Woodworking Equipment For Sale

1689 Results Found

$ 3,000

Hitachi Band Resaw. 7.5 HP motor with feed, 3 phase. New 4" carbide tipped blades. Ready to go to work. Call 800-459-2148 for more info.

Call for Price

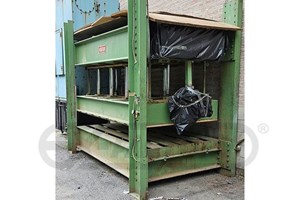

HOFER HOP 160 K Hydraulic Door/Veneer Heavy Duty Cold PressSpecifications:Platen size 63" deep x 98" long, Total Daylight/Opening 32".available. Currently set at about 13" opening. Top platen is hydraulically powered by a 2.2 KW power pack. and has (10 sets) of bolt holes for manual adjustment of daylight opening.Equipped with:(8) 3-1/4" Diameter Hydraulic cylinders, Rack & pinion platen leveling adjustment.Front and back loading (access on all sides).Heavy duty steel structural beams. Bolted top and bottom platens.Features:Pneumatically loaded 3 +1 rows of idle rollers on bottom platen for ease of feeding the load in and out front of press. Air valve for up/down selection of bottom platen rollers.Hydraulic closing speed adjustment.Electrical controls on right hand side.Dimensions/Weight: 124" x 72" x 122" H. Approx. 12,000 Lbs.

Call for Price

Call for Price

HOFFMANN PU 2 DOVETAIL ROUTER (SINGLE SPINDLE) Pneumatic Dovetail Routing Machine - Dovetail routing machine for use with HOFFMAN dovetail butterfly connectors. - Maximum routing height 4", Max. workpiece height 5-3/4" - Table size 15-1/2” x 27-1/2” x 36-1/2” H - Production speed: Approx. 16 SPM (2 Complete rectangular frames) - (1) HOFFMANN "UAD 33 F" 33,000 RPM 1,000 W Router motor - 45° Fence, Accurately positions material with guide in table keyway, Quick adjustments made by adjusting fence plate - Pneumatic hold-down, Pneumatic foot pedal Includes: - Extra HOFFMANN "UAD 33 F" 33,000 RPM 1000 W Router Motor - 2007 HOFFMANN "FM1000" 35,000 RPM 1,000 W Router Motor - (2) 16” x 48” x 35” H Left-Hand & Right-Hand Aluminum Frame Tables, with 3/4” Thick Top, & 2” x 2” Aluminum frame - Palletized Dimensions: 42” x 42” x 60” H

$ 28,900

HOLYTEK - KL-36PC, ...2-Head Sander 2-Head Planer Sander 36" with planer head & combination head.Description: -- Planing head (P) of a 6'' dia. made of steel with spiral design for heavy stock removal. 228 TCT Tips: 15 x 15 x 2.5 mm each disposed on (6) rows. Each knife has (4) usable cutting edges. Easy access to planing head for tips rotation or replacement. -- Precise dial indicator showing the exact positioning of the sanding pad. Quiet & smooth oscillation! Pneumatic oscillation system controlled electronically by an infrared system, which is not affected by dust. -- Combination Head (1 drum & 1 sanding pad) (C) for superior quality of finishing. A sanding belt with a grit of 120 or 150 allows a finishing sanding in a single-pass. -- Elevation table: (4) Screws. -- Infeed roller table extension 15 3/4" -- Outfeed roller table: 15-3/4" with (2) Rollers. -- Centralized Control Panel with: Electronic digital readout (Metric or Imperial) for elevation. Precise positioning at the elevation requested. -- Ammeter indicating the electrical intensity on the spiral cutterhead and the combination head motors. -- Electrical box with: CSA Approved electrical components ensuring maximum dependability and an outstanding long-lasting performance.Specifications: -- Spiral cutterhead motor: 20 HP, 600 V, 60 Hz, 3 Ph -- Combination head motor: 15 HP, 600 V, 60 Hz, 3 Ph -- Table elevation motor: 0.25 HP, 600 V, 60 Hz, 3 Ph -- Feed motor: 2 HP, 600 V, 60 Hz, 3 Ph -- Spiral cutterhead dia.: 6'' -- TCT Tips dim.: 15 x 15 x 2 mm (228), (6) rows -- Max. working width: 36" -- Min. working length: 12" -- Max. working thickness: 5" -- Sanding belt dim.: 37" x 75" -- Dust hoods dia.: 4'' x 2 & 5" x 2 -- Machine dim.: 71" L x 76" W x 77'' H -- Net weight: 1,450 kG or 3,190 Lbs.

$ 19,100

HOLYTEK - HK 400, ...Top & Bottom PlanerSpecifications: -- 16" x 8" Cap., top & bottom helical insert knife heads, 4,000 RPM cutterhead rotation. -- 15 HP Top & 10 HP bottom; 10" min. stock length. -- 2 HP Variable feed speed from 23 - 65 FPM; sectional feed rolls & chipbreaker. -- 0.5 HP Motorized opening w/micro-adjustable table. Complete with: -- Heavy swing-out carriage with a built-in micro-dial; supports bottom cutterhead, pulled out for "quick & easy" replacement of knives.

$ 21,500

HOLYTEK HK 610 Double-Sided Strato Planer -- 24" x 8" Cap. Double Surface Planer, spiral carbide cutterheads belt driven by 20 HP top and 15 HP bottom motors at 5,000 RPM. -- Spriral cutter head 125 mm diam. with 96 inserts 30 mm X 12 mm X 1.5 mm -- Variable feed motor delivers a range of 6 M./min to 25 M./min. (9.5 FPM to 82 FPM), -- Feed motor 3 HP, corrugated sectional infeed rollers and (4) table rollers provide superior feeding regardless of the type of wood being processed; -- Hard-chromed table surface precision ground to provide smooth performance and maximum wear resistance at high speeds.Technical Specifications:• Maximum width 635 mm (25")• Minimum length: 300 mm (11.9")• Maximum thickness 200 mm (7.87")• Minimum thickness 10 mm (.39")• Table size: 686 mm x 2616 mm (27" x 103")Features: ● Dovetailed slideways on the table elevation ensure stability and rigidity; Mechanical readout provides accurate details of table positioning adjustment; ● Thickness limit guard is provided at the infeed end as a safety feature. ● Machine weight 6,600 Lbs

HOLYTEK - HRS-12TK, ...Straight Line Rip Saw with Glue Joint CutSpecifications: -- Overhead saw arbor, 15 HP motor belt driven, 4,500 RPM arbor. -- 12" Dia. max. saw blade. -- 3-3/8" Max. depth of cut. -- 18" Max. throat depth. -- 2 HP Stepped feed speeds of 50 - 65 - 83 - 100. -- Automatic lubrication of chain. -- Magnetic controls. -- Saw is glue line rated.Equipped with & Features: -- Overhead holddown rolls. -- Double-row of antikickback fingers. -- (6) Pressure rollers. -- Infeed adjustable fence line. -- Cast Iron table with rip fence.Also Included: -- Laser light -- Glue joint cutting capacity

$ 33,500

HOLYTEK MHB 242 Top/Bottom Wide Belt SanderHeavy-duty and powerful double surface sander providing significant time saving and improved productivity.Smooth and quiet oscillation. Belts oscillation controlled electronically by an infrared system which resists dust.Pneumatic sanding belts tensioning ensuring fast and easy belt replacement.Independent motor for each sanding belt.Pneumatic disc brake system automatically activated if power supply is interrupted, thus preserving the sanding belts from being damaged. Top and bottom 24" wide belt sanderFeatures: -- Spiral grooved 8" (D) rollers (R) and 3-1/2" (D) rollers (K) keep the sanding belts cool. -- Sanding belts: 75" Long. -- Elevation of table with digital readout and activated by independent motor. -- Control panel with: Ammeters indicating main motors current. Specifications: -- Upper Drum motor: 15 HP; 600 V; 60 Hz - 3-Ph. -- Upper Combination head motor: 10 HP; 600 V; 60 Hz - 3-Ph. -- Lower Drum motor: 15 HP; 600 V; 60 Hz - 3-Ph. -- Lower Combination head motor: 10 HP, 600 V, 60 Hz - 3-Ph. -- Feeding motors: 2 HP (x2). -- Table elevation motor: 0.5 HP. -- Electrical intensity: 53 A. -- Drums: 8" (D) - 75 DUROS. -- Max. working width: 24". -- Min. working length: 13-3/4". -- Working thickness: 3/16" ~ 5" -- Sanding belts dimensions: 25" x 75". -- Variable feeding speed: 8 - 16 MPM. -- Dust hoods Top: 4 x 4"(D); Bottom: 3 x 4"(D). -- OAL 127" x 70" x 75" high. -- Weight: 9,460 Lbs.

$ 5,500

$ 32,500

HOLYTEK HK 610 Double Sided Planer with THOMAS MANUFACTURING Return ConveyorHOLYTEK HK 610 Double Sided Planer specifications - -- 24" x 8" Cap. Double Surface Planer, spiral carbide cutterheads belt driven by 20 HP top and 15 HP bottom motors at 4,000 RPM. -- Spriral cutter head 125 mm diam. with 96 inserts 30mm X 12 mm X 1.5 mm -- Variable feed motor delivers a range of 7 M./min to 20 M./min. (19.5 FPM to 82 FPM) -- Feed motor 3 HP, corrugated sectional infeed rollers and (4) table rollers provide superior feeding regardless of the type of wood being processed; hard-chromed table surface precision ground to provide smooth performance and maximum wear resistance at high speeds. -- Machines are currently wired for 220 Voltage.Technical Specifications:• Maximum width 610 mm (24")• Minimum length: 300 mm (11.9")• Maximum thickness 170 mm (6.69")• Minimum thickness 8 mm (.31")• Table size: 686 mm X 2616 mm (27" X 103")• Dovetailed slideways on the table elevation ensures stability and rigidity; a mechanical readout provides accurate details of table positioning adjustment; thickness limit guard is provided at the infeed end as a safety feature. • Machine Dimensions - 109" Long x 46" Wide x 68" High, Machine weight 7,280 lbsTHOMAS MANUFACTURING Return Conveyor specifications -37" Wide x 144" Long Receiving Table that transfers to a 20" Wide x 240" Long Return Conveyor1 HP - 3 Phase Variable-Speed DrivePhotoelectric SensorRemote ControlSolid State TimerSwing-Out Section that is 20" Wide x 90" Long

$ 14,800

Holytek 37DA Wide Belt Sander (2) Heads37" Width cap Drum, Combination Head1st Head: 7" Dia. spiral grooved rubber covered contact roller, 20 HP motor;2nd Head: Combination sanding head with 5" dia. spiral grooved rubber covered contact roll & 2" wide polishing platen, 15 HP motor.Specifications -- Abrasive belt size of 37" x 60" -- Pneumatic belt tensioning and electronic abrasive belt tracking -- 12" min. working length. -- 2 HP Conveyor belt motor, -- Variable feed speed from 13 - 52 FPM,Equipped with & Features -- Infeed & outfeed rubber covered holddown rolls; -- 0" - 4" motorized thickness adjustment by 0.5 HP motor. -- Safety stop bar, emergency rail stop across the front of conveyor -- Motor load meters.

HOLYTEK - HRS-12TK, ...Straight Line Rip SawSpecifications: -- Overhead saw arbor, 15 HP motor belt driven, 4,500 RPM arbor. -- 12" Dia. max. saw blade. -- 3-3/8" Max. depth of cut. -- 18" Max. throat depth. -- 2 HP Stepped feed speeds of 50 - 65 - 83 - 100. -- Automatic lubrication of chain. -- Magnetic controls. -- Saw is glue line rated.Equipped with & Features: -- Overhead holddown rolls. -- Double-row of antikickback fingers. -- (6) Pressure rollers. -- Infeed adjustable fence line. -- Cast Iron table with rip fence.

$ 4,950

HOLYTEK SS-512 TS Shaper with Tilting Spindle, and Power FeederSpecifications: -- 1-1/4" Interchangeable spindle, 7.5 HP motor with (5) spindle speed settings of 3,000 - 4,000 - 6,000 - 8,000, & 10,000 RPM. -- Approx. 6" max. cap. under nut, 31" x 39" cast iron table. -- Insert ring diameters 2.8", 4/3", 6" and 8". -- Tilting spindle +10° and -45° -- Vertical movement of the spindle 7" -- sliding tableComplete with: -- Reverse rotation switch, adjustable fence assembly, and dust hood. -- 3-Roll Power Feeder

$ 65,000

HOLZ-HER CUT 6220 Dynamic FRONT LOAD, AUTOMATIC PANEL SAW with 20'+ RIP cutting capacity!: -- Specifications: 4,300 mm (169.2") Max. rip cut cap., 6,250 mm (246") pull back pusher stroke; 105 mm (4.1") saw blade projection;28 HP (21 kW) Main saw motor, 3 HP (2.2 kW) scoring motor. -- Saw Carriage:Variable feed speed from 3 - 426 FPM (1 - 130 MPM ), return speed of 492 FPM (150 MPM).Automatic cutting length limiter adjusts the cutting length at the end of the workpiece, automatic saw carriage lubrication. -- Pusher Fence:(10) Material gripper clamps; 82 FPM (25 MPM) forward positioning speed, 328 FPM (100 MPM) return speed.Rack & pinion movement on both sides to assure the pusher remains parallel. -- Operator & Machine Control:PC Front-End with "CUTCONTROL 2" + "EasyPlan" + Windows operating system,19" TFT Display with unlimited program storage; keypad for data entry, USB & RS-232 serial port, "CUTCONTROL 2" offers Real-Time 3D Graphics, diagnostic for errors or machine malfunction by means of an error signal code, incremental or absolute programming in mm or inches."CUTCONTROL 2" allows the operator to easily input information for absolute, serial, format, grooves, perforations, & position cutting which allows the machine to easily adapt to various situations & materials"Opti-Cut" & "EasyPlan" is a very user friendly on-board Optimizing System for all types of various cutting patterns, including angled cutting -- Complete with: Non Marking rear roller support rails; Solid Air Cushion Table before & after the cutting line, ensures easy panel handling. Pneumatic crosscut side aligner, adjustable from 0" - 82.6" (0 - 2,100 mm);Automatic saw blade height adjustment; Electronic positioning of the scoring blade through the NC control.(4) Adjustable via "pneumatic locking" air support tables, ea. 70.8" x 24" (1,800 x 509 mm); -- Actual Model is HOLZ-HER CUT 6220 Dynamic

$ 38,500

HOLZ-HER CUT 6120 FRONT LOAD, AUTOMATIC PANEL SAW: -- Specifications: 3,900 mm (153.5") Max. rip cut cap., 3,900 mm (153.5") pull back pusher stroke; 82 mm (3.2") saw blade projection.15 HP (11 kW) Main saw motor, 1.5 HP (1.1 kW) scoring motor. -- Saw Carriage:Variable feed speed from 3 - 320 FPM (1 - 100 MPM ), return speed of 416 FPM (130 MPM).Motorized bi-directional grooving capabilities with electronic adjustment for 0 mm - 35 mm.Automatic cutting length limiter adjusts the cutting height & cutting length at the end of the workpiece. -- Pusher Fence:(7) Material gripper clamps, (1) Double Finger mounted at the cross-cut fence location for narrow strip cutting & (6) standard clamps. 82 FPM (25 MPM) forward positioning speed, 328 FPM (100 MPM) return speed.Variable pressure settings for delicate materials. Pressure beam has an integrated "Last Cut" operation to achieve a "0" mm panel dimension.Rack & pinion movement on both sides to assure the pusher remains parallel. -- Operator & Machine Control:PC Front-End with "CUTCONTROL 2" + "EASY-PLAN" + Windows operating system,19" TFT Display with unlimited program storage; keypad for data entry, USB & RS-232 serial port, "CUTCONTROL 2" offers Real-Time 3D Moving Graphics, diagnostic for errors or machine malfunction by means of an error signal code, incremental or absolute programming in mm or inches."CUTCONTROL 2" allows the operator to easily input information for absolute, serial, format, grooves, perforations, & position cutting which allows the machine to easily adapt to various situations & materials."Opti-Cut" & "EASY-PLAN" is a very user friendly on-board Optimizing System for all types of various cutting patterns, including angled cutting -- Complete with: Non-Marking rear roller support rails: Solid Air Cushion Table before & after the cutting line, ensures easy panel handling. Pneumatic crosscut side aligner, adjustable from 0" - 82.6" (0 - 2,100 mm). Side aligner is "Fully Automatic" adjustment when panel is less than 1,300 mm (51")"Quick Change" Blade system with automatic saw blade height adjustment; Electronic positioning of the scoring blade through the NC control.(3) Adjustable via "pneumatic locking" air support tables, ea. 70.8" x 23.6" (1,800 x 600 mm); -- Actual Model is HOLZ-HER CUT 6120 Dynamic

$ 49,500

HOLZ-HER CUT 85 FRONT LOAD, AUTOMATIC PANEL SAW: -- Specifications:4,250 mm (167") Max. rip cut cap., 3,800 mm (149") pull back pusher stroke; 97 mm (3.8") saw blade projection.15 HP (11 kW) Main saw motor, 3 HP (2.2 kW) scoring motor. -- Saw Carriage:Variable feed speed from 3 - 328 FPM (1 - 100 MPM ), return speed of 328 FPM (100 MPM).Automatic cutting length limiter adjusts the cutting length at the end of the workpiece, automatic saw carriage lubrication. -- Pusher Fence:(7) Material gripper clamps; 259 FPM (80 MPM) forward positioning speed, 259 FPM (80 MPM) return speed.Rack & pinion movement on both sides to assure the pusher remains parallel. -- Operator & Machine Control:PC Front-End with CUTCONTROL "Direct Cut" + "OPTIPRO" + Windows 2000 operating system,15" TFT Display with unlimited program storage via floppy disk, keypad for data entry, USB & RS-232 serial port, CD ROM & 1.44 MB disk drive for additional storage of programs.CUTCONTROL offers Real-Time Graphics, diagnostic for errors or machine malfunction by means of an error signal code, incremental or absolute programming in mm or inches."Direct Cut" allows the operator to easily input information for absolute, serial, format, grooves, perforations, & position cutting which allows the machine to easily adapt to various situations & materials."OPTIPRO" is a very user friendly on-board Optimizing System for all types of various cutting patterns, including angled cutting. -- Complete with: Rear roller support rails; automatic crosscut side aligner; automatic saw blade height adjustment.(3) Air support tables, ea. 78" x 24" (1,981 x 509 mm). -- Actual Model is HOLZ-HER CUT 85 4300.

HOLZ-HER 1488V TRIATHLON (W/PRE-MILL & CORNER ROUNDING): -- Specifications:PC Controller which has the ability to program all functions including, thickness, edge feed, glue application, side pressure, end trimming, flush trimming, bevel/radius trimming, shaping, buffing. Virtually eliminates set-up time by selecting & loading program that automatically activates all functions simultaneously.Basic Capacity Data: Max. 1" (25 mm) solid wood banding, thin PVC, veneer, HPL & 3 mm PVC cap., 2-3/8" max. panel thickness and 7" min. panel length.Front-End Equipped With: -- Granulate Gluing System (#1907), w/flat glue-nozzle only 3° angle of approach ideal for solid wood edgebanding & "quick melt" feature. -- Automatic Edge-Magazine (1901) for coil, strip & solid wood edgebanding with TRACTOR-BELT feed system, with Heavy Duty guillotine for 4 mm PVC. -- Pressure Section (1926K MOT) with (3) large dia. rollers, each w/individual pneumatic plunge and pressure control; Programmable with servo motor positioning. Powered 1st roller with electronic speed control synchronized with chain feed speed.EDGEBANDING WORKSTATIONS: -- End Trimming Unit (#1916.1), (2) "HF" motors @ (1 HP - 2,480 RPM ea.) with "Uni-Point Swivel", quick change from flush to 0° - 15° bevel programmable from operator panel. -- Flush Trimming Unit (#1962), (2.6 HP - 200 Cy HF motors), w/servo controls, (3) motors, for compl. workstation forward/backward, vertical copy-wheels +/-. -- Fine/Bevel/Radius Trimming Unit (#1966M), w/5-axis servo motors, (1.5 HP - 200 Cy HF motors), bevels 0° - 45°, plus SIKO digital readouts. -- Scraper Unit (#1927), "Super Duty" for positively smooth finishing thick PVC for radius range from 2 - 5 mm, vertical & horizontal tracing wheels, positioning enabled through (1) servo motor function from control panel, as well as SIKO readouts for easy setup. -- Edge Shaper (#1932 MOT), w/jump control for vertical or horizontal shaping or grooving, 3.8 KW (5 HP) spindle motor, 12,000 RPM spindle speed, max. cutter dia. 135 mm (5.3"), max. cutter width 60 mm (2.36"), servo motor positioning for shaper base and SIKO digital readouts. -- Flat Glue Scraper (#1964), top & bottom for removal of potential glue squeeze-out w/air pressure nozzles to prevent shavings build-up. -- Jump Buffing Unit (#1944), w/programmable jump action for cleaning & polishing of edges (two 0.25 HP - 3,600 RPM motors), tilts 0° - 5°. -- Edge Sanding Unit (1935), vertical oscillating, belt size 120 x 2100 mm (4.75 x 82.75"), pneumatic pressure control for sanding pad, anti-dubbing device for leading & trailing edges.Equipped with and Includes: -- Microprocessor with color LCD screen, 90% of all set-ups can be adjusted from the control panel, programmable for a large variety of edges like solid lumber, veneer strips or coils, HPL, thin & thick PVC. Line control so there are no mechanical limit switches along the chain track. -- Variable feed speed from 8 - 24 MPM (26 - 67 FPM), panel overhang

HOLZ-HER CONTRIGA 1368 EDGEBANDER (W/PRE-MILL & CORNER ROUNDING) -- Specifications: NC Controlled Edgebander has the ability to program all functions including: Panel thickness, edge feed, glue application, end trimming, radius/fine trimming, corner rounding, scraping and buffing. - Virtually eliminates set-up time by selecting & loading program that automatically activates these functions simultaneously.Coil edgebanding up to 3 mm PVC cap.; 2-3/8" max. panel thickness and 7" min. panel length; powered pressure beam opening adjustments. Equipped with: --"1961" Pre-milling Station: PC Controlled with up to 45 mm (1-3/4") milling height; (2) motors @ 2 kW (2.6 HP) - 9,000 RPM each. -- Features: Granulate glue system with: Hopper System with "floating" applicator nozzle & "quick melt" feature. -- Automatic magazine for coil, strip & solid edgebanding model "1901" with: TRACTOR-BELT Feed system, Heavy-Duty guillotine for 3 mm PVC. -- "1914" Pressure Section for 12 mm thick edgebanding with: (3) Rollers, each w/individual pressure control, powered 1st roller with electronic speed control synchronized with chain feed speed; Servo motor adjustment for edgebanding thickness from PLC. Workstations: --"1819-1" Double motor (1 HP - 6,000 RPM motor ea.) end trim units with: "Uni-Point" Swivel system; "quick change" from flush to 0° - 15° bevel from operator panel. -- "1962" Top & Bottom flush trim unit: 2.6 HP - 200 Cy HF motors; 12,000 RPM cutter speed; NC Servo control, non-tilt. -- "1966" Top & Bottom fine trim unit with: Motorized 5-axis positioning; 1.5 HP - 200 Cy HF motors;, 12,000 RPM cutter-head speed; bevels 0° - 45°, Servo control; all adjustments programmable through the PLC. -- "1933 & 1934" 4-Motor corner rounding unit for top & bottom of leading & trailing corner when edgebanding all (4) sides; 0.7 HP - 200 Cy ea.; both motors with Servo positioning from control panel; Servo adjustment of entire unit (base). -- "1927" Scraper Unit: Finishing up to 5 mm thick PVC banding for radius range from 2 - 5 mm; vertical & horizontal tracing wheels, Servo positioning enabled through "PC"; Servo controlled in/out of base. -- "1964" Top & Bottom Glue scraper. -- "1851" Oscillating buffing unit: Cleaning & polishing of panel; (2) 0.25 HP - 1,440 RPM motors; tilts 0° - 45° vertically and 0° - 20° swivel on horizontal plane.Other Specifications & Features: --Variable feed speed up to 25 MPM (81 FPM); panel overhang beyond chain 35 mm (1.38"); features automatic track pad lubrication. -- Includes: PPC-231 Controller for line control, glue temperature & flow, feed speed setting, and motorized hold-down pressure beam adjustment. -- Frequency inverter, outboard panel support, and sound enclosure w/interior lights over all milling units. -- Only (6,227 hours) on the clock!

$ 6,950

HOLZ-HER 1402 HF Compact EdgebanderFeatures: -- Cartridge glue system, 3 mm edge thickness cap., -- Semi-automatic feed magazine, coil stock feeds automatically with guillotine cutoff, all strip stock is fed manually with pusher bar to advance the edging. Digital glue height indicator.Workstations: -- Double motor end trim (1 HP - 10,500 RPM motor ea.) -- Universal top & bottom fine trim (1942M) for bevels from 0° - 15³; allows simultaneous bevel & profile trimming (1 HP - 18,000 RPM motor ea.; trim motors are 0.6 kW HF - 300 Cy). -- Top & bottom PVC scraper unit (1929) for 0.8 - 3 mm radius. -- Top & bottom buffing (1940), 0.3 HP - 1,620 RPM motor ea. -- Single feed speed of 35 FPM. -- Complete with: Fixed outboard panel support, frequency converter, sound enclosure, and used tooling.

.gif)