Woodworking Equipment For Sale

1988 Results Found

QUICK R-RCGS-2-63 Top & Bottom Glue Spreader63" wide Top and Bottom glue spreader with 0.04" - 1.75" thickness Capacity. Specifications: -- 2-Sided Roller Coater. -- Working thickness: adjustable from 0 to 45 mm (0 to 1.77"), adjustable via single hand wheel. -- Maximum material width: 1,600 mm (63"). -- (2) Application rollers, 210 mm (8.27") in diameter. -- Application roll material: SBR rubber, 60 durometer. -- Application roll grooving: 20 grooves per inch. -- Doctor roll quantity: (2). -- Doctor roll material: NBR rubber, 98 durometers. -- Doctor roll diameter: 175 mm (6.9"). -- Doctor roll grooving: none (smooth rolls). -- Drive motor power: 1.5 kW (2 HP). -- Feed rate fixed at 64 FPM. -- Voltage is 220 V, 3-phase.Includes: -- Emergency stop bars at front and back of machine. -- Stainless steel waste glue drip pan. Complete with: -- Safety stop bars and roll guard hood; all-aluminum drip pan catches clean-up water.

QUCIK F-CGAP-32-11-17 Conveyorized Glue Applicator;Can cover up to 32" of material.Specifications: -- 11' Long infeed conveyor and 17' long outfeed conveyor allows for easy handling of long materials. -- Grooved rubber roller offers durability and easy maintenance. -- Stainless steel doctor blade and glue pan remove easily for cleaning. -- The all steel frame includes (3) twin leg sections that features independent foot levelers. -- Commerical 1/4 HP motor includes a slip-clutch driving the glue applicator. -- Unit is finished with a long lasting urethane. Contact your EX-FACTORY representative about the optional holddown roller should you plan to glue handrails, laminated beams, face-glue or warped and twisted boards.

24" Wide Top and Bottom Glues spreader with 0.04" - 1.75" thickness capacity. -- Features: (2) Grooved rubber covered 8" glue rollers (20 TPI) are acid and heat resistant, (2) 5.8" chrome covered doctor rolls. -- Converts quickly to Top only glue application when needed. -- Comes standard with a fixed 64 FPM feed rate (Optional 40 - 118 FPM Variable Speed Drive). -- Durable chain drive gives years of trouble-free operation. -- Simple to access hand wheels allow the operator to make quick adjustments when panel thicknesses change. -- Complete with: Safety stop bars roll guard hood, stainless steel drip pan catches clean-up water. -- Available Widths: -- 17" Wide -- 36" Wide -- 48" Wide. -- 54" Wide. -- 63" Wide.

12" Conveyorized Glue Applicator, model "F-CGAP-12-10-20", 12" wide grooved rubber covered roller with stainless steel doctor blade. Large knobs for easy adjustment or removal of doctor blade. Limit switch with wand for automatically stopping the slat blade conveyor when stock reaches the RF Press or Clamp Carrier. -- Heavy Duty, 3-phase 0.5 HP motor drives the conveyor and glue roll; motor is equipped with an adjustable slip clutch to prevent damage in case of a material jam. -- All components are Heavy Duty for years of trouble free operation. The stainless steel glue pan and doctor blade are easily removed without tools for quick clean-up. Conveyer system is 32' in overall length, 10' before the glue roller and 20' after. - Optional: 12" wide holddown roll for face gluing of stock

QUICK R-RCGS-2-54-10 Top & Bottom Glue Spreader54" Wide Top and Bottom Glue Spreader with 0.04" - 10" thickness Capacity. Specifications: -- (2) Smooth rubber covered 8.3" glue rollers are acid and heat resistant, (2) 7" Chromed doctor rolls. -- Converts quickly to Top only glue application when needed. -- Comes standard with a fixed 80 FPM feed rate (Optional 40 - 118 FPM Variable Speed Drive for additional $900.).Features: -- Durable chain drive gives years of trouble-free operation. -- Simple to access hand wheels allow the operator to make quick adjustments when panel thicknesses change. -- Complete with: Safety stop bars roll guard hood, all aluminum drip pan catches clean-up water. -- Stock photograph, does not represent actual machine.

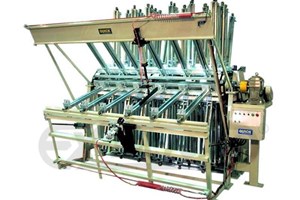

²QUICK 14-Section Pneumatic Clamp Carrier with 10-1/2' width capacity With (8) Standard zinc plated clamps per section (112) clamps total), 38" opening on clamps Standard Features include: -- Clamps jaws are 2-1/2" high x 4-3/4" wide with 1° inward draft to keep stock securely held down. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. For face gluing, Rocking Plates available as optional equipment -- Panel Flattener with easy-to-use controls. -- Pneumatic Clamp Tightener; 3,000 RPM air wrench is 5 to 10 times faster than competitive tighteners; a two-handed, trigger-activated tightener is more confidence-inspiring than the old ergonomically awkward "swing-style" clamp tighteners. Fast tightening and full-length clamp screws eliminate the need for manual adjustment of rear clamp jaws. -- Electric Motor Rotation; push button, automatic cycle with indexing. -- Automatic Rotation Cycle includes the entire sequence; reverse rotation, front-rest out, forward rotation, front-rest in, and lay clamps on front rest. Perfectly! Every time! Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high-quality urethane finish coating, and toolbox with spare parts & tools. -- A 14-Section Clamp will produce approx. 300 panels

Call for Price

QUICK '6-SECTION HEAVY DUTY-P CLAMP CARRIER (Pneumatic). -- Overall Data: Heavy Duty 16.5' wide (16.5' maximum stock length capacity), 6-section Thick Stock Pneumatic Clamp Carrier with (72) 3.5" high, 40" opening clamps; (12) clamps per section. -- Includes: Pneumatic Clamp Tightener, Pneumatic Panel Flattener, Electric Motor Drive with Automatic Rotation Cycle. -- Major Parts & Components list as follows:Qty Part# Description Each Total (1) A-CCFP-16.5-06 CC Frame Pneumatic, 16.5' wide, 6 Sect. $9,900.00 $9,900.00(72) B-CLMP-3.5-40 Clamp, 3.5" high jaw, 40" opening 82.00 5,904.00(1) C-PCT1-16.5-06 Pneumatic Clamp Tightener, 16.5' wide, for 6-sect. CC 4,450.00 4,450.00(1) D-PPF1-16.5 Pneumatic Panel Flattener, 16.5' wide 2,200.00 2,200.00 (1) E-EMDR-06-16.5 Electric Motor Drive for 6 Sect. CC, 16.5' wide, #135 2,450.00 2,450.00 TOTAL ..................................................................................................................................... $ 24,904.00.OPTIONAL(24) B-CLMP-3.5-40 Clamp, 3.5" high jaw, 40" opening 82.00 $1,968.00 -- Note: Lead time is about (8 - 10) weeks.

Conveyorized Glue applicator that can cover up to 20" of material width. -- 8' long infeed conveyor and 8' long outfeed conveyor allows for easy handling of long materials. -- Grooved rubber roller offers durability and easy maintenance. -- Stainless steel doctor blade and glue pan remove easily for cleaning. -- The all steel frame includes (3) twin leg sections that features independent foot levelers. -- Commerical 1/4 Hp motor includes a slip-clutch driving the glue applicator. -- Unit is finished with a long lasting urethane paint. -- Contact your FactoryNew representative about the optional holddown roller should you plan to glue handrails, laminated beams, face-glue or warped and twisted boards.

Grooved rubber covered glue rollers are SBR / acid and heat resistant. -- Easy to clean, 6-7/8" hardened rubber doctor roller. -- Comes standard with a fixed 80 FPM feed rate. -- Durable chain drive gives years of trouble-free operation. -- Simple to access handwheels allow the operator to make quick adjustments when panel thicknesses changes up to a 1-3/4" opening. -- Complete with: Safety stop bars and roll guard hood, all aluminum drip pan catches clean-up water. -- Also Avalable with: -- 17" Wide -- 24" Wide -- 36" Wide. -- 48" Wide. -- Variable speed drive of 40 to 118 FPM. -- 6" or more Opening.

$ 4,690

QUICK CRFT-08 Clamp Rack The QUICK Clamp Rack’s moderate cost, ultra high-quality clamps, super-strong frame and efficient use of floor space makes it the ideal gluing station for the small to mid-sized cabinet shop, furniture manufacturer or millwork producer.Includes: -- 8' width capacity, 6-row (3 rows on each side) Clamp Rack with (16) heavy-duty, zinc-plated, hand-tightened clamps. Clamps are 40" opening (32" opening is available), with 3.5" high x 4.75" wide jaws, with 1° inward draft.Standard Features: -- Standard features include super heavy-duty frame with 4" x 4" structural tubing cross beams, 4" x 6" structural tubing legs, and 4" x 4" structural tubing feet. -- Two-position feet can be configured for one-sided or two-sided Rack operation. -- All tubing ends are angled and/or closed for maximum strength and proper aesthetics. -- High-quality urethane finish. -- Clamps are exceptionally heavy-duty, with full box frame construction, and feature quick-release rear jaws and long, smooth handles for maximum ease-of-use.

1' x 10' pressing capacity via (10) 1' x 1' platens. Pod Press produces 78,000 lbs. total platen force (7,800 lbs. per platen) at 120 PSI supply air pressure; suitable for lighter-duty (high-pressure laminates to composite substrates) and heavier-duty (wood veneering) applications. 40" fixed daylight; vertical structural frame members and hinged containment fences arrangement for end-loading and side loading the press. -- Horizontally-adjustable vertical containment fences keep laminated material from sliding while under pressure. (10) 10"" maximum diameter air pods with 5" stroke; each air pod with separate hand-operated air valve; each air pod / platen activates individually. Main air valve controls all "activated" air pods at once; various pods are controlled together, or each pod can be controlled separately. -- NOTE: Special Press configuration for use in stile and rail entry and passage door operations.

QUICK 6-SECTION, 10'-1/2' Wide Pneumatic "Standard" Clamp Carrier: 6-Section Clamp typically produces (48) high quality edge glued panels per day (3 panels per section x 6 sections x 8 hours). Equipped with: -- (6) Sections with (8) clamps per section and 10-1/2' width capacity. -- (48) Clamps with 50" opening and 2-1/2" high x 4-3/4" wide jaws with 1° inward draft. Clamps use 3/4" dia. full-length screws; corrosion resistant, zinc plated, full box frame. Features: -- Electric motor drive. -- Pneumatic Panel Flattener for 10-1/2' wide Carrier with easy to use controls. -- Pneumatic Clamp Tightener with 3,000 RPM air wrench is (5 -10) times faster than competitive tighteners; 2-handed, trigger activated tightener is more confidence inspiring than the older, ergonomically awkward "swing-style" clamp tighteners. -- Fast tightening and full-length clamp screws eliminate need for manual adjustment of rear clamp jaws. Complete with: -- Foot levelers, coiled air lines, flexible conduit for electric wires, automatic air line oiler, high quality Urethane finish coating, and tool box with spare parts & tools. --

Call for Price

QUICK MACHINERY N-P80 Air Pod style Cold Press. -- Heavy Duty I-beam construction with machined steel plates for flat smooth pressing surface.Specifications: -- Platen pressing area size: 49" x 97" with end loading on 49" side. -- 80 PSI Platen pressure over the entire surface area with 102 PSI supply air pressure. Pressure is applied by 12.8" dia. air pods with 5.9" stroke; (28) air pods total for this size press. -- Air powered raise and lower idler rollers in the bed of the press for loading & unloading panels; raising & lowering of conveyor by control button on panel. -- Motorized Adjustable Daylight Opening from 2" to 40"; push button controls operate an electrically powered chain driven worm gear drive system for precise positioning of upper platen setting/opening. -- Controls: 60-Min cycle timers provide visual and audible signals at the end of each cycle and automatically releases platen air pressure at the end of each cycle if desired. -- Single platen 49" X 97" . -- The press model shown in pictures is a dual platen powered feed through end load press. -- Actual model is N-P80-04-08-EL-1PL-M-40-R-1Z

Call for Price

QUICK MACHINERY N-P80 Air Pod style Cold Press. -- Heavy Duty I-beam construction with machined steel plates for flat smooth pressing surface.Specifications: -- Platen pressing area size: 62" x 146" with end loading on 62" side. -- 80 PSI Platen pressure over the entire surface area with 105 PSI supply air pressure. Pressure is applied by (60) 12.8" dia. air pods with 5.9" stroke; -- Air powered raise and lower idler rollers in the bed of the press for loading & unloading panels; raising & lowering of conveyor by control button on panel. -- Motorized Adjustable Daylight Opening from 2" to 40"; push button controls operate an electrically powered chain driven worm gear drive system for precise positioning of upper platen setting/opening. -- Controls: 60-Min cycle timers provide visual and audible signals at the end of each cycle and automatically releases platen air pressure at the end of each cycle if desired. -- Single platen 62" X 146". (2) Air pressure zones for upper platen: (4' x 8' and 5' x 12') -- Optional powered roller tracks for an additional fee. -- The press model shown in pictures is a dual platen powered feed through end load press. -- Actual model is N-P80-05-12-EL-1PL-M-40-2Z

Call for Price

QUICK MACHINERY N-P50 Air Pod style Cold Press. -- Heavy Duty I-beam construction with machined steel plates for flat smooth pressing surface.Specifications: -- Platen pressing area size: 62" x 146" with side loading on 146" side (also available as end loading). -- 50 PSI Platen pressure over the entire surface area with 90 PSI supply air pressure. Pressure is applied by 12.8" dia. air pods with 5.9" stroke; (36) air pods total for this size press. -- (2) Pressure air pressure zones: 5' x 12' and 4' x 8'. -- Air powered raise and lower idler rollers in the bed of the press for loading & unloading panels; raising & lowering of idle conveyor roller tracks by control button on panel. -- Motorized Adjustable Daylight Opening from 2" to 40"; push button controls operate an electrically powered chain driven worm gear drive system for precise positioning of upper platen setting/opening. -- Controls: 60-Min cycle timers provide visual and audible signals at the end of each cycle and automatically releases platen air pressure at the end of each cycle if desired.

Call for Price

QUICK MACHINERY N-P50 Air Pod style Cold Press. -- Heavy Duty I-beam construction with machined steel plates for flat smooth pressing surface.Specifications: -- Platen pressing area size: 62" x 146" with side loading on 146" side. -- 50 PSI Platen pressure over the entire surface area with 93 PSI supply air pressure. Pressure is applied by 12.8" dia. air pods with 5.9" stroke; (36) air pods total for this size press. -- Air powered raise and lower idler rollers in the bed of the press for loading & unloading panels; raising & lowering of conveyor by control button on panel. -- Motorized Adjustable Daylight Opening from 2" to 40"; push button controls operate an electrically powered chain driven worm gear drive system for precise positioning of upper platen setting/opening. -- Controls: 60-Min cycle timers provide visual and audible signals at the end of each cycle and automatically releases platen air pressure at the end of each cycle if desired.Actual Model is a N-P50-05-12-SL-1PL-M-40-R-1Z.• Maximum platen pressure: 50 PSI at 93 PSI supply pressure• Lower platen dimensions: 5' x 12'• Side-loading design• Number of upper platens: 1• Upper platen dimensions: 5' x 12'• Vertical opening: Motorized adjustable from 2" to 40"• Lower platen roller tracks: Yes, non-powered roller tracks• Number of 12.8" diameter, 5.9" stroke air pods: 36• Number of air pressure zones: 1 (5' x 12' pressing)Optional powered roller tracks are available. -- The press model shown in pictures is a dual platen powered feed through end-load press.

QUICK L-HLPP-2-20-43-8-12 ...2-Sided Hydraulic Laminating Press: -- Number of working sections: (2) -- Working width, section #1: 6" and 8" -- Working width, section #2: 8", 10"; and 12" -- Maximum working length: 6,200mm (20.3') -- Maximum working height: 1,100mm (43.3") -- Pressure at the glue line: Up to 175 PSIMain Laminating Cylinders: -- Number of cylinders, section #1: (14) -- Number of cylinders, section #2: (21) -- Size of cylinders: 100 mm dia. x 80 mm strokeHolddown Cylinders: -- Number of cylinders, section #1: (14) -- Number of cylinders, section #2: (21) -- Size of cylinders: 40 mm dia. x 150 mm strokeLift Cylinders: -- Number of cylinders: (2) on each side = (4) -- Size of cylinders: 63 mm dia.Hydraulic Pump: -- Drive motor: 10 HP -- Maximum pressure: 140 kG/cm² -- Maximum Holddown Cylinder Pressure: 50 kG/cm² -- Maximum Side Lift Cylinder Pressure: 50 kG/cm² -- Shipped without hydraulic oil in the oil tank

Call for Price

QUICK MACHINERY N-P80 Air Pod style Cold Press -- Heavy Duty I-beam construction with machined steel plates for flat smooth pressing surface. -- Specifications: -- Platen pressing area size: 38" x 98"; with end loading on 37" side. -- 80 PSI Platen pressure over the entire surface area with 105 PSI supply air pressure. Pressure is applied by 12.8" dia. air pods with 5.9" stroke; -- Air powered raise and lower idler rollers in the bed of the press for loading & unloading panels; raising & lowering of conveyor by control button on panel. -- Motorized Adjustable Daylight Opening from 1" to 40"; push button controls operate an electrically powered chain driven worm gear drive system for precise positioning of upper platen setting/opening. -- Controls: 60-Min cycle timers provide visual and audible signals at the end of each cycle and automatically releases platen air pressure at the end of each cycle if desired. -- Single platen 38" X 98". -- Optional: powered roller tracksSpecifications:QUICK Laminating Pod PressN-P80-03-08-EL-1PL-M-40-R-1Z• Maximum platen pressure: 81 psi at 90 psi supply pressure• Lower platen dimensions: 3' x 8' (38" x 98")• End-loading or Side-loading: End-loading• Number of upper platens: 1• Upper platen(s) dimensions: 3' x 8' (38" x 98")• Vertical opening: Motorized adjustable from 2" to 40"• Lower platen roller tracks: Yes, Non-powered roller tracks• Number of 12.8" diameter, 5.9" stroke air pods: 24• Number of air pressure zones: 1 -- The press model shown in pictures is a dual platen powered feed through end-load press.

Call for Price

QUICK N-P50 Fixed Daylight Opening Air Pod PressThis Pod Press can produce a maximum 50 PSI platen pressure over the entire surface at 100 PSI supply air pressure. Press has a fixed vertical daylight opening of 44". The (18) 12.8" max. diameter air pods have 5.9" stroke.Material conveyance is via automatically extending and retracting (via pneumatic cylinders) non-powered roller tracks. A cycle timer provides visual and audible signals at the end of each cycle if desired, and also automatically releases platen air pressure at the end of each cycle, if desired.Specifications: -- Maximum platen pressure: 50 PSI at 100 PSI supply pressure. -- Lower platen dimensions: 4' x 8' -- End-loading or Side-loading: End-loading -- Number of upper platens: 1 -- Upper platen(s) dimensions: 4' x 8' -- Vertical opening: Fixed at 44" -- Lower platen Non-powered roller tracks. -- (18) 12.8" diameter, 5.9" stroke air pods. -- Number of air pressure zones: 1Lead Time: Approximately (12) weeks from time of order.Actual Model: N-P50-04-08-EL-1PL-F-44-R-1ZNOTE: Please let us know of any "Special or Specific" safety equipment requirements that you may have prior to order

QUICK MODEL L-HLPP-1-36-43-6 SINGLE SIDED HYDRAULIC LAMINATING PRESS FOR POSTS AND BEAMS: -- Number of working sections: 1 -- Maximum working length: 36'. The 36' length achieved by manufacturing the machines in two 18' long pieces; the two 18' pieces are then joined together, resulting in 36' total working length. -- Maximum working width: 43" -- Maximum working thickness: 6"Main Laminating Cylinders: -- Number of cylinders: (30) -- Size of cylinders: 80mm dia. x 80mm strokeHolddown Cylinders: -- Number of cylinders: (30) -- Size of cylinders: 40mm dia. x 150mm strokeSide Lift Cylinders: -- Number of cylinders: (2) per section = (4) -- Size of cylinders: 63mm dia.Hydraulics: -- Hydraulic pump drive motor: 7-1/2 HP -- Maximum pressure: 140kg/cm2 -- Maximum Holddown Cylinder Pressure: 50kg/cm2 -- Maximum Side Lift Cylinder Pressure: 50kg/cm2 -- NOTE: Shipped without hydraulic oil

.gif)