Woodworking Equipment For Sale

2036 Results Found

$ 13,900

EMC PIONEER 2RK Wide Belt Sander, (2) Head: 37" Width capacity. Drum, Combination Head.Head Configuration: 1st Head: -- Rubber covered contact roll 180 mm diameter.2nd Head: -- Combination Head, rubber covered roller with padSpecifications: -- Useful working width: 950 mm (37"). -- Working thickness min/max: 3 - 170 mm. -- Abrasive belts length: 1,900 mm. -- Abrasive belt width: 975 mm. -- (2) Feed speeds: 5 - 10 m/min. -- Electronic digital display for working thickness. -- Abrasive belt oscillation by electronic photocell. -- Main drive motor 15 HP -- Feed drive 2 to 19 Meter/min.

$ 259,000

EMC ROTOPLUS 1350 – LUC (1)5 + BRILL 15 Polishing & Buffing LineHeavy Duty Automatic Polishing & Buffing line for high gloss lacquered panels, consisting of: -- Infeed Conveyor -- ROTOPLUS 1350 LUC 5+1 - Polishing and Wax Application machine -- Intermediate Conveyor -- ROTOPLUS 1350 BRILL 15x - Buffing Polishing machine -- Outfeed Conveyor -- Synchronization of feed speed of all equipment in the line, the Rotoplus machines including all conveyorsFollowing are the full specifications: -- Infeed Conveyor, 1.500 x 1.350 mm (59" x 53") Constant pass line 900 mm (35") +/- 40 mm (1-9/16"). Variable feed speed inverter controlled and electronically controlled for synchronized speed and transfer with all other machines of the line.Feed speeds from 0,4 to 8 m/Min (1,3 - 26 FPM). -- ROTOPLUS 1350 LUC 5+1Polishing and Wax application machine for high gloss lacquered wood panels for Polyurethane lacquer or brilliant straight, brushes adjustable at different angles. Equipped with (1) longitudinal Brush Head plus (5) rotating brushes on carousel.1st STATION - Longitudinal Polishing Brush:Cleaning polishing cotton brush diameter 275 mm (10-13/16").Length of the brush 1,420 mm (55-5/16").Brush inclined 3° in respect to the parallel 180°.Automatic low pressure Spraying Gun.Longitudinal chain rail system for gun movement.Electric adjustment of the working pressure, operated from main touch screen control unit.Main motor power 7,5 kW (10 HP).Rotating speed adjustable from 260 to 960 RPM by means of inverter 7,5 kW (10 HP). 2nd STATION - Polishing Carousel: CAROUSEL with (5) Brushes.Max. Brush diameter: 350 mm (13-3/4").Spindle diameter 80 mm (3-1/8").Spindle length: 400 mm (15-3/4").(5) Independent motors, 5,5 kW (7,5 HP) each, with counter bearing supports.The working angle of the brushes is adjustable.Variable speed adjustable from 3 to 36 RPM by means of electronic inverter, driven by 4 kW (5,5 HP) motor.Clockwise and anti-clockwise direction of rotation.Programmable speed control operated from main electronic touch screen display. (5) Special shafts for brushes support EXTRA in addition to the standard ones.(5) Cotton rags 350 mm (13-3/4") to fit the shafts.Automatic System for Abrasive Wax application:Pressurized tank (50) liters for liquid abrasives, with automatic miscellaneous bottom exit and pressure regulator for gun.Low pressure spraying gun for liquid abrasives.Electronic valve for spray gun control.Infrared high precision photocell to detect the panels and activate the spraying gun.Adjustable support for spraying gun positioning.Software and graphic control, programmable through PLC and touch screen. Software and Plug for Telemetry. Computer remote diagnostics control: Direct computer connection between EMC and customer, for online support. -- Intermediate Conveyor, 1.500 x 1.350 mm (59" x 53"), Constant pass line 900 mm (35") +/- 40 mm (1-9/16"). Variable feed speed inve

Call for Price

EMC FLEXY 1350 2RP Finishing Sander with (2) Sanding Heads, Roller and Segmented Finishing PadUseful working width 1,350 mm (53"). Working thickness min./max. 3 - 180 mm (1/8" - 7-1/16"). Head configuration:1st Head: Roller "R" Belt dimensions: 2,620 x 1,370 mm (103" x 54"). -- Roller diameter: 250 mm (10"). -- Roller rubber hardness 85 Shore. Constant control to any position with accuracy 0.02 mm. -- Electronic motorized roller pressure adjustment "grit-set system". -- Rotation: Against feed (clockwise). -- Motor power: 22 kW (15 HP). Automatic star-delta starter. -- Abrasive belt cutting speed: 18 m/Sec (59 FPS). Oscillating abrasive belt blower for the roller unit.2nd Head: Segmented Finishing Pad "P" Electronic PAD segmented in (50) sections. -- Belt dimensions: 2.620 x 1.370 mm (103" x 54"). -- Width of the segmented element (section): 27.0 mm (1-1/16"). -- Rotation: Against feed (clockwise). -- Timed oscillating abrasive belt blower. -- Motor power: 11 kW (15 HP) with electronic inverter variable abrasive belt speed 3 to 18 m/Sec (9.8 - 59 FPS).Feed system:Constant pass line, 900 mm (35.4") from floor Vacuum conveyor bed, 4 kW Vacuum unit for holddown of smaller parts, mounted inside of the machine base. Idle table rollers support in infeed and outfeed. Rubber covered presser rollers, grooved. Variable feed belt speed, adjustable from 3 to 18 m/Min (9.8 - 59 FPM) Inverter Controlled. Large diameter screws on machined guides with columns and pistons. Automatic feed belt centering device.General Machine Features: -- Independent main motors. -- Analog ammeters, for each motor, on main control cabinet. -- Electronic motorized "grit set" system; control from touch screen for each working group (head).Electronic programmable color TOUCH SCREEN display, 10" wide PLC with micro-processor of latest generation, modular and expandable Connection USB, RS232, Ethernet 10/100/1000 Memory capacity: 100 working programs or more Graphic synoptic to facilitate programmingSoftware facilities: -- Automatic motor sequence starting. -- Display report and reset of alarms (self diagnostic) with memory records. -- Command, programming and display for: all electronic pad functions thickness feeding all inverters and for selected groups (heads). blowers, including compressed air saving function.Centralized Control Cabinet: IP 54 protection against dust & moisture. Analog ammeter on main control cabinet. Table lifting-lowering thickness system electrically controlled. AUTOMATIC Delta - Star starter on abrasive belt motors. Centralized Independent Pneumatic Control Cabinet: IP 54 protection. Pneumatic air filter with automatic water-drain system. Pneumatic adjustment for "Grit set system". Pneumatic plant working without lubrication. Compressed air pressure 6 bar (85 PSI) Options Available: Tampico Brush natural fiber brush for cleaning of

$ 44,500

EMC EXPLORER 1100 2RK ... Wide Belt Sander with (2) Sanding Heads; Roller and Combination head roller/pad.Versatile, medium duty machine, ideal for cabinet shops etc.TECHNICAL DATA: -- Useful working width 1,100 mm (43"). -- Working thickness min./max. mm 3 - 170 (1/8" - 6-11/16"). -- Abrasive belt dimension (length) 1,900 mm (75") x (width) 1,120 mm (44"). -- Feed belt speeds adjustable by electronic inverter from 3 to 17 m/Min (10 - 55 FPM). Head configuration:1st Head: Steel Contact Roller -- Roller diameter 142 mm (6") -- Automatic abrasive belt grit compensation with "Grit-Set System". -- On/Off Selector control with pneumatic piston to select roller. -- Motor power 11 kW (15 HP). -- Automatic Star-delta starter. -- Speed rotation: 18 m/Sec (59 FPS).2nd Head: Combination Roller & Pad. -- Roller diameter 142 mm (6"). -- Rubber covered roller with hardness 45 Shore. -- Automatic abrasive belt grit compensation with "Grit-Set System". -- On/Off Selector control with pneumatic piston to select roller. Flexible sanding pad. Quick Change System for removable pad with felt, rubber and graphite. Rotating cutting speed 17 m/Sec (55.8 FPS). --Driven by same main motor.Abrasive belts oscillation by means of electronic photocell sensor.Feed System: -- Working thickness min./max. mm 3 - 190 (1/8" - 7-1/2"). -- Motorized table lifting including fine adjustment, on 4 precision screws. Natural rubber conveyor belt, machined. Automatic feed belt centering device. Electronic digital display for working thickness; resolution 0.1 mm (0.004"). -- Feed belt speeds adjustable by electronic inverter from 3 to 17 m/Min (10 - 55 FPM). Centralized Control Cabinet: -- Control panel with self-diagnostics alarm control unit. -- Analog load meters on main control cabinet. -- Table lifting-lowering thickness system, electrically controlled. -- AUTOMATIC Delta - Star starter on main motor and IP 54 protection against dust & moisture. Centralized Independent Pneumatic Control Cabinet: -- Pneumatic air filter with automatic water-drain system. -- Pneumatic adjustment for "Grit set system". --Pneumatic plant working without lubrication. Compressed air pressure 6 bar (85 PSI). IP 54 protection against dust & moisture. Safety Features: -- Anti-kickback infeed protection. -- Oversized parts infeed protection by swinging bar. -- Emergency push buttons front & rear. --Automatic brakes on main motor. -- Automatic emergency stop and alarm displayOption: TAMPICO Cleaning Brush, 150 mm (6") diameter. Please add ...$3,400USA UL or Canada CSA Safety Features

Call for Price

EMG SEMI-AUTOMATIC Twin Stair Trencher; 2" x 12" Max. stringer size, semi-automatic operation. The feed/indexing of boards is automated and the routers are moved manually for the stair cuts.Specifications: -- (2) 3 HP Belted motors to "top & bottom" 18,000 RPM spindles, 1-1/2" depth of plunge cut, T & B heads are arranged to advance in-and-out to facilitate open plain stairs. -- Pneumatic advance and twin table clamps each rated at over 2,000 Lbs.Features: -- Any rise and run, whether straight or tapered, can be achieved in just a few minutes of setup. Includes: -- Overload protection with on-control resets, individually timed motor startup with adjustable 2nd delay.NOTE: Available with CNC fully automatic operation. the top automated section is a bolt-on to the base of the semi-auto frame. Please ask for a Quote.

Call for Price

3" Min. & 16" max. wedge length, taper from 1/2" to 2" thickness, mixed in hopper, angle & width of wedge is fully adjustable with one face at 90°. -- Equipped with: 10" Dia. saw blade with 2 HP direct drive motor, hopper feeds material up to 16" long with a width up to 8"; air operated with 6 CFM compressed air requirement, 1.8 Sec/stroke, 4-3/4" dust outlet. -- Features: Walk away, "hands free" operation. Auto-shutoff feature and capability to cut glue blocks. -- Complete with: Self-diagnostics, built-in starter, automatic shutoff feature, air filter & lubricator.

$ 1,250

Used for the accurate radius measuring of cutterheads; allows for speedy tool changes on moulder. 12" Long x 6-1/2" base, 1-1/2" dia. arbor will handle up to 9-1/4" long tool body. -- Digital caliper rides up and down on precision machined octagonal bar. -- Options: T-bushings for 1-13/16" dia. & 40mm dia., please specify.

Call for Price

37" width capacity Single head 60" belt length Digital thickness controller Electronic belt tracking vVariable speed drive

$ 17,999

EXTREMA EXCESS XS-1E37 SINGLE HEAD WIDE BELT SANDER37" Width capacity, 0" to 6" conveyor bed opening. Mono-block construction for solid, vibration free operation and increased durability. -- Equipped with: Combination sanding head with rubber covered contact roll & graphite covered platen. -- Over thickness material feeding safety device. -- Digital material thickness controller setting with LED readout accurate to a thousandths of an inch. -- "Automatic Thickness Setting" device for easy setup. -- OMRON Electronic abrasive belt tracking. -- GOODYEAR Endless conveyor belt with automatic belt tracking. -- 20 HP Main motor. -- REGAL Variable feed speed drive unit; 2 HP motor. -- 1/2 HP Power elevation motor. -- Large cabinet style doors for easy service access. -- Pneumatic abrasive belt tensioning. -- Double infeed & outfeed covered holddown rollers. -- Infeed conveyor extension with safety stop bar, emergency stop button and motor load meter. -- Operations manual & free box of 3M Sanding Belts. -- Optional 460 Volt / 3 Phase.

Call for Price

EXTREMA XP-124TV Single Head PlanerSpecifications: -- Solid cast iron construction. -- 15 HP Main drive motor, 1 HP feed motor 20 to 70 FPM, 1/2 HP elevation motor. -- Precision ground cast iron table w/motorized programmable adjustment. -- Scale & pointer readout for accurate thickness adjustments. -- "VECTOR" insert cutterhead with (4) sided inserts. -- Fixed feed speed setting for consistent stock removal. -- Sectional steel infeed roller & segmented chipbreaker. -- Independently adjustable feed rollers. -- (2) Externally adjustable bed rollers.Features: -- Hinged top for easy access to cutterhead & gear assembly. -- Self-braking motor. -- Magnetic starter & thermal overload switch. -- Emergency stop. -- Operations manual, parts list & tool kit. -- Options: Single-phase power, please add ...$ 100, 460 volt add...$ 150.

$ 14,999

EXTREMA XP-610 SINGLE SIDED PLANER24" Width capacity, 8-3/4" thickness, solid cast iron construction. -- 10 HP main drive motor -- Precision ground cast iron table w/motorized height adjustment, with digital thickness display; 1/2 HP elevation motor. -- Scale & pointer readout for accurate thickness adjustments. -- "VECTOR" cutterhead with (6) rows of 4-sided inserts. -- Variable feed speed from 20 to 42 FPM; 1 HP feed drive. -- Sectional steel infeed roller & segmented chipbreaker. -- Independently adjustable feed rollers. -- (2) Externally adjustable bed rollers. -- Hinged top for easy access to cutterhead & gear assembly. -- Self-braking motor with magnetic starter & thermal overload switch. -- Emergency stop. -- Operations manual, parts list & tool kit.

Call for Price

EXTREMA XP-615AZ Single Sided Head PlanerSpecifications: -- Width: 24" -- Main HP: 15 HP -- Feed HP: 1 HP -- Elevation HP: 0.5 HP -- Max. Thickness: 8.75" -- Min. Thickness: 0.375" -- Max. Cut: 0.25" -- Min. Length: 10.5" -- Cutterhead Speed: 6000 RPM -- Feed Speed: 20-42 ft/min -- Air Requirements: 1000 CFM -- Thickness Adjustment: PLC ControllerBed Roller Adjustment: External -- Powered Bed Rollers: Top and Bottom -- lnfeed Roller: Standard -- Amps (230V / 460V): 41A/20A -- Weight: 2345 LbsFeatures: -- Solid cast-iron construction -- Sectional infeed rollers -- Huge 8-3/4"thickness capacity -- 6000 RPM cutterheads -- Anti-kickback fingers -- Segmented chip breakers -- Sectional feed rollers -- XP-615 Digital Controller -- Motorized table elevation -- Available with straight, STEALTH, or ilECTDFi cutterheads -- Heavy duty screwjack elevation system -- Easy access internal workings -- External bed roller adjustmentsOptional: -- In-feed Roller

Call for Price

Manufacturers Specification - ? [Specifications](https://extremausa.com/product/magnum-xp-series-25-double-sided-planer/#tab-test_tab) Horsepower: 40 / 30 HPVoltage: 230V / 460VPhase(s): 3 PHWidth: 25"Top Motor: 40 HPBottom Motor: 30 HPElevation Motor: 2 HPFeed Motor: 5 HPMax Thickness: 8"Min Thickness: 3/8"Min Stock Length: 16"Cutterhead RPM: 6000Top Cutter Access: Super SlideBottom Cutter Access: Super SlideDisc Brakes: YesFeed System: CarpetDrive System: ShaftFeed Speed: 20-110 ft/minCFM Requirements: 3000AMPS (220V/440V): 188 / 94Weight: 9300 lbs

Call for Price

$ 9,950

EXTREMA XP-126A PLANER WITH HELICAL HEAD26" x 11-3/4" Cap., 5/16" max. material removal, 10-1/2" min. part length; 20 HP WESTINGHOUSE / TIKO belt driven motor, STEALTH helical carbide insert cutterhead - 6,000 RPM, variable speed feed 20 - 75 FPM. -- Equipped with: Powered raise-and-lower of 27" x 35-1/2" table, digital thickness controller, sectional chipbreakers, sectional infeed roller & dual outfeed rollers, and (2) adjustable bed rollers.

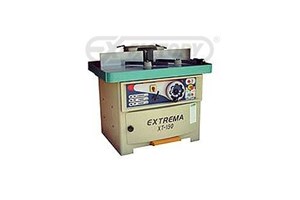

$ 2,539

EXTREMA ET-100 Fixed Spindle Shaper; "Extremely" well-built and with solid features. -- Single phase with 3 HP or 3-phase with 5 HP motor. -- Interchangeable spindles of 1-1/4" and 3/4". -- (2) Spindle speeds of 7,500 & 10,000 RPM. -- Heavy cast iron table with a 6" max. table ring. -- Spindle lock, micro-adjustable back fence and reversing switch. -- Miter gauge, 1/2" router collet adapter and cutterhead guard.

$ 3,025

EXTREMA ET-120 Spindle Shaper;"Extremely" Well-built and with solid features. -- 5 HP Single-phase motor. -- Interchangeable spindles of 1-1/4" & 3/4" and (1) router collet adapter. -- Dual drive belts and (2) spindle speeds of 7,500 & 10,000 RPM. -- Heavy cast iron table with a 6" max. table ring. -- Spindle lock, micro-adjustable back fence and reversing switch. -- Complete with: Miter gauge, 1/2" router collet adapter and cutterhead guard.

$ 2,528

EXTREMA ET-120.3 Shaper w/Fixed Spindle; "Extremely" Well-built and with solid features. -- 5 HP motor. -- Interchangeable spindles of 1-1/4" & 3/4" and (1) router collet adapter. -- Dual belts and (2) spindle speeds of 7,500 & 10,000 RPM. -- Heavy cast iron table with a 6" max. table ring. -- Spindle lock, micro-adjustable back fence and reversing switch. -- Miter gauge, 1/2" router collet adapter and cutterhead guard.

$ 6,600

"Extremely" Well-built and with solid features. -- Solid spindle of 1-1/4" with 5-13/16" under nut. -- Dual belts and (3) spindle speeds of 5,500 - 7,500 & 10,000 RPM. -- Heavy cast iron table with a 12-3/8" max. table ring. -- Spindle lock, micro-adjustable back fence and reversing switch. -- Large 7.5 HP motor. -- Miter gauge, cutterhead guard assembly, operators manual, and tool kit.

$ 7,200

EXTREMA ET-160 Fixed Spindle Shaper;"Extremely" Well-built and with solid features.Specifications: -- Solid spindle of 1-1/4" with 5-13/16" under the nut. -- Large 10 HP motor. -- (3) Spindle speeds of 5,500 - 7,500 & 10,000 RPM. -- Heavy cast iron table with a 12-3/8" max. table ring. -- Spindle lock, micro-adjustable back fence, and reversing switch. -- Miter gauge, cutterhead guard assembly, operator's manual, and tool kit.

.gif)