Woodworking Equipment For Sale

2037 Results Found

$ 1,800

15" Width cap. with 1/4" - 8" thickness opening, 1/16" max. depth of cut; 3 HP single-phase motor belt drives 3-knife, 3-15/64" dia. cutter-head at 5,000 RPM; head with high-speed steel knives, max. thickness 8", min. 3/16"; dual feed speed of either 16 or 30 FPM; 16" x 42" cast iron table, table extensions on infeed/outfeed. Complete with: Magnetic controls, 2" dia. metal infeed & outfeed rollers, open fabricated steel base, and large hand wheel for cutter-head assembly adjustment.

3/4 HP Single Shaper with Team B&B Tiltrod Shaping Gig!Precision-ground cast iron table, independently adjustable fence halves, Push button ON/OFF switch.Includes: Miter gauge and starting pins, Cast iron body construction, Pre-formed steel stand, shielded & permanently lubricated spindle bearings, Reversing switch Includes Team B&B Tiltrod Shaping Gig. Features: -- Motor size: 3/4 HP -- Motor Speed: 3450 RPM -- Table size: 15-5/8" x 17-3/4", Working Height: 34-1/4" -- Vertical Spindle travel: 7/8" Spindle speed: 8500 RPM

$ 1,000

2021 Grizzly Extreme band saw, S/N 210-10180 Model G0513X2BF, 17" wheels W/ 2 HP motor w/ motor brake & foot pedal w/ tilting table 23 5/8 x 17 1/4 single phase 200V 131 1/2" band length Ref #204, Contact 931-797-6284

Call for Price

//This machine is in an Auction on exfactoryauctions.com// //Link to machine: http://exf.ac/i60 GRIZZLY G0673 5,360 CFM 4-Bag Portable Dust Collector Specifications: 10 HP, Cloth filtration bag size 23-5/8" Diameter x 70" L, 2.5 micron, plastic collection bag size 23-5/8 Diameter x 54" L, Total collection bag capacity 48 cu. ft. Airflow capacity: 5360 CFM, Intake port(s): 5 x 4 in., Sound rating 98 dB Includes: (4) Waste Barrels NOTE: The above specs are taken from literature and considered accurate. As always please take advantage of the inspection period to verify. Items seen in the background are NOT a part of this Lot.

$ 1,350

GRIZZLY - G1026, ...Single Speed Shaper w/Feeder & Mobile Base3 HP - 3,450 RPM Motor; 1/2", 3/4" & 1" dia. interchangeable spindles; 2-1/2" spindle cap. under the nut and with 3" spindle travel. -- (2) Spindle speeds of 7,000 or 10,000 RPM; reversing spindle switch. -- Features: 28-1/4" x 21-3/4" table; 34" table height.Complete with: Magnetic spindle brake, adjustable fence & 3" dia. dust extraction outlet.3-Roll 4-Speed Power Feeder & Mobile Base!

Call for Price

3 HP motor 20” x 24” tilting table 20@ wheels 20” throat 13-7/8 cutting height rack & pinion guide adjustments 154-1/2” blade

GRIZZLY G4185 BORING (HORIZONTAL) ---Price Negotiable---Make an Offer!--- 3-Spindle Horizontal Boring Machine, Will Accept 2-Spindle Boring Head - Maximum stock width 7-1/2” - Table size 9-3/4” x 15-3/4”, Maximum table height 35”, Table height adjustment 3-1/2” - Maximum bit capacity 9/16” (Right-hand threaded), Spindle travel adjustment 3”, Spindle speed 4,000 RPM, Maximum speed 12 SPM at 90 PSI - Hold-down force 600 Lbs. - 2 HP 3,450 RPM TEFC Direct drive motor - Pneumatic spindle travel - 2-1/4” Pneumatic hold-down - Pneumatic foot pedal control - Steel stand - Includes: GRIZZLY "G5953/3C-W20" 3-Spindle Boring Head, Maximum bit capacity 15 mm (0.59"), Bit threads 7/16 - 14 TPI Right-hand, Spindle speed 4,000 RPM

GRIZZLY G4185 2-Spindle Horizontal Boring Machine, Will Accept 3-Spindle Boring HeadSpecifications: -- Max. stock width 7-1/2";. -- Table size 9-3/4"; x 15-3/4";, Max. table height 35";, Table height adjustment 3-1/2";. -- Max. bit cap. 9/16"; (Right-hand threaded), Spindle travel adjustment 3";, Spindle speed 4,000 RPM, Max. speed 12 SPM at 90 PSI. -- Hold-down force 600 Lbs.Equipped with: -- 2 HP 3,450 RPM TEFC Direct drive motor. -- Pneumatic spindle travel. -- 2-1/4"; Pneumatic hold-down. -- Pneumatic foot pedal control. -- Steel stand.Complete with: -- GRIZZLY "G5952"; 2C-W19"; 2-Spindle Boring Head, Max. bit cap. 5/8";, Bit threads 7/16 - 14 TPI Right-hand, Spindle speed 4,000 RPM.

GRIZZLY G5394 STROKE SANDERModel G5394 - Motor 3 Ho - Volt 220 - HZ 60 - Phase 1 - MFG No M05227 - Date 2008/09SPECIFICATIONS: -- Motor: 3 HP, 220V, single-phase, 17A -- Sanding belt speed: 3500 SFPM --Sanding belt size: 6" x 186" -- Table Size: 58" x 23-3/4" -- Table vertical travel: 24" -- Platen horizontal travel: 59" -- Table lateral travel: 18" -- Drive roller diameter: 8" -- Footprint: 70" L x 30-1/2" W -- Overall dimensions: 93-3/4" W x 38" D x 50" H -- Approximate shipping weight: 690 lbsORIGINAL MODEL NUMBER: CT-1500

Call for Price

//This machine is in an Auction on exfactoryauctions.com// //Link to machine: http://exf.ac/i62 GRIZZLY G7214Z Shaper Specifications: 1-1/4" Dia. interchangeable spindle, 7.5 HP - 3,450 RPM motor; 3,600, 5,100, 8,000 & 10,000 RPM spindle speeds via 4-step V-pulley. 5-1/8" Cap. under nut when using the 1-1/4" spindle, 3-1/4" spindle travel, 34-3/4" x 35-1/2" cast iron table, 43" working height. Table Counterbore: 7" dia. x 5/8" deep Complete with: Adjustable Fence with integrated 4" dust collection shroud, reversing switch & magnetic controls, 3-roll power feeder

$ 11,950

GRIZZLY H2934 2-HEAD WIDE BELT SANDER2-Head Wide Belt Sander, 36-1/2" width cap. -- Head configuration: - 1st Head: Rubber covered contact drum; 2nd Head: Combination head with rubber covered contact drum and adjustable platen; Abrasive belt size 37" x 60". -- 0" to 6" Thickness cap., LED digital depth encoder; 14" min. board length and 12" infeed conveyor. -- 1st Abrasive belt surface speed of 3,543 SFPM; 2nd abrasives belt surface speed of 2,554 SFPM. -- Conveyor speed from 14 - 60 FPM. -- 20 HP - 50/25 Amp Sanding motor; 1 HP - 3.4/1.7 Amp conveyor motor; 0.25 HP - 1.2/0.6 Amp table lift motor. -- Complete with: Rubber covered holddown rolls, adjustable felt platen, Amp/load meter, and disc brake for emergency stop.

Call for Price

Call for Price

GRIZZLY G9981 Heavy-Duty Overarm Pin Router Specifications: Throat 25-19/32". Table size 29-3/4” LR x 21-1/2” FB with Table tilt 0° - 45° Forward, Table height 36-1/2" - 42-3/4".Vertical table travel 8". Spindle speeds 10,000 & 20,000 RPM. Spindle travel 3-15/16". Equipped with: 5 HP - 3,450 RPM Motor. Foot pedal control.

Call for Price

Call for Price

Call for Price

$ 12,900

GUBISCH MODEL CP-230 4 HEAD PUSH FEED MOULDER: -- 4-Head (T-R-L-B), working capacity 6" x 4". -- Head sequence: Top 15 HP, right/left 15 HP and bottom 15 HP motor. -- Spindle dia. 1-13/16" all heads with cutterhead speed of 6,000 RPM on vertical spindles and 7,000 RPM on horizontal spindles. Heavy duty, built-in profile jointers on spindles #2, #3 and #4. -- Mechanical adjustment for spindle settings. Spindle adjustments from the front side of machine. -- Variable speed feed drive via 7-1/2 HP, variable speed motor with speeds from 16 to 120 FPM; with (2) powered rollers from the top and (2) powered rolls in the table. -- Infeed table;chromed table plates. --Pneumatic jointers on all 4 heads Amazingly well built Moulder; off-the-shelf parts accessibility; low maintenance/operating costs.

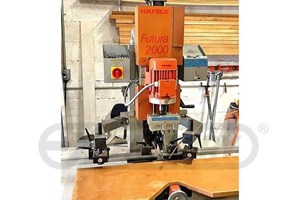

RAFIX - Futura 250: Hinge Boring & Inserting Machine with 1-1/2 HP MotorSpecifications -- High-quality air cylinder (80 mm bore with 650 ft. Lbs of pressure @ 90 PSI) rated for 3-1/2 million 3" strokes.A skilled Operator can bore & insert in (3 - 4) seconds. -- Features: (2) Types of boring depth adjustment: Drawbar style for quick and easy adjustment and a solid stop adjustment for the changing of door thickness applications. This allows changing of the door thickness and still bore the same depth without adjustment. -- Fixed table with: Adjustable back rail to control the tab location. -- Enclosed cutting area for better chip removal with blow off nozzle to assist in chip evacuation and adjustable 2" & 4" vacuum hookup. -- Pneumatic drilling unit with push button control. -- Includes: Adjustable cutting speed control; indicator light; reset thermal circuit breaker; emergency stop button; drill & insert buttons (2-hand activation for Operator safety); rotary switch for pair of pneumatic holddown clamps; 600 mm ruler & (4) flip stops.

Call for Price

Vent Block Drill VBD New never used Motor: Heavy Duty 5 HP - 3 phase - 220v or 440 v (Please specify when ordering) Block Sizes: 2 x 4 through 2 x 12 on center 2 x 14 and larger off center Air Supply: 100 psi Drills: 3-wing Carbide Tipped Spindles: Alloy Steel - Double ended Frame: 2" Steel With Powder Coat Finish Covers: 10 Gauge (1/8" Thick) Aluminum Dimensions: Height - 60 inches, Width - 60 inches, Depth - 33 inches Shipping weight: 750 lbs. - (Including crate) New Never Used!!

.gif)