Woodworking Equipment For Sale

1988 Results Found

Call for Price

Weeke BHP 007/430 CNC Router 13 HP HSK 63F Spindle with air blast nozzles 8 Position Rack Style ATC 7 Spindle Boring Block 4x8 Table Part location pins (2) Becker 7 HP vacuum pumps Woodwop Light Barrier safety system

Call for Price

Weeke BHP 007/430 CNC Router 13 HP HSK 63F Spindle with air blast nozzles 8 Position Rack Style ATC 7 Spindle Boring Block 4x8 Table Part location pins (2) Becker 7 HP vacuum pumps Woodwop Light Barrier safety system

Call for Price

//This machine is in an Auction on exfactoryauctions.com// //Link to machine: http://exf.ac/i5h VANTEDGE MM 6.5 EDGEBANDER (W/PRE-MILL & CORNER ROUNDING): + EVA & Polyolefin Adhesive ready. Specifications: Working Capacity: Edgebanding thickness 0.4 - 3 mm coil stock capacity & 10 mm strip capacity. Min. panel width 85 mm (3.3"); min. panel length 125 mm (4.9"); panel thickness 10 - 60 mm (0.39" - 2.36"). Tape and Panel Infeed System: 750 mm Coil support table; adjustable track feed speed 14, 16 & 20 MPM (66 FPM). Heavy-Duty large solid polished steel panel infeed fence guide system. Large industrial digital adjustment for the Premill panel material removal amount. Top Pressure Beam Adjustment: Automatic adjustment from the PLC control; pneumatic Pop-Up Stop system. Red LED panel feed indicator light for correct panel spacing. Equipped with: Dual 3 HP Pre-milling motors w/diamond cutter heads; pneumatic "JUMP In/Out function. Misting unit prior to Pre-milling; large dual dust housing ports to help clean the Pre-milling system. Quick change Glue Reservoir for EVA & PO glues; Pressure Section/Infrared Heat Lamp System. Heavy-Duty automatic shear type Guillotine with: "Auto-Set" automatic intervention for strip & coil materials. (4) Pneumatic polished Pressure Rollers with manual digital adjustment to edge thickness. (1) Rubber infeed Tape Roller, (1) metal infeed Tape Roller; direct Universal Drive system - NO Chains. Teflon-coated glue pot; digital thermostats with automatic kick down when the machine is in idle mode. Workstations: End Trimming Unit: Dual 0.5 kW (0.67 HP) high frequency End Trim motors on precision "Auto Lube" Linear Guideways; 90° to 10° pneumatic tilt cut adjustment. Electronic sensors to safely monitor motor positions; thumb screw pneumatic adjustments for simplicity. Tilting Super Finish Top & Bottom Trimming Station: Dual High Frequency 0.65 kW (0.75 HP) motors with Combi Finish insert tooling.Top Servo driven positioning of motors for different edge trimming profiles & positions. Corner Rounding Unit: Motors on precision billet aluminum swing tracer arms with pneumatic guidance and Face Copy System. (2) Independent motors can be adjusted to match tape thickness via digital scales. Profile Scraping Unit: Top, bottom & side Copy Wheels to properly follow your panels edge. Panel Nesting System: Triple Copy System for panels with blind dados & hinge cup holes. Digital adjustment for fine-tuning the unit to the proper tape thickness. Flat Scraping Unit: Large copy wheels. Buffing Unit: Top & bottom Buffing Unit; 0.5 HP (0.37 kW) - 2,800 RPM motors; units tilt 0° - 30°. Dual Hot Air Blowers: To re-embellish edge materials. Operator Interface 10" Color touchscreen PLC with swivel Control Panel. The PLC controls all working units & the adhesive thermostats with 1-touch icon programmable selections. Photo indicator alarms to easily troubleshoot errors/issues. Complete with: I

$ 175,000

VECTOR - REVOLUTION 180 CNC: Contour Edgebander + Vector Vision UpgradeNumerically controlled automatic Edgebanding Machine precisely applies ABS & PVC edgebanding automatically to square or irregularly shaped parts as the banding head travels on a bridge gantry along the X - Y & Z axis.Machine FeaturesBanding unit simultaneously rotates on a high precision C-Axis; AC Brushless Servo motors with: Digital drives and linear guides ensure high speeds & accuracy with a smooth acceleration-and-deceleration. -- NO PROGRAMMING required; extremely simple changing from one tape size to another; Operator only has to make simple adjustments like: Setting the start position, glue height, feeding the new width of tape, and adjusting tape guide height. All else is performed by the machine. -- Cartridge Glue System: Glue height is set by positioning a pin in a hole in the index ring setting for the glue dosing rod; standard positions are: 16 mm (5/8"); 19 mm (3/4"); 25 mm (1.0"); 28 mm (1-1/8"); and 31 mm (1-1/4") eliminating any need for fine adjustment. -- Working Field:X-Axis 139.7" (3,550 mm); Y axis 72" (1,830 mm); 0.63" - 1.57" (16 - 40 mm) min. - max. material thickness.0.79" (20 mm) Min. external radius & 1.97" (50 mm) min. internal radius, depending on the type of banding materials. 1 mm Minimum banding material thickness & 3 mm maximum banding material thickness. (NOTE: 1 mm PVC is not suitable for butt joints). -- WorktablePhenolic worktable with: Embedded vernier scales in X & Y axes allow simple & flexible positioning of 2-stage vacuum pods. Worktable allows single or pendulum processing with: (2) 48" x 72" (1,219 x 1,828 mm) Work Zones for processing small to large parts. With average cycle times under (2) minutes, the Contour Edgebander consistently produces quality parts, including 360° lap joints.Workpiece supported by means of: Vacuum cups sitting on a large flatbed; enables absolute flexibility in positioning pods to ensure the workpiece is held securely. Full vacuum achieved with: 100 cbm/Hr Vacuum Pump. Pump is mounted inside the frame of the machine reducing noise and avoiding airborne dust.Exact workpiece positioning is not critical as the patented VECTOR Revolution 180 Operating System is unaffected by panel position.Patented process is controlled by a simple & intuitive interface does not require CNC programming. -- Edge Banding UnitVECTOR Revolution 180 Uses: Cartridge & nozzle glue extrusion system, which is ideally suited to this Contour Banding application.Cartridge Glue Nozzle: Closed system, which only heats the glue as it is used. Glue is not exposed to the atmosphere. RESULT: No burning of the glue or discoloration, and the original color of the glue & its properties are maintained.Another benefit of the Glue Nozzle System: Close proximity to the 1st pressure roller. When slowing for corners, the glue remains molten until pressed onto the panel by the 1st pressure roller. This is important when banding tight radii as the g

Call for Price

VECTOR - REVOLUTION 180: CNC Contour Edgebander Numerically controlled automatic Edgebanding Machine precisely applies: ABS & PVC Edgebanding automatically to square or irregularly shaped parts as the banding head travels on a bridge gantry along: "X", "Y" & "Z" axes.Machine FeaturesBanding unit simultaneously rotates on a high precision "C" axis; AC Brushless Servo motors with: Digital drives & linear guides ensure high speeds & accuracy with a smooth acceleration & deceleration. -- NO PROGRAMMING Required: Extremely simple changing from one tape size to another; Operator makes simple adjustments: Setting the start position & glue height; feeding the new width of tape; adjusting the tape guide height. All else done by the machine. -- Cartridge Glue System. Glue height set by: Positioning a pin in a hole in the index ring setting for the glue dosing rod; standard positions are: 16 mm (5/8"), 19 mm (3/4"), 25 mm (1.0"), 28 mm (1-1/8"), 31 mm (1-1/4") eliminating any need for fine adjustment. -- Working Field"X" Axis 139.7" (3,550 mm); "Y" axis 72" (1,830 mm); 0.63" - 1.57" (16 - 40 mm) min. - max. material thickness.0.79" (20 mm) Min. external radius; 1.97" (50 mm) min. internal radius, depending on the type of banding materials. 1 mm Min. banding material thickness & 3 mm max. banding material thickness (NOTE: 1 mm PVC is not suitable for butt joints). -- WorktablePhenolic worktable with: Embedded vernier scales in "X & Y" axes allows for simple & flexible positioning of 2-stage vacuum pods. Worktable allows single or pendulum processing with: (2) 48" x 72" (1,219 x 1,828 mm) Work Zones for processing small to large parts.Average cycle times under (2) minutes; the Contour Edgebander consistently produces quality parts, including 360° lap joints.Workpiece: Supported by means of vacuum cups sitting on a large flat bed; enables absolute flexibility in positioning pods to ensure the workpiece is held securely. Full vacuum is achieved with a 100 cbm/Hr vacuum pump. The pump is mounted inside the frame of the machine reducing noise & avoiding airborne dust.Exact workpiece positioning is not critical, as the patented VECTOR Revolution 180 Operating System is unaffected by panel position.Patented process controlled by: Simple & intuitive interface that does not require CNC programming. -- Edgebanding UnitVECTOR "Revolution 180" uses: Cartridge & nozzle glue extrusion system, which is ideally suited to this Contour Banding application.Cartridge Glue Nozzle. Closed system, which only heats the glue as it is used. Glue is not exposed to the atmosphere: This means no burning of the glue or discoloration; original color of the glue & its properties are maintained.Benefit: Glue Nozzle System is in close proximity to the 1st pressure roller; meaning: Even when slowing for corners, glue remains molten until pressed onto the panel by the 1st pressure roller. This is important when banding tight radii, as glue does not have an opportunity to chill before bei

Call for Price

VECTOR - REVOLUTION 180: CNC Contour Edgebander + Vector Vision UpgradeNumerically controlled automatic Edgebanding Machine: Precisely applies ABS & PVC edgebanding automatically to square or irregularly shaped parts as the banding head travels on a bridge gantry along the "X", "Y" & "Z" axis.Machine FeaturesBanding Unit: Simultaneously rotates on a high precision "C" axis; AC Brushless Servo motors with: Digital drives & linear guides ensure high speeds & accuracy with a smooth acceleration-and-deceleration. -- NO PROGRAMMING required; extremely simple changing from one tape size to another; Operator only has to make simple adjustments such as setting: Start position the glue height; feed the new width of tape; adjust the tape guide height. All else is taken care of by the machine. -- Cartridge Glue System: Glue height is set by positioning a pin in a hole in the index ring setting for the glue dosing rod; standard positions are: 16 mm (5/8"); 19 mm (3/4"); 25 mm (1.0"); 28 mm (1-1/8"); 31 mm (1-1/4") eliminating any need for fine adjustment. -- Working Field"X" Axis 139.7" (3,550 mm); "Y" axis 72" (1,830 mm); 0.63" - 1.57" (16 - 40 mm) min. - max. material thickness.0.79" (20 mm) Min. external radius & 1.97" (50 mm) min. internal radius depending on the type of banding materials. 1 mm Min. banding material thickness; 3 mm max. banding material thickness. (NOTE: 1 mm PVC is not suitable for butt joints). -- WorktablePhenolic worktable with: Embedded vernier scales in "X & Y" axis; allow simple & flexible positioning of 2-stage vacuum pods. Worktable allows single or pendulum processing with: (2) 48" x 72" (1,219 x 1,828 mm) work zones for processing small to large parts. With average cycle times under (2) minutes, the Contour Edgebander consistently produces quality parts, including 360° lap joints.Workpiece is supported by: Means of vacuum cups sitting on a large flat bed; enables absolute flexibility in positioning pods to ensure the workpiece is held securely. Full vacuum is achieved with: 100 cbm/Hr vacuum pump. Pump is mounted inside the frame of the machine reducing noise & avoiding airborne dust.Exact workpiece positioning is not critical, as the patented VECTOR Revolution 180 Operating System is unaffected by panel position.Patented process is controlled by: Simple & intuitive interface that doesn't require CNC programming. -- Edge Banding UnitVECTOR Revolution 180 uses: Cartridge & nozzle glue extrusion system, which is ideally suited to this Contour Banding application.Cartridge Glue Nozzle is: Closed system, which only heats the glue as it is used. Glue is not exposed to the atmosphere, meaning there is no burning of the glue or discoloration & the original color of the glue & its properties are maintained.Another benefit of the Glue Nozzle System: Close proximity to the 1st pressure roller, meaning when slowing for corners, the glue remains molten until pressed onto the panel by the 1st pressure roller. This is important when

This listing Is for a complete line that consists of a Flow Coating line that feeds into a cross transfer oven and back out on to an outfeed conveyor making a 180 degree circuit. The heat exchanger needs to be heated by means of a hot water boiler or similar. Maximum Part width: 305 mmSpeed range: 2 - 10 m/min.Pos. 1 - FEEDING BELT CONVEYOR:For feeding the batches into the flowcoater, Belt with marked area to built a gap for the angle transfer, Technical Data: length: 2300 mmPos. 2 - IMPREGNATION MACHINE VEN FLOW:For flowcoating of profiles in continious production with a waterbased impregnation (viscosity similar to water)The material is is sprinkled on the surface and remains for appr. 10 seconds. After this time a high pressure air knife nozzles will blow the acess materialfrom the surface. The whole cabin is built with fall to the side to collect the rest of the material. It is reused after passing a filter system. The cabin is built of stainless steel. The blowing off of the access material by air knife is effected by a high pressure fan.The machine comprises:1 conveyor system with spray protected roller system length 3000 mm1 sprinkling zone with two nozzle systems adjusted to reach the whole surface of the workpiece. length: 200 mm1 penetration area length ca. 1000 mm time of residence ca. 10 sec1 blowing zone with adjustable knife nozzles air supply with high pressure fan air flow adjustable by frequency converter length ca. 1000 mmair speed ca. 40 m/sec. material supply to supply the two sprinklers with fluid and collector for recovered material.workpiece tolerances:twist: max. 1° on the whole length, straightness max. 0,5mm deviation/m in horizontal and vertical weight distribution: evenly on whole length coating material: waterbased impregnation. Unstable components can not be repositioned when tilted.Pos. 3 - MOULDING ANGLE TRANSFER VEN TRANS 90°conveying from lengthwise direction to crosswise, comprising:1 excenter-transfer arms integrated into the driven infeef roller conveyor. The tacted transfer system allows a minimum distance between the singlemouldings on the following cross transfer system.Technical Data:length of roller conveyor: 4500 mmroller pitch: 185 mmnumber of transfer arms: 22spacing 185 mmtacting cycle: max. 30/min.Pos. 4 - MOULDING CROSSWISE V-BELT CONVEYOR:Mouldings are conveyed by means of various v-belts along the system. The unit is fitted with an insulation cover between the conveyor. A drying tunnel is fitted on top of the unit.Technical data:length: 4000 mmoperating width: 4200 mmnumber of belts: 22distance of belts: 185 mmoutfeed prepared for an additional angletransfer:position of driving shaft in the middlegaps for passing of the carriers of the angle transferPos. 5 - JET DRYING TUNNEL 70 °C:Made of sandwich elements with fire preventing insulation material. The even distribution of air over the full operating width is reached by using slot nozzles on the full width of the tunnel. One combined heating-, fan

$ 100,550

Viet Opera 5-4.3 RRRR, (4) Head Wide Belt SanderCalibrating Sander (89 Hours)53″ wide cap. - Drum, Drum, Drum, DrumHead Configuration1st Head: 9″ Helical grooved steel drum powered by a 22 kW or 29.5 HP motor.2nd Head: VARIABLE SPEED (via VFD) 9″ helical grooved rubber drum powered by a 18.5 kW or 25 HP motor. 3rd Head: VARIABLE SPEED (via VFD) 11″ helical grooved rubber drum powered by a 15 kW or 20 HP motor. 4th Head: VARIABLE SPEED (via VFD) 11″ helical grooved rubber drum powered by a 15 kW or 20 HP motor.5th Station: Dust brush powered by a 1.27 kW or 1.7 HP motorSpecifications -- The durometer does get softer from head 2 to 3 and then from head 3 to 4. -- It has 53″ width capacity and a 200 mm or 7.87″ thickness capacity. -- Right above the machine's infeed, you will find inspection LED lighting, a digital thickness calibration unit, and a wireless Mitutoyo Digimatic Caliper that communicates with the Opera’s operating system. -- The vacuum bed is powered by an 11 kW or 15 HP blower under the sander to save space. -- The feed mat is powered by a 5.5 kW or 7.5 HP motor with variable speed via a VFD with feed speeds from 9.8 to 52.4 FPM.Equipped with & Features -- Inside you will find interior LED lighting while all the controls on this Opera are upfront via a touch screen -- Constant pass lineNOTE : This calibrating sander has a total of 1,982 power on hours and ONLY 89 run (conveyor) hours. This is a very loaded, LOW Viet Viet Opera 5 (4) Head 53″ Calibrating Sander

$ 25,470

VIET - S211 R+ KRT, 2-Head Wide Belt Sander43" Width. cap.: Drum and Combination head.Head Configuration:1st Head: 160 mm 6.3″ Helical grooved rubber drum. 25 HP motor2nd Head: 160 mm (6.3") Helical grooved rubber drum with a platen combination head., 25 HP motorSpecifications: -- Each heads are powered by a 25 HP motor. -- The heads can be programmed to pneumatically raise & lower along with the platen and do (3) sanding combinations (with the twist of a button). -- Digital height readout and a calibration unit to the left side of the conveyor. -- Conveyor speed is controlled via a variable frequency drive 2.5 HP . -- Max width: 43″. -- Max. height: 6-1/4". -- Variable speed conveyor belt drive from: 3 - 16 MPM (11 - 52 FPM).Equipped with & Features: -- Both heads are equipped with: 1,130 x 1900 mm (44-1/2" x 75"). -- Roller & pressure shoe holddowns. -- Pneumatic tension of sanding belts and feed conveyor. -- Load meter on main motor. -- Disc brake on main motor. -- Emergency stops front & back. -- Roller table extensions front & back.NOTE: This is an extremely low-hour 2012 BIESSE Viet S1 dual head 43″ calibrating Wide Belt Sander.

$ 88,000

Biesse Viet Opera 5 (3) Head 53″ Wide Belt Sander With (3) Segmented Platens53" Width cap, Head configuration1st Head:Variable speed (.2-16 m/s), segmented platen, 6″ wide cross belt with a chevron belt, powered by a 18.5 kw motor that also has air wands.2nd Head: Variable speed (3-13 m/s), segmented platen, 6″ helical grooved combination head, powered by a 22 kw motor that also has air wands. 3rd Head: Variable speed (2.8-12.5 m/s), segmented platen head, with a chevron belt, powered by a 15 kw motor with air wands.4th Station: Scotch-Brite head powered by a 1.1 KW motor after whichSpecifications -- 53″ wide calibrating sander has a total of 3,277 run (conveyor) hours. -- Constant pass line --3 mm-200 mm or 7.87″ thickness capacity. (To the right above the infeed of the machine is a digital thickness calibration unit ). Equipped With & Features -- The feed-mat is powered by a 4 kw motor with variable speed via a VFD -- Feed speeds from 4 to 18 m/min. -- The feed-mat also has air wands underneath. All the controls on this Opera are up front via a touch screen.

$ 68,885

BIESSE - Viet Opera5 RRRF: Wide Belt Sander (4-Head) w/53" width cap.Head Configuration1st Head: Drum Unit The Roller Working Unit is: Characterized for the precision & effectiveness of the work it does.Main motor: 22 kW (30 HP).Drum: 240 mm; Steel Linear blower cleaning sanding paper A.S.S. (Air Saving System).Infeed pressure shoe.The pressure beam is used to guarantee the maximum precision when calibrating; flattens the deformed or thin pieces.Chromed anti-wear metal removable tips.Outfeed pressure shoe.2nd Head: Drum UnitMain motor: 18.5 kW (25 HP).Drum: 300 mm; 70 Shore.Linear blower cleaning sanding paper: A.S.S. (Air Saving System).Infeed pressure shoe.Outfeed pressure shoe.3rd Head: Drum UnitMain motor: 15 kW (20 HP).Drum: 300 mm - 40 shore.4th Head: Superfinishing UnitSuper-finishing pad: The evolution of the pad unit (VIET patent, 1978). The pad unit has a "chevron belt" running between the pad itself and the abrasive belt that guarantees top-quality finishing and a longer performance to the abrasive.Main motor inverter: 15 kW (20 HP).Pneumatic “air cushion"; pad: Pneumatic pad is the ideal tool to solve finishing problems.Contact insert for pneumatic pad made of: Steel + felt + graphite.Linear blower cleaning sanding paper: A.S.S. (Air Saving System).Infeed pressure shoe.Specifications -- Working width: 1,350 mm (53.15"). -- Constant Pass (Fixed Table): Heads adjust up/down by program. -- Working Height: 200 mm (7.87").Equipped with and Features -- Laser Electronic Positioning for working thickness. -- Motors with amp meters. -- IPC Compact 15" Color Touchscreen Controller. -- Vacuum Table with: 7.5 HP Motor. -- Electronic System: IPC Control with feed speed up to 75 FPM. -- 50 Shore Rubber Conveyor. -- Vacuum bed for: Short parts. -- Front & Rear Extension Rollers (2 each).

Call for Price

BIESSE-VIET OPERA 5-3.3 Denibbing Sander with 53" Width Capacity:53" Width cap. Denibbing Sander with a patented combination of rollers and rotating/oscillating discs make the VIET Opera Sanding Machine the ideal finishing solution for entry doors, cabinet doors, drawer fronts, sheet goods, shutters, face frames, furniture, and much more. Ideal solution for all sanding applications including whitewood, stain, and sealer coats. Sanding Drums - Made of steel, mounted on eccentric Shaft, to adjust the sanding belt thickness - Drum rubber with helicoidally grooves, balanced and rectified - Dust collection hoods with special design for best performance - Pneumatic ON/OFF of unit from panel control - Sanding belt tension rollers made of steel, balanced and rectified - Front pressure rubberized roller (1 roller) - Back pressure rubberized roller (1 roller)Head Configuration: -- 1st Unit: (15) Rotating discs with Slide-out system for easy setup. 11 kW (15 HP) Electronic Inverter with inverter speed control. -- 2nd & 3rd Units: 300 mm dia. Teflon hub for 36 strips. Oscillating System with electronic 4 kW (5.5 HP) inverter speed controlled. Specifications: -- Working Width: 1,350 mm (53.15"). -- Constant Pass Line TM (Fixed Table). -- Working Height Opening: 200 mm (7.87"). -- Laser Electronic Positioning for working thickness. -- Min. processing thickness 3 mm, Max. processing thickness 200 mm. -- (2) Longitudinal rotating brush-backed sanding rollers. -- 5" Rotating sanding discs. -- Forward speed 3-16 m/Min. -- Vacuum Table with 7.5 kW (10 HP) Motor, Electronic System, IPC Control. -- 60-Shore Rubber Conveyor belt with ground laminair surface. Pneumatic belt tracking -- Front & Rear Extension tables with rollers. -- Emergency stop.Equipped with: -- IPC Touch-screen control: Simple & user-friendly "TOUCH SCREEN" IPC control with a color monitor. This control system supports the management of all machine parameters. -- PC processor provides control and feedback information to the machine in real-time. -- The software version can be configured for right and left-handed operation. -- Text-free user interface; icons facilitate the operator's task. -- Optional rotating blower attachment at the back to blow off dust particles as items come off the machine. Electric Cabinet: -- "Check panel" alarms with LED - Automatic Star/Delta starter for main motors - Pad-lockable main switch - Thermal relay protections on all motors - Amperometer for all main motors - Electronic digital readout with automatic thickness positioning - Motor protection IP 54Actual model is OPERA 5-3.3 XLL. Year on nameplate is 2020 but not connected until 2021. Weight is 4600 KG (10,200 Lbs).This machine works great and has been very lightly used in a small shop that found with the small volume of work this machine was Too High in capacity so better off hand sanding.

Call for Price

VIET (BIESSE) OPERA 5-3.3 XLL Denibbing Sander with 53" Width Capacity:53" Width cap. Denibbing Sander with a patented combination of rollers and rotating/oscillating discs make the VIET Opera Sanding Machine the ideal finishing solution for entry doors, cabinet doors, drawer fronts, sheet goods, shutters, face frames, furniture, and much more. Ideal solution for all sanding applications including whitewood, stain, and sealer coats. Head Configuration: -- 1st Unit: (11) Rotating discs with Slide out system for easy setup. 15 HP Electronic Inverter. -- 2nd & 3rd Units: 300 mm dia. Roller Brushes (Hub for 36 strips). Oscillating System with electronic 7.5 HP inverter. Specifications: -- Working Width: 1,350 mm (53.15"). -- Constant Pass Line TM (Fixed Table). -- Working Height Opening: 200 mm (7.87"). -- Laser Electronic Positioning for working thickness. -- Min. processing thickness 3 mm, Max. processing thickness 200 mm. -- (2) Longitudinal rotating brush-backed sanding rollers. -- 5" Rotating sanding discs. -- Forward speed 3-16 m/Min. -- Vacuum Table with 5.5 HP Motor, Electronic System, IPC Control. -- 50-Shore Rubber Conveyor. -- Front & Rear Extension Rollers. -- Emergency stop.Equipped with: -- IPC Touch-screen control: Simple & user-friendly "TOUCH SCREEN" IPC control with a color monitor. This control system supports the management of all machine parameters. -- PC processor provides control and feedback information to the machine in real time. -- The software version can be configured for right and left-handed operation. -- Text-free user interface; icons facilitate the operator's task. -- Optional rotating blower attachment at the back to blow off dust particles as items come off the machine. -- Includes matching transformer for 600 V to 460 V.

$ 5,950

VIRUTEX - EB 25: Hot Air EdgebanderFor preglued PVC, veneer and melamine laminate coil stock; 0.4 - 1.0 mm edge thickness; up to 65 mm panel thickness cap.; automatic coil & single edge strip feed.Equipped with: -- Thermostatically controlled hot air blower; 3,300 Watts for up to 500° C temperature; (2 - 3) Min heat up time. -- Guillotine type front & rear end trim (with fast speed, flying knife); top & bottom flush trims with single motor drive to cutterheads. -- Overhead belt type feeder; 15 FPM feed speed. -- Mounted on machine base with panel support table.Includes: Used tooling on the machine.

Call for Price

Vitap Quartz Edgebander Hot air Edgebander for pre-glued edging material 0.4-1.2 mm Will accept panels up to 35mm thick Electronically controlled temperature setting up to 650^F Guillotine style end trim & top/bottom flush trim 16 FPM feed 67" x 48" x 60" 220#

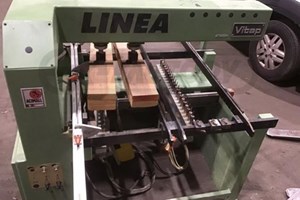

VITAP LINEA 42 Line Boring SystemSpecifications: -- (2) Drill heads of (21) spindles ea., drills from bottom up, ea. support with 2 HP motor and (21) spindle boring block w/panel support mounted on top; -- Drills panels from 100 - 3,000 mm in length, and 100 - 950 mm in width. Complete with: -- Digital readouts for boring blocks, 2,000 mm bar scale fence with (5) adjustable flip stops. -- (2) Moveable overhead pneumatic holddown cylinders, foot pedal for clamping & boring cycle.

VITAP ALFA - 27: Construction/Line Borer27-Spindle boring head on 32 mm centers; drills vertically from bottom-up and head rotates to horizontal position for edge boring; head rotation is pneumatic with switch control. -- 2-3/4" Max. drilling depth; 2-1/2 HP - 2,800 RPM motor; pneumatic drill head advance with speed control; head height adjustment with mechanical digital readout; 34" x 20" table size; max. workpiece width 31-1/2". -- Equipped with: Left- & right-side fences for construction boring; (2) pneumatic holddown clamps; 118" line boring fence w/flip stops; pneumatic foot pedal control; magnetic starter; overload protection.

$ 4,100

VITAP - 27-Spindle: Boring MachineSpecifications: 27-Spindle boring head: On 32 mm centers; drills vertically from bottom up, and head rotates to horizontal position for edge boring; head rotation is pneumatic with switch control. -- 2.5 HP - 2,800 RPM Motor; pneumatic drill head advance with speed control; head height adjustment with mechanical digital readout; 14" x 42" table size.Equipped with: (4) Pneumatic holddown clamps; 118" line boring fence with: (4) Flip stops; pneumatic foot pedal control.

$ 1,350

For pre-glued PVC, veneer, & melamine laminate coil stock; 0.4 - 1.2 mm edge thickness; up to 35 mm panel thickness cap., automatic coil feed. -- Equipped with: Electronically controlled temperature setting for hot air blower; 3,000 Watts for up to 650° F temperature; (1) Min heat up time. -- Guillotine type front & rear end trim (with fast speed, flying knife); top & bottom flush trims with single motor drive to cutterheads. -- Overhead belt type feeder; 16 FPM feed speed. -- Mounted on machine base with panel support table.

.gif)