Woodworking Equipment For Sale

1726 Results Found

$ 14,500

Sanding wheel shaper for the production of profiles on the sanding wheels. -- Template carrier holds metal or plexiglass template (same as can be used on the moulder knives). -- Spindle length 5" with 1" diameter arbor for wheel support. Handles 8" diameter wheels (3) included with the machine. -- X and Y axis on dovetail slide with lineal bearing support for smooth movement during the wheel grinding. Pneumatic clamping on grinding wheels. Depth of grinding 1.5" for raised panel. -- Tilt capabilities from 0 to + 30°. -- Grinds all types of varda wheels on 1 HP motor with speed of 1,750 RPM. --You can customize this machine to you needs.

G & P - EPN, ... Pump Sander (Double-Sided), -- Double-end direct-drive pneumatic Drum Sander. -- 2 HP Motor - 3,600 RPM motor speed. -- (2) 1-1/4" Dia. x 10" long shafts.

Call for Price

Gabbiani Double End Tenoner Available approx August 1, 2023 Can also be paired with a direct transfer to a [Homag DET](https://www.carolinamachinerysales.com/listings/4073344-used-2006-homag-fl20-double-end-tenoner) at the same site.

$ 125,000

GABBIANI GT 2 115 38/38 REAR LOAD AUTOMATIC PANEL SAW: -- Specifications:Working capacity 149.6" (3,800 mm) Rip & Cross-cut pull-back. Main saw blade projection is 4.5" (115 mm).30 HP (22.4 kW) Inverter driven, variable RPM main motor & 3 HP (2.2 kW) scoring motor. Automatic exclusion of scoring unit. Pneumatic quick-change system for blades -- Saw carriage: Feed speed from 3 - 492 FPM (1 - 150 MPM), return speed of 492 FPM (150 MPM.Automatic cutting stack height & length limiter adjusts according to the program dimensions. Automatic saw carriage lubrication. -- Pusher Fence: 0 - 230 FPM (0 - 70 MPM) Forward positioning speed, 230 FPM (70 MPM) return speed.Rack & pinion movement on both sides to assure the pusher remains parallel. (8) Total Material gripper clamps, with (4) of the grippers in the cross-cut section independent & programmable according to the cutting pattern.All gripper clamps open to 4.5" (115 mm); -- Operator Interface:PC Front-end controller with SCM "MaestroCUT" + Windows operating system.21" LCD "Touch Screen" monitor display with real-time graphics + function control keypad. Virtually unlimited program storage via USB ports; RS-232 serial port, keyboard, mouse.Maestro software features machine functions, programming, run time, diagnostics, production reports, imports, language and unit of measurement, optimization cut software (Maestro Pattern)Maestro Cut 3D editor: Label printing software, 3D simulator, graphic editor, panels editor, cutting editor for figured panels, semi-automatic macro.Easy Import: This software imports from an Excel file all data related to part of a cutting list previously selected by the user to Maestro Pattern, Diagnostic for errors or machine malfunction by means of an error signal code, incremental or absolute programming in mm or inches. All enclosed in an air-conditioned control cabinet. -- Rear Lift Table:4-Post screw type powered rear load lift table 149.6" x 63" (3,800 x 1,600 mm); max stack height 23.62" (600 mm) without a pit or risers; -- Complete with: Automatic Side alignment device. Min. part width 2.36", Max. part width 149". Automatic saw blade height adjustment. "Quick-change" blade system. (4) Air support tables 78" x 24" (1,981 x 609 mm), with (1) common blower. -- Options Include:Zebra label printer. Powered Rear In-Feed conveyor with fork cutouts. -- Actual Model is GABBIANI GT2 115 38/38

GANNOMAT COMBI 110 CONSTRUCTION LINE BORER(23) Spindle head, 2 HP - 2,800 motor, 31-1/2" max. working width, 3" drilling stroke, drills vertically from bottom and horizontally from rear, tilts pneumatically from lower to rear position with positive stop at 45° for angle drilling. -- Holddown clamp assembly tilts 90° for clamping short panels vertically for edge boring, no need to swivel boring head, hydraulic brake for through boring. -- Complete with: (4) Pneumatic holddowns, mirror imaging fences, 4,000 mm line boring fence w/stops and 1,500 mm butt joint fence with (2) flip stops.

Call for Price

25 Spindles 10 Dowel inserters 2 Dowel hoppers Glue tank Water tank Left and right adjustable fences 4 Pneumatic clamps foot pedal controlControl Panel

Call for Price

Gannomat Pro-Line 50 • Row of holes as well as line drilling in the SYSTEM 32 mm • 50 (2 x 25) holes in one drilling cycle

Sutorbilt Legend 5M -- Standard, medium-pressure -- Diameter (inlet/outlet): 4" NPT -- Shaft size: 1.125" -- 2,350 Max RPM

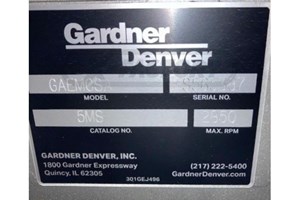

GARDNER-DENVER 2BV5121 15 HP Liquid ring pump:11.4 kW (15 HP), Volume flow 360 CFM; operates at a low noise level of 74 dBA.Specifications: -- The "2BV5121" series are compact plug-and-play systems for easy on-site installation; pumps are air-cooled, 100% oil-free, and do not require additional water during operation. -- Due to contact-free compression, they are virtually wear-free in operation and require no periodic maintenance. -- The patented discharge-air cooling system ensures that the pumps will not heat up by more than 15K above room temperature; pumps work reliably in continuous operation and are steam resistant & insensitive to condensation of the pumped air. -- Vacuum power units of the "2BV5121" split type are standardized liquid ring pump circulation systems with patented exhaust air cooling for large volume flows. -- A considerable amount of the water contained in the cool exhaust air condenses, remains in the system, and is available as operating water; as a result, many applications no longer require additional operating water.(2) Available, buy both for less than $9,000.

Laminating Rolls: 61" (155 cm) roll face with thermally conductive high release silicone surface; upper and lower main rolls internally heated; temperature controlled by state-of-the-art infrared sensors and digital PID controllers Laminating Opening: 1.5" (3.8 cm) maximum opening controlled with dual air cylinders. Laminating Material Uses heat activated and pressure-sensitive materials 0 - 55" (0 - 140 cm) wide on a 3" (7.6 cm) ID core Laminating Speeds 0 to 14.5 fmp (0 to 4.5 mpm) Post Lamination: Fanless cooling system provides uniform, filtered air for thermal shock without exposure to dangerous fan blades. Vinyl Transfer Complete roll to roll transfer, lamination, and edge trimming in one pass Safety Features • Two emitter-receiver photoelectric systems protect rolls from damage. • Emergency kick cables front and rear. • All electrical and moving mechanical parts are located in bolted cabinets • Four emergency stop buttons Installation Requirement 220 to 240 VAC, 50/60 Hz, 55A. 32 A per phase. Air: 2 cfm at 100 psi, minimum(0.5 m3 at 700 vPa)

$ 1,000

GENERAL - 350 10", ...Tilting Arbor Table Saw with: 5 HP Motor & Rip FenceSpecifications: -- Table size: 20" LR x 28" FB x 34-1/2" H. -- Arbor dia. 5/8"; tilt 0° - 45° to right; blade speed: 4,000 RPM. -- Max. depth of cut: 3-1/8" at 90°; 2-1/8" at 45°; max. width of dado cut 13/16". -- Max. rip cap.: 52" Right.Equipped with: -- 8" Left & right table extensions. -- 5 HP Motor.Complete with: -- DELTA "Unifence Saw Guide"; 43" L x 3-1/2" H Rip Fence System. -- Blade Guard. -- Miter Gage.

Call for Price

Call for Price

GIBEN KG-468-JKS EDGEBANDER (W/PRE-MILL & CORNER ROUNDING): -- Specifications:Working Capacity: 0.4 - 3 mm Edge thickness capacity; minimum panel width 80 mm; minimal panel length 120 mm; panel thickness 10 - 60 mm adjustable feed speeds 10/15/20 MPM; motorized adjustment of the upper pressure beam. -- Equipped with: PREMELTING Glue System with: Quick change glue pot; top pot capacity 5 kG (11 Lbs); lower pot capacity 2 kG. -- Adjustable pressure roll section with: (1) Driven roller and (3) idler rollers.Workstations: -- 2-Motor Pre-milling Unit with independent adjustments. -- 2-Motor End Trimming Unit. -- Top & Bottom rough trim station. -- Top & Bottom radius fine trim station. -- 2-Motor Corner Rounding Unit. -- Top & Bottom profile scraping station. -- Top & Bottom flat scraping station. -- Top & Bottom Buffing station.Complete with & Features: -- "DELTA" PLC Control. -- Sound cabin for all workstations. -- Adjustable 700 mm outboard panel support. -- Actual Model is: GIBEN KG-468-JKS

Call for Price

Giben K305 Edgebander Manufacturer specs (to be confirmed): Standard Configuration Panel Thickness: 10~60mm Edge Thickness: 0.4~3mm Motor Power: 2.35Kw Maximum Curve Radius: 20mm Cutter Maximum Range: 50mm Working Pressure: 0.6 MPa Outline Dimension: 960 x 950 x 1000mm Gross Weight: 280Kg Voltage: 220-480V

$ 16,750

GIBEN KS26J Edgebander with Pre-Milling & Corner RoundingSpecifications: -- Edge thickness 0.4 - 3 mm. -- Minimum panel width 80 mm, Panel thickness 8 - 50 mm. -- Feed speed 16 MPM, Mechanical adjustment of the upper pressure beam.Equipped with: -- 2 Liter Glue Teflon coated tank with Quick heating system. -- Adjustable pressure roll section with (1) Driven roller & (3) Idler rollers.Workstations: -- 2-Motor Pre-milling unit with Diamond tooling and with Independent adjustments. -- 2-Motor End trimming unit. -- Top & bottom trim station with diamond radius tooling . -- Double motor Corner Rounding unit. -- Top & bottom radius scraping station. -- Top and bottom Buffing unit.Complete with: -- PC Touch screen control. -- Sound cabin for all workstations. -- Adjustable outboard panel support.

$ 66,000

GIBEN KG486JK EDGEBANDER (W/ PRE-MILL & CORNER ROUNDING): -- Specifications:Working Capacity 0.4 - 3 mm Edge thickness capacity. Minimum panel width 80 mm. Panel thickness 10 - 60 mm. Variable feed speeds 12 -20 MPM. Electronic adjustment of the upper pressure beam. -- Equipped with: PRE-MELTING GLUE SYSTEM With quick change glue pot (top pot capacity 5 kG / 11 Lbs), lower pot capacity 2 kG. -- Adjustable pressure roll section with (1) driven roller, and (3) idler rollers.Workstations: -- 2-Motor Pre-Milling Unit with independent adjustments. Diamond cutters included. -- 2-Motor End Trimming Unit. -- Top & bottom rough trim station. -- Top & bottom radius fine trim station. -- (4) Motor Corner Rounding Unit. -- Top and bottom edge scraping station -- (2) Top and bottom radius scraping stations, (1) for 1 mm & (1) for 3 mm. -- (2) Top & bottom Buffing stations for a super clean finish.Complete with & Features: -- "DELTA" Front-end "Touch Screen" Control. -- Cleaning/Release Agent sprayers at the front & back end of the machine. -- Sound cabin for all workstations. -- Adjustable outboard panel support. -- Actual Model is GIBEN KG486JK

Call for Price

ModelG4 49G4 510G4 512Table size2700 x 1300mm3100 x 1600mm3700 x 1600mmMax speed x/y/z80/80/30 m/min80/80/30 m/min80/80/30 m/minMain spindle18hp Max rotation speed24000rpm24000rpm24000rpm Vertical drills5 x 55 x 55 x 5 Rotation speed4500rpm4500rpm4500rpm Tool changer 8 position ride along Suction flow rate160m3/h160m3/h160m3/hDust extractionF200mm × 2 150mm x 2F200mm × 2 150mm x 2F200mm × 2 150mm x 2Overall size4500 x 10000 x 2500mm4500 x 12000 x 2500mm5000 x 13500 x 2600mmNet weight7100kg7500kg8000kg - The G4 Full line is a 3 axis cnc router designed for production needs in mind. - Standard 18hp main spindle with rotation of up to 24000rpms. - Drill block sizes: standard 5 x 5 and an optional 10 x 7. - Auto loading and off-loading helps create high efficiency and max parts output. Using a pusher bar with dust extraction and offload table with two additional ports to help maintain a clean shop and parts. - Standard features that separate the G4: auto-lubrication, meehanite cast ron table, fixed tool touch off device, and blast gate for dust extraction. - A ride along carousel type, tool changer with 8 tool capacity, mounted next to the spindle for fast and efficient tool change operations. - Optional 12 tool changer. - Optional auto label printing gantry or label printing mounted by the off-load table.

$ 3,950

Gomad "DFDA-455" Sliding Table Single Spindle Shaper -- Specifications: 2 -1/64" (55 mm) spindle currently, 7.5 HP belt drive motor, (4) speeds 4,000/6,000/8,000 & 10,000 RPM, 3-9/16" spindle travel, 3/4" up to 2-11/64" dia. interchangeable spindle, reversing spindle rotation; heavy duty 36" x 40" cast iron table, (3) pneumatic clamps, double end fence, 4.5" dia. dust chute. -- Complete with: 13" wide sliding table, (4) Hold down springs, mounting collars & bolts, miter gauge with stop rod, and foot brake, capable of doing arch moulding work.NOTE: Great running condition before disconnect in 2013, currently stored in facility basement.

Call for Price

GOODSPEED HF 412 AO Vertical Oscillating Chair Back Sander Specifications: Table size 30” x 30” x 34-1/4” H. Equipped with: 12" W x 25" L Horizontal abrasive belt, with 12” H x 4” Dia. Aluminum & Spiral rubber drums, 12” H x 3-1/2” Dia. Spiral rubber feed drum, with 2 HP Motor & Variable feed speed control. 60 W Feed & Oscillation motors.

.gif)