded aluminum support table for "Hinge Plate" router spindles. Machining: -- (4) Manually adjusted 0.5 HP (0.37 kW), 12,000 RPM air-cooled "Hinge Plate" router spindles with ERC 32 collets, RH rotation. -- (1) NC Controlled 3 HP (2.2 kW) air-cooled 12,000 RPM horizontal "Case Lock" router spindles with ERC 32 collets, RH rotation. -- (2) NC Controlled 2 HP (1.5 kW) air-cooled 12,000 RPM vertical "Hardware" router spindles with ERC 32 collets, RH rotation.Operator & Machine Control: -- Separate control console with "ADTECH CNC 4640" Controller with numerical and function keyboard; -- Monitor displays programming graphics, machine data & subroutines, runs production programs while programming and editing -- Programming storage for 30 individual programs. -- Includes: Owner’s Manual with mechanical & electrical schematics. -- Engineered & Manufactured by COMEVA S.L, in Spain.

$ 47,900

COMEVA - C-250, ...Programmable Door Milling Machine Specifications: -- Working field "X-axis" 90.55" (2,300 mm) max. door length. -- Working field "Y-axis" 23.6" - 39.3" (600 - 1,000 mm) min/max. door width. -- Working field "Z-axis" 1.18" - 2.36" (30 - 60 mm) min/max. door thickness. -- Positioning:NC Controlled working table for "X", "Y", and "Z" part positioning & processing."X", "Y", and "Z" Axis movement via hardened round ways & ground ball screws. -- Worktables:(2) NC Controlled extruded aluminum support rails with: (4) Non-marking manually positioned pneumatic panel clamps.(1) NC Controlled extruded aluminum support table for "Hinge Plate" router spindles -- Machining: (4) NC Controlled 0.5 HP (0.37 kW), 12,000 RPM air cooled "Hinge Plate" router spindles with: ERC 32 Collets & manual spacing adjustment, RH rotation.(1) NC Controlled 3 HP (2.2 kW) air-cooled 12,000 RPM horizontal "Case Lock" router spindles with ERC 32 collets, RH rotation.(1) NC Controlled 2 HP (1.5 kW) air-cooled 12,000 RPM vertical "Hardware" router spindles with ERC 32 collets, RH rotation. -- Operator & Machine Control: Separate control console with: "DELTA" 12" TFT touch screen control with numerical and function keyboard;Monitor displays programming graphics, machine data & subroutines, runs production programs while programming, and editing.Programming storage for (30) individual programs. -- Complete with: 1-Year Mfg. Warranty, User's operator/maintenance manuals & backup disks. -- Available Options at additional cost:Additional 0.5 HP (0.37 kW), 12,000 RPM air-cooled "Hinge Plate" router spindles with ERC 32 collets = $ 1,976.00 each.Additional 2 HP (1.5 kW) air-cooled 12,000 RPM vertical "Hardware" router spindles with ERC 32 collets = $ 3,240.00 each.Actual Model is COMEVA - C-250, ...CNC DOOR MILLING MACHINEIncludes: Owner’s Manual with mechanical & electrical schematics and parts breakdown; covered by a 1-Year Factory Warranty on parts.

$ 59,700

COMEVA - C-400 B Programmable, ...European Door Milling Machine: Specifications: -- Max. door length X-Axis 96" (2,440 mm); max. machining length from center-to-center of the farthest slots is 74.8" (1,900 mm) based on a 120 mm hinge length. -- Working field Y-Axis 23.6" - 39.3" (600 - 1,000 mm) min/max. door width. -- Working field "Z-axis" 1.18" - 2.36" (30 - 60 mm) min/max. door thickness. Positioning: -- NC Controlled working table for X-, Y- & Z-axis part positioning & processing; X- Y- & Z-Axis movement via hardened round ways & ground ball screws.Worktable: -- (2) NC Controlled extruded aluminum support rails with (6) Non-Marking manually positioned pneumatic panel clamps. -- (1) NC Controlled extruded aluminum support table for "Hinge Plate" router spindles. Machining: -- (4) Manually adjusted 0.5 HP (0.37 kW), 12,000 RPM air cooled "Hinge Plate" router spindles with ERC 32 collets, RH rotation. -- (1) NC Controlled 3 HP (2.2 kW) air cooled 12,000 RPM horizontal "Case Lock" router spindles with ERC 32 collets, RH rotation. -- (2) NC Controlled 2 HP (1.5 kW) air cooled 12,000 RPM vertical "Hardware" router spindles with ERC 32 collets, RH rotation.Operator & Machine Control: -- Separate control console with: "ADTECH CNC 4640" Controllers touch screen control with numerical and function keyboard. -- Monitor displays programming graphics, machine data & subroutines; runs production programs while programming and editing. -- Programming storage for (30) individual programs. -- Includes: Owner’s Manual with mechanical & electrical schematics and parts breakdown; covered by a 1-Year Factory Warranty on parts.Available Options at additional cost (when ordered with machine from the factory): -- Additional 0.5 HP (0.37 kW), 12,000 RPM air-cooled "Hinge Plate" router spindles with ERC 32 collets at ...$ 1,976.00 each. -- Engineered & Manufactured by COMEVA S.L, in Spain.

Call for Price

COMEVA NICRON CNC Door Machining Center: Flexible Door Machining Center to machine Hinges, Locks, Grooves, etc. A device to allow machining of door jambs is an option available. Also vertical top router head with Automatic Tool Changer is available. See options below.Specifications: -- Max. door length, X-Axis 102.3" (2,600 mm). -- Max. door width, Y-Axis 47.2" (1,200 mm). -- Max. travel on Z-Axis 7.87" (200 mm)Working Heads: -- The machine is equipped with a (2) motors/heads 5 HP (3.5 kW) - 12,000 RPM each, routing/milling units: (1) vertical unit and (1) horizontal double spindle head.Working table: -- Table dimensions: 51.2" x 102,3" (1,300 x 2,600 mm). -- Manual table loading system with vacuum cup hold-down for the doors. For the optional jamb (door frame) table fixturing includes an air cylinder clamping system.Operator & Machine Control: -- Separate mobile control panel with powerful CNC to handle all the functions of the machine. -- Includes the unique COMEVA DOOR Software specially designed for machining of doors. It controls the movements of all axes, reference stops, vacuum zones and workgroups. It is user-friendly with macros(subroutines) for most of the hinges/locks on the market so operator can input the job parameters instead of complicated programs.Complete with: -- Users operator/maintenance manuals & back up disks.Engineered & Manufactured by COMEVA S.L, in Spain. - Stated price includes Machine (Jamb device not included), Software and Safety Barrier.Includes: Owner’s Manual with schematics; covered by a 1-Year Factory Warranty on parts.

Call for Price

COMEVA C-600 TOP CNC Door Milling Machine with (7) Axes and Rotary style (ATC) Automatic Tool Changer. The faster and more versatile version of the COMEVA NICRON DOOR models which can perform two jobs simultaneously on the door, ie. mill the hinges and machining the lock at the same time.Milling all types of hinges, including security locks and the recess for the bezel, the longitudinal recess for safety lock, front holes for knob handle, lock, digital locks, peepholes, machined holes or windows (stained glass), and floating probe. Operations performed in minimal time via two separate working channels. Will machine the top and bottom, resize, and bevel doors. Also available with optional loading and unloading of doors. -- Construction: Heavy duty Bridge configuration with two drives, one on end of the Gantry which ensures maximum reliability in the movement of the machine without any oscillation at minimum clearances. Top quality component brands for all linear guides, bearings, brushless servo and reducer. -- General Specifications: Maximum door length 118.1" (3,000 mm). Maximum door width 51.18" (1,300 mm); Minimum door width 15.75" (400 mm). Max door thickness 3.15" (80 mm). Gantry movement, the X axis, max. speed is up to 230 FPM (70 m/Min). Machine features (7) interpolated axes with (2) channels that work independently. -- Horizontal Heads - Hinge & Lock Milling: (2) high frequency motors at 2 HP (1.5KW) on the left and right side. -- Horizontal heads - Top and Bottom of doors: Top/bottom of doors is achieved with one 3 HP (2.2 KW) double-end head which swivels 180°. -- Vertical Milling Router: HSD Motor with ISO 30 ATC of 12 HP (9 KW) for routing hole for handle, crank, standard lock, security lock, electronic locks for hotels/commercial doors; milling or grooving work on the upper side of the door, with upper sensor for automatic measurement.The main milling router with variable speed from 1,000 to 24,000 RPM from the CNC programmable. Ceramic bearings are installed and it has right-left turn. The 10-position ATC is a the Rotary style mounted on the vertical head. -- Vertical Floating Motor: Vertical group also has a floating milling motor head for machining lines or groves top face of the door. Motor is 0.5 HP (0.37 KW). -- Vacuum Unit: BECKER vacuum producer at 100 m³/Hr. -- Production capacity: C-600 max. productivity can be less than one minute per door. Machine has an automatic calibration and automatic detection system of the door, plus roller guides to help load the door.The horizontal working groups on both sides (hinge and lock) work simultaneously allowing time for milling standard doors below (1) minute, approximately. -- Numerical Control/CAD Software: Advanced numerical control type S500 ETX 800 LX AMD PC (or equal) for the control of its (7) interpolated axes. It comes with a 19" display screen. The included COMEVA DOOR software is a special purpose package designed to facilitate the machining of all door ele

.gif)

.jpg?width=300&height=200&mode=pad)