Gang Rip Saws For Sale

Category

Gang Rip Saws

119 Results Found

Call for Price

CANTEK MRS-610M-4 GANG RIPSAW WITH (4) SHIFTING BLADES: Specifications: -- (4) Shifting Blades and 4.2" Max. cutting thickness without pressure plate, 3.7" with pressure plate; 24" Max. cutting width; 35.4" Max. material width of pass-through; -- 60 HP Saw motor (larger optional); 2.8" (70 mm) Saw arbor diameter turning at 3800 RPM; 12" Min. or 14" max. Sawblade diameter; 2.8" (70 mm) Sawblade bore when mounted directly on shaft, 3.5" (90 mm) when mounted on saw sleeve; -- 5 HP feed motor with variable feed speeds from 25 to 200 FPM; 1/2 HP pressure roller raising motor; 24" Min. stock length; 31.9" Min. stock length with board under (2) rollers.Features and Benefits: -- The main frame is cast iron, all the main parts are enclosed, ensuring protection and perfect stability -- Nickel chrome steel saw arbor with 70 mm OD double keyed quick removal sleeve. -- Heavy duty precision straight line feeding caterpillar chain type. -- Feed chain with easily replaceable bolt in cast steel or urethane pads - optional. -- The top pressure roller system is electronically positioned from the front control panel with regard to lumber thickness with position readout. -- Top roller hold down system is mated to the servo positioning short stock shoe providing optimum straight-line ripping performance and comprehensive safety. -- Pneumatic pressure (infinitely variable) to the holddown feed rollers provides better control of the lumber. -- Nickel chrome steel saw arbor. -- Variable feed speeds of 16 - 200 FPM. (5 - 60 m/min) via an inverter motor and speed control with led readout. -- Electronic overload sensing system is integrated to the inverter feed system providing automatic speed reduction under heavy amperage load. -- New - short stock cutting device included. -- Digitally controlled lubricator for chain. -- Centralized lubrication system. -- (2) Powered top & bottom outfeed rollers are a standard feature. The powered roll system facilitates positive flow of the stock through the gang saw and onto outfeed conveyors or transfers. -- (3) Rows of anti-kickback fingers. -- Telemechanique - automatic star-delta starter (low amperage soft-start) and low voltage controls -- Controls are mounted on the saw for easy convenient machine operation. -- Includes 12' infeed table -- Gang saw sleeve is an optional extra. -- Electrics to 230/460 or 575-volt, 3-phase, 60-cycle to UL/CSA standards -- Complete Shifting Fence Infeed Tables and complete Outfeed Sweep Systems, handling decks and Stacking Systems are available.Options available: -- Add a 75 HP saw arbor motor instead of 60 HP - including a Wye-Delta low amp Starter. -- 100 HP Saw arbor motor in lieu of 60 HP - including Wye-Delta low amp Starter -- 125 HP Saw arbor motor instead of 60 HP - including Wye-Delta low amp Starter. -- Short Stock Feeding device (min. length 12" - must use 12" blades for max. thickness of cut of 2.16" (55 mm). -- 20 mW Laser (FP MLC1320W) & Laser Holder w/12" B

$ 61,700

CANTEK MODEL MRS-175 6.9"; THICK CUTTING HEAVY-DUTY GANG RIPSAW: -- FEATURES: -- Massive cast iron base provides incredible absorption characteristics for high quality deep cutting operations -- Precision chain and rails (dip chain) system facilitates straight line cutting -- Equipped with a blade mist cooling device providing cooling and cleaning for sawblades during cutting increasing blade life and improved cut quality. -- Motorized saw arbor and thickness adjustment for operator convenience. -- Specially designed auxiliary powered outfeed roller assures maximum smoothness of workpiece outfeed especially when working on extra thick, heavy and moist wood. -- A digitally controller lubrication unit is provided to provide consistent oil protection to the feed chain and guide rails. If the oil level drops below a safe level a warning lamp will light up and the feed chain will stop automatically. -- Equipped with an electronic amperage display which is tied in to an overload protection where if the saw motor exceeds a rated amperage the feed chain slows down automatically. This prevents the potential damaged to the saw arbor and/or blades and also prolongs blade life up to 20%. -- Variable feed speed adjustment by frequency inverter from the front of the machine. -- Please note. with safety cover non-CE -- Measurement: 255x210x170(cm)N.W./G.W.:3,150KGS/3,350KGS -- SPECIFICATIONS -- Max. cutting thickness, 6.9"; -- Max. cutting width, 13-3/4"; -- Fixed inside blade to column, 14.9"; -- Min. working length, 27-1/2"; -- Max. saw blade diameter, 14"; to 18"; -- Sawblade bore, 70 mm or 90mm – double keyed -- Saw arbor diameter, 70 mm without sleeve - 90mm with sleeve -- Saw arbor speed, 2500 RPM -- Saw arbor motor, 75 HP (100 HP optional) -- Saw arbor elevation motor, 1/2 HP -- Feed motor, 3 HP (5HP optional) -- Variable feed speed, 8 – 80 FPM (higher speed optional) -- Powered raise & lower of rolls, 1/2 HP -- Dust hood dia., 8"; -- Table height (pass line), 29.3"; -- Electrics – to UL/CSA standards 230/460 or 575-volt, 3-phase, 60-cycle -- Table area (L x W), 72.4"; x 31.1"; -- Overall dimensions (L x W x H), 95.5"; x 90.5"; x 63";, Net weight 6,600 lbs.

Call for Price

CANTEK MRS-340M-1 GANG RIPSAW WITH (1) SHIFTING BLADE and the following specifications and features: Capacities are: -- 4.3" Max. thickness with 14" dia. fixed blade(s); 3.3" with 12" fixed blade(s); 4" with 14" moveable blades and 2.95" with 12" moveable blades; 13.4" max. working width between outside saws. 25.6" max. overall width; -- 5.5" Max. distance to fence from inside fixed blade; 0.59" to 13.38" max. saw travel; 23-1/2" min. stock length; 19.7" possible with optional short stock holddodwn (reduces thickness capacity. -- With 70 mm dia. x 13-3/4" long saw arbor powered by a 50 HP motor driving the blades at 3,800 RPM; 3 HP feed motor provides feed speeds from 15 to 135 FPM;1/2 HP lift motor for hold-down roll; infinitely variable saw shifting speeds from 0.78" to 3.15" per second; (2) 15 mW laser lights; (2) 12" or 14" dia. x 90 mm bore blades; 72" x 31" table size sits 30" from the floor. Features include: -- Cast iron main frame with main parts enclosed to ensure protection and perfect stability; HD precision straight line caterpillar type feed chain with easily replaceable bolt-in cast steel or Urethane chain ads (optional); -- Fully programmable position sets (10) programs of (10) sets each or infinitely variable foot pedal position set; user friendly Touch Screen control (free standing operators control console) is integrated with 32 bit micro processor and (2) RS232 ports for incredible positioning speeds and EXACT blade positioning. -- Touch Screen with full and easy programming capabilities and joystick control; saw blade positioning is accomplished by industrial series Servo Motor and control; blade speed is infinitely adjustable from 0.78" to 3.54" IPS to match all operations; blade positioning can be initiated by electronic joystick control (efficient & quick) or the touch screen controls. Equipped to shift (1) saw independently or (2) saws per shifter (optional as a cluster) or with a single or bank of saws with spacers can be set up on the inside of the saw arbor to gang rip if desired. New short stock cutting device included -- Top pressure roll system is electronically positioned from the front control panel for lumber thickness; includes position readout; top roll hold down system is mated to the servo positioning short stock shoe to provide optimum straight line ripping and safety; top rolls are spring tensioned and tension is adjustable (pneumatic pressure is optional). -- Specially designed and Patent Pending Precision Glide Lock with nickel chrome steel saw arbor with super technology for easy maintenance and free saw shifting; (2) shifting saw bushings are equipped with specially designed rollers for most accurate and very fast saw positioning. -- (3) Rows of anti-kickback fingers; variable feeding speeds from 16 to 135 FPM inverter motor and speed control with LED readout; electronic overload sensing system is integrated to the inverter feed system providing automatic speed reduction under heavy amperage lo

Call for Price

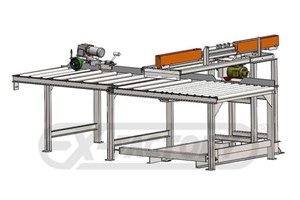

Cooper Optimizer Gang Rip Saw Cooper Edger Both set up inline and ready to be removed.

Call for Price

Call for Price

Call for Price

Call for Price

Diehl Model 75 Straight Line Rip Saw Chain is in good shape. Left and right chains are worn evenly. Includes: Laser Variable Speed: 4-speeds

Call for Price

The seller has upgraded to a new machine and no longer needs this rip saw. This machine still runs a few times a week at the shop. 15 HP Motor 2 HP Feed Motor 2" Arbor 16" Max blade capacity Chain drive

$ 19,800

Extrema XG12 Gang Rip SawSpecifications -- 12" long arbor for 11-3/4" max. cutting width and powered -- 50 HP main motor; --10" to 16" dia. blade running at 3,200 RPM and with cutting depth from 1/8" to 5-1/8". -- Min. working length is 9-1/8".Equipped with & Features -- 3 HP feed motor for variable speed feed 30 to 130 FPM. -- Feed system provides power to Heat treated chain for positive feeding; automatic lubrication of chain and race; low oil shutdown; -- (6) individually spring loaded top rollers; table is 15" wide x 109" long. -- .25 HP motor for power raise and lower of top feed rolls. -- Disc arbor brakes, cardan shaft driven system, and interchangeable blade sleeves including sleeve changing rack. -- Swivel control panel and Square D electrical controls, solid cast-iron construction. -- Soft start, -- Triple anti-kickback fingers, and replaceable pressure plate. -- (4) Overhead LasersNote from the seller: Gang Rip Saw comes from a small 3 man shop.

$ 16,020

4INDUSTRIES 12-200 Roll Feed Multiple Blade Rip SawSpecifications: -- 12" maximum width -- 1/2" to 2" thickness -- Minimum length 16" -- Feed speed up to 200 FPM with driven bottom feed rollers, non driven top roller -- Main saw motor 40 HP -- Feed motor 7.5 HP -- Saw blade 12" diameter

Call for Price

$ 135,395

KENTWOOD - R340SM3: Gang Rip Saw w/(2) Movable BladesSpecifications -- Saw blade motor: 50 HP. -- Saw arbor diameter: - 55 mm/2. -- 165" Saw arbor height adjustment: 1/4 HP Motor. -- Saw arbor length: 340 mm. -- Feed Motor: 3 HP. -- Variable speed. -- Feed chain width. -- 15" Infeed pressure rolls.Equipped with & Features -- Push-button controls for Saw; wired for 460 V - 3 PH. -- Infeed anti-kickback fingers. -- Outfeed pressure rolls. -- Sound/safety enclosure.Infeed System -- Advantage Rip / Infeed. -- Deck Size: 140" x 85". -- Photoeyes: Every 12". -- Measure for: Board shape, width, and nominal length. -- (2) Pin Stops standalone. -- BECKOFF: User control Pedestal. -- Touchscreen year: 2015.

Call for Price

LEADERMAC LMC-101-900 HD 36" HD Multi-Blade "Roll Feed" RIP SAWSpecifications: -- Working width: 0.6"; – 36"; -- Working thickness: 0.4"; – 4"; -- Up & Down motor: 1 HP -- Feed motor: 7-1/2 HP with VFD -- Spindle HP: 75 HP, larger motors optional -- Spindle diameter: 3.15"; double keyed -- Spindle RPM: Std. 4,000 RPM, 5,000 RPM optional -- Saw Blade Diameter, 14"; diameter -- Feed speed, infinitely variable: 20 – 50 FPM, 100 or 200 FPM optionalStandard Features: -- Extra Heavy Main Frame – Stress Relieved -- Sound & Safety enclosure included – with internal strobe-free lighting -- High Precision Spindle - Double Keyed assembly with Hydro-Lock outboard bearing assembly on outboard side -- Spindle assembly slides out on support for Quick, Easy and Precision Saw Setting & Changing -- Hardened & Hard Chromed Feed Tables -- (7) Sets of Top Power Driven Rolls – full width -- (5) Bottom Power Driven Rolls – full width -- Infinitely Variable Pneumatic Pressure to Top Feed Rolls -- Top & Bottom Feed Rolls driven by Cardan Shaft Drive with HD Gearboxes Interconnected -- 1st Top & 1st Bottom Powered Roll Combination and then (2) Rows Anti Kick Back Finger Units Full Width and then to the rest of the Powered Top & Bottom Rolls provide the best Feeding Capability with excellent safety features -- HD VFD – 7-1/2 HP Feed System – Infinitely Variable -- Main motor has Wye-Delta low amperage soft start -- Electrics are 230, 450 or 575 volts 3/60 with all controls to CSA/UL Specifications -- Documentation: Maintenance manual, Operation manual, Electrical diagrams, Parts list & Tool Box (Electronic Version on Request) -- (8) Dust outlets consisting of (4) top & (4) bottom 6"; diameter dust hoods -- Saws, Dado Heads &/or cutterhead(s) and spacers optional extra Options Included In Price: -- Hanging Control Panel – in lieu of Control std. setup as shown in machine photo, Included -- Moveable Main Electrical Panel with 10 ft. of main cable, Included -- Amp Meter for the Arbor Motor, Included -- 4"; Thickness capacity in lieu of standard 2"; thickness, Included Available Options: -- To 3" Thickness Capacity – using 12"; blades, P.O.R. -- To 3"; or 4"; thickness Capacity – using 14"; blades, P.O.R. -- To 100 FPM Top Feed Speed – Infinitely Variable – 4"; Thickness Capacity, POR -- To 200 FPM Top Feed Speed – Infinitely Variable – 2"; max. Thickness, P.O.R. -- 100 HP saw spindle motor, P.O.R. -- 125 HP saw spindle motor, P.O.R. -- 150 HP saw spindle motor, P.O.R. -- Front or Rear 10 HP Side Heads (Please discuss if interested), P.O.R. -- 15 HP or 20 HP Side Head motors in lieu of 10 HP, P.O.R. -- Adjustment of the Rear guide with digital readout from the front of the machine (only desirable if Side Heads are supplied), P.O.R. -- Scoring Saw Arbor ahead of main saws if desired, P.O.R. -- Saw Spacers for Main Arbor quick Setup, P.O.R. -- Mechanical Quick Lock Saw collars if de

Call for Price

LEADERMAC SYC 300M Heavy Duty Roll Feed Ripsaw: Features & General Description: -- Cast Iron base with easily accessed Anchor Bolts; lift up sound enclosure with light for quieter and safer operation; Hydro-Loc Outboard Bearing System for best gang sawing shaft support, includes grease gun; HD Cardan shaft feed (chainless) drive throughout. -- (6) Full width, close coupled driven top feed rollers; (4) full width driven bed rollers; top rolls are air tensioned; variable pressure controls on top feed rolls; motorized lift to top rolls; infeed table is hard chromed with approx. 0.012"; - 0.014"; chrome. -- Easily adjusted roll holdover on the infeed table; saw spindle has motorized lift and lowering; multiple HD V-belt driven saw spindle with special HD belt tensioner; saw blades cut from below, hence better dust removal and a heavier sturdier design. -- Saws are pre-mounted on a slip-on sleeve for quick change; (3) sets of anti-kickback devices included; central lube system; pneumatic pressure controller safety switch – if air pressure to the top rolls drops below the set to run level, the feed will automatically stop. -- Controls include: VFD Control to feed speeds and Digital Speed Readout in FPM or MPM; TECO-WESTINGHOUSE main electric motor; I.E.C. – TELEMECANIQUE-SQUARE-D Electricals meet or exceed UL/CSA Standards. -- Machine is equipped with WYE-DELTA Soft-Start (low Amperage) starters & main disconnect, multiple “E-Stops" operate at low amperageSPECIFICATIONS: -- Max. thickness, 5.1"; (130 mm); Note – to 4-1/2"; with std. 14"; diameter blades; to 5.1"; with optional 16"; Blades. -- Saw sleeve usable length of 12.3"; (312 mm) - max. dist. between outside saws; minimum length material, 10"; (250 mm) – at slower speeds. -- Saw Blades with 10"; min. to 14"; max dia. x 70 mm Bore (double key), 16"; (400 mm) optional – no charge; Saw spindle with 50 mm dia. runs at 3,200 RPM; Saw sleeve – included, 70 mm OD with double keyways. - Includes (1) set of spacers. -- Main Motor – 75 HP (50, 60, or 100 HP optional); top feed rolls – rise & fall, 1 HP; Feed Drive of 7.5 HP with VFD infinitely variable speed control, 20 to 165 FPM (6 to 50 MPM) to 200 FPM – 60 MPM – optional). -- (4) 150 mm Dust collection outlets; approx. weight – net, 5,060 Lbs.; WYE-DELTA – low Amperage - Soft Start for main motor starter; electrics to UL/CSA Standards and wired to 230/460 or 575/3/60. - Note: Stock machines are with 50 HP – 460/3/60 electrics machine and can be easily and inexpensively transformed to other voltages.Optional Extras. -- 75 KVA Auto Transformer to run machine on 230/3/60 electrics, please add ...$ 2,045. -- 16"; (400 mm) Dia. blade with 5.1"; max. Thickness N/C; NOTE: – Contact us to see if stock machine has this capacity. -- Extra Saw Sleeve, add ...$ 995. -- Additional Sets of spacers for saw sleeve, P.O.R. -- 20 MW Laser & Laser Holder w/12"; Bolt o

$ 29,800

LHI MBR-10 ROLL FEED GANG RIPSAW: Saw arbor with 25 HP arbor motor (30 HP and 40 HP available, see Options for pricing).Specifications: -- 1-15/16" Saw arbor bearings and 10" usable arbor. 12" useable arbor available. Uses 12" dia. x 1-3/4" bore saw blades. -- 1/8" to 2" Max. cutting depth on hardwoods and softwoods; 18" minimum stock length; 17" maximum stock width; removable and replaceable phenolic throat plates. -- Unique “swing down arbor frame"; for easy and fast blade changing. Blades are positioned using spacers.Feed system with: -- (2) 1 HP Feed motors with constant feed speed to be determined from thickness of wood, type of wood, and maximum number blades (average speed is set at 80 FPM). -- (6) Non-marking steel drive rollers; top and bottom rolls are powered for superior feeding capabilities; hand crank for easy feed roll height adjustment. -- Includes safe, fully enclosed belt and chain guards and double anti-kickback device. Features: -- Simple design, low cost, high performance. -- High production, fast setup, workhorse. -- Off-The-Shelf Parts are found locally for ease of maintenance.Options: -- 30 HP arbor motor & starter, add $1,150, -- 40 HP arbor motor and starter, add $2,300, -- Variable Speed Drive with speeds from 10 to 100 FPM, add $2,450. -- 12" Useable arbor space, add $2,950. -- 12" x 24T Blade,1.75" Bore, $115 each. -- 12" x 30T Blade,1.75" Bore, $165NOTE: PRICING DOES NOT REFLECT Mfg's 7% MATERIALS SURCHARGE

$ 88,500

LHI MODEL RFPR ROLL FEED PANEL RIP SAWWith the following Standard and Optional Equipment: -- Roll Feed Panel Rip Saw - 72" Arbor - 50 HP motor -- 10 to 80 FPM (4-speed programmable or potentiometer) -- (8) Polyurethane feed rollers -- 10" Dia. blades (thickness-1/8" to 1-1/4") Infeed Scissors Lift 4,500 Lbs capacity -- 4' x 8' top -- (3) 2"; x 3"; support tubes for fork access -- 110 VAC / 1-Ph power unit -- Foot pedal control -- Automatic up-indexingOutfeed Scissors Lift 4,500 Lbs capacity -- 4' x 8' top -- (3) Support ramp/cross-bars to allow for access -- Auto down indexing -- 110 VAC / 1 Ph power unit -- Foot pedal controlSawblades: -- (10) 10" x 40T x 4-3/16 Bore, TGC Blades -- (10) Blade Collars, 3-15/16" ID x 4.18" bore x 1.25" wide Quick-change arbor setup with the second arbor: -- Arbor change cart (included with the arbor setup that comes with the saw to allow roll-out) Second Arbor Setup Includes: -- Cart -- Blade Box -- Arbor, Bearing -- Sheave -- Throat Plate Rack -- (6) Throat Plates Quick Change Kit: -- Belt Guide -- Belt Tensioner -- Hyd. Arbor Lock Quick Change Kit permits the operator to release the belt and unlock the arbor from the front side of the machine. Without the kit, the operator must open the rear guard to remove the belt and unlock the arbor -- (10) Blades for the second setup -- (10) Collars for the second setup 16-week ESTIMATED delivery: -- Delivery assumes order and down payment are received within (1) week of the date of quotation. Installation technical assistance for $115/Hr plus travel time and expenses Customer responsible for rigging Quote assumes customer will deliver material for testing (if required) Warranty: (1) Year mechanical parts (electrical controls excluded) This quotation is valid for 30 days. ESTIMATED DELIVERY DATE:The delivery date is quoted as 'estimated' because the equipment we manufacture is built to order and to our customer's specifications. This estimate is made under the assumption that there will be no interruptions of labor, material shortages, or any environmental or other unforeseen circumstances. LHI is not responsible for any installation or production costs resulting from actual delivery dates which exceed the quoted estimated delivery dates. Accurate dates for the delivery will not be available until the equipment is in the manufacturing phase. If there are custom features for the quoted equipment then accurate delivery dates will be available when testing is complete. Please consult with the factory for updates to the expected delivery date.NOTE: PRICING DOES NOT REFLECT FACTORY'S 7% MATERIALS SURCHARGE

$ 84,714

LHI MODEL RFPR ROLL FEED PANEL RIP SAW WITH THE FOLLOWING STANDARD AND SPECIAL EQUIPMENT: Specifications: -- 72" Useable Arbor and 50 HP Arbor Motor -- 14 - 80 FPM Variable Speed Feed Rate (4-speed programmable or potentiometer) -- (8) Polyurethane feed rollers -- Arranged for 14" dia. blades and 4"; max cutting thickness -- Single Point Thickness Adjustment from 1/2" to 4" -- Arbor Quick-Change KitComplete with: -- Additional Arbor Setup, Includes: Cart, Blade Box, Arbor, Bearings, Sheave, Throat Plate Rack, and (6) Throat Plates -- (15) Blade Collars: 3-15/16" ID x 4.18" bore x 1.25" wide -- (15) 14" Carbide Tipped Blades: 40 Tooth with 4.188 bore -- Delivery ESTIMATED at (14) weeks; assumes order and down payment are received within (30) days of the date of this quotation. -- Technical Installation assistance - $125/Hr plus travel time and expenses -- Buyer is responsible for rigging -- Quote assumes customer will deliver material for testing (if required) -- Warranty: 1 Year mechanical parts (electrical controls excluded) -- This quotation is valid for 30 days.

$ 52,733

LHI PIGTAIL Crosscut saw with conveyor and air stopSpecifications -- 62" Cut width --Saw motor 5 HP -- 14 FT gravity conveyor cutting surface -- Cam Lock adjustable stop -- Power feed wheel for rip saw infeed assist -- Blade dia. 12"Equipped with and Features -- 4,500 lb lift with loading ramps 1 HP, 30" X 72" platform -- 4,500 lb Outfeed lift with 3 ramps, 48" X 96" Platform, Auto down indexing -- 10" X 40T X 4-3/16" , 30 Blades -- 3-15/16" ID x 4.18" bore x 1.25" wide 30 collars -- 32 Throat Plates

$ 132,700

LHI RFPR ROLL FEED PANEL RIPPER - "BUILT TO ORDER SYSTEM" with the following equipment: -- Ripsaw: -- 72" Arbor - 50 HP arbore motor and 14 to 80 FPM Variable Speed Feed Rate (4-speed programmable via VFD) -- (8) Polyurethane Feed Rollers -- Arranged for 10" dia. blades to rip panel thickness from 1/8" to 1-1/2"; -- Single Point Thickness Adjustment -- Quick-Change Arbor Kit Additional Arbor Setup Including: -- (1) Arbor Cart, (1) Blade Box, (1) Arbor Shaft, (1 set) Bearings, (1) Arbor Sheave, and (1) Throat Plate Rack Automatic Infeed System: -- 4,500 Lbs. Capacity Hydraulic Scissors Lift with (4) loading ramps to feed and align 4’ x 8’ sheets into Panel Saw -- 110VAC/1PH Scissors Lift power unit -- Auto-Cycling Rake Feeder -- 6’ Line-Up Conveyor With Power Pinch WheelOutfeed Scissors Lift: -- 4,500 Lb. Capacity Hydraulic Scissors Lift with 4' x 8' top, (3) support ramps/cross-bars to allow fork access -- 110VAC / 1Phase power unit -- Auto Down Indexing -- Auxiliary Foot Pedal Control Blades, Collars and Throat Plates: 10" x 40T x 4 3/16 Bore, TGC, $105 eachBlade Collars: 3-15/16" ID x 4.18" bore x 1.25" wide, $135 eachAluminum Throat Plates, $35 each TERMS AND CONDITIONS: -- Delivery: 16-18 Week ESTIMATED delivery date assumes your order is received within one week of date of this quotation. -- A 5% Tooling & Steel Surcharge to be added to the machinery price when the total is known -- Installation technical assistance, $125/hr. plus travel time and expenses (if required) -- Customer responsible for own rigging -- Quote assumes customer will deliver material for testing (if required) -- Warranty: 1-year mechanical parts (electrical controls excluded) -- FOB: Shannon, MS 38868. ESTIMATED SHIPPING DATE: 16 TO 18-WEEKS --The delivery date is quoted as “estimated"; because the equipment manufactured is built to our customer's specifications. This estimate is made under the assumption that there will be no interruptions of labor, material shortages, or any environmental or other unforeseen circumstances. -- LHI is not responsible for any installation or production costs resulting from actual delivery dates which exceed the quoted estimated delivery dates. Accurate dates for the delivery will not be available until the equipment is in the manufacturing phase. If there are custom features for the quoted equipment then accurate delivery dates will be available when testing is complete. Please consult with the factory for updates to the expected delivery date.NOTE: PRICING DOES NOT REFLECT FACTORY'S 10% MATERIALS SURCHARGE

.gif)