Woodworking Equipment For Sale

1726 Results Found

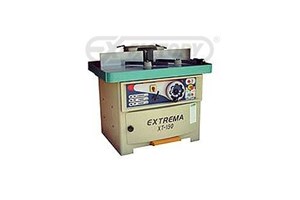

$ 2,528

EXTREMA ET-120.3 Shaper w/Fixed Spindle; "Extremely" Well-built and with solid features. -- 5 HP motor. -- Interchangeable spindles of 1-1/4" & 3/4" and (1) router collet adapter. -- Dual belts and (2) spindle speeds of 7,500 & 10,000 RPM. -- Heavy cast iron table with a 6" max. table ring. -- Spindle lock, micro-adjustable back fence and reversing switch. -- Miter gauge, 1/2" router collet adapter and cutterhead guard.

$ 6,600

"Extremely" Well-built and with solid features. -- Solid spindle of 1-1/4" with 5-13/16" under nut. -- Dual belts and (3) spindle speeds of 5,500 - 7,500 & 10,000 RPM. -- Heavy cast iron table with a 12-3/8" max. table ring. -- Spindle lock, micro-adjustable back fence and reversing switch. -- Large 7.5 HP motor. -- Miter gauge, cutterhead guard assembly, operators manual, and tool kit.

$ 7,200

EXTREMA ET-160 Fixed Spindle Shaper;"Extremely" Well-built and with solid features.Specifications: -- Solid spindle of 1-1/4" with 5-13/16" under the nut. -- Large 10 HP motor. -- (3) Spindle speeds of 5,500 - 7,500 & 10,000 RPM. -- Heavy cast iron table with a 12-3/8" max. table ring. -- Spindle lock, micro-adjustable back fence, and reversing switch. -- Miter gauge, cutterhead guard assembly, operator's manual, and tool kit.

$ 17,999

EXTREMA EXCESS XS-1E37 SINGLE HEAD WIDE BELT SANDER37" Width capacity, 0" to 6" conveyor bed opening. Mono-block construction for solid, vibration free operation and increased durability. -- Equipped with: Combination sanding head with rubber covered contact roll & graphite covered platen. -- Over thickness material feeding safety device. -- Digital material thickness controller setting with LED readout accurate to a thousandths of an inch. -- "Automatic Thickness Setting" device for easy setup. -- OMRON Electronic abrasive belt tracking. -- GOODYEAR Endless conveyor belt with automatic belt tracking. -- 20 HP Main motor. -- REGAL Variable feed speed drive unit; 2 HP motor. -- 1/2 HP Power elevation motor. -- Large cabinet style doors for easy service access. -- Pneumatic abrasive belt tensioning. -- Double infeed & outfeed covered holddown rollers. -- Infeed conveyor extension with safety stop bar, emergency stop button and motor load meter. -- Operations manual & free box of 3M Sanding Belts. -- Optional 460 Volt / 3 Phase.

$ 22,999

EXTREMA XS-1E43 Single Head Wide Belt Sander42" Working width, up to 5" max. opening with electronic digital microprocessor thickness control.Equipped with: -- Rubber-covered contact drum and 2-1/2" wide finishing platen, 25 HP main motor; -- 43" x 60" Abrasive belt, TRU-TRAK solid-state electronic belt sensing with pneumatic tracking. -- GOODYEAR Endless conveyor belt with pneumatic tracking, 2 HP variable speed feed motor from 15 - 48 FPM. -- 0.5 HP Motor to raise & lower table via (4) jack screws, an over-thickness bar at the infeed of machine, and AUTO-SET thickness device. Complete with & Features: -- Double infeed & outfeed rubber covered holddown rolls. -- Air operated disc brakes on main motor, front & rear emergency stop buttons, and motor load meter. -- SQUARE D Electrical controls; magnetic Starter with overload protection, and electrical interlock at sanding belt access doors.NOTE: Also available wired for ...460V operation.

$ 3,399

EXTREMA ESO-108.1 Oscillating Edge Sander with End Sanding Kit. -- 6" Wide x 108" long belt, with 1/4" oscillation travel -- 6" x 40" Graphite covered platen. -- 1-1/2 HP Single-Phase motor w/magnetic switch. -- 7" Diameter drive pulley, and 3" Idler pulley. -- 8" x 37" Front table with 5-3/4" vertical adjustment. -- Adjustable 12" x 19" End table for radius work with a 5-3/4" vertical adjustment. -- Heavy laminated tables, fabricated steel base and dust hood with 4" dust collection port. -- CFM Requirements: 400. -- Weight: 425 Lbs.

$ 17,895

EZ SANDER EZ-3760 Wide Belt SanderEZ-Sander's are built to with the ability to hold very tight tolerance (+/-.003) side to side when set up properly.Specifications: -- The sanding head is a combination head that consists of a 5" rubber-covered contact drum for the more aggressive sanding and then followed by an adjustable 2-1/2" graphite-covered felt polishing platen for doing very fine finishing sanding using a 37" X 60" abrasive belt. -- The conveyor belt speed is set to run at 10 - 30 FPM and is controlled via AC variable speed unit mounted in the main control panel. Simply adjust the dial setting to your desired feed speed. -- Double infeed and outfeed hold-down rolls are provided to help ensure proper part feeding through the Sander. -- The conveyor table/bed opening has a 0" to 5" opening allowing the operator to sand some parts as thick as 5" and the ability to sand very thin parts as well. -- Power raising and lowering of the conveyor bed is standard. -- Digital thickness display is standard.Complete with & Features: -- EZ Sander is equipped with a state-of-the-art electronic tracking system for the abrasive belt. -- Emergency stop heavy-duty caliper disc brakes bring the sanding head to a stop within 4 to 5 Sec when activated by the machine's safety interlock system. -- Limit Switches on both sides of the abrasive belt to keep the belt from over-travel. NOTE: -- Available in single phase with a 7.5 HP or 10 HP 3-Phase main drive motor. -- Voltage change to 440 Volt ...$275.

Call for Price

Fanuc Robot with Controller Box and Teach Pendant Model: S-420iF Type: A05B-1313-B501 Part #: R98Y03430 Date: 1998.11

Call for Price

Call for Price

FELDER FORMAT 4 - C-EXPRESS 920 CNC MACHINING CENTER (FEED THRU W/ROUTING): -- Specifications: Automatic CNC Feed Through Point to Point Boring Machine that combines flexibility and high productivity.A perfectly suited solution for small to midsize companies & artisans in need of an automatic solution for precision drilling with a low cost investment.Parts can be discharged at the opposite end of the machine for automated material handling or returned to the Operator for manual unloading. -- Working Field:Max. panel size on X-Axis 118" (3,000 mm); Y-axis is 36.2" (920 mm); Z-axis is 2" (50 mm).Min. panel on size X-axis is 11" (280 mm); Y-axis is 7.1" (180 mm); Z-axis is 0.4" (10 mm).Max. Panel weight 66 Lbs (30 kG). -- Positioning Speed: Panel feeding speed of 229 FPM (70 MPM), Y-axis at 229 FPM (70 MPM), Z-axis at 65 FPM (20 MPM).Axes positioning by AC drives & brushless Servo motors; the Panel moves in X-axis & the boring head moves in Y- & Z-axes. -- Work Area:NC Controlled "Optical Laser Sensor" creates a zero-panel reference point by reading the panel's ends; this ensures that RH & LH (mirror image) panels will always be symmetrical.High precision clamping automatically positions the workpiece. Automatic presser moves independently and adjusts to workpiece thickness. Pneumatic side pusher makes locating workpiece accurate and efficient. LH Side pressure clamp with automatic adjustment & pneumatic locking according to the panel width.Scratch resistant rollerball table makes for ease of loading parts into the machine. -- Boring Unit:3 HP (2.2 kW) Motor, variable speed from 4,500 - 8,000 RPM.(9) Independent vertical spindles on 32 mm centers: (5) Spindles in X-axis & (4) spindles in Y-axis.(6) Horizontal spindles with: (2 + 2) in X-Axis & (1 + 1) in Y-axis.(1) X-Axis grooving saw for max. 120 mm dia. blade, variable speed from 5,500 - 10,000 RPM. -- Machining:5 HP (3.7 kW) Motor, variable speed from 1,000 - 18,000 RPM with ER 32 adaptor & manual tool change system. -- Operator & Machine Control: PC-Based user-friendly icon driven Control housed on the main machine base + "WOODFLASH" Operating System. 19' LCD Displays programming graphics, functions, machine data. -- Complete with: User & Maintenance Manuals; handheld pendant. -- Options Include: ● Special side clamping device for min. panel size in Y-axis of 2-3/4" (70 mm). ● Additional retractable infeed support table with roller balls. -- Actual model is: FELDER FORMAT 4 - C-EXPRESS 920 CLASSIC

Call for Price

Call for Price

Call for Price

Call for Price

Call for Price

Call for Price

Call for Price

Felder Format 4 Edgebander Model: Tempora 6012 Return conveyor is no longer available.

$ 6,940

Large table size, extendable in all three directions by up to 39" (1,000 mm) without the requirement of tools. Comfortable one-handed lever operationHeavy-duty eccentric clamp, usable on the left and right-hand side.Specifications: -- 3 HP motor, tilting head, manual hand lever control for mortise length and depth; 13" x 22" table with eccentric clamp -- 3000 RPM, reversible motor that caters for left and right cutting bits and a solid quad-jaw chuck with clamping range from 0–20 mm -- Lateral range of motion is 250 mm, cut depth is 160 mm, available height adjustment is 130 mm and there are solid locking stops in all three directions for setting precise stops.Features: 2-Jaw chuck with 5/8" capacity, Dust control collection tray below the cutter out to an 80 mm outlet,Complete with (2) adjustable and removable extension wings; fence for 90° & 45° mortises, extended stop bar on each side of table.

$ 9,750

FELDER G-330 EDGEBANDER0.4 - 3 mm Edge thickness cap. and 40 mm panel thickness; 3" min. width and 4-3/4" min. panel length.Equipped with: -- Quick Melt Teflon coated glue pot for granular hot-melt adhesive. -- Heavy Duty guillotine for up to 3 mm thick PVC. -- Integrated Operator PLC controls and an LCD display. -- "Anti-slip" rubberized surface chain pads.Workstations: -- Single motor, Double Blade End Trim with HF motor - 12,000 RPM. -- Top & Bottom Flush/Bevel Trim, bevels 0° - 15° (0.5 HP motor - 12,000 RPM each). -- Open space at out feed . -- Single feed speed of 26 FPM.Complete with: -- Sound & Safety enclosure over trim stations and outrigger panel support, and used tooling.NOTE: Seller states that the equipment has less than 500 hours of use!

.gif)