Woodworking Equipment For Sale

1689 Results Found

Call for Price

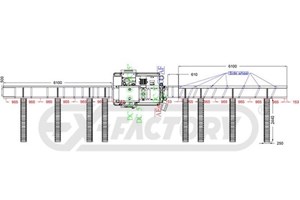

CAM-WOOD INFEED AND OUTFEED PLANER TRANSFER LINE: 20"; Wide X 20’ Long Roller Conveyors and Consisting of the following: IDLE INFEED RIGHT ANGLE ROLLER TRANSFER CONVEYORS -- (4) Conveyor Sections, each 8"; Wide X 5’ Long (SEE DRAWING). -- 2-11/64"; Roller Diameter -- Rolls on 3"; Centers to Handle 2"; x 4"; and Wider -- Supports up to 3,500 Lbs.POWERED INFEED CANTED ROLLER CONVEYOR -- With VFD Drive -- 20"; Wide X 20’ Long (Longer with Owner Provided Outboard Roller) -- Heavy Duty 3-11/32"; Roll Diameter -- Rolls on 36"; Centers -- Back Side Adjustable Fence -- Includes (4) Sections of Pneumatically Jumped Skate Rolls --Heavy Duty Type, Sections are 6"; Wide X 20"; LongPOWERED OUTFEED STRAIGHT ROLLER CONVEYOR -- With VFD Drive -- 20"; Wide X 20’ Long (Longer with Owner Provided Outboard Roller) -- Heavy Duty 3-11/32"; Roll Diameter -- Rolls on 36"; Centers -- Includes (4) Sections of Pneumatically Jumped Skate Rolls -- Heavy Duty Type, Sections are 6"; Wide X 20"; LongIDLE OUTFEED RIGHT ANGLE TRANSFER ROLLER CONVEYORS (SEE DRAWING) -- (4) Conveyor Sections, each 20"; Wide X 5’ Long. -- 2-11/64"; Roller Diameter. -- Rolls on 3"; Centers to Handle 2"; x 4"; and Wider -- Supports up to 3,500 Lbs. -- Each Section with Pneumatic Pop-Up Stops

$ 67,990

CAM-WOOD SM-324D 4-Sided Planer for L-Shape MouldingSpecial Design for “L"; Shape Mouldings; One set of Cutter heads IncludedSpecifications: -- Maximum Working Width 12";, Max. Thickness 4"; -- Hard chrome-plated table for maximum wear resistance. -- Anti-impact plate for over-width and over-thickness protection. -- Oversized top and bottom rollers run synchronized, ensuring smooth feeding. -- FRP plastic steel safety guard provides maximum durability and impact resistance. -- The three independent sections; pneumatic pressures for the infeed rollers, in-process rollers, and outfeed rollers can be set with individual pressure allowing for consistent feeding and outstanding results. -- The smooth initial feeding of the stock is achieved by the independently powered infeed rollers. -- Specifically designed template inserted pressure plate suits various stock thicknesses and profile variations. -- A special pressure plate based on the table feeding roller design provides smooth and precise cutting of dry and wet wood, reducing the possibility of material jams.Features: -- The base is machined by CNC machine equipment to ensure the utmost working accuracy. -- The first bottom horizontal spindle can be fitted with a trimming cutter for trimming a groove on the workpiece side to achieve perfect straightness. -- The specially designed short stock feeding mechanism combined with auxiliary pressure wheels permits the machine to perform machining on extra short stocks. -- All spindles are precision constructed and specially heat treated to provide maximum cutting stability and permanent accuracy. -- Each spindle is equipped with a mechanical digital readout giving accurate adjustment. -- Every cutter spindle can be adjusted "up and down" and "in and out" for quick setup. -- Industrial full-power motors for maximum cutting capacity.Capacity and Heads: -- Max. Working Width 12"; -- Max. Working Thickness 4-3/4" -- Min. Working Length 9½" -- Vertical stroke of side head 30 mm (1.18") -- 1st Spindle Horsepower 10 HP -- 2nd, 3rd, 4th Spindle Horsepower 10, 10, 10 HP -- Feed Motor 7½ HP -- Elevation motor 1 HP -- Spindle arbor Diameter 40 mm -- Cutter Speeds (RPM) 6,500 -- Variable Feed Speeds (FPM) 16 ~ 82Cutterhead Diameter -- 1st Bottom Head 6"; Dia x 12"; L -- 2nd & 3rd Vertical Head 6"; Dia x 3"; L -- Top Head 6"; Dia x 12"; L -- Pneumatic Air 90 PSI (CFM) 5 -- Dust Outlets Diameter 5" x 4 outlets -- N.W. (Lbs) 9800Option: -- Sound enclosure Add ...$10,900

$ 33,900

CAM-WOOD RD-5412-SC Tenoner with Dowel DrillTenoning/Coping machine for straight or miter material. Great machine for miter door production or stile and rail stock. Equipped with: -- 6" High stackable spindle by pneumatic up & down with (3) different stops; easily and accurately setup for each cutter position. -- Drill heads for dowel hole at each end. -- One shaper head at each side of the table. -- Table moves from right to left by variable speed Pneumatic-Hydraulic power to achieve the fully cutting power. -- Twin table moves in and out separated for tongue and groove, end match application. -- Twin heavy-duty pneumatic pistons hold down the workpieces tightly to the table during the cutting process.Features: -- Rigid construction on the heavy sheet metal frame, cast iron table & base for durability usage. -- Heavy-duty industrial motor is suitable for heavy duty cutting under full load. -- Linear guide rails and bearings let the operator moving the table smoothly. -- Cast iron fence locks in the table groove to finish 45° cut easily. -- Automatic cycle function, just place the material against the stops, the machine will automatically clamp, move in for shaping/tenoning, come out and release the hold down.

$ 24,500

CAM-WOOD 0400-SCX 40" AUTOMATIC COPY SHAPER Specifications: -- 3" to 40" shaping capacity; 15" x 35" rectangular capacity; table diameter is 27"; -- 1.5 to 6 RPM table speed; cutterhead speed is 9,000 RPM powered with a 7-1/2 HP motor; 1" dia. x 5-1/2" long spindle accepts up to 6" dia. cutterheads. -- 2" dia. follower wheel and 2 HP feed motor -- All controls are located on the control panel for easier touch up to operation. -- Equipped with PC program control for easy maintenance and durability usage. -- Easy set up at any position, variable speed table makes it possible for the machine to be operated at any cutting speed. -- The variable feed rate can be adjusted to give optimum output according to stock thickness and component shape. -- Unique design of table runs clockwise and counter-clockwise to help eliminate tearout while cutting with or against the direction of grain. -- Advanced timer control of overlap table rotation to eliminate cutter joint mark. -- Cutter head feed is controlled by pneumatic-hydraulic system to smoothly apply even pressure for fast and smooth cutterhead feed. -- Heavy duty motor for maximum cutting capacity. -- Precision sealed long life, high speed bearing for durability usage. -- Heavy sheet metal frame and cast iron table. -- Cutter head feed designed to automatically slow down when approaching to the work piece, assures no bumping to eliminate cutter marks left at the starting point for an exceptionally smooth finish. -- Those models are designed for medium size shaping & profiling. Easy & convenient to operate. -- SETUP KIT, INCLUDES CUTTER & TEMPLATE, ADD $1,098

$ 5,190

CAM-WOOD SP-35G Fixed Spindle ShaperA Shaper with plenty of cast iron... a solid piece of machinery!Features & Specifications: -- .Precision ground cast iron table and T-slot miter gauge slot. -- Perfect alignment, rigid spindle supported by a power transfer system for accuracy. -- Individual micro adjustment fence on both sides of the spindle by hand wheels. -- Large hand wheel for fast movement and lock protection. -- Magnetic switch for overload protection. -- Spindle travel is operated by a rack and scroll gear. -- Two spindle speeds for versatile cutting. -- Forward and reverse switch for cutting directions. -- Heavy gauge metal cabinet base. -- Alloy steel spindle for durability usage. -- Sealed long-life ball bearings. -- Standard equipment: Full power motor, dust chute, table insert, spring hold-downs, miter gauge. -- Table Dimensions: 30" x 40". -- 1-1/4" Standard Spindle Dia. --Spindle Speed: 4,000 - 10,000 RPM. -- 5 HP Motor. -- 4" Dust Hood.

$ 2,490

CAM-WOOD SP-30 Fixed Spindle ShaperA Shaper with plenty of cast iron... a solid piece of machinery!Features & Specifications: -- 5 HP Motor with reversing switch. -- Interchangeable spindle as standard with a 1" & 3/4" spindles. -- Spindle with 4" under nut. -- (2) Spindle speeds of 8,000 & 10,000 RPM. -- Large 30" x 28" cast iron precision ground table. -- 7" Max. table ring. -- Easily locked spindle for cutter change. -- Micro-adjustable back fence with material spring holddowns. -- Includes Miter gauge, cutterhead guard assembly, and operators manual.NOTE: Available in 3-Phase and 1-Phase electric.SP-305C 2-PCS ROUTER BIT COLLECTOR SET $ 89.00.

$ 8,180

CAM-WOOD SP-750x Heavy Duty Shaper. 7.5 HPSpecifications: -- Table size: 48 x 36.5'' -- Height of Working Table: 35-1.2". -- Spindle 1'',1.25''. -- Motor: 7.5 HP (10 HP Opt.). -- Speed (RPM): 3,000/4,500/7,500/10,000. -- Dimensions: 53' 'x 43'' x 51''. Weight: 1480 LbsFeatures: --Designed for heavy industrial work. -- Industrial powerful motor for maximum cutting capacity. -- Quick-change spindles. -- Forward / reverse switch. -- Individual two-sided micro adjustable fence. -- Precision ground large cast iron table. -- Three spindle speeds for versatile cutting. -- Sealed long-life ball bearing. -- Metal 4"; dust hood. Heavy sheet metal cabinet base for durability usage. -- Magnetic control for overload protection.

CAM-WOOD T4-1000S 4-Spindle Auto Copy Lathe/Shaper w/Sanding of Asymmetrical parts .via a template. Shaping with (4) cupped cutters and sanding with individual belts.Specifications: -- Capacity: (4) Spindle duplicating/carving/copy heads with (4) copy belt sanders for asymmetrical parts. Working length 6-3/8"- 39.5" -- Working dia. 1-1/8" - 8-1/4". Cutter diameter approx. 1.4" -- Speeds: Spindle Speed : Variable 2000 - 6000 RPM. Cutting Circle 2 - 12 times/min. -- Features: (4) Spindles with pre-loading centering station and pneumatic clamping. -- Drives: Hydraulic carriage motor 3 HP; Cutter drive motor 7.5 KW (10 HP). Sanding heads motor 2 x 1 HP. -- Electrical controls: 220 V Relay style. -- Overall Dimensions: 120" long x 47" deep x 110" high -- Approx. net weight: 6,240 Lbs. -- NOTE: Larger diameters are possible by using every second carriage position, ie. (2) heads instead of four heads.

Call for Price

This is a two year old system. The seller changed their machinery footprint and no longer needed. This system is meant to package material to bring to another line, not for shipping. Designed to nest/stack/pack up to 36” in height This system consists of the following components (1) Cameron Automation Scoop lifter system for material up to 6” in width Dual length measurement sensors Cameron Automation Computer (1) Cameron Automation Plywood Kicker (1) Cameron Automation Plywood Belt Driven Roller Conveyor Produces bundles up to 15” wide x 36” high Includes the big bundle nester option General specifications: Flooring lengths from 8” to 8’6” Flooring widths from 1½” to 6” Flooring thickness from 3/8” to 1” Pack width: up to 46” Production capabilities: 55 lineal feed per minute Capable of (36) 7’ bundles per hour 5,000 sq. ft. per shift Semi-automatic infeed approximately 31’ long Singulator Operating voltage: 440v, 3PH

Call for Price

Cameron Automation Flooring Nesting Line Buffer Table for making 2'-10' flooring into nested bundles. Makes a new bundle every 30 seconds. Feeds from right to left

$ 13,300

CANTEK SS-512TSB Tilting Spindle and Sliding Table Shaper:7.5 HP - 3-Phase motor, overall table dimensions 31.50" x 39.40", sliding table 10.25" x 39.40". -- Spindle stroke 7"; 1-1/4" dia. spindle with 5 MT receiver and 4-3/4" cap. under the nut. Spindle tilts -5° & +45°. -- (5) Spindle speeds: 3,000, 4,000, 6,000, 8,000 & 10,000 RPM.Complete with: Spindle reversing switch, micro-adjustable fence 6" x 43", thermal overload protection and dust hood.16 weeks delivery.

$ 10,500

CANTEK SS512CSB Heavy Duty Production Shaper with Sliding Table & Spindle Brake7.5 HP Features: -- Cast iron sliding table runs on ball bearing for smooth table transition. -- Cast iron ground & polished table with insert rings; table size: 31- ½"; x 39.4″. -- Precision ground and electronically balanced spindle. -- V-belt drive with (5) feed speeds is easily accessed from the front of the machine. -- Electric spindle brake for added safety. -- Spindle lock - with limit switch safety, machine will not start with lock engage. -- Micro spindle height adjustment with dial indicator. -- Interchangeable cutter spindle. -- Forward/reverse spindle rotation. -- Adjustable "finger" type fence Independent micro-fence adjustment on both sides. -- Includes the following standard equipment: 1- 1/4" Spindle, (1) 5"; dust chute on guard & (1) 4"; dust chute in the table, safety guard, Miter tenon jig, and Telemecanique magnetic controls.Net weight 1034 Lbs. Machine dimensions 48.4"; x 39.4"; x 52 ¾";. Shipping weight 1166 Lbs.Shipping dimensions 45 ¼"; x 37"; x 41";

$ 11,200

CANTEK - SS512TB Tilting Spindle ShaperSpecifications: --Tilting spindle from -5° to +45° and 6" x 43" fence. --1-1/4" interchangeable spindle is standard (other sizes available). -- Large cast-iron table is ground and polished for maximum stability and durability. -- Powerful 7.5 HP motor for even the most demanding profiling work. -- Five spindle speeds can be easily adjusted to suit your tool diameter. -- 5-1/2" Useable spindle length, above table 13-¼"; below table 8-¼". -- Electronic spindle brake for added safety and facilitates fast changeover. -- Precision fence assembly with micro-infeed and outfeed fence adjustment. -- The finger-style fence allows the fence to be adjusted around the cutter for added safety and workpiece stability. -- Table size 31 ½"; x 39.4″. -- Dust port (1) 5″ on guard, (1) 4" into the table.

CANTEK C-12RSH Overcutting Straight Line Rip Saw;Ruggedly constructed with cast iron & ground tables, cast iron pressure housing with (8) holddown rollers and solid welded steel base chassis.Specifications: -- 3.35" Max. thickness cap; 8" min. length; variable feed speeds from 50 to 120 FPM and powered by a 1 HP feed motor. -- 1" Dia. saw arbor powered by 15 HP arbor motor; swings 8" thru 12" dia. blade at 4,500 RPM; with 18" distance from blade to saw column. -- Arbor runs in precision angular contact type ball bearings (eliminates any radial run-out & axial thrust) - V Belt driven from below. -- 31-7/8" From floor to top of table; table is 39" wide x 57" long. -- Rigid machine body consists of a thick welded steel frame with an integral table which is fitted with a sturdy cast column. Feed & Chain: -- 1-Piece cast iron chain with a diamond cut surface for positive material feeding and absolute straight line feeding. -- Precision caterpillar chain and double "VEE" guide rails are made of special cast iron. -- Equipped with high-frequency hardened chain Guide Rails. -- The chain connecting pins are made of high grade steel - heat treated & ground for high durability and low wear. -- (8) Hold-down rolls for increased control and precise straight line cutting (6 rows).Features: -- Easy to access adjustments and controls. -- Mechanical operation Chain Oiler (Best) provides consistent lubrication to the chain track and automatically adjusts to your feed speed. -- Equipped with: (3) Sets of anti-kickback fingers; (2) top and (1) set in the table. -- (1) 5" dia. dust outlet. -- Soft start, Star Delta starter - Telemechanique-Square D, Magnetic Wye/Delta Starters - Low Amperage Soft-Starter on the arbor motor - Electrics to UL/CSA Standards.Available Options when order with machine: --20mW Laser (FPIMLC1320W) & Laser Holder (FPICAN03) – made in N.A.... $ 495.00 -- KANEFUSA 12" Glue Joint Carbide Rip Saw Blade...$ 165.00

$ 16,100

CANTEK - C14RS, ...Straight Line Rip SawSpecifications: --Overcutting Rip Saw. -- 4.92" Max. thickness cap; 8" min. length. -- Variable feed speeds from 49 to 128 FPM and powered by a 2 HP feed motor. -- 1-1/2" Dia. saw arbor powered by 15 HP arbor motor. -- 31-7/8" From floor to top of table; table is 50" wide x 75" long. Equipped with & Features: -- (3) Rows of antikickback fingers: (2) Top & (1) Bottom, for safe operation. -- (8) Holddown rolls for increased control and precise straight line cutting (6 rows). -- 6" (150 mm) Wide chain track runs on double-V guide rails, which are made of special cast iron for added wear. -- Magnetic Controls.

CANTEK - C 12 RSH, ...Straight Line Rip SawRuggedly constructed with cast iron & ground tables; cast iron pressure housing with (6) guide rollers, and solid welded steel base chassis.Specifications: -- Saw blade dia. 8" - 12"; saw arbor dia. 1"; saw arbor speed 4,400 RPM. -- 15 HP Saw arbor motor, 2 HP feed motor, 45 - 120 FPM variable speed range. -- Min. workpiece length 8", max. cutting thickness 3-3/8", distance from column to center of chain 18". -- Table size is 39" x 57"; table height 31-1/2". Features: -- The cast iron upper-pressure housing provides a stable mounting for the precision ground & Nickle chrome steel saw arbor and can be easily adjusted by hand wheel for thickness changes. -- 1-Piece cast iron chain with a diamond cut surface for positive material feeding.Approx. (600) Hours production time.Total amperage is 21.5 amp and the gross weight is approx. 2,530 Lbs.

CANTEK - C 12 RSH, ...Straight Line Rip SawRuggedly constructed with cast iron & ground tables; cast iron pressure housing with (6) guide rollers, and solid welded steel base chassis.Specifications: -- Saw blade dia. 8" - 12"; saw arbor dia. 1"; saw arbor speed 4,400 RPM. -- 15 HP Saw arbor motor, 2 HP feed motor, 45 - 120 FPM variable speed range. -- Min. workpiece length 8", max. cutting thickness 3-3/8", distance from column to center of chain 18". -- Table size is 39" x 57"; table height 31-1/2".Equipped with & Features -- The cast iron upper pressure housing provides a stable mounting for the precision ground & Nickle chrome steel saw arbor and can be easily adjusted by hand wheel for thickness changes. --:1-Piece cast iron chain with a diamond cut surface for positive material feeding.Total amperage is 21.5 and the gross weight approx. 2,530 Lbs.

CANTEK - C 12 RSH, ...Straight Line Rip Saw:Ruggedly constructed with cast iron & ground tables, cast iron pressure housing with (6) guide rollers, and solid welded steel base chassis.Specifications: -- Saw blade dia. 8" - 12", -- Saw arbor dia. 1", saw arbor speed 4,400 RPM. -- 16 HP Saw arbor motor, 2 HP feed motor, 45 - 120 FPM variable speed range. -- Min. workpiece length 8", max. cutting thickness 3-3/8", -- Distance from column to center of chain 18". -- Table size is 39" x 57", table height 31-1/2".Equipped with & Features -- The cast iron upper pressure housing provides a stable mounting for the precision ground & nickel chrome steel saw arbor and can be easily adjusted by hand wheel for thickness changes. -- 1-Piece cast iron chain with a diamond-cut surface for positive material feeding.

CANTEK C10RSStraight Line Rip SawSpecifications -- 12" Over cutting Rip Saw ruggedly constructed with cast iron & ground tables, -- Cast iron pressure housing with (6) guide rollers and solid welded steel base chassis -- Saw blade dia. 8" - 12", -- Saw arbor dia. 1", -- Feedspeeds of 50, 65 and 85 FPM - 4,500 RPM, --10 HPsaw arbor motor; 1 HP feed motor, --Min. workpiece length 8", max. cutting thickness 3-3/8", --13 3/4" distance between saw and column, -- 30" X 50" table size, 31-1/2" table height.Equipped with & Features: -- Cast iron upper pressure housing provides a stable mounting for the precision ground & nickle chrome steel saw arbor and can be easily adjusted by hand wheel for thickness changes. -- (1)-piece cast iron chain with a diamond cut surface for positive material feeding.Included: Manual , and several blades and the toolkit.

$ 29,190

CANTEK C-14RS Straight Line Rip Saw; Absolute straight line feeding Rip Saw. Rigid machine body consists of a thick welded steel frame with an integral table which is fitted with a sturdy cast column. Excellent precision work accuracy and durability.Specifications: -- 4.92" Max. thickness cap; 8" min. length; variable feed speeds from 50 to 120 FPM and powered by a 1 HP feed motor. -- 1" Dia. saw arbor powered by 20 HP arbor motor; swings 12" thru 16" dia. blade at 4,500 RPM; with 24" distance from blade to saw column. -- 31-7/8" From floor to top of table; table is 50" wide x 75" long.Feed System & Chain: -- Precision caterpillar chain and double "VEE" guide rails are made of special cast iron. The chain connecting pins are made of high grade steel - heat treated & ground for high durability and low wear. -- (8) Hold-down rolls for increased control and precise straight line cutting (6 rows). -- Mechanical operation Chain Oiler (Best) provides consistent lubrication to the chain track and automatically adjusts to your feed speed. When oil runs out the machine track stops running to avoid damage to track. Features: -- Precision Built Saw Arbor constructed of nickel chrome steel, large diameter, accurately ground and dynamically balanced. The arbor runs in precision angular contact type ball bearings (eliminates any radial run-out & axial thrust) - V-Belt driven from below, with easy to access adjustments and controls. -- (3) Sets of anti-kickback fingers; (2) top and (1) set in the table. -- Soft start - Star Delta starter. Telemecanique U/L magnetic starters.Options available at additional cost: -- 20mW Red Laser (FPIMLC1320WFL) & Laser Holder (FPICAN03)..................................... $ 495.00 -- Extra Saw Blade: 14";x0.157"; kerf x 1.5"; bore x 60T (CANC14RS-BLADE-14)........... $ 118.00

.gif)