Cooper Machine Company, Inc.

478-252-5885

Block Saw

Carriage (Sawmill)

Chip Screen

Chop Saw

Conveyor

Conveyor General

Conveyor-Vibrating

Debarker

Edger-Board

Edger-Slab

Gang Saw

Log Merchandising System

Lumber Stacker

Metal Detector

Misc

Misc

Operator Cab

Resaw-Band

Resaw-Circular

Resaw-Stave Band

Scragg Mill

Trim Saw

Trim Saw

Unscrambler

Wood Chipper - Stationary

Cooper Machine Twin Band Overhead

Twin Bands ranging in sizes 8" up to 12" are available with either the Skewing Overhead or the Standard Overhead. Cooper Machine sells MIT S.A. band saws or we can use the customer's choice. Models are available to cut from 36” up to 20’ in length. This machine is also available with Chipping Heads and can be run with Cooper controls or 3D Scanning (Lewis Controls or your choice).

Cooper Machine Conventional Sharp Chain

Cooper Machine offers several versions of the Sharp Chain Scragg. The Standard Sharp Chain uses 100 roller chain with drags to run inside 3 x 4 x 3/8 tubing with 3/8 x 1 AR wear strips. It is built to accommodate smaller diameter (from 3 ½” to 12”) low grade logs with standard feed speeds from 40” to 20’ long. The Sharp Chain Scragg is also available with manual setworks, the Cooper profiling and measuring system or Lewis Controls 3D scanning. This equipment is manufactured from heavy duty steel and parts to create a long lasting machine with low maintenance costs.

Cooper Machine Yield Champ

The Yield Champ Scragg is a combination Sharp Chain Scragg and Edger for further processing the cant. It utilitizes an optimized log turner and sharp chain feed system. A great benefit of the Yield champ is it requires minimum man power (only one man is needed to operate both the Sharp Chain Scragg and Edger). Once the log is through the 44”, 48” or 56” diameter saws (depending the customer’s requirements), the cant is rotated 90 degrees and then fed into a second saw(s). There it is cut into a three or four sided cant or into two cants and two slabs with the three saw option. This mill is available with Cooper computer controlled saw setworks (which provides precise cutting of cants) as well as several options depending on customer needs including an infeed deck and slab recovery system. All of this equipment is manufactured from heavy duty steel and parts to create a long lasting machine with low maintenance costs.

Cooper Machine Top Arbor Two or Three Saw

The top arbor two or three saw trimmer trims three sided cants or slabs. This is a great option behind the Yield Champ to edge the cants or three sided pieces.

Cooper Machine Cant/Tie Stacking System

This Cant Stacking System from Cooper Machine is available with a wide variety of pocket combinations. System available with unscrambler, end trimmer, cab and stacking pockets. Stacked cants are removed using a forklift. Great easy system to stacking those cants and ties!

Cooper Machine Multi Saw Pallet Trimmer

Trimmer can be set up from two to give heads. Can by automatically fed or manually fed. 20" saws for up to 7" tall cants. Comes with guard cages, dust guard, and trim block and sawdust waste belt built into the frame. For more information or a quote, please give us a call. Trimmers also available for three sided flitches and boards.

Cooper Machine MIT 1275 Center Split Resaw

The SCI-1275 is MIT's largest center split resaw. It comes with 55" diameter fabricated solid steel wheels for either 6 or 8" bands. Variable speed hydraulics feed from 0 to 227 feet per minute. Fixed pressure guides. Electric motor for quick change of saw. High tension band with pneumatic systems. Air strain system with air bags. Includes hydraulic tank, pump, electrical motor, valves etc. With 75hp 50/60 htz electric motor and complete electrical panels. This machine can either center split or offset cut. Now includes MIT PLC and touch screen.

Cooper Machine Heavy Duty Debarker

Now introducing the Cooper Stave Debarker. Debark logs 18” to 46” long and 8” to 34” in diamter. Comes with infeed plate slides, 48” long Stringer Bark King Debarker Head with 2 15/16” shaft and bearings, 125hp 1200RPM drive motor and drive, depth gauge plates in head, eyes for opening and closing log holding arm position, 1” AR log cage arm assembly with 3 7/16” Can Am pivot shaft bearings, 6”@20 beam, Six 21”OD, 1” AR Bull Wheels for Log Rotating and Removal. Debarked logs are dropped out below. You can open the cage and pass logs through if hog is down. Debarker will fit in the same spot as existing debarker. Comes with VFD and Soft Starter, Control Panel with Computer/PLC and Software to Auto Run Debarker. Cut down on your labor! One person can run the Stave Cutup System and Debarker. If you have short pallet logs you want debarked, this machine can handle that too!

Cooper Machine MIT Carousel Block Cutter

MIT Carousel Block Cutter has a carousel with ten clamping stations, mechanical press and a manual regulation cutting head with digital measure. Will process up to a 5.5" cant. Has a minimum height cut of @" and maximum of 28". Comes with a special flat WEG motor 7.5hp 60htz. Optional belt conveyor for block output. Uses a 19 11/18" saw blade (not included). Comes with power and control panel. Weighs approximately 4500lbs. This is a great machine to cut up to 90 blocks per minute!

Cooper Machine MIT S. A. Center Split Resaw SCI-1400 Model

The SCI-1400 is MIT's largest center split resaw. It comes with 55" diameter fabricated solid steel wheels for either 6 or 8" bands. Variable speed hydraulics feed from 0 to 227 feet per minute. Fixed pressure guides. Electric motor for quick change of saw. High tension band with pneumatic systems. Air strain system with air bags. Includes hydraulic tank, pump, electrical motor, valves etc. With 75hp 50/60 htz electric motor and complete electrical panels. This machine can either center split or offset cut. Now includes MIT PLC and touch screen.

Cooper Machine Tree Length Merchandising Saw

Cooper Machine manufactures a tree length cutup system with infeed log trough, 76" cutoff saw, outfeed trough with length stops and also push kickers or rotary kickers (if needed). The diameter of the log is determined by using ultrasound. The log tree length cutup system automatically cuts logs to predetermined lengths. The cutup system is designed to fit your application. Different size cutoff saws are available.

Cooper Machine Stave Horizontal Resaw 1000 model

The 1000 model horizontal resaw works well with cants, slabs and staves. For staves, after the bot goes through the Halving Saw, it continues into a thin kerf Vertical Quartering Saw and then. Further downstream, a Horizontal Resaw will cut a stave blank that will be separated and the remaining quarter will continue on the runaround. This machine has heads mounted on a reinforced frame, 40” (1000mm) diameter fabricated solid steel wheels for 2 or 4” bands. It has one 60hp electrical motor on each head. A variable speed drive for principle motor is included along with a polychain belt drive. Built heavier than other resaws on the market for long usage life and low maintenance.

Cooper Machine MIT S. A. Center Split Resaw SCI-900

MIT has Two models of center split resaws to fit your needs. The SCI-900 model has 3 foot diameter fabricated solid steel wheels for 4 inch vertical band. Wheels will be flat ground unless otherwise specified. Has a high tension band with pneumatics systems. Includes a fixed pressure guide system. There are two modes where you can run it with a center split or off to one side. Manual setworks included (optional Mudata system available). Variable speed to 200 feet per minute. The principal motor is 30hp 50/60 htz and it comes complete with electrical panel.

Cooper Machine MIT Headrig

Cooper Machine has been representing MIT equipment since 1996. We are offering headrigs to replace your headrig on your existing carriage. Available as fixed or movable headrig. 1400 model with 54" wheel is pictured with an 8" band. Smaller headrigs are available and one larger size with up to a 12" band is also available. Includes fixed pressure guides. An electric motor system raises and lowers the flywheel for ease in blade removal. Comes complete with electrical panel and starters. Available with MIT or Cooper controls.

Cooper Machine MIT Barrel Recovery Machine

MIT S.A. is located in Santiago, Chile in one of the world's prominent wine making regions. This machine is recover used barrels with a maximum height of 41" and a minimum height of 33", a minimum diameter (from the extremes) of 19" and a maximum diameter (from the extremes) of 25" and a minimum diameter (from the center) of 19" and a maximum diameter (from the center) of 33". It has a cutter head assembled on a support for inside of the barrel with a forward and reverse. The bed of the barrel holder comes with rubber drive wheels. Full automatic cycle work and electrical panel. The actual cutting element is not included.

Cooper Machine Stick Gang Rip Saw

These small gangs can cut battons, kiln sticks and strips with ease. Heavy fabricated steel frame with guards. Includes an electrical panel and VFD feed drive. Available with different configurations, so call to find the solution that works for your application.

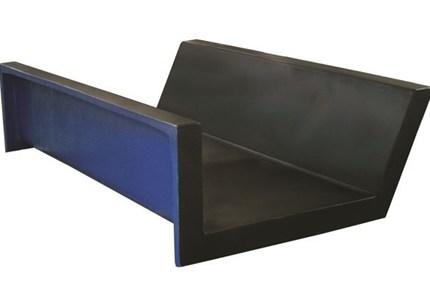

Cooper Machine Operators Cab

Cooper Machine makes several different sizes of cabs. 6 x 6' and 6 x 8' are the most common cab sizes but they can be made to fit your specific application. Generally comes with heat/air and seat. Plenty of room for the control console and a camera system to see what's going on in the mill.

Cooper Machine MDI TWA-HD Surround

Cooper Machine is a representative of MDI Metal Detectors. Feel free to give us a call for more information or a quote. The TWA-2000 Surround Metal Detector Systems with proven MP-4 Digital Technology provide superb reliability and unmatched performance. The TWA-2000 Series Metal Detectors are the number one systems in the industry and they are proven to be the best investment you will make to protect your equipment and business from downtime and to ensure the quality of your product. Contact us for more information on which system is appropriate for your application. Not all mills are designed alike and not all mills are constructed to accommodate a metal detector where it is needed. The TWA-2000-HD, with MP-4 Digital Technology, will meet expectations in demanding installations and consistently provide top performance in areas where other metal detectors have failed. A Nolco fiberglass section is also available.

Cooper Machine MDI XR-3000 Under Conveyor

The new XR-3000 system and its respective components have been designed to retrofit into exiting MDI analog under conveyor metal detector systems built since 1965, preserving our pledge to the customer that no MDI System will become obsolete in our dedication to product advancement. The XR-3000 joins our family of digitally controlled metal detectors with the new XR-8F Digital Function Block and entirely new internal search coil design that utilizes our groundbreaking Diamond Construction Process. The XR-8F represents a new series of MDI Digital Technology and is guaranteed to surpass the performance of all previous Function Blocks while providing the consistent reliability of digital technology. The advanced filtering provided by the Function Block in combination with our new coil design provides near immunity to CB radio and static interference. XR-3000 Features: Economical Protection The XR-3000 is an economical metal detector designed to give consistent protection

Cooper Machine MDI Nolco Fiberglass Section

Cooper Machine also sells MDI Nolco Fiberglass Sections: Pound per pound, fiberglass has a tensile strength even greater than that of steel. This combined with our hand-laminated process using layers of woven roving and polyester resin provides a higher density monolithic section, which has a greater tensile strength and abrasion resistance than sections manufactured with a chopper gun using fiberglass strand. NOLCO Features: All NOLCO fiberglass conveyor sections are custom fabricated to your exact specifications. “Undeniably built better & stronger than any other fiberglass section you can buy.” NOLCO has built its reputation on workmanship, quality, longevity, and customer satisfaction. No section is too unusual or too big for NOLCO. When others say it can’t be done... we do it.