Wood-Mizer Products, Inc.

800-553-0182

800-553-0182

800-553-0182

800-553-0182

Since 1982, Wood-Mizer has become the world’s largest manufacturer of portable band sawmills with tens of thousands of bandmills sold. Today, Wood-Mizer offers portable & industrial sawmills, resaws, edgers, kilns, log splitters, bandsaw blades and blade maintenance equipment for woodworking hobbyists and forestry professionals all over the world.

Wood-Mizer introduces Heicor Enterprises, LLC as their industrial authorized sales center in the Pacific Northwest. Heicor will provide all industrial products along with select professional products from Wood-Mizer. Wood-Mizer Oregon, the established branch office near Portland, Oregon, will continue to provide sales and service for Wood-Mizer professional sawmill equipment and blades in the area.

In addition to their world-leading portable sawmill equipment, Wood-Mizer’s equipment line has grown significantly and now includes machinery for the pallet industry, remanufacturing operations, cabinet and millwork shops, small log sawmill processing systems, headrigs, multirips, and sawmill systems that can produce tens of thousands of board feet of lumber per shift. “Wood-Mizer is committed to serve the needs of hobbyist, professional, and industrial-level wood processing clients throughout the world,” said Greg Bacon, Wood-Mizer Sales Director. “It became apparent that Heicor was the best choice to represent Wood-Mizer industrial products in the Pacific Northwest because of their experience and industry knowledge. We’re confident that Heicor can successfully represent Wood-Mizer in a way that is beneficial for both our company and our customers for years to come.”

Located in Monmouth, Oregon, Heicor Enterprises was founded in 2016 by Glen Heiner and Kevin Corder who both have extensive experience with Wood-Mizer. Kevin spent 27 years at Wood-Mizer and was the head of the Industrial Products Division, and Glen was an Industrial Sales/Service Specialist at Wood-Mizer for more than a decade. Glen also has experience on the user side as the owner of Portland Specialty Lumber, a millwork firm in Portland, Oregon.

Kevin Corder, President of Heicor Enterprises, said “We are very excited to become an industrial sales center for Wood-Mizer. Glen and I are both former long-time employees and it’s great to be ‘back in the saddle’ again! We are eager to present Wood-Mizer machines as a solution to many of the needs and opportunities in this region. We know the function and quality of these products along with the legendary support will fit well into the markets we will serve.”

For more information, contact Heicor Enterprises at 971-271-8070, or by email at [email protected].

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a world-leading wood processing equipment manufacturer with a strong legacy from its innovative sawmilling products. From forest to final form, Wood-Mizer offers an extensive line of equipment including narrowband portable and industrial sawmills, wideband sawmilling equipment, band resaws, board edgers, wood kilns, planer/moulders, firewood processing equipment, pallet recycling equipment, material handling equipment, bandsaw blades, and blade maintenance equipment for woodworking and forestry hobbyists and professionals all over the world. Visit woodmizer.com for more information.

At the Forest Products Equipment Expo 2019 in Atlanta, Georgia, USA, Wood-Mizer will display two new sawmills including the high-production WM4500 industrial sawmill and the wide capacity LX250 sawmill, in addition to other professional sawmilling equipment.

Visitors to Wood-Mizer Booth 1039 at the Forest Products Equipment Expo 2019 at the Georgia World Congress Center will be met with one of the largest displays of forestry and wood processing equipment at the Expo. Wood-Mizer’s industrial sawmilling equipment will be represented which includes the company’s new flagship WM4500 industrial sawmill. Continuing Wood-Mizer’s tradition of providing commercial sawmilling solutions for high-production lumber processing operations through the world, the WM4500 includes many key innovations to the sawmill head and sawmill bed for enhanced durability and dependability. In addition, the new LX250 wide capacity sawmill with a 54 ½” width of cut will be displayed at the event. Additional products including the new HR250 twin band horizontal resaw, EG400 industrial board edger, and more professional sawmilling equipment will be represented at the event.

“The Forest Products Equipment Expo in Atlanta gives Wood-Mizer the ability to showcase two of our newest sawmills alongside our industry-leading equipment range,” said Darryl Floyd, Wood-Mizer North America President. “The innovations that have become the WM4500 industrial sawmill and the LX250 wide capacity sawmill both represent our commitment to providing sawmill equipment that fits the various needs of sawmillers throughout the world."

According to the Expo, more than 100,000 square feet of the Georgia World Congress Center will be dedicated to showcase a broad range of forestry and wood processing equipment during the 3-day exposition. Since 1950, the Expo has provided the forest products industry with a quality venue to discuss trends, discover new technologies and focus on manufacturing success.

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a world-leading wood processing equipment manufacturer with a strong legacy from its innovative sawmilling products. From forest to final form, Wood-Mizer offers an extensive line of equipment including narrowband portable and industrial sawmills, wideband sawmilling equipment, band resaws, board edgers, wood kilns, planer/moulders, firewood processing equipment, pallet recycling equipment, material handling equipment, bandsaw blades, and blade maintenance equipment for woodworking and forestry hobbyists and professionals all over the world. Visit woodmizer.com for more information.

Wood-Mizer introduces the compact and versatile HR150 and HR250 super horizontal band resaws designed to easily integrate into pallet and lumber operations without taking up valuable production space. The HR150 and HR250 join the Wood-Mizer range of single and multi-head band resaws that capitalize on thin-kerf blade technology to produce accurate lumber while reducing material, labor, energy, and maintenance costs.

The HR150 super horizontal resaw is primarily designed to resaw cants and boards into two pieces with each pass. It can also be used as a recovery saw for slabs, flitches, and jacket boards. The HR250 is a twin blade version of the HR150. By placing one blade directly over the other blade within one compact head, the HR250 can make one or two horizontal cuts to resaw cants and boards into two or three pieces with each pass. It also works well with resawing stressed material.

HR150 and HR250 Super Features

- 11 ½” (290mm) wide x 10” (250mm) high capacity

- 0 – 90 ft/min (0 – 27 m/min) variable feed

- Setworks with digital blade position controls

- Air-over-oil hydraulic blade tension

- Pneumatic hold-down top rollers

- Variable blade speed

- HR150 starts at $13,295 USD

- HR250 starts at $19,995 USD

“Wood-Mizer is committed to providing our customers with the equipment necessary to be competitive in the lumber and pallet industry,” said Greg Bacon Sales Director. “The HR150 and HR250 are compact and affordable resaws that satisfy the needs of mid-size pallet and lumber operations throughout the world.”

The HR150 and HR250 are powered by 25HP (18kW) saw wheel motors and 2HP (1.5kW) gearbox motors. Both machines feature a material capacity of 11 ½” x 10” (290mm x 250mm) for the ability to resaw a variety of cants, boards, and jacket boards. With heavy-duty construction, premium components, and large 28” (710mm) diameter steel band wheels, the HR150 and HR250 resaws are built to last.

Control panel setworks with digital blade position controls in both imperial and metric ensure accurate height positioning of the blade when setting cut thickness. Each blade has its own setworks panel and is controlled and run independently. Pneumatic hold down rollers and an idle top roller keep material secure as it moves through the machine. Blade speed is variable to accommodate various cutting requirements and the variable feed speed is controlled by an electric motor for efficiency. Blade tension is automatic and controlled by an air-over-oil hydraulic system in order to maintain proper tensioning for longer blade life. Starting at $17,995 USD, the HR250 is also available in an economic manual version with manual saw wheel elevation, manual blade tensioning, and a single blade speed.

The HR150 and HR250 horizontal band resaws are now available to order. For more information, visit www.woodmizer.com or contact your local Wood-Mizer representative.

Wood-Mizer introduces the LX150 twin rail sawmill designed for hobbyists and professionals looking for a robust, portable sawmill with powered saw head controls and a large 35 ½” width of cut ideal for sawing wide, live edge slabs. As the second LX series sawmill offered by Wood-Mizer in North America, the LX150 joins Wood-Mizer’s world-leading range of portable sawmills.

A key innovation of the Wood-Mizer LX sawmill series includes the rigid LX Frame sawhead tower that holds the control panel, engine, and the sawmill head. Designed to accommodate a larger width and depth of cut, the LX Frame travels on twin parallel hardened steel rails on the bed and allows the operator to have better visibility while sawing.

LX150 Sawmill Features

Power Options

- 25HP Kohler Gas

- 24HP Yanmar Diesel

Cutting Capacity

- 36” max log diameter, 35 ½” max width of cut, and 11” max depth of cut

- 18’ 5” length of cut or unlimited with 6’ 1” bed extensions

Operation

- Powered head up/down & forward/reverse

- Optional SimpleSet Setworks & Debarker

Introductory Price

- Starting at $13,995 USD

“Wood-Mizer is dedicated to providing our customers with the best in-class sawmill and wood processing equipment on the market,” said Greg Bacon, Wood-Mizer Sales Director. “The LX150 gives sawyers a new twin-rail sawmill with a highly-durable bed configuration and saw head features such as optional SimpleSet Setworks and debarker for enhanced performance that are not available anywhere else in its class.”

The LX150 twin rail sawmill ships on a single pallet, comes with one Wood-Mizer sawmill blade, and requires minimal assembly time. With a 30-day money back guarantee, and 2-year sawmill warranty, the LX150 sawmill is backed by the same legendary service, quality, and safety features shared by the entire family of Wood-Mizer wood processing equipment. The LX150 is now available to order in North America, South America, and Oceania. For more information, visit www.woodmizer.com or contact a local Wood-Mizer representative.

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a leading wood processing equipment manufacturer with a strong legacy from its innovative sawmilling products. From Forest to Final Form®, Wood-Mizer offers an extensive line of equipment including narrowband portable and industrial sawmills, wideband sawmilling equipment, band resaws, board edgers, wood kilns, planer/moulders, firewood processing equipment, pallet recycling equipment, material handling equipment, bandsaw blades, and blade maintenance equipment for woodworking and forestry hobbyists and professionals all over the world.

Wood-Mizer introduces two new bandsaw blade options with 1” and 1 ¼” tooth spacing to satisfy the needs of high production, high horsepower resaw and sawmill operations. The new blade tooth spacing options further expand the industry-leading Wood-Mizer range that includes a large variety of bandsaw blades for nearly every type of sawing or resawing application.

Available in SilverTip carbon material, 1” tooth spacing blades are offered in a 10 degree all-purpose profile to saw any type of wood species. These blades are designed for high production resaw and sawmill operations that prefer 1” tooth spacing or for filing rooms that have blade maintenance equipment currently setup for 1” tooth spacing.

1” Tooth Spacing Blades

- .045 x 2”

- .055 x 1 ½”

- .055 x 1 ¾”

- .055 x 2”

Available in SilverTip carbon material, the 1 ¼” tooth spacing blades are offered in a Turbo 7 degree high-performance profile. With increased air flow and higher tooth penetration while sawing mixed species, Wood-Mizer’s exclusive Turbo 7 degree profile is tried, tested, and proven by high production, high horsepower, and high feed rate operations throughout the world. Combine this exclusive Turbo 7 profile with a wider 1 ¼” gullet to provide an ideal blade for high throughput grade resaw and sawmill operations.

1 ¼” Tooth Spacing Blades

- .045 x 2”

- .055 x 1 ¾”

- .055 x 2”

- .050 x 3”

Both 1” and 1 ¼” tooth spacing blades are now available to order in a variety of lengths to fit various sawmill and resaw brands and models. Wood-Mizer provides blade maintenance equipment and ReSharp services that are able to accommodate these new tooth spacing options.

Wood-Mizer offers an extensive range of blades with more than 100 combinations based on profile, width, thickness, tooth spacing, and alloy for any type of sawing or resawing application from green softwoods to abrasive hardwoods. For more information, visit www.woodmizer.com/blades or call 800.522.5760.

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a leading wood processing equipment manufacturer with a strong legacy from its innovative sawmilling products. From forest to final form, Wood-Mizer offers an extensive line of equipment including narrowband portable and industrial sawmills, wideband sawmilling equipment, band resaws, board edgers, wood kilns, planer/moulders, firewood processing equipment, pallet recycling equipment, material handling equipment, bandsaw blades, and blade maintenance equipment for woodworking and forestry hobbyists and professionals all over the world.

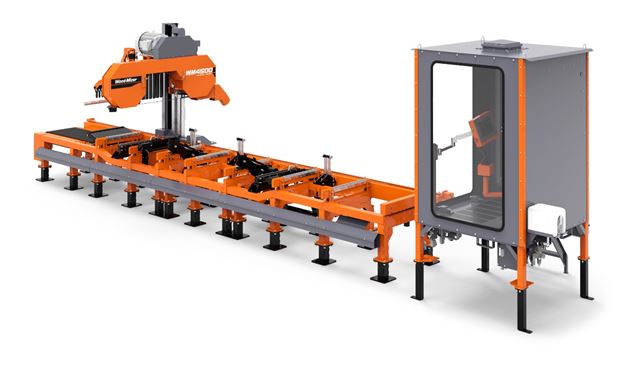

Wood-Mizer introduces the WM4500 industrial sawmill featuring several structural and performance enhancements to the sawmill head and bed for improved sawing productivity. As Wood-Mizer’s next generation flagship industrial sawmill, the all-new WM4500 continues a long tradition of providing commercial sawmilling equipment solutions throughout the world.

Featuring many benefits of Wood-Mizer’s world renowned industrial sawmill range, the WM4500 can be used to breakdown logs for further processing or to saw boards, grade or dimensional lumber. Alongside the complete line of Wood-Mizer sawmills, the WM4500 capitalizes on thin-kerf blade technology to produce accurate lumber while reducing capital, material, labor, energy, and maintenance costs.

WM4500 Features

Power

- 30 HP Electric (22.4 kW)

Cutting Capacity

- 40” (1 m) log diameter

- 21’ (6.4 m) cutting length with board removal

- 32 ¼” (819 mm) width of cut and 16” (405 mm) depth of cut

Blade Specifications

- 2” (51 mm) blade width capacity with steel band wheels

- 3” (76 mm) diameter blade guide rollers

Introductory Price

- Starting at $105,995 USD

“Wood-Mizer is dedicated to providing the best-in-class sawmilling equipment throughout the world,” said Greg Bacon, Wood-Mizer Sales Director. “The WM4500 is the result from years of customer feedback and rigorous testing to satisfy the needs and preferences of high-production operations.”

Key innovations of the WM4500 sawmill bed include reinforced dual-rod side supports, heavy-duty angled bed rails, 21’ cutting length with board removal, pull down cinch clamps for cants, and off-feed conveyor & roller with suspension. The robust sawmill head includes 2” blades with steel wheels, stronger head, mast, and strain system, 5HP feed motor, larger up/down gearbox, high pressure blade lubrication system, adjustable material drag back, modular toeboards, and durable 3” diameter blade guide rollers.

The WM4500 industrial sawmill is now available to order in North and South America. For more information, visit www.woodmizer.com or contact your local Wood-Mizer representative.

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a leading wood processing equipment manufacturer with a strong legacy from its innovative sawmilling products. From forest to final form, Wood-Mizer offers an extensive line of equipment including narrowband portable and industrial sawmills, wideband sawmilling equipment, band resaws, board edgers, wood kilns, planer/moulders, firewood processing equipment, pallet recycling equipment, material handling equipment, bandsaw blades, and blade maintenance equipment for woodworking and forestry hobbyists and professionals all over the world.

Wood-Mizer introduces the FS150 dual action 20 ton log splitter designed for homeowners and small landowners looking for an affordable and highly durable American-made log splitter. The FS150 log splitter expands the Wood-Mizer firewood processing equipment range that includes gas powered and skid steer commercial log splitter models ranging from $6,995 to $13,995 USD.

Starting at $2,595 USD, the FS150 combines a 7HP Kohler gas engine with 20 tons of splitting force to split hardwood and softwood logs up to 24” long. The log table height is 30” from the ground to provide a comfortable working height for the operator and the convenient operator panel features intuitive left/right controls for the log splitting wedge. Once a log is loaded for splitting, the 8 ½” high carbon steel wedge splits wood in both left and right directions for increased speed and efficiency. This unique two-way design can double firewood production compared to traditional one-way wood splitters. During the splitting operation, two side trays catch material for additional splitting or for convenience in handling wood when stacking. Featuring a compact design for easy storage and mobility, the FS150 also includes a standard trailer with a 2” hitch that is towable at speeds up to 45 mph.

FS150 Log Splitter Specifications

Introductory Price

• Starting at $2,595 USD

Features

• 7HP Kohler gas engine

• 20 ton splitting force

• Dual action splitting wedge

• 7 second cycle time

• Trailer for towing up to 45 mph

“Wood-Mizer is committed to providing landowners and homeowners the equipment necessary to process logs into boards, slabs, firewood, and other marketable wood products,” said Greg Bacon, Wood-Mizer Sales Director. “The FS150 is an American-made, affordable log splitter for residential use that stands up to the high-quality standards that is synonymous with Wood-Mizer wood processing equipment throughout the world.”

The FS150 dual action log splitter comes with a 1-year warranty, ships fully assembled on a single pallet, and is backed by the same legendary service, quality and safety features shared by the entire family of Wood-Mizer wood processing equipment. The FS150 log splitter is now available to order in North America, South America, Asia and Oceania. Visit woodmizer.com/logsplitters for more information.

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a leading wood processing equipment manufacturer with a strong legacy from its innovative sawmilling products. From forest to final form, Wood-Mizer offers an extensive line of equipment including narrowband portable and industrial sawmills, wideband sawmilling equipment, resaws, edgers, kilns, planer/moulders, firewood processing equipment, pallet recycling equipment, material handling equipment, bandsaw blades, and blade maintenance equipment for woodworking and forestry hobbyists and professionals all over the world.

Wood-Mizer will sponsor an urban wood seminar, "The Urban Wood Revolution is Now! Come Join the Movement," on Friday, August 24 at the International Woodworking Fair in Atlanta, GA.

The seminar will focus on the environmental and economical benefits of utilizing locally sourced urban wood while providing practical instruction and networking opportunities for sawyers, woodworkers, lumber suppliers, and lumber buyers.

Urban trees are used for lumber in order to make better use of wood from sources like our own yards, parks, and even near our city streets. Every urban tree used for lumber is one less tree that must be cut from our forests and one less piece of green waste that would otherwise be dumped in our landfills.

According to IWF, the seminar will also address:

> The unique "source local/buy local" marketing appeal of urban wood products and the interesting stories they tell

> The environmental advantages of utilizing urban wood

> How to find local sources of urban wood

> How to join or start a local urban wood network

> A Q&A session with an expert panel

The main speaker for the seminar is Jennifer Alger, CEO of Far West Forest Products of Sheridan, CA, and president of the newly founded Urban Salvaged & Reclaimed Woods, the first urban lumber trade network on the West Coast.

Dwayne Sperber will also be speaking at the event. Dwayne is the Wisconsin state lead for the Urban Wood Network, and the owner and founder of Wudeward Urban Forest Products, which supplies lumber to architects, designers, and builders.

"Throughout the past decade, Wood-Mizer has seen a major influx of successful businesses who are utilizing urban-sourced wood for their sawmilling operations and we are proud to manufacture a product that enables small businesses to be profitable with an underutilized resource," explains Wood-Mizer COO Darryl Floyd. "While Wood-Mizer has been educating woodworkers about the positive environmental and economic impact of urban wood for years, the Urban Wood Seminar at IWF 2018 will be another step forward in saving more trees from going into the waste stream."

Wood-Mizer is dedicated to sustainable forest management and the urban sawmilling movement. The company recently developed an Urban Sawmilling Video Series highlighting businesses in the USA and Canada who are using locally sourced and salvaged urban timber to make a difference in the wood industry, where many of the hardwoods and softwoods we love are burned, buried, ground, or simply thrown away.

Wood-Mizer has also published a guide to urban milling called "Salvaging, Sawmilling, and Marketing Urban Wood" which can be downloaded here.

The Urban Wood Network, along with Wood-Mizer, recognizes the need for sustainable forestry practices and has joined businesses and individuals in the Midwest to promote urban wood utilization. Part of UWN's mission is to "build a common understanding, language, commitment, and eventually, brand for the urban wood marketplace."

The Urban Wood Seminar is free of charge, but advanced registration is required to guarantee a seat. Learn more and register here.

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a leading wood processing equipment manufacturer with a strong legacy from its innovative sawmilling products. From forest to final form, Wood-Mizer offers an extensive line of equipment including narrowband portable and industrial sawmills, wideband sawmilling equipment, resaws, edgers, kilns, planer/moulders, firewood processing equipment, pallet recycling equipment, material handling equipment, bandsaw blades, and blade maintenance equipment for woodworking and forestry hobbyists and professionals all over the world.

The Wood-Mizer exclusive Vortex® dust-removal blade profile is now available in DoubleHard high-alloy steel resulting in a more durable blade that delivers up to twice the toughness and sharp life compared to carbon steel blades. Introduced in 2016, Vortex® dust-removal technology was previously an exclusive feature of SilverTip carbon steel material used primarily in high-production resawing operations.

Patent pending and trademarked for its revolutionary design, the Vortex® blade profile creates an extremely unique turbulence that removes sawdust from the cut. With a typical blade, sawdust can remain on the board by spilling out of the smaller gullet while sawing. By reducing the amount of sawdust left on the board, the Vortex® blade minimizes the need for additional sawdust removal after processing. In addition, Vortex® blades can be sharpened by Wood-Mizer’s blade maintenance equipment or ReSharp® blade sharpening service to extend the flex life of the blade and maintain cut quality.

"The Vortex blades leave 80% less sawdust than any other blades I have tried throughout the past 25 years,” said Mark Borneman with Timber Creek Resources in Antigo, Wisconsin. "We have eliminated the need for a deduster on a majority of our jobs.”

The Vortex® blade is now available to order in both SilverTip and DoubleHard material in a variety of widths, thicknesses, and lengths to fit various sawmill and resaw brands and models. Wood-Mizer offers an extensive range of blades with more than 100 combinations based on profile, width, thickness, tooth spacing, and alloy for any type of sawing or resawing application from green softwoods to abrasive hardwoods. For more information, visit www.woodmizer.com/blades or call 800.522.5760.

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a leading wood processing equipment manufacturer with a strong legacy from its innovative sawmilling products. From forest to final form, Wood-Mizer offers an extensive line of equipment including narrowband portable and industrial sawmills, wideband sawmilling equipment, resaws, edgers, kilns, moulders/planers, firewood processing equipment, pallet recycling equipment, material handling equipment, bandsaw blades, and blade maintenance equipment for woodworking and forestry hobbyists and professionals all over the world.

Wood-Mizer has acquired the Swedish company, MOReTENs AB, placing a full range of popular 4-sided planer/moulders, table saws, spindle moulders, and CNC routers into Wood-Mizer’s globally available product range.

Founded in 1980, MOReTENs designs and manufactures a popular range of woodworking machinery which includes 4-sided planer/moulder combination models, spindle moulders, and a workshop table saw. In addition, MOReTENs also supplies high-end, CNC-controlled routers and log home building machinery.

“Throughout our history, Wood-Mizer has been committed to providing the best quality equipment to process logs into finished wood products,” said Wood-Mizer President and CEO Richard Vivers. “The affordable and versatile planer and moulder product lines from MOReTENs have been proven worldwide for decades, and are now backed by the high-quality service and support network customers expect from Wood-Mizer.”

The founder and owner of MOReTENs, Bo Mårtensson, has joined Wood-Mizer as the General Director of the factory in Ostersund, Sweden. The factory in Sweden marks Wood-Mizer’s fifth manufacturing plant throughout the world including three facilities in the USA and one in Poland.

“Many years ago, I was a young engineer with carpentry experience when I started MOReTENs and began building woodworking machinery,” said Bo Mårtensson. “I’m proud to see my products in workshops worldwide, and now we are very pleased to be joining the Wood-Mizer team, which will see our existing products being available to a much wider customer base and will also accelerate our capability to introduce new products to meet our customers’ needs.”

Beginning in March 2018, Wood-Mizer will offer the new range of planer/moulders through their distribution network. The latest acquisition of MOReTENs builds on Wood-Mizer's position as a worldwide manufacturer and supplier of narrow band sawmills, now offering a full range of equipment that can seamlessly convert logs into dried lumber and finally into finished wood products - all backed by Wood-Mizer's expertise and commitment to excellent customer service.

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a leading wood processing equipment manufacturer with a strong legacy from its innovative sawmilling products. From forest to final form, Wood-Mizer offers an extensive line of equipment including narrowband portable and industrial sawmills, wideband sawmilling equipment, resaws, edgers, kilns, planer/moulders, firewood processing equipment, pallet recycling equipment, material handling equipment, bandsaw blades, and blade maintenance equipment for woodworking and forestry hobbyists and professionals all over the world.

Wood-Mizer introduces the WR series of zero turn mowers engineered for homeowners looking for a reliable mower with premium cut quality. The heavy-duty WR series joins the Wood-Mizer product range recognized throughout the world for first-class manufacturing, top-quality components, and exceptional customer service.

Built in the USA, the WR series mowers are available in 52” or 61” mowing decks and powered by a 26HP Kohler gas vertical shaftengine. Featuring fully welded-steel decks, heavy-duty fabricated frame, and a durable powder-coat paint finish, Wood-Mizer mowers ensure a durable, dependable zero turn mower that is engineered to last for years of heavy-use. Optimal control and comfort is accomplished by the ergonomically-designed adjustable operator control seat, large diameter control handles, easy height of cut adjustment, and large 22” diameter rear tires. Premium components including Kevlar belts and commercial-grade drive motors increase run times and require minimal maintenance.

WR Series Mower Specifications

Introductory Price

• Starting at $5,199 USD Features

• Built in the USA

• 26HP Kohler vertical engine

• 52” or 61” inch decks available

• Dual integrated hydrostatic transaxle Hydro-Gear ZT-3100 transmission

• 1” to 4.5” adjustable cut height

• Three 18” blades for 52” deck or three 21” blades for 61” deck

• Kevlar belts

• 22” diameter rear drive tires

• 3-year or 300 hour warranty

“Designing and selling premium mowers for high end golf courses for more than 25 years, Wood-Mizer owned company, Lastec, has successfully engineered a high-quality, zero turn mower that we can confidently offer to the market,” said Darryl Floyd, Wood-Mizer COO. “The addition of the WR series gives Wood-Mizer a new product range that is centered on our long-standing foundation of premium quality manufacturing and world-class customer service.”

The WR series lawn mowers come with a 3-year or 300 hour warranty and are backed by the same legendary service, quality and safety features shared by the rest of the family of Wood-Mizer equipment. The WR series lawn mower is now available to order in North America. Visit www.woodmizer.com/mowers or call 800.553.0182 for more information.

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a world-leading forestry equipment manufacturer with a strong legacy from its innovative wood processing products. Today, Wood-Mizer offers an extensive line of forestry and now landscaping equipment for residential and business professionals all over the world. For more information visit woodmizer.com.

Wood-Mizer introduces the EG100 twin blade board edger designed for sawyers looking for a low cost, highly durable edger to improve overall production and efficiency by edging sideboards and slabs. The EG100 twin blade edger joins the Wood-Mizer range of professional edgers that includes the EG50 manual feed single blade and EG200 twin blade power feed edgers as well as industrial and TITAN industrial edgers.

Available in 14HP gas or 10HP (7.5kW) electric power, the EG100 edger is generally operated by two people, one to feed the edger and the other to remove the finished boards. With one adjustable and one fixed 10” (254mm) diameter carbide-tipped circular blades, the EG100 can edge up to 20 ½” (520mm) wide flitches into a 12” (300mm) wide finished board with a maximum thickness of 2” (50mm).

EG100 Edger Specifications

Introductory Price

· Starting at $5,995 USD

Features

· 14HP Gas or 10HP (7.5kW) Electric

· 30 fpm (9m/min) belt driven feed rate (Gas) or variable 0-46 fpm (14m/min) feed rate (Electric)

· One fixed and one adjustable 10” (254mm) diameter carbide circular blades

· 20 ½” (520mm) max material width and 2” (50mm) max thickness

· 12” (300mm) max finished board width

· Removable board fence

"The EG100 is a cost effective solution and a valuable addition to small to medium sized sawmill operations,” said Dave Mann, Wood-Mizer Sales Manager. "Using an edger is one of the easiest ways to enhance material flow and boost productivity. With the EG100 this can be achieved on an affordable budget.”

The EG100 twin-blade board edger comes with a 2-year warranty, ships on a single pallet, and is backed by the same legendary service, quality and safety features shared by the rest of the family of Wood-Mizer wood processing equipment. The EG100 edger is now available to order in North America, South America, Europe, Africa, Asia and Oceania.

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a leading wood processing equipment manufacturer with a strong legacy from its innovative sawmilling products. From forest to final form, Wood-Mizer offers an extensive line of equipment including narrowband portable and industrial sawmills, wideband sawmilling equipment, resaws, edgers, kilns, moulders/planers, firewood processing equipment, pallet recycling equipment, material handling equipment, bandsaw blades, and blade maintenance equipment for woodworking and forestry hobbyists and professionals all over the world.

.gif)