704-841-2001

Backed with a massive machinery database considered to be “the blue book” of woodworking machinery), EX-FACTORY Auctions provides a complete assessment of your equipment and allows you to interact with the market real-time in our dynamic Online Auction!

2029 Results Found

704-841-2001

$29,000

SCMI OLIMPIC K 800 T-FR2 EDGEBANDER EDGEBANDER (W/PRE-MILL & CORNER ROUNDING): Specifications: -- Edge Capacity, 0.4 to 8 mm (0.016 to 5/16") for strip feeding. -- Panel Capacity, min. width 65 mm and 140 mm min. length, (2-3/8" and 5-1/2"). Panel thickness min./max. 8 - 60 mm (3/8" - 2-3/8"). Equipped With: -- Adjustable In-feed Fence: Manually pre-set with digital indicator and pneumatic panel spacing device. -- Pre-Milling Station, RT-E: Spindles 2 x 3.0 HP, 12,000 RPM, (1) with PLC controlled jump action and manual digital indicators positioning. -- Automatic Strip & Coil Feed Magazine: For straight edges and 3 mm guillotine for coils. -- Gluing Station: For EVA (Hot Melt) with Teflon coated glue tank and quick disconnect to change glue tanks fast if needed. Heat-up time approx. 10 Min. -- Pressure Section: Servo motor positioning, (4) pressure rollers, first larger, Teflon coated and powered. Workstations: -- End Trimming Station K-SEL: Front & rear 2 x 0.5 HP, 12,000 RPM motors mounted on THK guides, swivels 0ø - 15ø, rapid set up between straight and angled cutting with the automatic swivel cylinder. -- Flush Trimming Unit: Top/Bottom, 2 x 1.0 HP, 12,000 RPM with 2 pre-set pneumatic positions, flush and overhang, remote pneumatic in/out positioning. -- Bevel/Radius Trimming Unit: Programmable, servo motor positioning, 2 x 1.0 HP - 12.000 RPM motors for change-over on the fly. -- Corner Rounding / Trimming Unit: For additional top & bottom trimming of linear an/or vertical leading & trailing corner when edgebanding all (4) sides, 2 x 0.8 HP - 12,000 RPM motor. -- Profile Scraping Unit "RAS/1000": Top/Bottom with (2) indexed manual pre-sets. Large dia. copy wheels for max. accuracy and pneumatic in/out positioning. -- Glue Scraping Unit, "RC-V": Top/bottom flat glue scraper with pneumatic positioning through controller and air-blow off nozzle to keep the knifes clean. -- Buffing Unit "SPN": Top/bottom, oscillating 2 x 0.25 HP - 3,000 RPM motors, tilting up to 12°. -- Hot Air Unit: Single blower with adjustable heat range and directional heat shield for top/bottom coverage. Restores color luster on thick pvc edging materials that my be lost during the edge scraping process.Operator Interface: -- Startouch Controller, 12" color touch screen, swivels 270° at in-feed of machine. Capable to store (100) programs, (6) at the touch of a single key. Graphical display of all working units. Tracks production data, diagnostic information and monitors maintenance schedules. Complete With & Features: -- Feed-speed, 36/52 FPM, 1 x 2.5 HP feed drive motor, 200 Hz frequency inverter for all trimming units. -- Electronic, programmable hold-down pressure beam positioning, lighted safety/sound enclosure cover and outboard panel support. -- Actual Model: OLIMPIC K 800 T-FR2

Call for Price

SCMI OLIMPIC S1000 T-ERL EDGEBANDER (W/PRE-MILL & CORNER ROUNDING) -- Specifications:Edge Capacity, 0.4 to 15 mm (0.016 to 5/8") for strip feeding. -- Panel Capacity, min. width 50 mm and 140 mm min. length, (2.0" and 5-1/2"). Panel thickness min./max. 8 - 60 mm (3/8" - 2-3/8"). Equipped With: Adjustable In-feed Fence: Manually pre-set with digital indicator and pneumatic panel spacing device. -- Pre-Milling Station, RT-E: Spindles 2 x 5.25 HP, 12,000 RPM, (1) with PLC controlled jump action and manual digital indicators positioning and Diamond Cutter-heads. -- Anti-Adhesive Spraying System: Top/Bottom, positioned prior to the Pre-Milling Unit, it prevents glue buildup on the work-piece surfaces. It consists of (2) independent spray nozzles, and a tank for anti-adhesive liquids. -- Automatic Strip & Coil Feed Magazine: For straight edges and 3 mm guillotine for coils. -- Gluing Station, Vc/1000: For EVA (Hot Melt) with Teflon coated glue tank and quick disconnect to change glue tanks fast if needed. Heat-up time approx. 10 Min. -- Pressure Section: Servo motor positioning, (4) pressure rollers, first larger, Teflon coated and powered. Workstations: End Trimming Station K-SEL: Front & rear 2 x 0.5 HP, 12,000 RPM motors mounted on THK guides, swivels 0ø - 15ø, rapid set up between straight and angled cutting with the automatic swivel cylinder. -- Flush Trimming Unit, Rsp: Top/Bottom, 2 x 1.5 HP, 12,000 RPM with 2 pre-set pneumatic positions, flush and overhang, remote pneumatic in/out positioning. -- Bevel/Radius Trimming Unit, Ri/S: Programmable, servo motor positioning, 2 x 1.0 HP - 12.000 RPM motors for change-over on the fly. -- Corner Rounding / Trimming Unit, Round-K: For additional top & bottom trimming of linear an/or vertical leading & trailing corner when edgebanding all (4) sides, 2 x 0.8 HP - 12,000 RPM motor. Comes with (2) pre-set pneumatic positions to allow to go from thick to thin pvc automatically. -- Profile Scraping Unit "RAS/1000": Top/Bottom with (2) indexed manual pre-sets. Large dia. copy wheels for max. accuracy and pneumatic in/out positioning. -- Glue Scraping Unit, "RCA/2c": Top/bottom flat glue scraper with pneumatic positioning through controller and air-blow off nozzle to keep the knifes clean. -- Buffing Unit "SPN": Top/bottom, oscillating 2 x 0.25 HP - 3,000 RPM motors, tilting up to 12°. -- Hot Air Unit: Single blower with adjustable heat range and directional heat shield for top/bottom coverage. Restores color luster on thick pvc edging materials that may be lost during the edge scraping process.Controls: -- Startouch Controller, 12" color touch screen, swivels 270° at in-feed of machine. Capable to store (100) programs, (6) at the touch of a single key. Graphical display of all working units. Tracks production data, diagnostic information and monitors maintenance schedules. Complete With & Features: -- Feed-speed, 40/60 FPM, 1 x 2.5 HP feed drive motor, 200 Hz frequency inverter for all

$43,200

SCMI OLIMPIC K230R EVO EDGEBANDER (W/PRE-MILLING): -- Specifications:0.4mm to 3mm Edge thickness, Panel thickness 8mm to 50mm (0.3" to 1.96"), minimum part width 60mm (2.36"), minimum part length 160mm (6.30").Minimum distance between panels: 559 mm (22";), 29.5 FPM (98 MPM) Fixed feed speed, 1.0 HP (0.75 kW) feed drive.Pre-milling station: (2) 2.0 HP (1.5 kW) motors, to rectify/clean panels already sized. -- Adjustable In-feed Fence: Manually pre-set with digital indicator, pneumatic in/out positioning.Equipped with: 1.5 Kg Teflon-coated glue pot, glue roller application system complete w/automatic recycling device for unused glue.Digital thermostat adjustment for temperature control. pneumatic guillotine, heating time approx. 8-10 min.3-Roll pressure unit w/pneumatic controls for all pressure rollers. -- Automatic strip & coil feed magazineWorkstations:2-Motor front & rear End Trimming (0.5 HP - 12,000 RPM ea. motor.), tilts 0° - 15°, end trimmers mounted on THK guide. -- Top & bottom flush & bevel trims with quick release mount and plug-in motors for quick tooling changes(0.5 HP - 12.000 RPM motor ea.), bevels 0° - 15° with precision digital indicators for quick setup. -- Top & bottom scraping unit w/manual positioning. -- Top & bottom buffing unit (0.25 HP - 3,000 RPM motors), tilts up to 12°. Operator & Machine Control:Orion 1 Plus controller, located at the infeed of the machine. It is capable of operating all the work units via soft touch buttons.It pneumatically tilt’s the end trim unit from the control panel, it eliminates the use of micro switches, as well as control the temperature of the glue.The control is tilted slightly upward for a more ergonomically friendly position for the operator. -- Actual Model is SCM OLIMPIC K230R EVO.

Call for Price

SCM OLIMPIC K 360ERT HP COMPACT EDGEBANDER (W/PRE-MILL & CORNER ROUNDING):Specifications: -- Edge Capacity, 0.4 to 6 mm (0.016to 1/4") for strip feeding. -- Panel Capacity, min. width 65 mm and 140 mm min. length, (2-3/8" and 5-1/2"). Panel thickness min./max. 8 - 60 mm (3/8" - 2-1/2").Equipped With: -- Adjustable In-feed Fence: Manually pre-set with digital indicator, pneumatic in/out positioning. -- Pre-Milling Station, RT-VP: Spindles 2 x 2.0 HP, 19,000 RPM, (1) with PLC controlled jump action and diamond cutter heads. -- Automatic Strip & Coil Feed Magazine: For straight edges and 3 mm guillotine for coils. -- Gluing Station: For EVA (Hot Melt) with Teflon coated glue tank and quick disconnect to change glue tanks fast if needed. Heat-up time approx. 10 Min. -- Pressure Section: Manual digital positioning, (3) pressure rollers, first larger, Teflon coated and powered. Workstations: -- End Trimming Station: Front & rear 2 x 0.25 HP, 12,000 RPM motors mounted on THK guides, swivels 0° - 15°, rapid set up between straight and angled cutting with the automatic swivel cylinder. -- Trimming Unit Flush/Bevel/Radius: Top/Bottom remote (via control panel) pneumatic positioning for (3) settings, flush/bevel/radius trimming, 2 x 0.7 HP - 12.000 RPM motors with precision digital indicators for quick setup. -- Profile Scraping Unit "RAS/V": Top/Bottom, manual pre-set up with digital indicators. Large dia. copy wheels for max. accuracy and pneumatic in/out positioning. -- Buffing Unit: Top/bottom, 2 x 0.25 HP - 2,800 RPM motors, tilting up to 12°. Controls: -- Orion 1 Plus Controller, fixed at in-feed of machine. with "Touch Screen" control with soft keys, graphics and LCD display panel. It handles most machine set-up functions and workstations. Complete With & Features: -- Feed-speed, 36 FPM fixed, 1 x 2.0 HP feed drive motor; 200 Hz frequency inverter for all trimming units. -- Manual adjustable hold-down pressure beam, full sound enclosure cover and outboard panel support. -- Actual Model is SCM OLIMPIC K 360ERT HP

$5,700

SCMI Compact 22/S 4-Head Moulder4-Head (B-R-L-T), working cap. 8-5/8" x 4-11/16". -- Head sequence: Bottom 5.5 HP motor, right/left 7.5 HP motor and top 5.5 HP motor. -- Spindle dia. 35 mm with cutterhead speed of 6,000 RPM. Variable feed speed 14 to 72 FPM with a 2 HP motor. -- Complete with: 2M (6'6") Infeed straightening table, sound insulation hood, dust hoods, and Owner's Manual.

SCM STARTECH CN - CNC MULTI SPINDLE DRILLINGFeatures: -- Easy Motion Work Table -- 7" Touchscreen -- (7) Independent Vertical Boring SpindlesSpecifications: -- Maximum Panel Dimensions X-Y-Z (3050mm x 800mm x 50mm), Minimum Panel Dimensions X-Y-Z (300 mm X 90 mm x 10 mm) -- Drilling/Grooving working area: 0mm x 800 mm/0mm x 800 mm ÷X-Axis Stroke: 750 mm÷X-Y maximum axis speed: 25m/Min. -- Vertical Spindles: 7 (4X-4Y one of them is shared) Horizontal Spindles: (along Y-axis): 2 (1+1) -- Horizontal Spindles: (along X axis): -- 1 Fixed Integrated Blade (cutting into direction): X Blade Diameter: 100 mm Maximum Blade Thickness: 5 mm -- Motor Power: 3 HP (2.2 kW) Spindle Rotation Speed: 3350 RPM÷Blade Rotation Speed: 4300 RPM -- Electrical Supply: 230 Volt (60 Hz) Installed Motor Power: 4.5 KVAHigh-performance numeric controlled (NC) Drilling Machine engineered for full-production woodworking shops and craftsmen. The Startech CN drilling head's seven (7) independent vertical spindles, the spindle and blade in the “X"; axis, and the possibility of drilling in the “Y"; axis make it both flexible and ideal for batch furniture productions. This machine allows the operator unparalleled flexibility for tailored products without the need of operator intervention for the worktable and machine set-up according to the panel dimensions.

SCM OLIMPIC K230-EVO SINGLE SIDED EDGEBANDERSpecifications: --0.4mm to 3mm Edge thickness, Panel thickness 8mm to 50mm (3/8" to 1-15/15"), minimum part width 110mm (4.33"), minimum part length 160mm (6.30"). -- Equipped with: -- 1.5 Kg Teflon-coated glue pot, glue roller application system complete w/automatic recycling device for unused glue, digital thermostat adjustment for temperature control. pneumatic guillotine, 3-Roll pressure unit w/pneumatic controls for all pressure rollers. -- Automatic strip & coil feed magazine --Workstations: --÷Double motor front & rear (0.4 HP - 12,000 RPM motor ea.), tilts 0° - 15°, end trimmers mounted on 45° THK guide. --Top & bottom flush & bevel trims with quick release mount and plug-in motors for quick tooling changes (0.7 HP - 12.000 RPM motor ea.), bevels 0° - 15° with precision digital indicators for quick setup. --Top & bottom scraping unit w/pneumatic positioning from the control panel. -- Top & bottom buffing unit (0.25 HP - 2,800 RPM motors). 29.5FPM Fixed feed speed, 0.75 HP feed drive.

$11,950

SCM S 630 PLANER WITH TERSA HEADSpecifications: -- 24" Width cap.; 12 HP main motor, 2 HP feed motor; 4-3/4" dia. with reversible knife TERSA Planer Head rotates @ 4,500 RPM; -- 1/8" - 11-3/4" Thickness opening via motorized bed with LED readout for fine adjustment. -- Max. depth of cut 5/16"; 10" min. length of work piece; variable infeed speed from 20 - 56 FPM.Equipped with: -- 20-3/4" x 39" Cast iron table, sectional chip breaker, sectional grooved infeed & solid outfeed rollers, adjustable bed rollers. -- neoprene out feed rollersComplete with: -- Magnetic starter and dust hood w/6" dia. dust outlet.Owner states: Condition- like new 24" thickness planer- third owner in a one man shop. Machine has seen very few hours of operation.

Call for Price

SCM PRATIX S-15-B FLAT TABLE MACHINE (W/ATC/BORING): -- Specifications:Single 5' x 12' traveling "Bridge Gantry" and stationary aluminum dual vacuum table with a MATRIX square grid pattern for fixturing parts.Grid pattern allows use of vacuum pods or closed cell rope gasketing material and use of spoil boards for "nested base machining".(8) Part location pop-up pins mounted on the table perimeter. -- Working field:"X" Axis is 145.11" (3,686 mm); "Y" axis is 61.2" (1,555 mm); "Z" axis stroke is 9.8" (250 mm); max. material thickness 4" (100 mm). -- Positioning Speed:"X" & "Y" Axis 115 FPM (35 MPM); "Z" axis at 82 FPM (26 MPM); closed loop AC Servo drive system.High precision "Rack & Pinion" system in "X" & "Y" axis & ground ball screws "Z" axis; all axes ride on extra large precision profile linear guideways. -- Boring Unit:3 HP (2.2 kW) - 6,000 RPM motor; (7) vertical spindles on 32 mm centers, (5) in "X" axis & (2) in "Y" axis. -- Machining:(1) 9 HP (6.7 kW) Air-cooled electro spindle with HSK F63 adaptor; variable spindle speeds from 1,500 - 24,000 RPM.(1) 14-Position ATC tool rack mounted to the machine base. -- Operator & Machine Control:PC Front End with: "XILOG Plus" + Windows "XP Pro" Operating System; 17" high resolution LCD; ergonomic keypad.USB Ports, serial ports RS-232 & RS-242 & Ethernet adaptor; programs can be transferred via disk or downloading by wire is possible.All computer components are mounted on a mobile stand.XILOG Plus Offers: Incredible list of functions from: (a) Auto-diagnostic to (z) zooming; controlled acceleration & deceleration, encoder feedback, dynamic tool correction via PLC due to active tool wear using space-and-time criteria. -- Additionally equipped with:Onboard mini-CAD with built-in programming for writing circles, ellipses & angles with only a few keystrokes; Onboard cycle optimization, onboard calculator, mirror-imaging, and repeat imaging. -- Complete with:(1) 300 m³/Hr Vacuum Pump; external transformer 208/230/480 Volt; safety enclosure around the spindle carriage; tool length probe sensor; manual centralized lubrication.Includes: (1) Universal Remote Pendant, 7" color display allows for the effective management of all machine functions from manual Jog Mode to loading & execution of a program.The pendant is fitted with a USB port to allow quick load & setup of new programs; safety "bump-stop" bumpers; emergency stop rope & manuals. -- Actual Model is SCM - PRATIX S-15-B.

SCMI ROUTECH RECORD 125 N FLAT TABLE MACHINE (W/ATC/BORING): -- Specifications:5' x 10' Single Table machine: stationary extruded aluminum table is machined with a square grid pattern for fixturing parts,Grid pattern allows use of vacuum pods or closed cell rope gasketing material and use of spoil boards for "nested based machining". -- Working field:"X" axis 125" (3,175 mm), “Y"; axis 60"; (1,524 mm) , "Z" axis stroke is 12" (305 mm). -- Positioning speed:"X" axis 260 FPM (80 MPM), "Y" axis 180 FPM (55 MPM), "Z" axis 82 FPM (25 MPM);Closed loop AC Servo drive system driving precision ground ball screws, all axes ride on extra large precision profile linear guideways. -- Boring Unit:(12) Independent vertical spindles, (7) in "X" axis & (5) in "Y" axis;(6) Horizontal spindles with (2+2) in "X" axis & (1+1) in "Y" axis. -- Machining:(1) 15 HP (11.2 kW) Liquid Cooled "Power 2000" Electro spindle w/lifetime lubrication & HSK F63 adaptor, spindle speeds from 6,000 - 18,000 RPM;(1) 12-position ATC tool plate mounted on the head for "on the fly" ATC. -- Operator & Machine Control:PC Front end with "ESA-GV Kavara6" + WINDOWS operating system; "NUM 1000" PLC featuring (3) axes simultaneous control,15" high resolution CRT; 1.2 GB Hard drive, ergonomic industrial keyboard & mouse; 1.44MB floppy disk drive; serial ports for RS-232; all housed in a separate dust free cabinet -- Complete with:(1) 250 m³/Hr + (1) 100 m³/Hr vacuum pump; Pressure safety mats. -- Actual Model is SCMI Routech Record 125 N.

Call for Price

SCM ROUTECH RECORD 130 FLAT TABLE MACHINE (W/ATC/BORING): -- Specifications:4' x 10' Single Table machine: stationary extruded aluminum table is machined with a square grid pattern for fixturing parts,Grid pattern allows use of vacuum pods or closed cell rope gasketing material and use of spoil boards for "nested based machining". -- Working field:"X" axis 120" (3,048 mm), “Y"; axis 49.2"; (1,250 mm, "Z" axis stroke is 12" (305 mm). -- Positioning speed:"X" axis 260 FPM (80 MPM), "Y" axis 180 FPM (55 MPM), "Z" axis 82 FPM (25 MPM).Closed loop AC Servo drive system driving precision ground ball screws, all axes ride on extra large precision profile linear guideways. -- Boring Unit:(12) vertical spindles, (7) in "X" axis & (5) in "Y" axis;(6) Horizontal spindles with (2+2) in "X" axis & (1+1) in "Y" axis. -- Machining:(1) 10 HP (7.5 kW) "Power 2000" Electro spindle w/lifetime lubrication & HSK F63 adaptor, spindle speeds from 6,000 - 18,000 RPM;(1) 12-position ATC tool plate mounted on the head for "on the fly" ATC. -- Operator & Machine Control:PC Front end with XILOG Plus + WINDOWS operating system; "NUM 1000" PLC featuring (3) axes simultaneous control,15" high resolution CRT; 1.2 GB Hard drive, ergonomic industrial keyboard & mouse; 1.44MB floppy disk drive; serial ports for RS-232; all housed in a separate dust free cabinet -- Complete with:(1) 12 HP "BECKER" vacuum pump; safety BUMP stop. -- Actual Model is SCMI ROUTECH RECORD 130-121.

SCMI ROUTECH RECORD 125 N FLAT TABLE MACHINE (W/ATC/BORING): -- Specifications:5' x 10' Single Table machine: stationary extruded aluminum table is machined with a square grid pattern for fixturing parts,Grid pattern allows use of vacuum pods or closed cell rope gasketing material and use of spoil boards for "nested based machining". -- Working field:"X" axis 125" (3,175 mm), “Y"; axis 60"; (1,524 mm) , "Z" axis stroke is 12" (305 mm). -- Positioning speed:"X" axis 260 FPM (80 MPM), "Y" axis 180 FPM (55 MPM), "Z" axis 82 FPM (25 MPM);Closed loop AC Servo drive system driving precision ground ball screws, all axes ride on extra large precision profile linear guideways. -- Boring Unit:(12) Independent vertical spindles, (7) in "X" axis & (5) in "Y" axis;(6) Horizontal spindles with (2+2) in "X" axis & (1+1) in "Y" axis. -- Machining:(1) 15 HP (11.2 kW) Liquid Cooled "Power 2000" Electro spindle w/lifetime lubrication & HSK F63 adaptor, spindle speeds from 6,000 - 18,000 RPM;(1) 12-position ATC tool plate mounted on the head for "on the fly" ATC. -- Operator & Machine Control:PC Front end with "ESA-GV Kavara6" + WINDOWS operating system; "NUM 1000" PLC featuring (3) axes simultaneous control,15" high resolution CRT; 1.2 GB Hard drive, ergonomic industrial keyboard & mouse; 1.44MB floppy disk drive; serial ports for RS-232; all housed in a separate dust free cabinet -- Complete with:(1) 250 m³/Hr + (1) 100 m³/Hr vacuum pump; Pressure safety mats. -- Actual Model is SCMI Routech Record 125 N.

Call for Price

//This machine is in an Auction on exfactoryauctions.com// //Link to machine: http://exf.ac/i6d SECO SK-20BS 20" Vertical Band Saw Specifications: Actual throat 18-1/4". Table size 22-3/4” LR x 20-1/4" FB, with 45° Tilt. Max. height under guard 12". Blade length 155", Blade width 1". Wheel speed 800 RPM. Equipped with: 3 HP - 3,450 RPM Motor. 20” Rubber-covered cast aluminum wheels. Complete with: Work light.

Call for Price

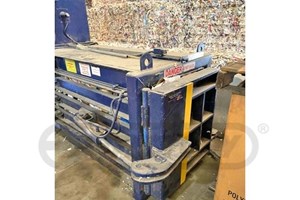

SELCO - HLO-608-A40: Wide Mouth Auto-Tie Horizontal BalerSpecifications: -- Bale size: 48"; x 40"; x 72";. -- Main motor: 50 HP. -- Cylinder: 8". -- Twister motor: 2 HP. -- Cooler motor: 2 HP. -- (4) Tension cylinders: 5" Bore.Available NOW!

Call for Price

SELCO HSO-128A50: Horizontal Auto-Tie Baler -- Type: Open end. -- Cylinder: 8". -- Motor: 50 HP. -- Infeed opening: 36" x 28-1/2". -- Bale size: 30" x 40" x Variable. -- Bale weight: Up to 1,200 Lbs (OCC). -- Production capacity: 2 to 4-1/2 TPH. -- Shear blade. -- Hopper size: 36" x 28-1/2". -- Ram face pressure: 103 PSI. -- System pressure: 2,400 PSI. -- Platen force: 120,637 Lbs. -- Cycle time: 11-1/2 Sec (no load).

Call for Price

SELCO - HL-12-LH: Horizontal Baler with Infeed Conveyor• Motor: 20 HP. • Main Cylinder: 6";.• Hopper Opening: 50"; x 28";.• Cycle Time (No Load): 15 Seconds.• System Pressure: 2,000 PSI.• Total Compression Force: 56,556 Lbs.

$18,900

SELCO EB 70 L CNC Front-Load Horizontal Beam CNC Panel SawSpecifications & features: -- 126" (3,200 mm) Overall cutting length, 2.75" cutting height (80 mm saw blade projection), 10 HP main & 3 HP scoring motor. -- Modular roller rear machine table, side aligning device for squaring ripped strips out to 59". -- Variable saw carriage travel speed from 0 - 164 FPM (0 - 50 MPM). -- Electronically controlled overhead program fence, rack & pinion driven, forward speed of 80 FPM, 131 FPM return speed.Equipped with: -- (6) Clamps (open up to 70 mm - 2-3/4"), (3) are closely spaced in crosscut area & (4) are at equal distance in rip cut area; AC Servo motor drives on both saw carriage & pusher fence. -- PC Controller with: Graphics color monitor & "Assist Line"; LED readout integrated into "high tech" look operator control panel (displays cutting dimensions & patterns), (400) cutting patterns with (50) different dimensions for ea. pattern, self-diagnostic. Machine features: -- 1,500 mm (59") Long crosscut fence (front-to-back), (1) side/crosscut aligner. -- (1) Front mounted air flotation table in the crosscut area and (2) front mounted air flotation tables with patented rounded front for moving panel from rip to crosscut position (24" x 59" each). -- 36" Working height; rear of machine partially enclosed for safety.

$17,900

SELCO EB 90 CNC Front Load Panel SawSpecifications: -- 173" Overall cutting length, 173" pull back; 3.3" (85 mm) max. saw blade projection, 12 HP (9 kW) main saw motor, 2.4 HP (1.8 kW) scoring motor. -- Modular roller rear machine table, side aligning device, and (2) longitudinal aligners to accurately position book of panels on rear saw table prior to cutting. Equipped with: -- Variable saw carriage travel speed from 0 - 197 FPM (0 - 60 MPM), return speed of 197 FPM (60 MPM). -- Electronically controlled overhead program fence, rack & pinion driven, forward speed of 0 - 197 FPM (0 - 60 MPM), return speed of 197 FPM (60 MPM). -- (9) Clamps (open up to 85 mm); AC Servo motor drives on both saw carriage and pusher fence.CNi "NC 400 Plus" control with: Color monitor and "Assist Line" w/LED readout (displays cutting dimensions & patterns, virtually unlimited storage capacity of cutting patterns & different dimensions. "Assist Line" with: Real-time graphics, self-diagnostic, data input by keyboard or possible direct downloading from an office PC. Complete with: -- 90" (2,300 mm) Long crosscut fence (front-to-back), (2) side/crosscut aligners, "Quick Change" saw blade replacement system. -- (4) Front mounted air float tables with rounded front 24" x 79" for moving panel from rip to crosscut position. -- Includes: -- Rear roller module support rails; rear of machine enclosed for safety.

$13,950

SELCO - EB 120: CNC Frontload Panel SawSpecifications -- 14.4' 4,400 mm) Overall cutting length & 4.7" (120 mm) max. saw blade projection; 18 HP main & 2.4 HP scoring motor; modular roller rear machine table; side aligning device; (2) longitudinal aligners to accurately position the book of panels on the rear saw table prior to cutting. -- Variable saw carriage travel speed: 0 - 328 FPM; electronically controlled overhead program fence; rack & pinion driven; forward speed 196 FPM; return speed 196 FPM.Equipped with: -- (6) Clamps (open up to 122 mm), of which (3) are closely spaced in crosscut area and the other (3) are at equal distance in rip cut area. -- AC Servo Motor drives on both: Saw carriage and pusher fence. Operator & Machine Control: -- The front-end controlled by PC: Color monitor integrated into a high-tech-look Operator control panel (which displays cutting dimensions and patterns); panel has virtually unlimited: Cutting pattern storage capacity; self-diagnostic. Data can be input by keyboard or downloaded directly from the office PC. Complete with: -- 2,300 mm Long crosscut fence stroke (side to side); (2) side/crosscut aligners. -- (3) Front mounted air float tables with: Rounded front for moving panel from rip to crosscut position (24" x 79" each). -- Rear of machine partially enclosed for safety.

SELCO - HLO-608-A40, ...Wide Mouth Auto-Tie Horizontal BalerSpecifications: -- Bale size: 48"; x 40"; x 72"; -- Main motor: 40 HP -- Cylinder: 8" -- Twister motor: 2 HP -- Cooler motor: 2 HP -- (4) Tension cylinders: 5" BoreEquipped with: -- Conveyor controls -- Shear bar (tapered & serrated)Available NOW!